Patents

Literature

502results about How to "Curb consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

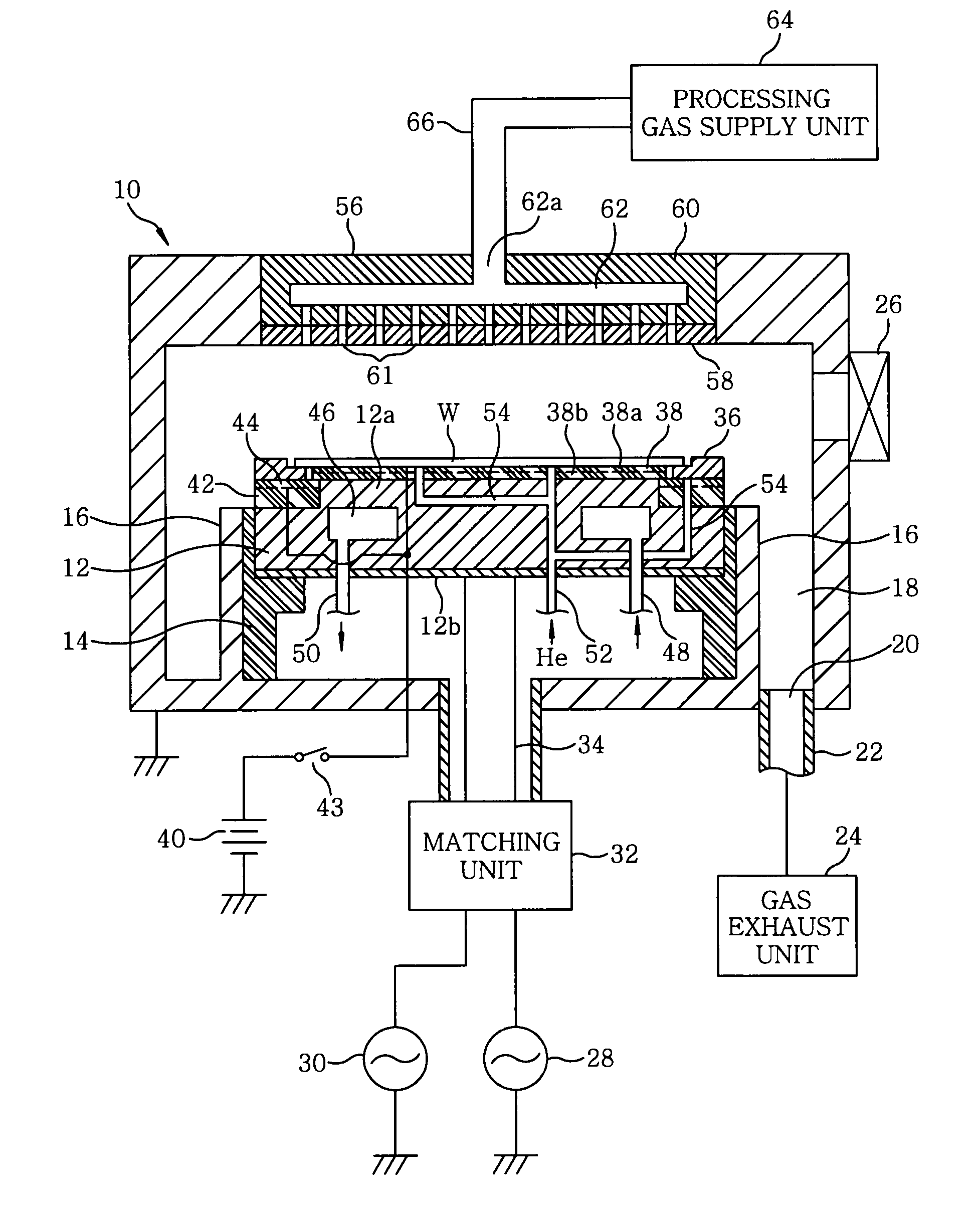

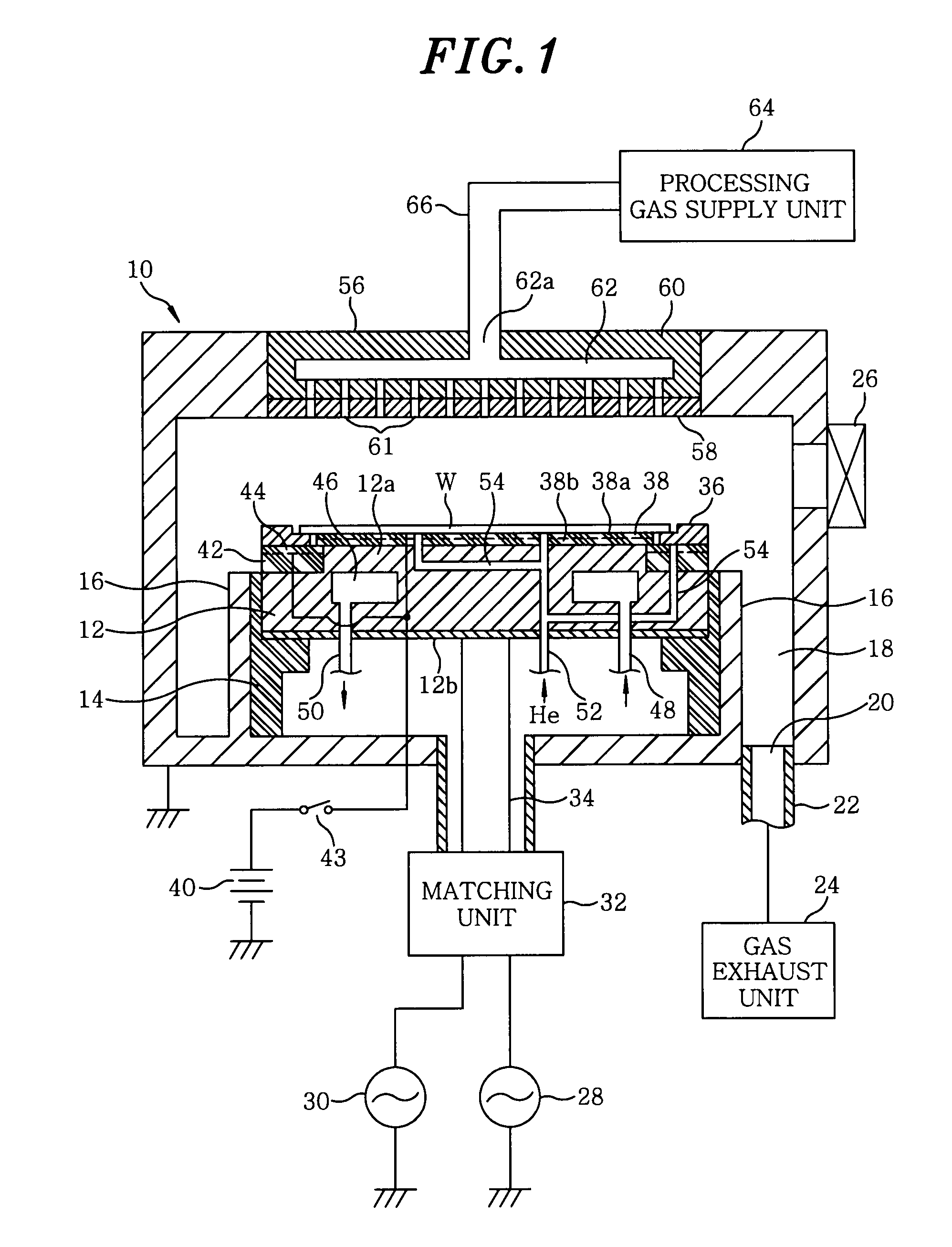

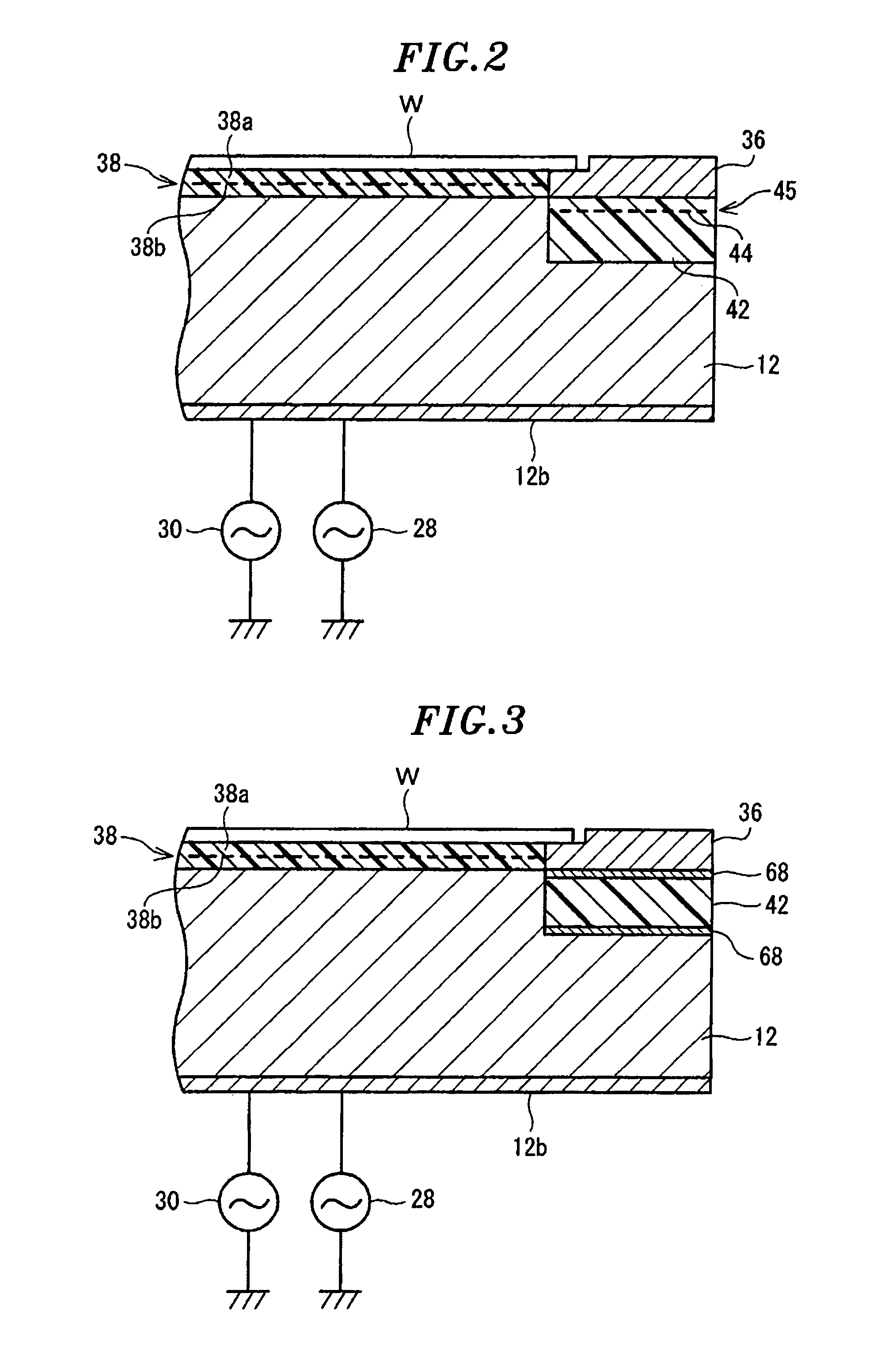

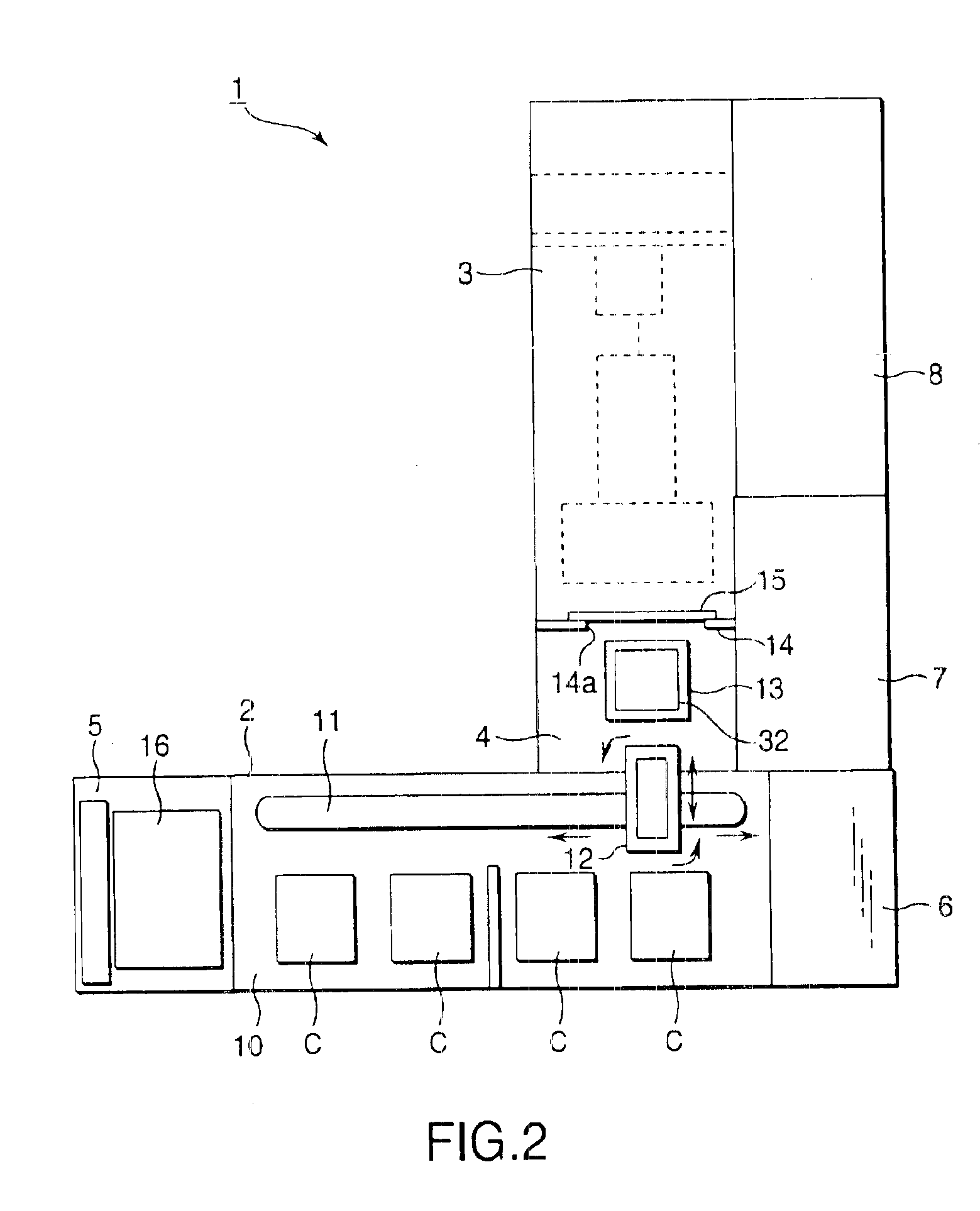

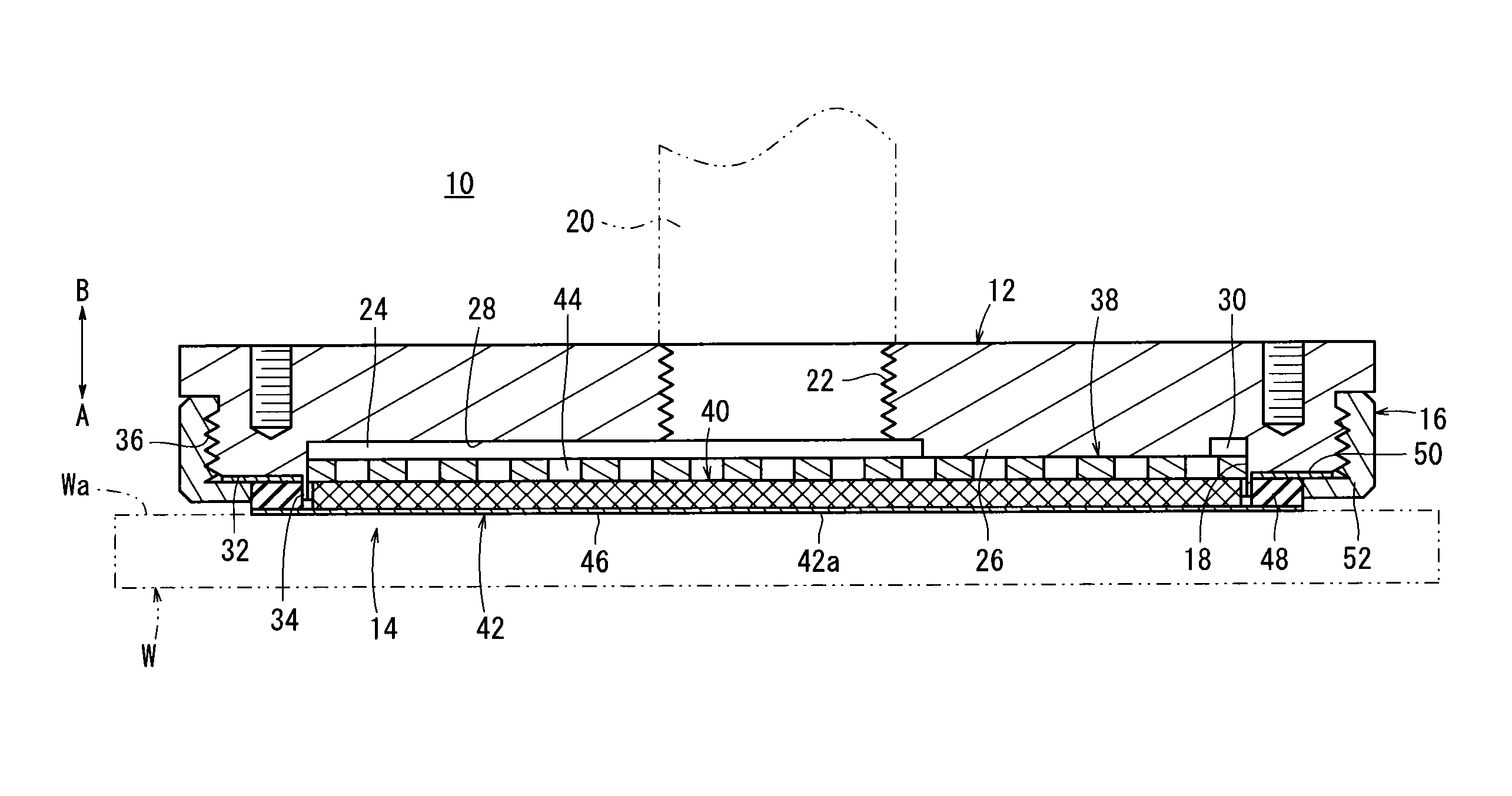

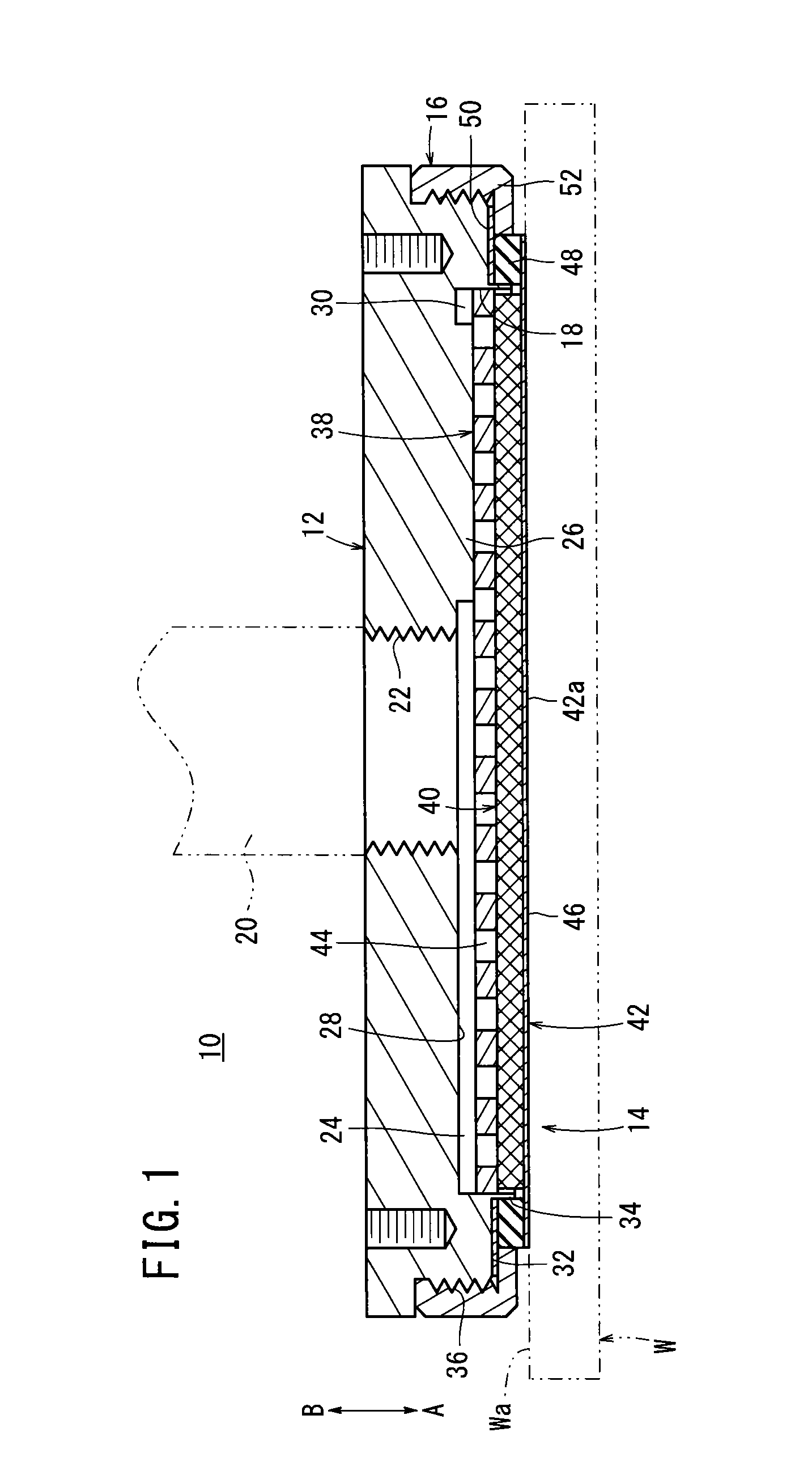

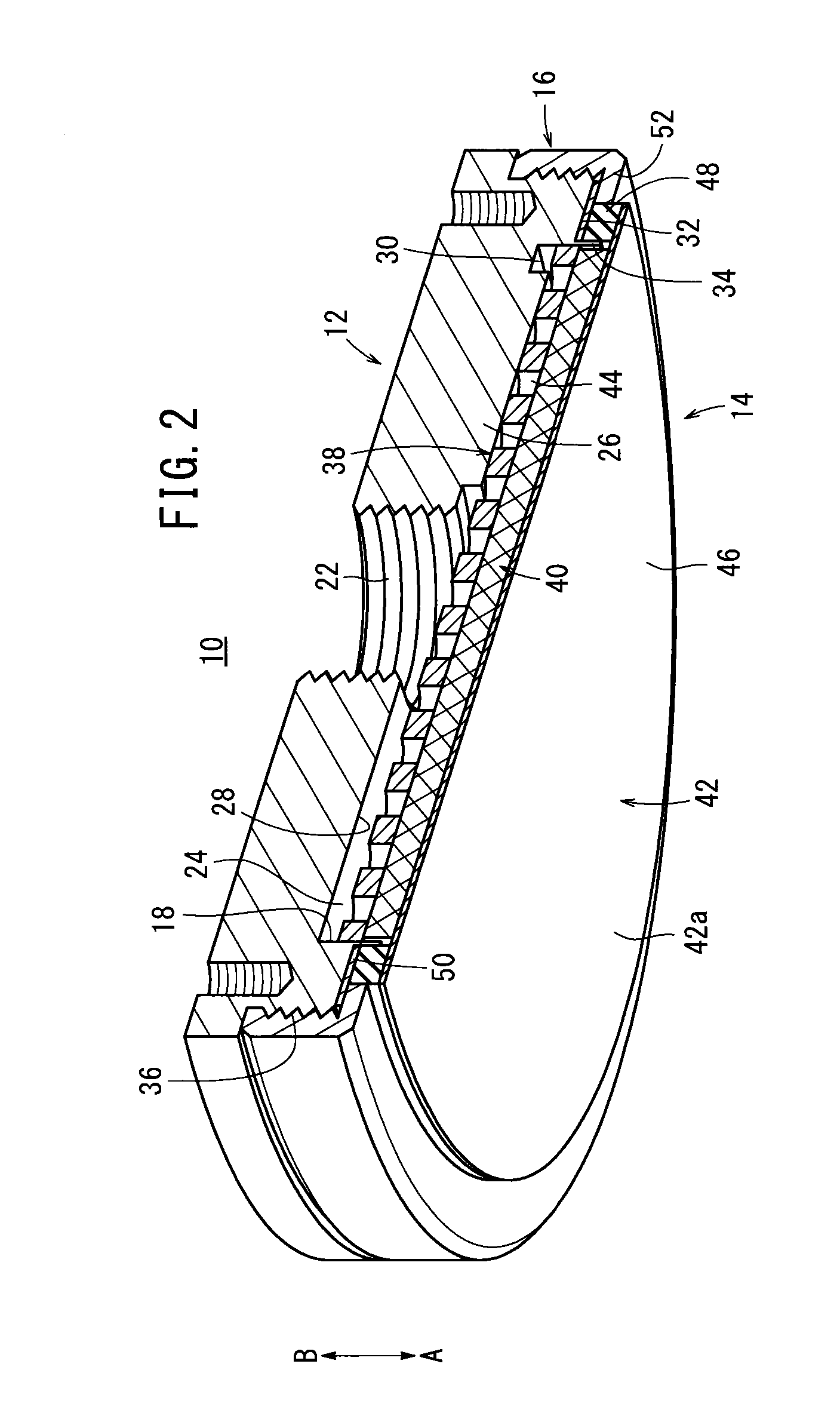

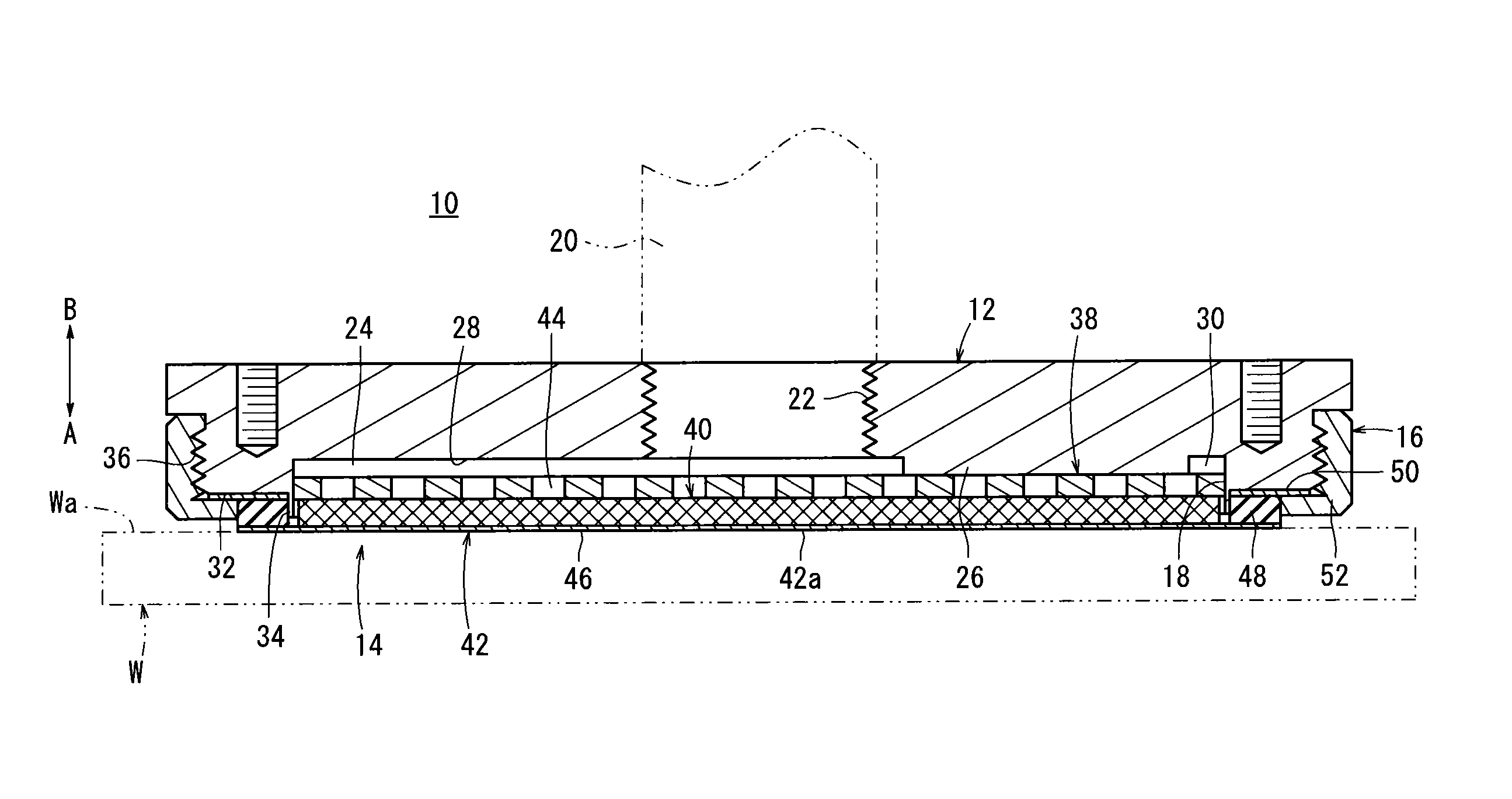

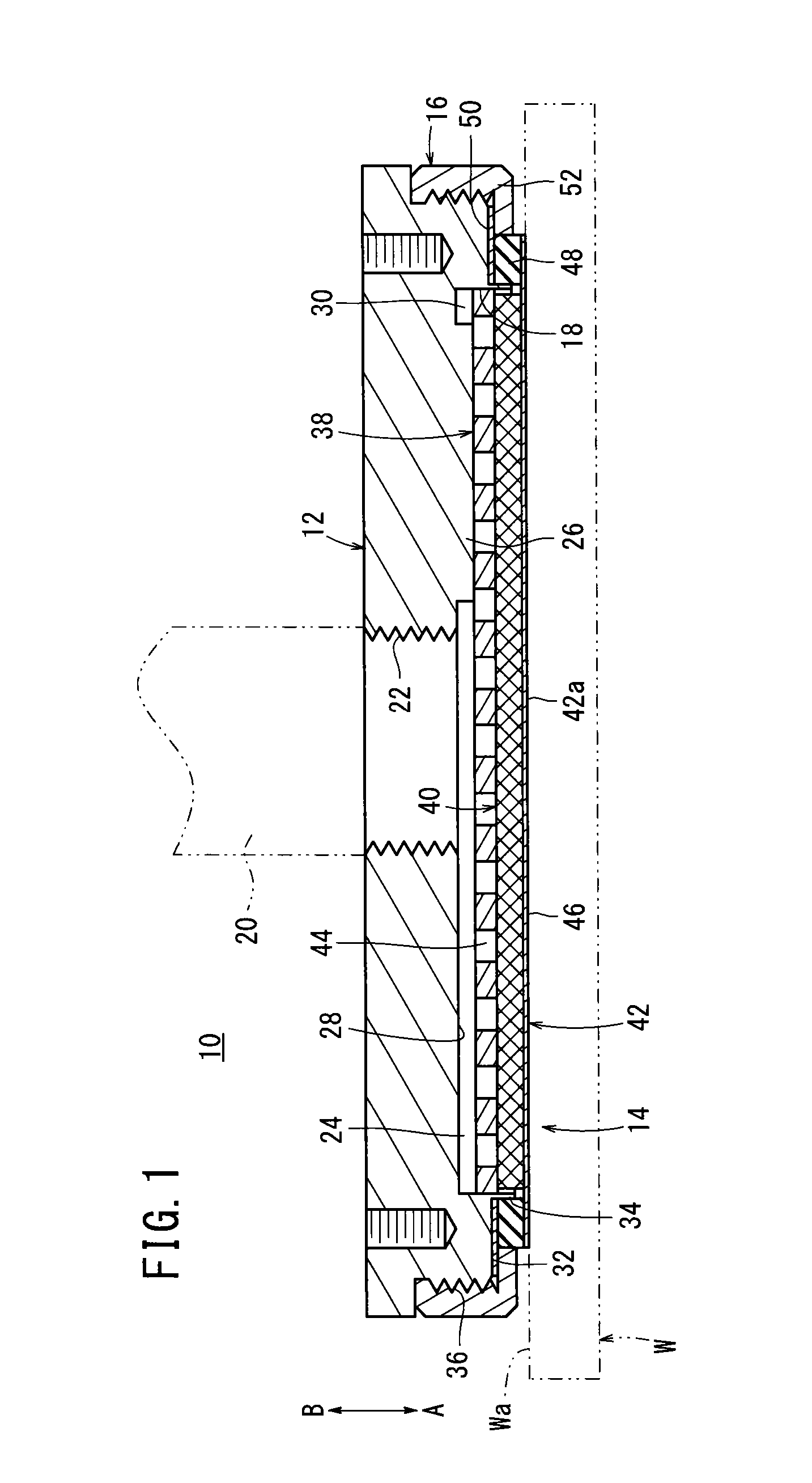

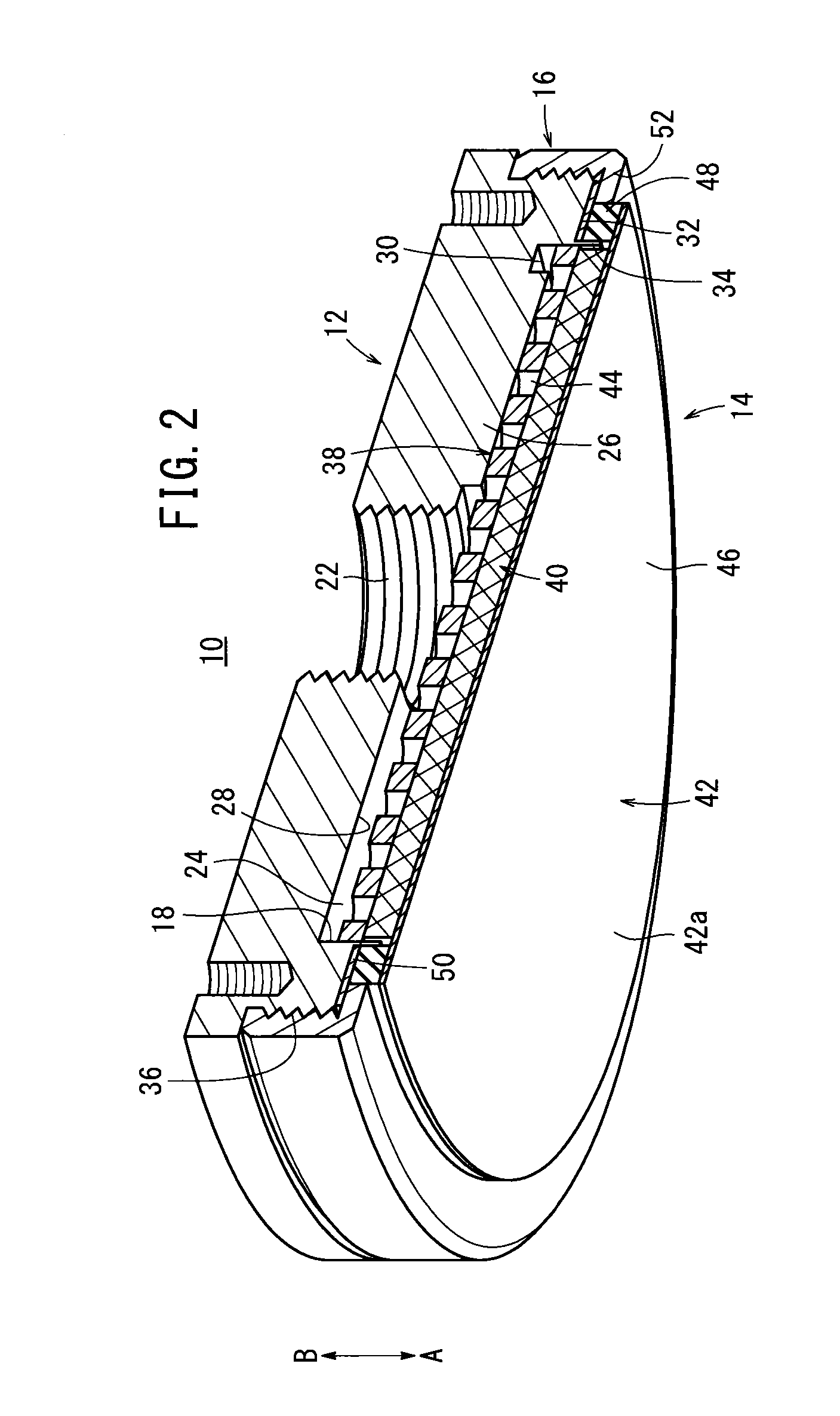

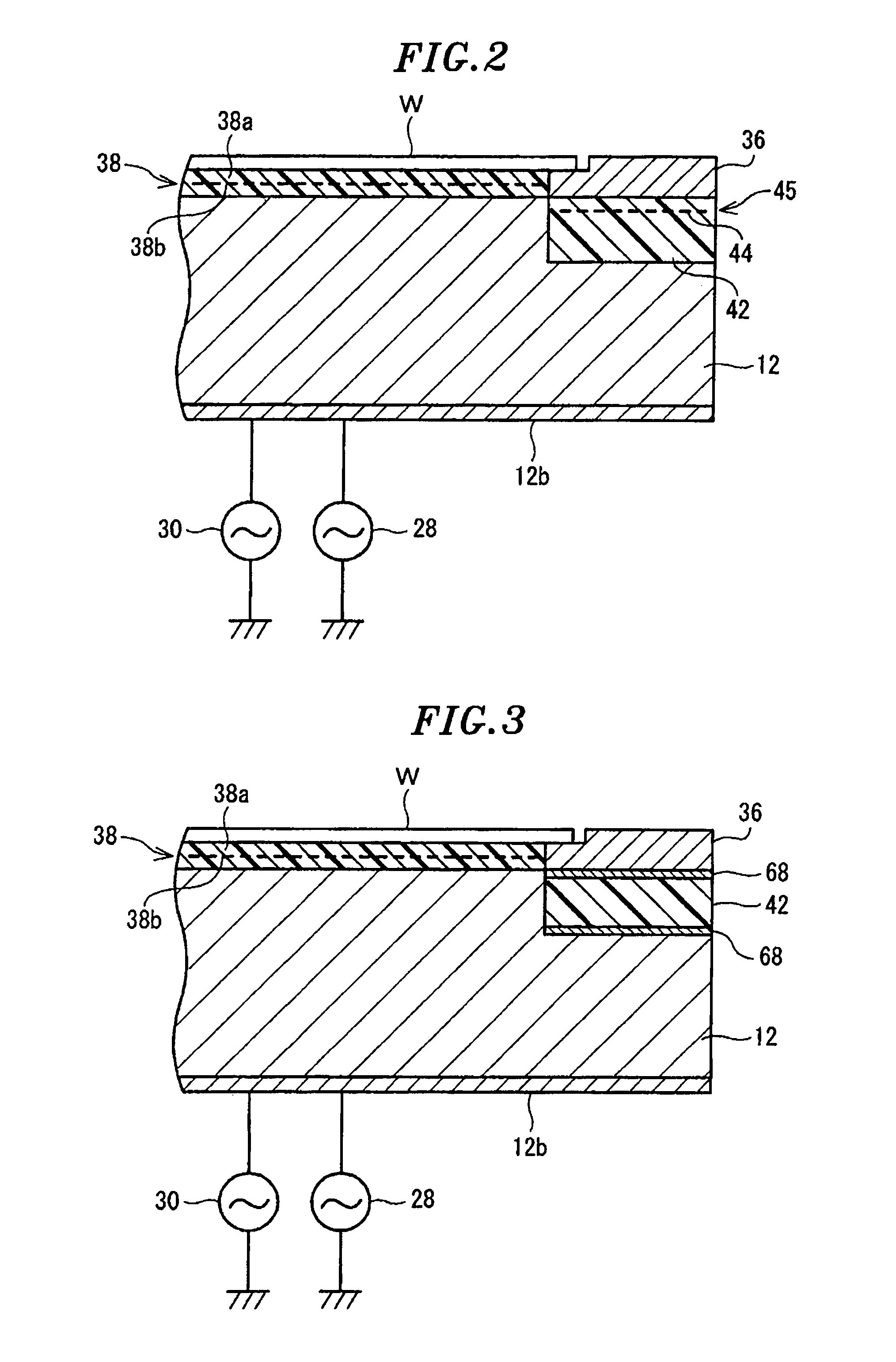

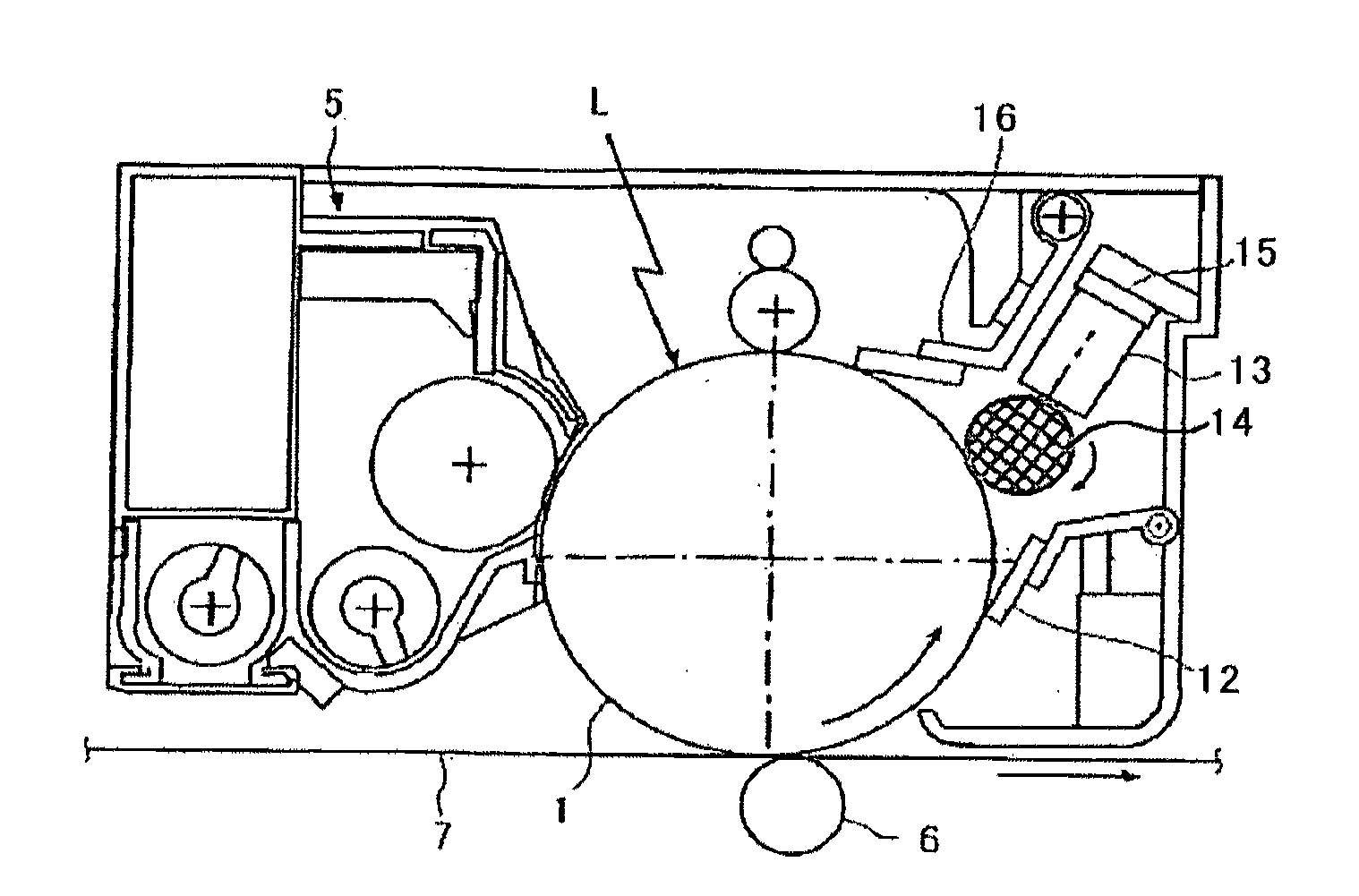

Plasma processing apparatus

ActiveUS20080236749A1Suppresses consumptionEffectively suppressing a consumption of a focus ring without substantially affecting processesElectric discharge tubesSemiconductor/solid-state device manufacturingCapacitancePlasma processing

A plasma processing apparatus includes a processing chamber, a first electrode and a second electrode disposed to face each other, a high frequency power supply unit for applying a high frequency power to either the first electrode or the second electrode, a processing gas supply unit for supplying a processing gas to a processing space, and a main dielectric member provided at a substrate mounting portion on a main surface of the first electrode. A focus ring is attached to the first electrode to cover a peripheral portion of the main surface of the first electrode and a peripheral dielectric member is provided in a peripheral portion on the main surface of the first electrode so that an electrostatic capacitance per unit area applied between the first electrode and the focus ring is smaller than that applied between the first electrode and the substrate by the main dielectric member.

Owner:TOKYO ELECTRON LTD

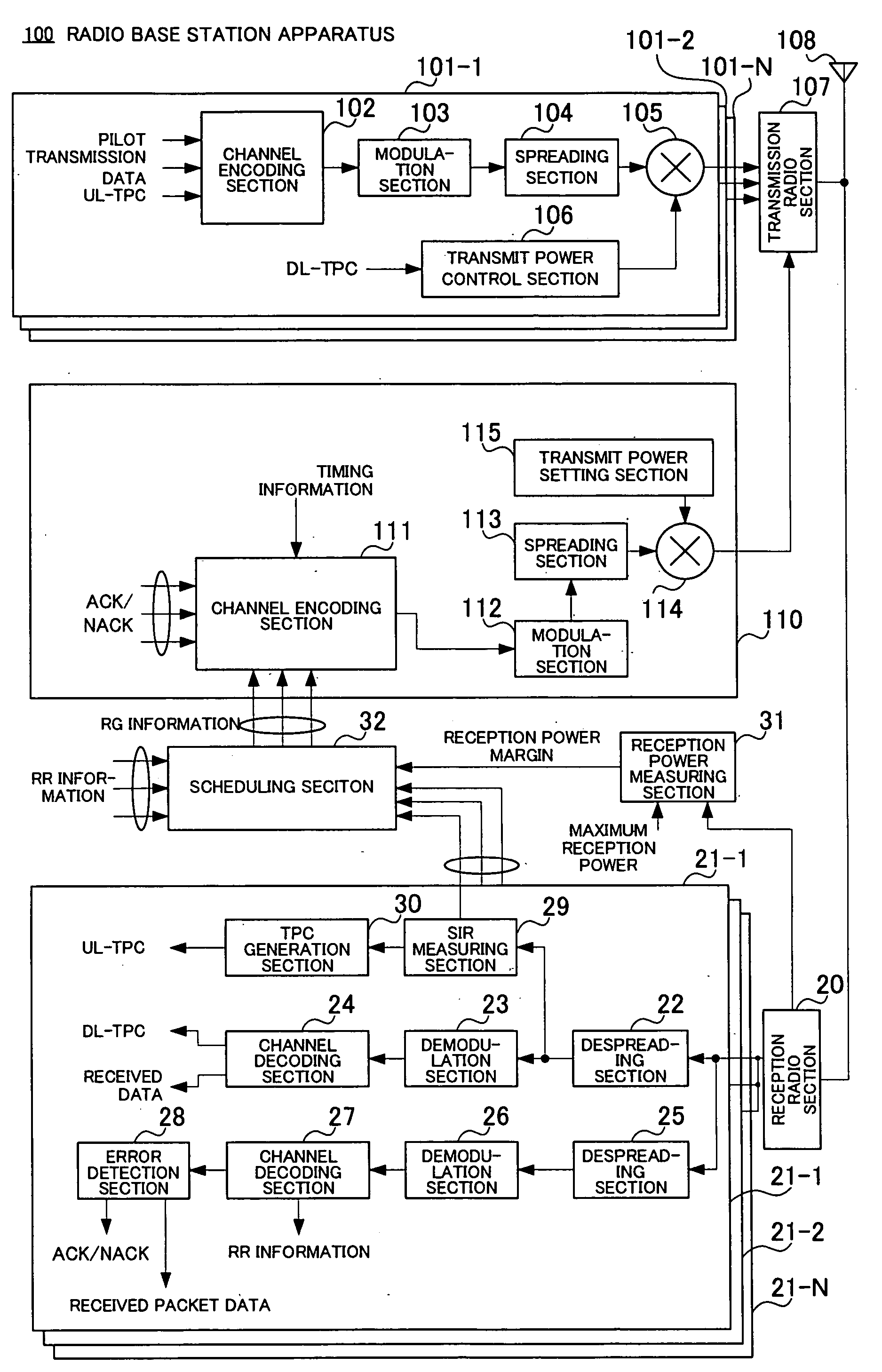

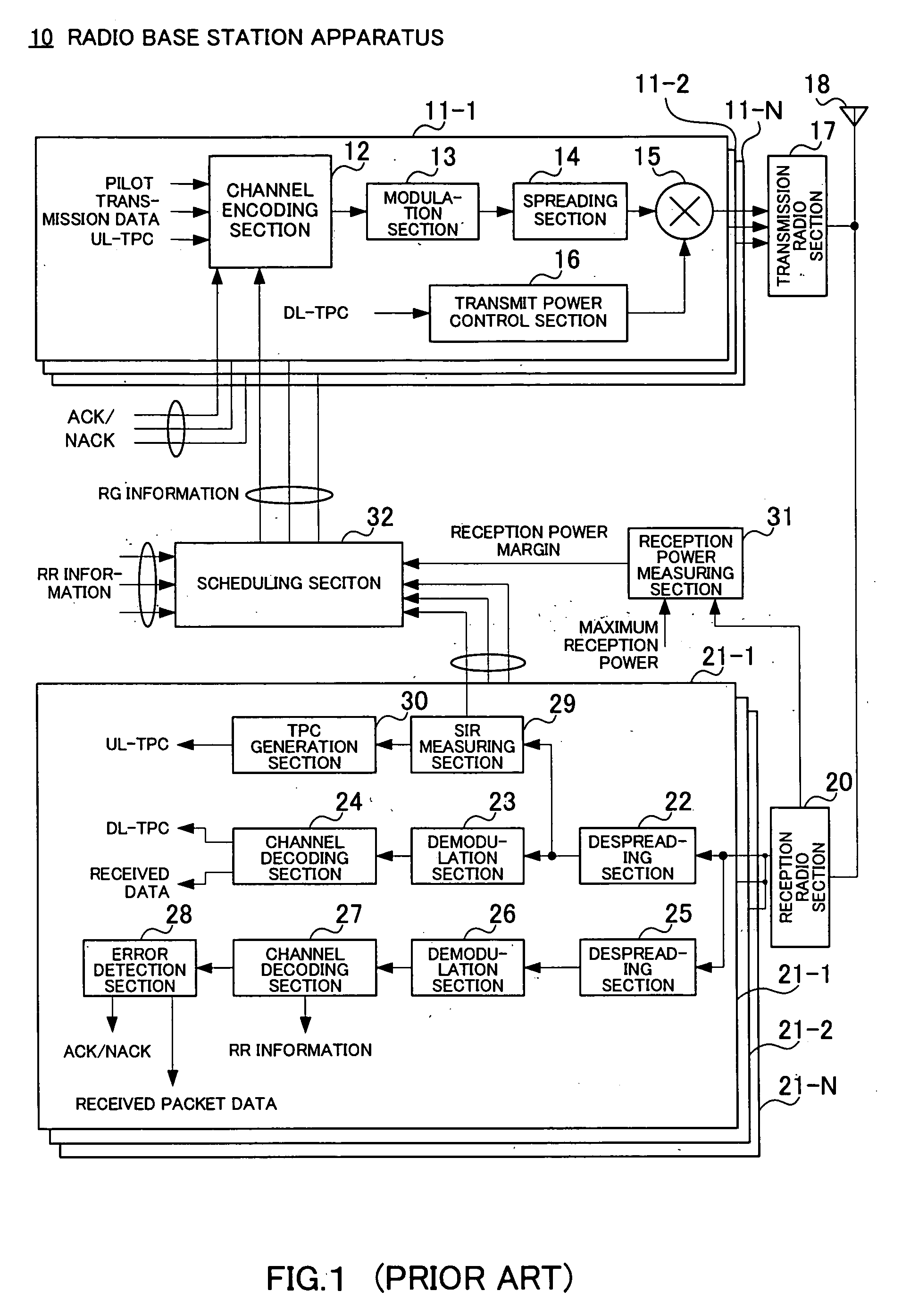

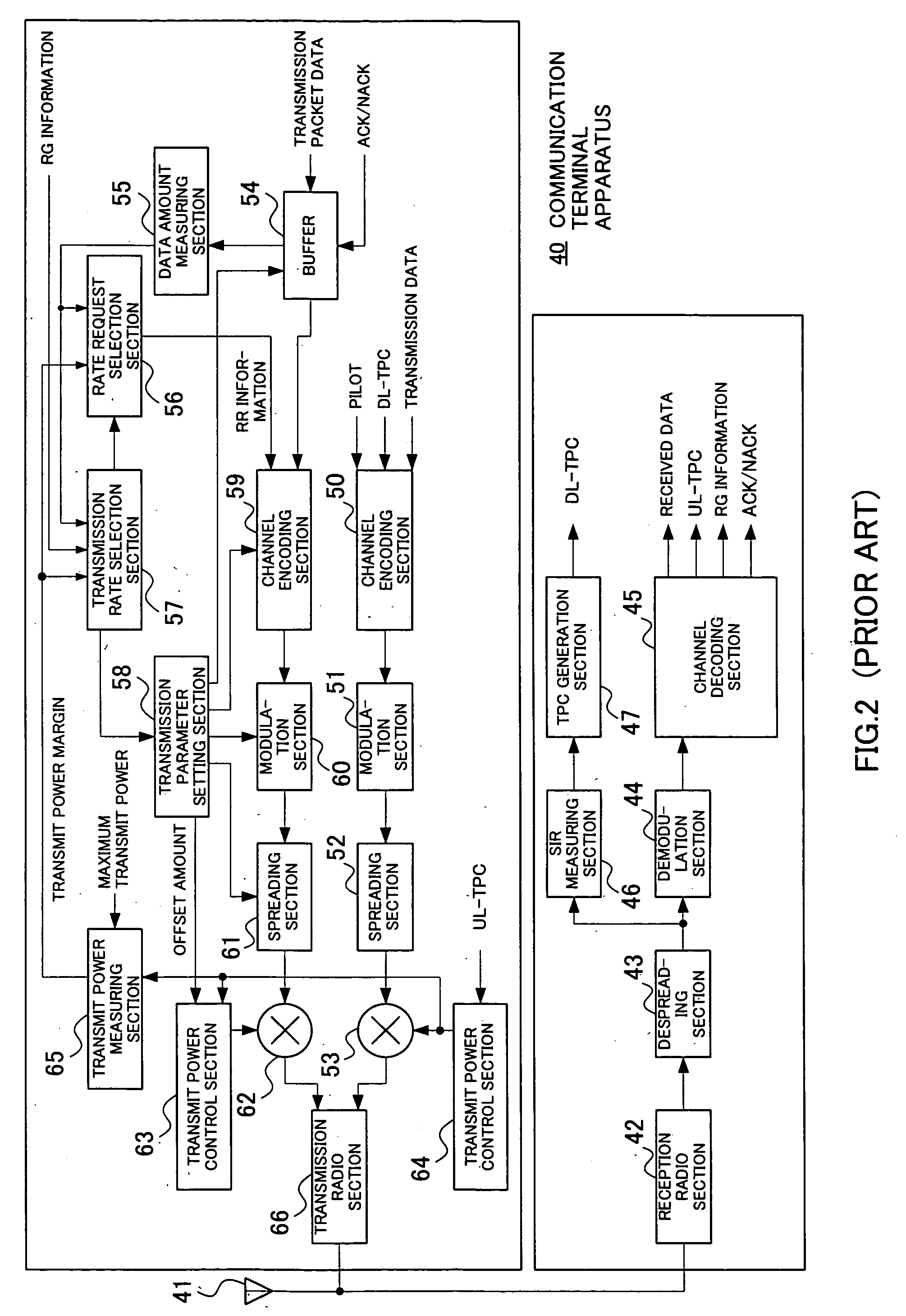

Radio base station device, communication terminal device, and control information transmission method

ActiveUS20050238053A1Curb consumptionFully extractedPower managementNetwork traffic/resource managementMultiplexingInformation transmission

In addition to dedicated channel signal formation units 101-1 to 101-N, control information channel signal formation unit 110 is provided and this control information channel signal formation unit 110 forms control information for carrying out uplink packet transmission. The control information channel signal formation unit 110 multiplexes control information (RG information, ACK / NACK, etc.) directed to a plurality of communication terminals through a channel encoding section 111 according to a multiplexing rule preset between the base station apparatus and each communication terminal and spreads the control information using a spreading code common to the communication terminals through a spreading section 113 and thereby forms a control information channel signal for uplink packet transmission.

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA

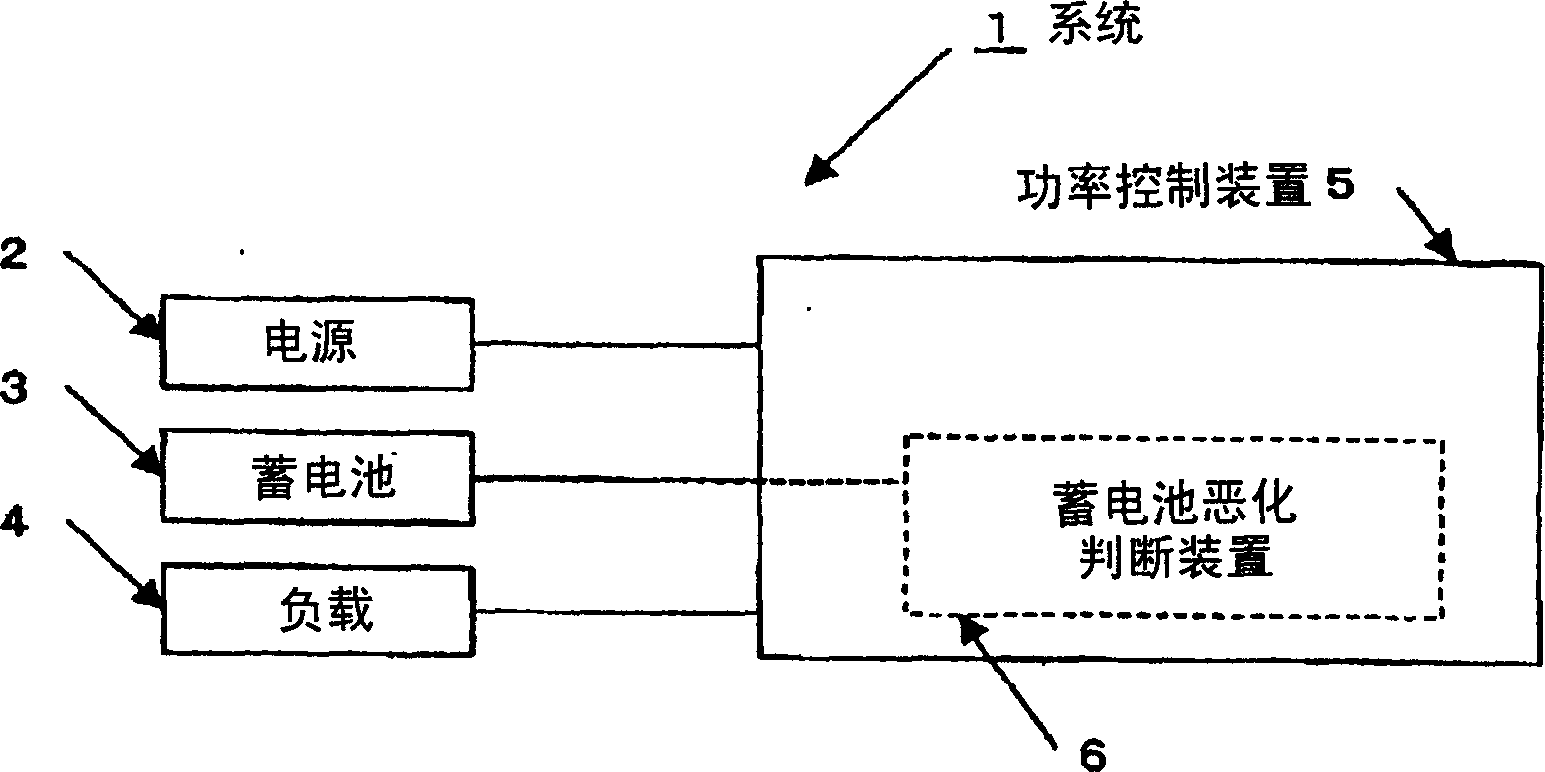

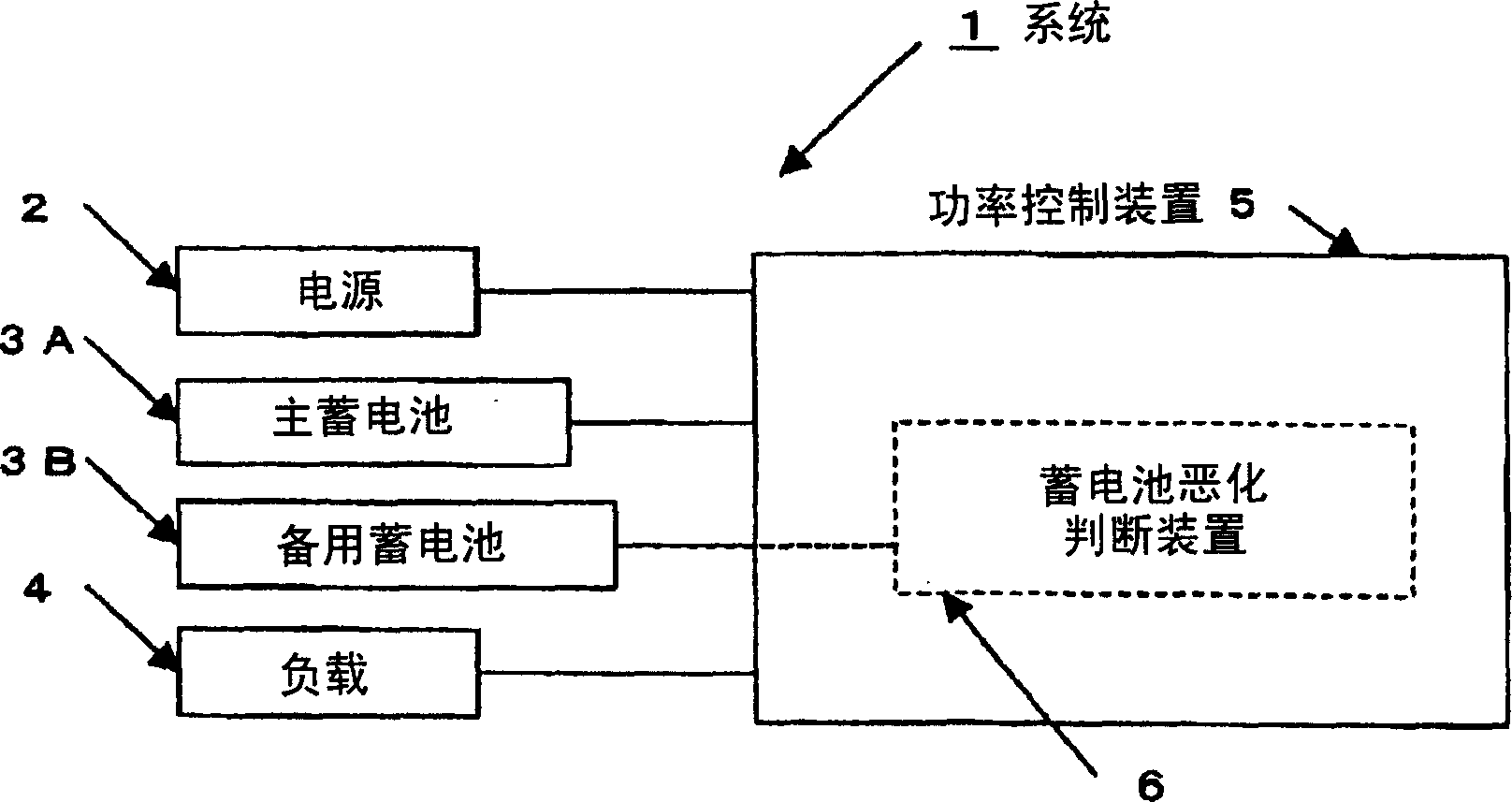

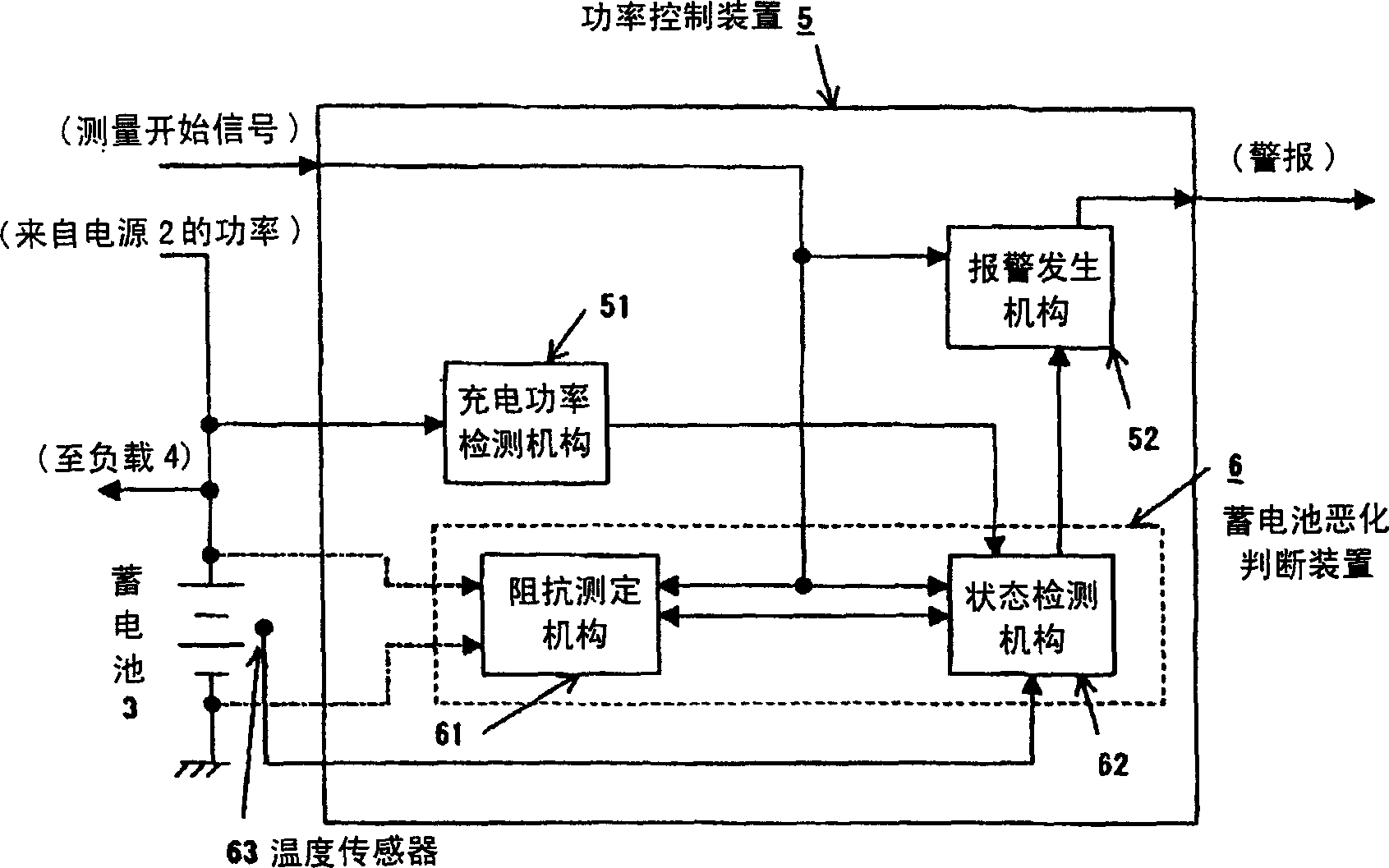

Method for judging deterioration of accumulator, method for measuring secondary cell internal impedance, device for measuring secondary cell internal impedance, device for judging deterioration of sec

ActiveCN1791804AAccurate judgmentCurb consumptionElectrical testingElectrical resistance and conductanceCharge current

To provide a method for measuring internal impedance of a secondary battery, an charging current or discharging current is used as an input current of the secondary battery, the input current and a response voltage is measured, a plurality of current measuring values and voltage measuring values are obtained on a time line; each frequency components of the input current and the response voltate iscalculated under a predetermining frequency by performing Fourier transform the plurality of current measuring values and the plurality of voltage measuring values; and the ratio of the frequency component of the input current and the frequency component of the response voltage are obtained, and the internal impedance of the secondary battery is calculated under the predetermining frequency.

Owner:FURUKAWA ELECTRIC CO LTD

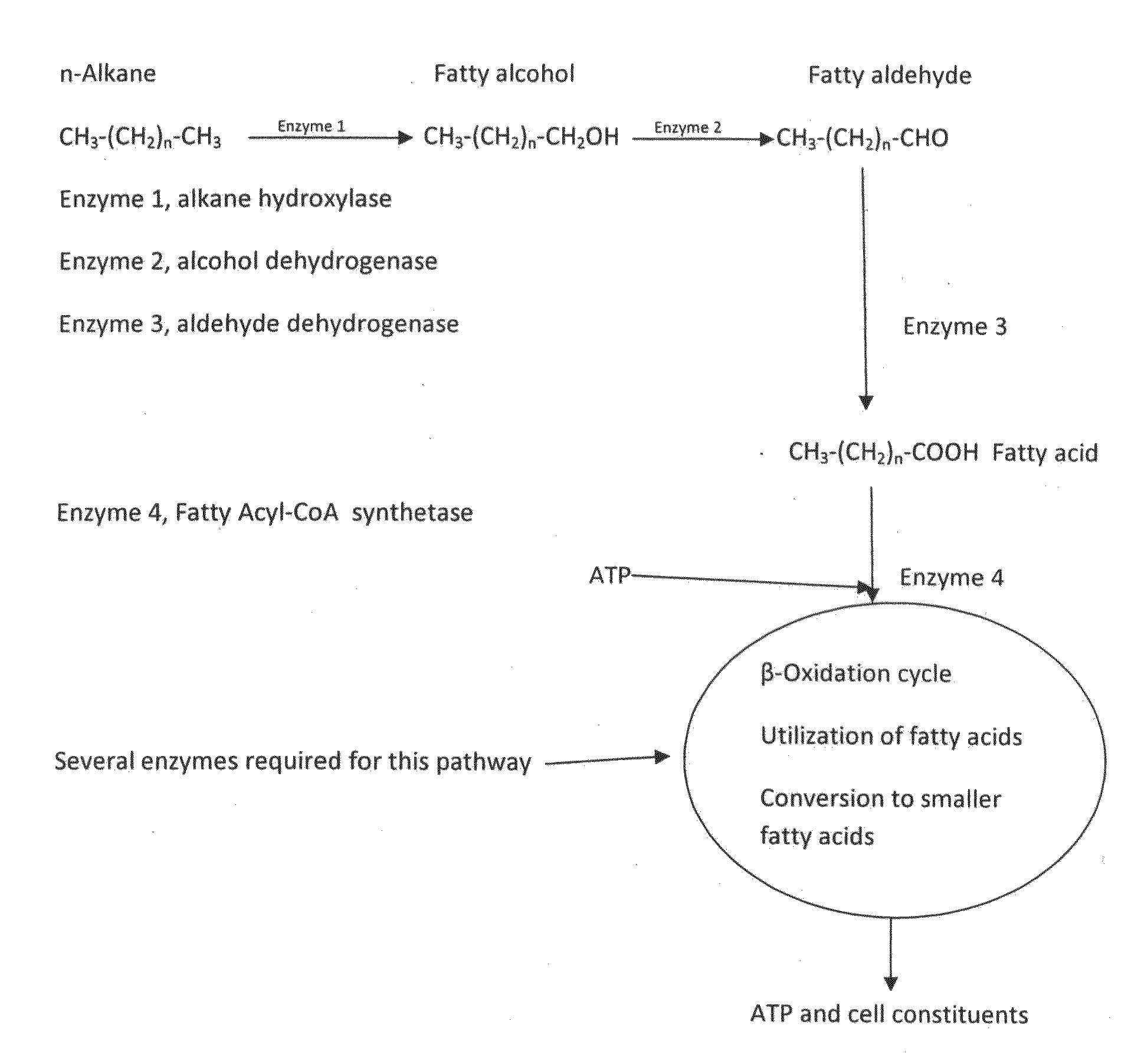

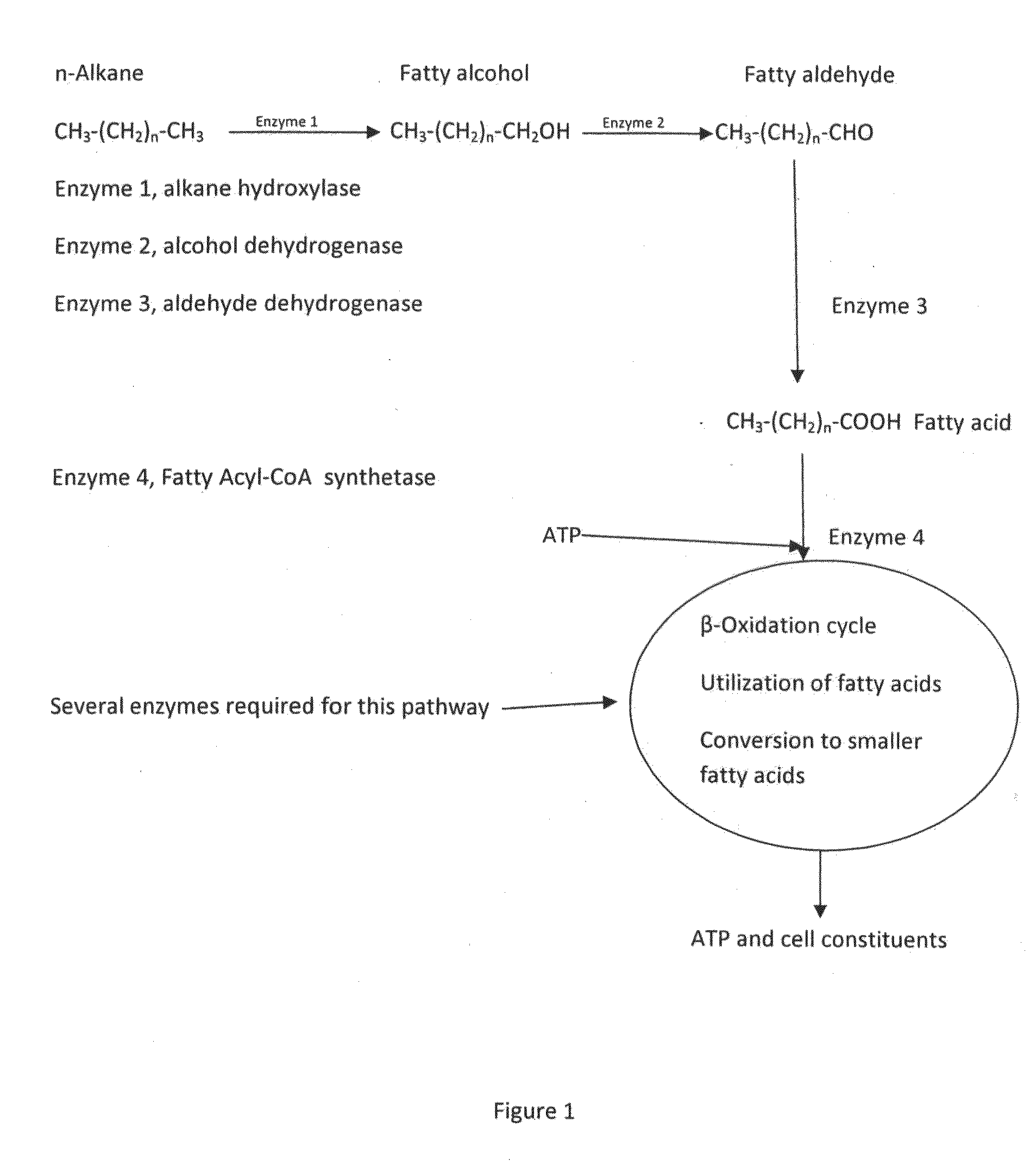

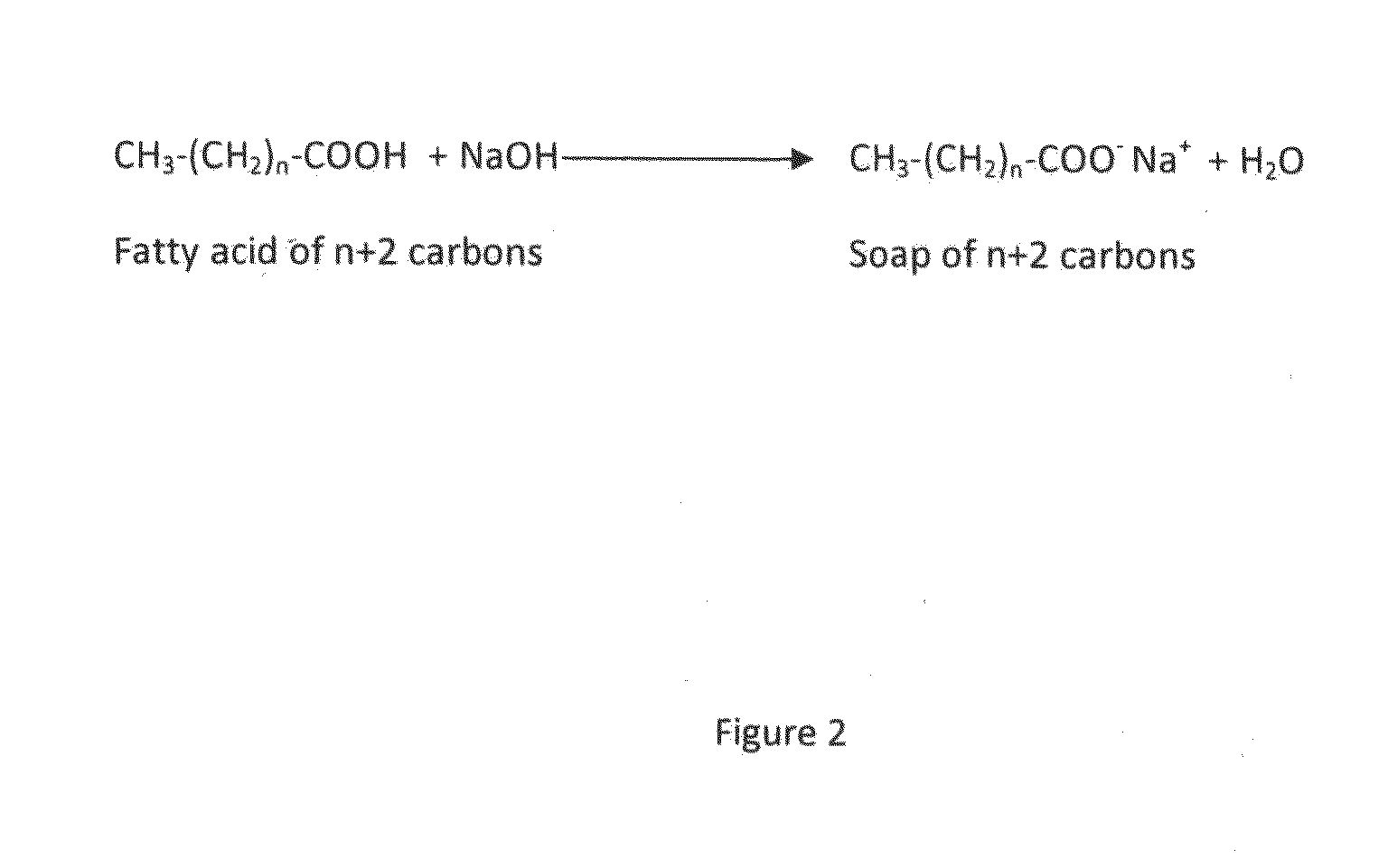

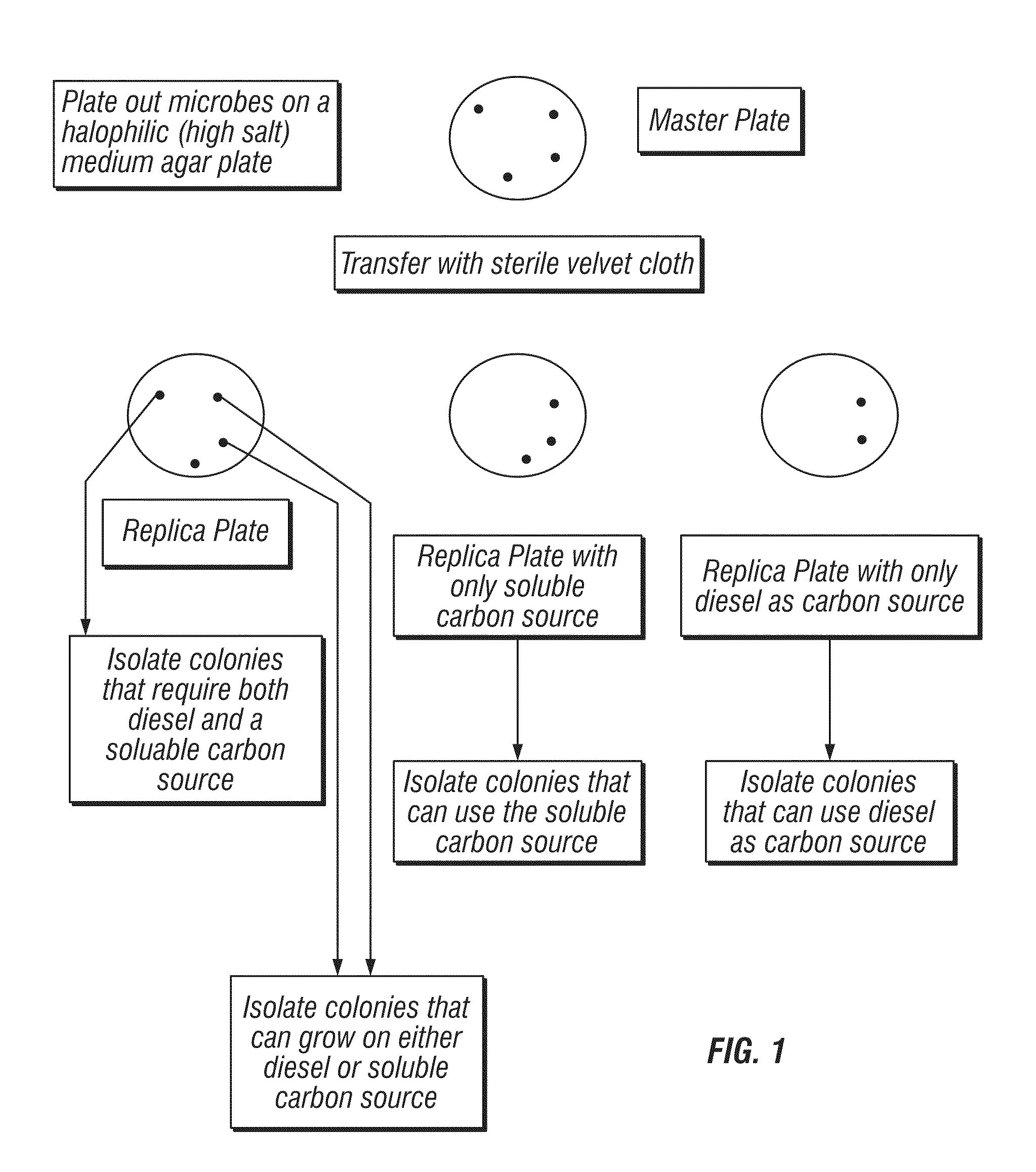

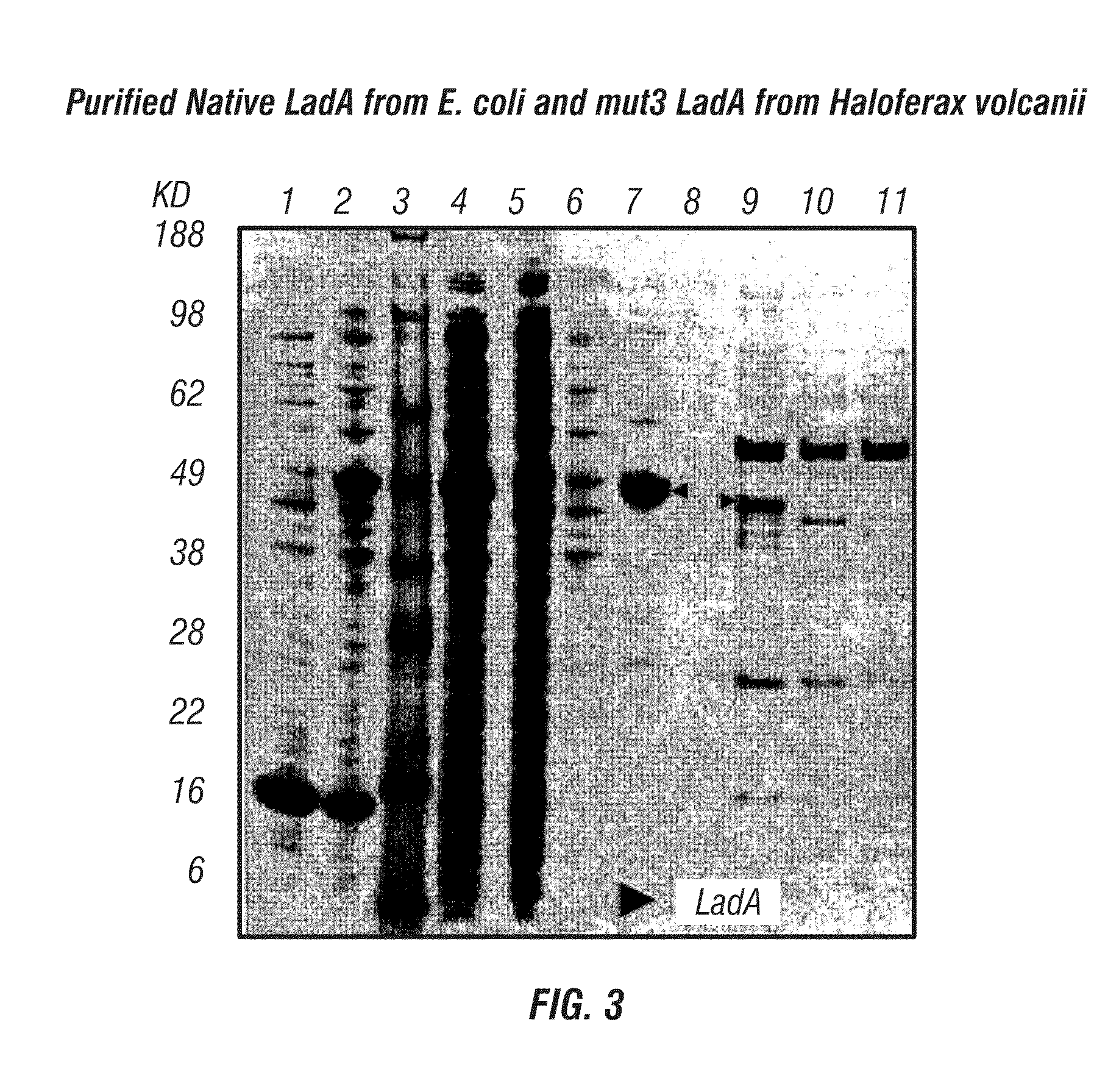

Alkaline microbial enhanced oil recovery

ActiveUS20130062053A1Promote recoveryCurb consumptionBacteriaUnicellular algaeBiotechnologyMicrobial enhanced oil recovery

The present invention is related to the field of microbial enhanced oil recovery (MEOR). In particular, the invention concerns new, efficient, economical and environmentally safe microbial methods to enhance oil recovery, as well as microorganisms useful in such methods.

Owner:GEO FOSSIL FUELS

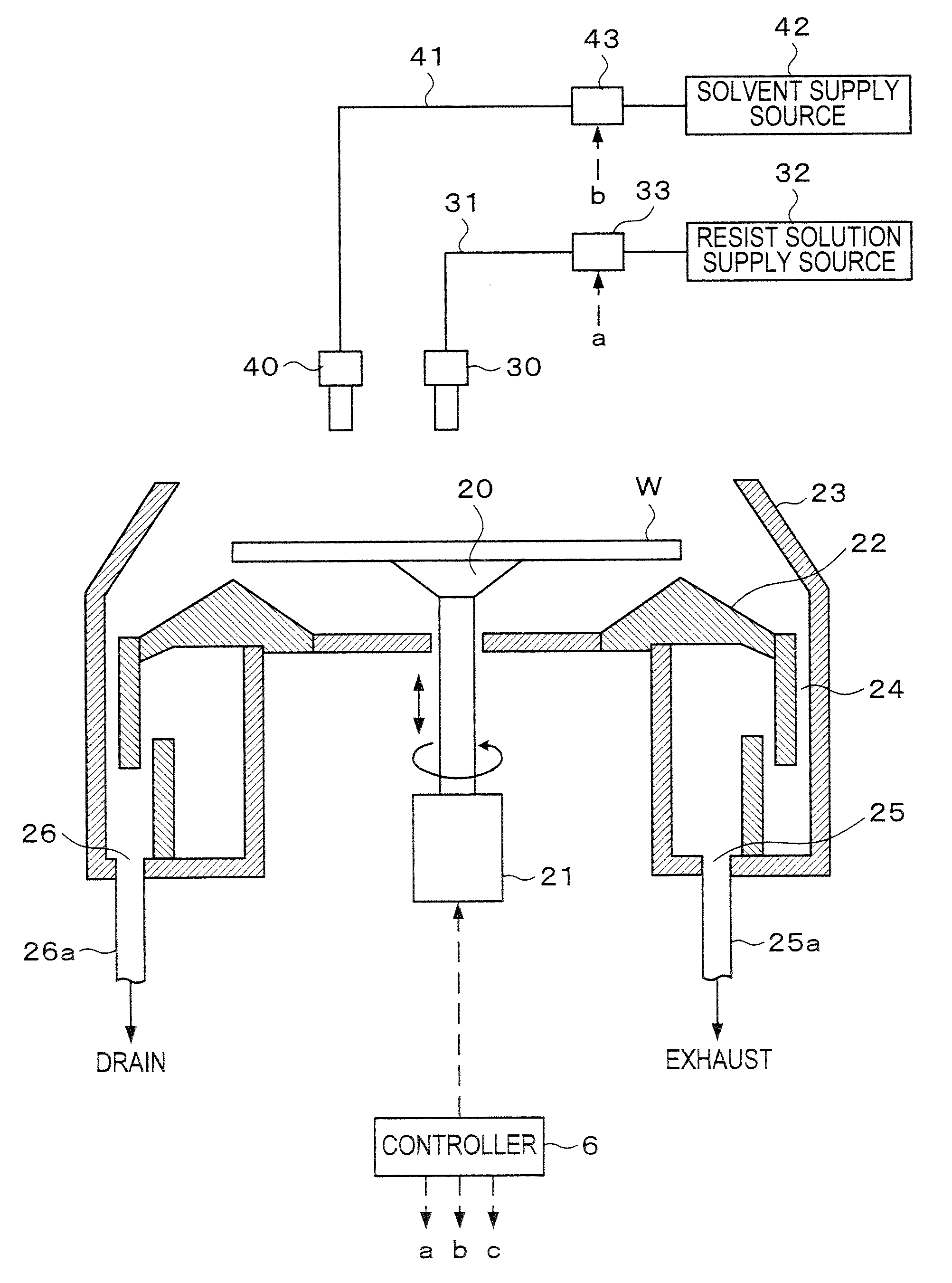

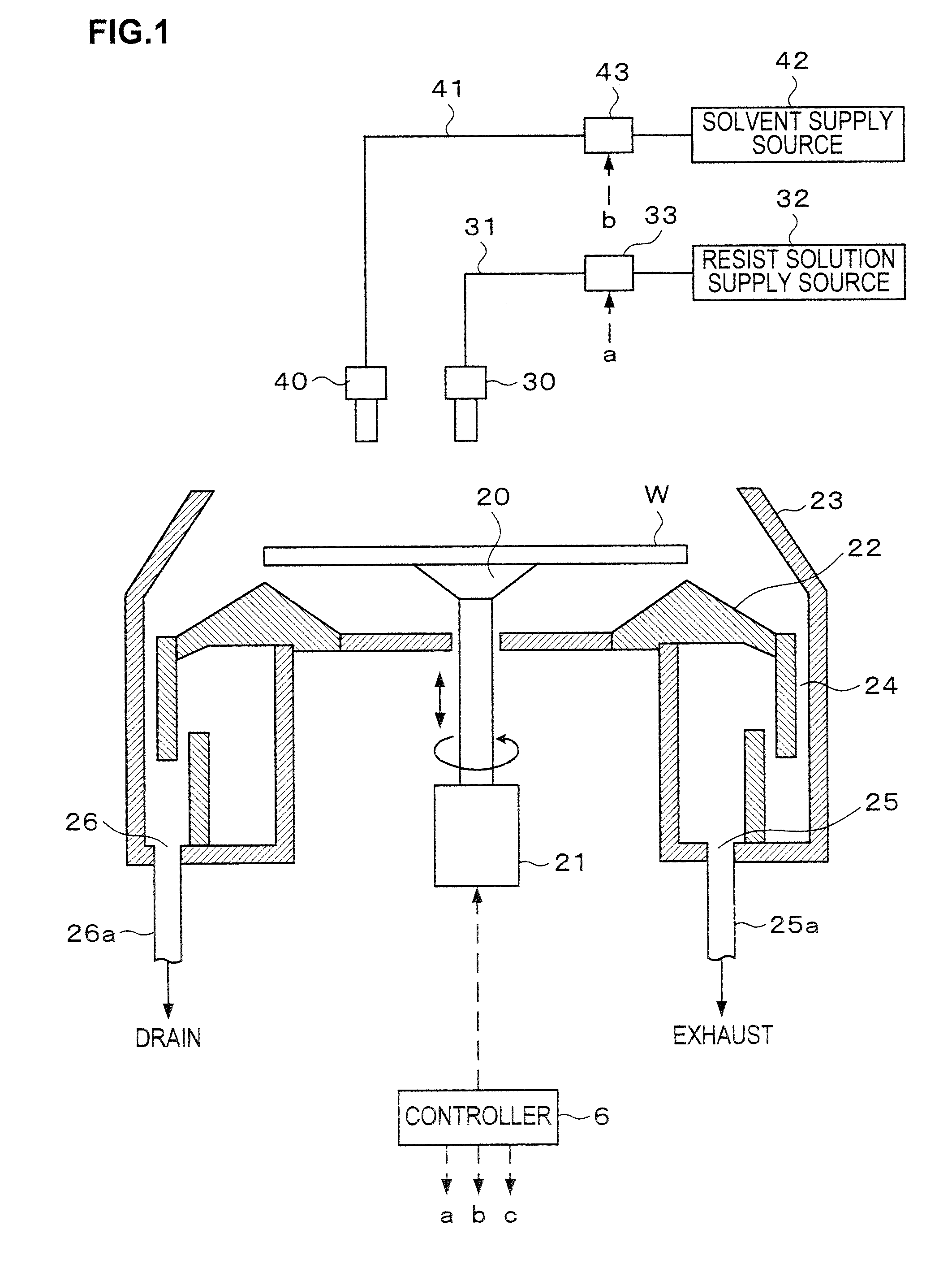

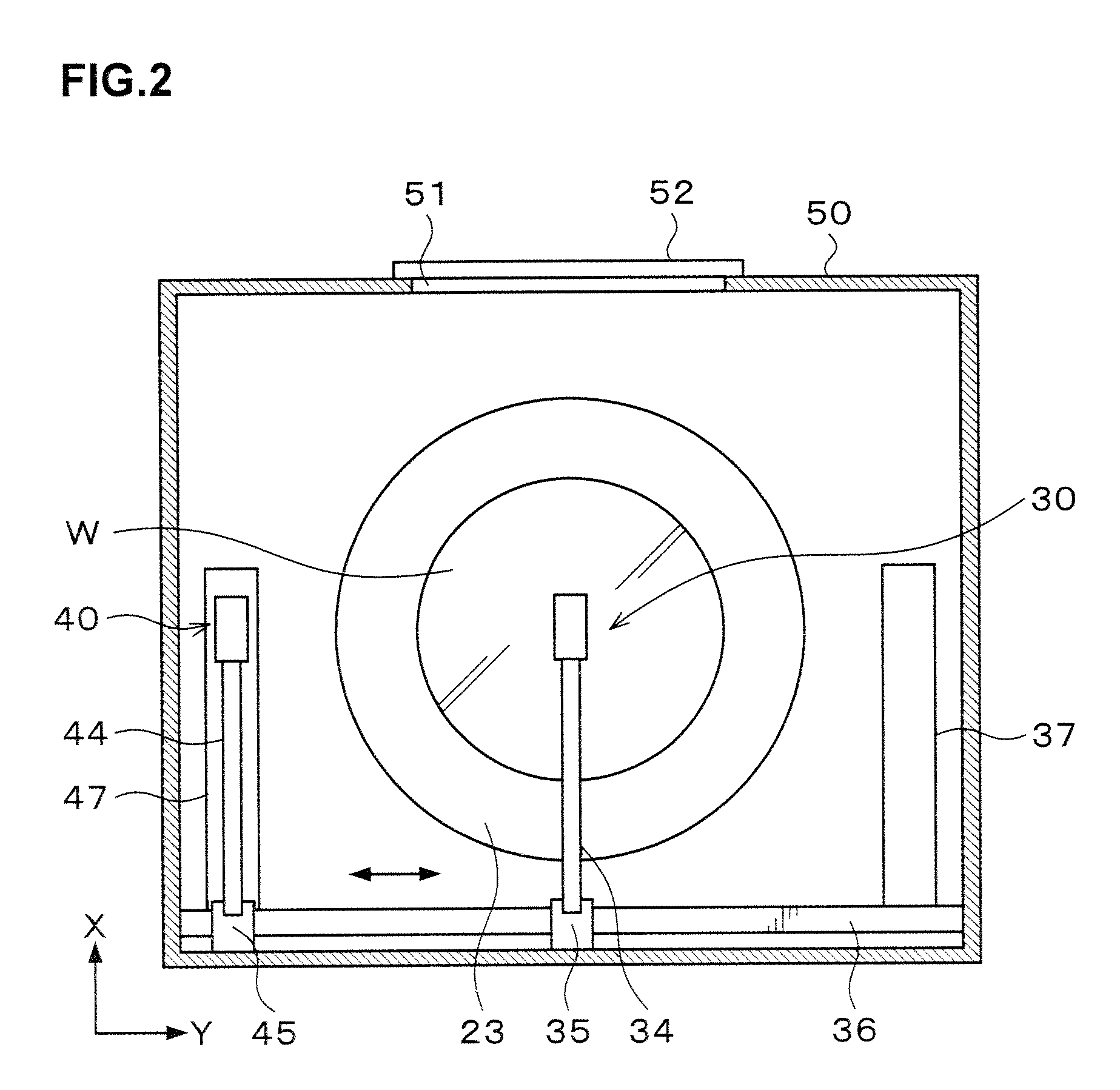

Coating treatment method

ActiveUS20080069948A1Low viscosityFlowability of solution increaseSpraying apparatusPhotomechanical apparatusResistIn plane

The present invention supplies a solvent to the front surface of a substrate while rotating the substrate. Subsequently, the substrate is acceleratingly rotated to a first number of rotations, and a resist solution is supplied to a central portion of the substrate during the accelerating rotation and the rotation at the first number of rotations. Thereafter, the substrate is deceleratingly rotated to a second number of rotations, and after the number of rotations of the substrate reaches the second number of rotations, the resist solution is discharged to the substrate. The substrate is then acceleratingly rotated to a third number of rotations higher than the second number of rotations so that the substrate is rotated at the third number of rotations. According to the present invention, in application of the resist solution by spin coating, the consumption of the resist solution can be suppressed, and a high in-plane uniformity can be obtained for the film thickness of the resist film.

Owner:TOKYO ELECTRON LTD

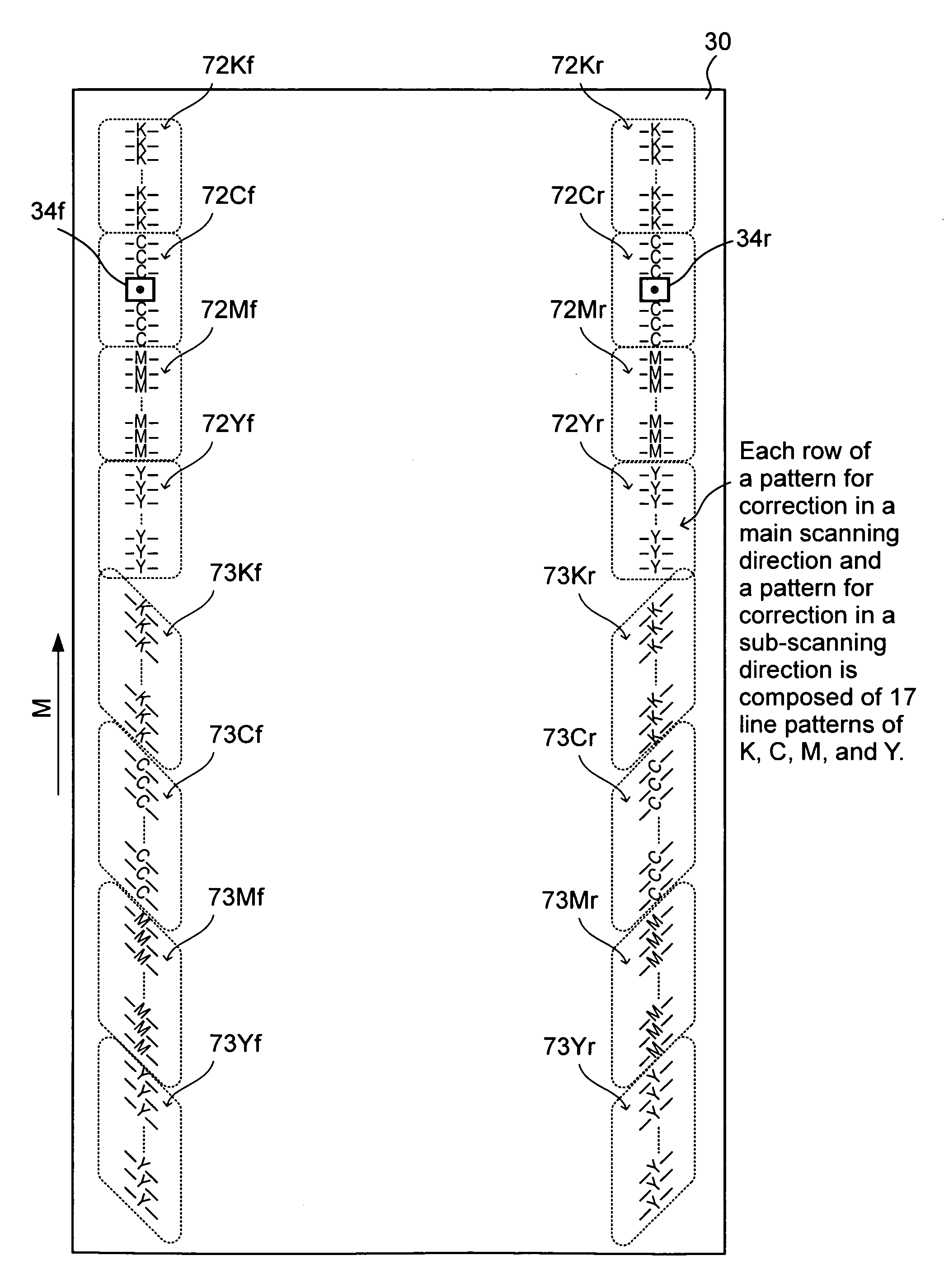

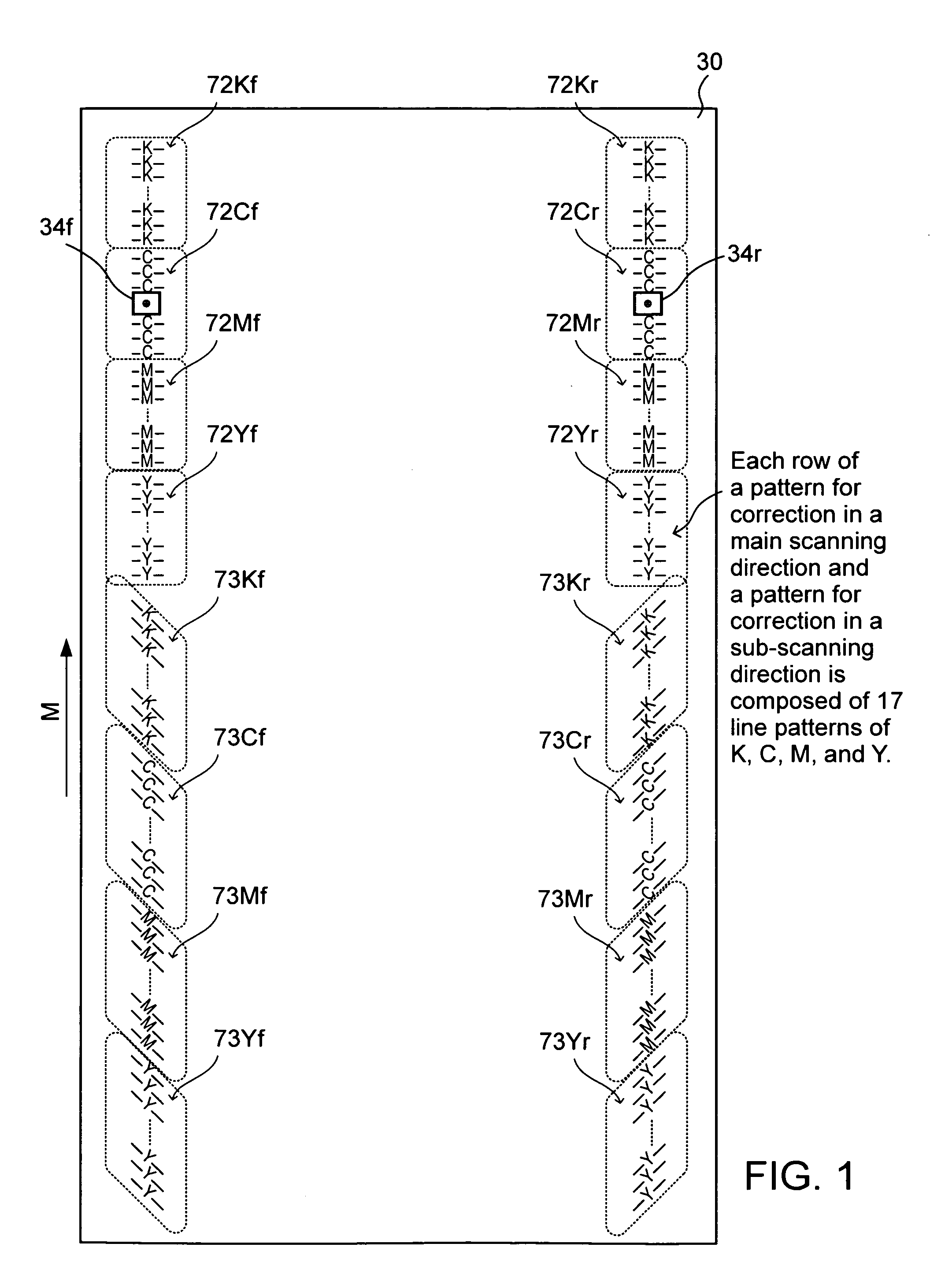

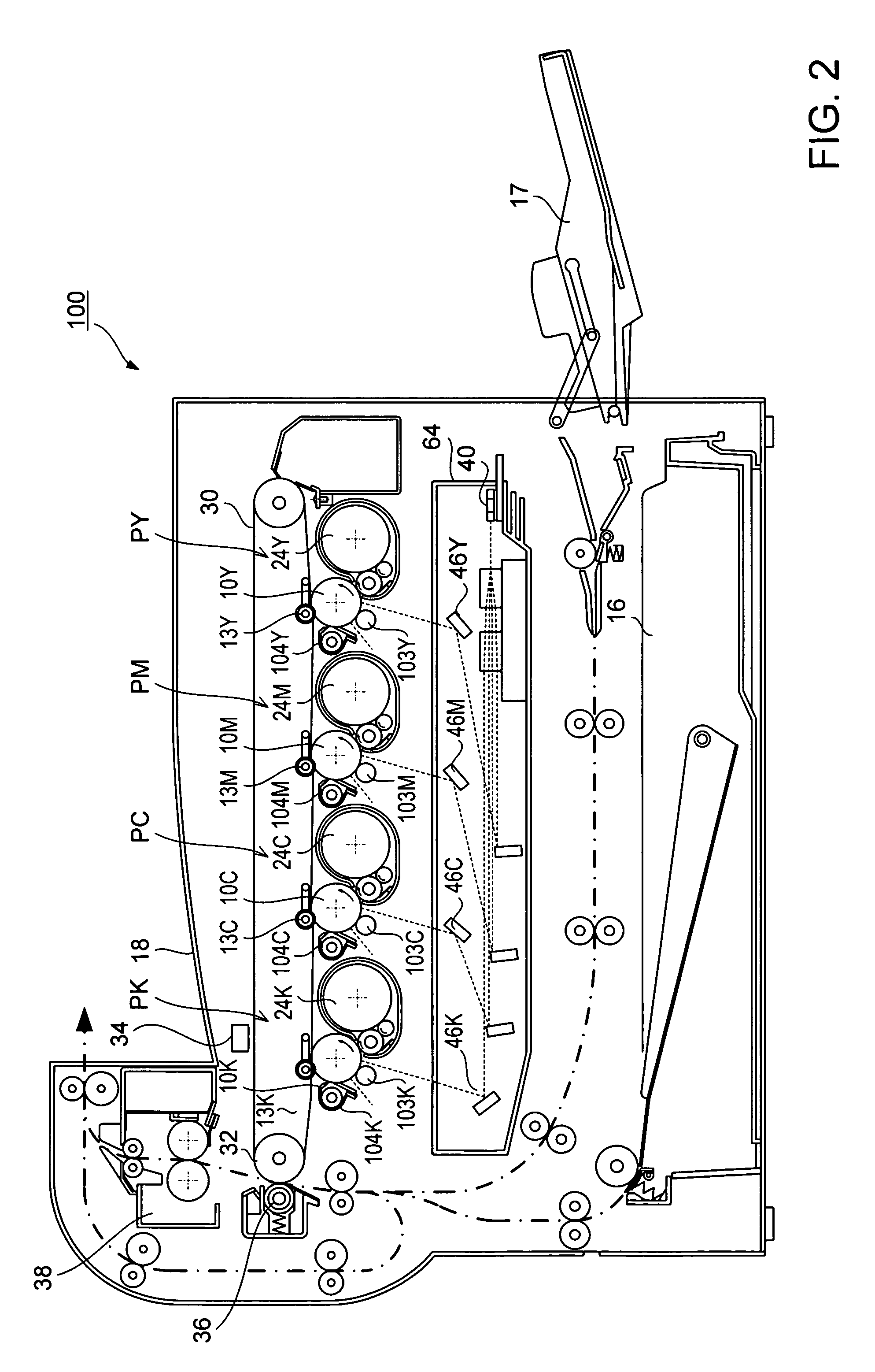

Image forming apparatus with image adjusting function, image adjusting method and image adjusting program

InactiveUS20080226361A1Reduced adjustment accuracySuppression of interference effectsElectrographic process apparatusImage formationComputer science

Owner:SHARP KK

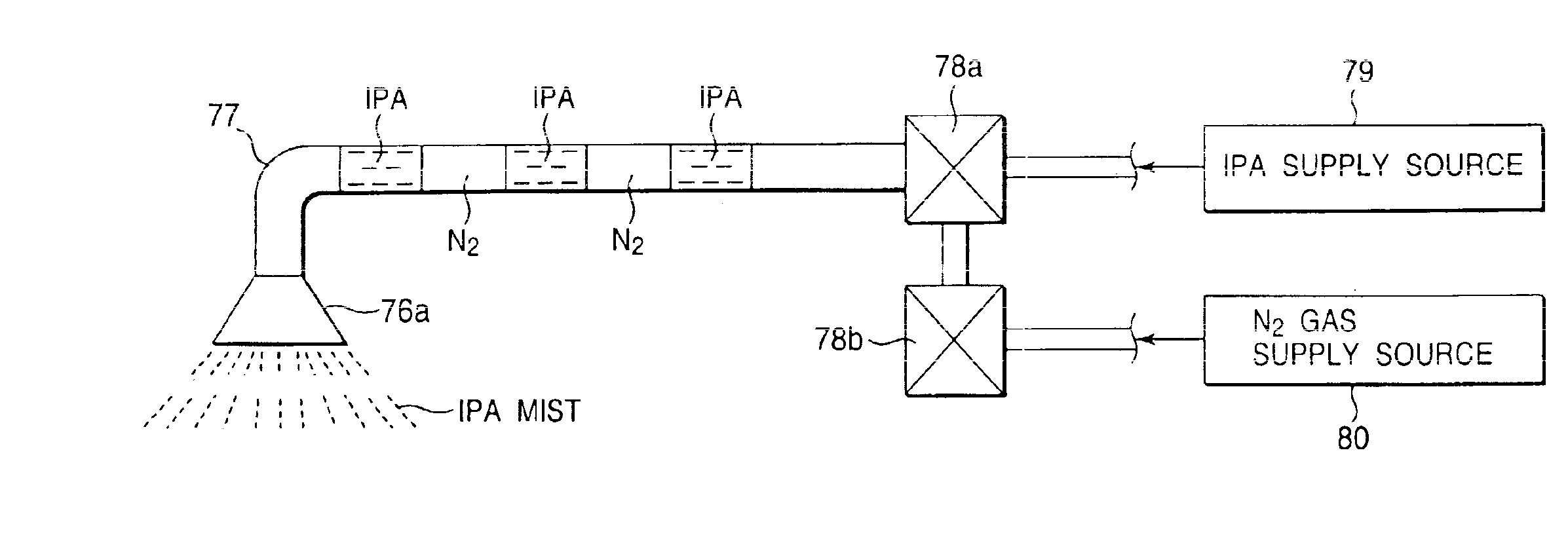

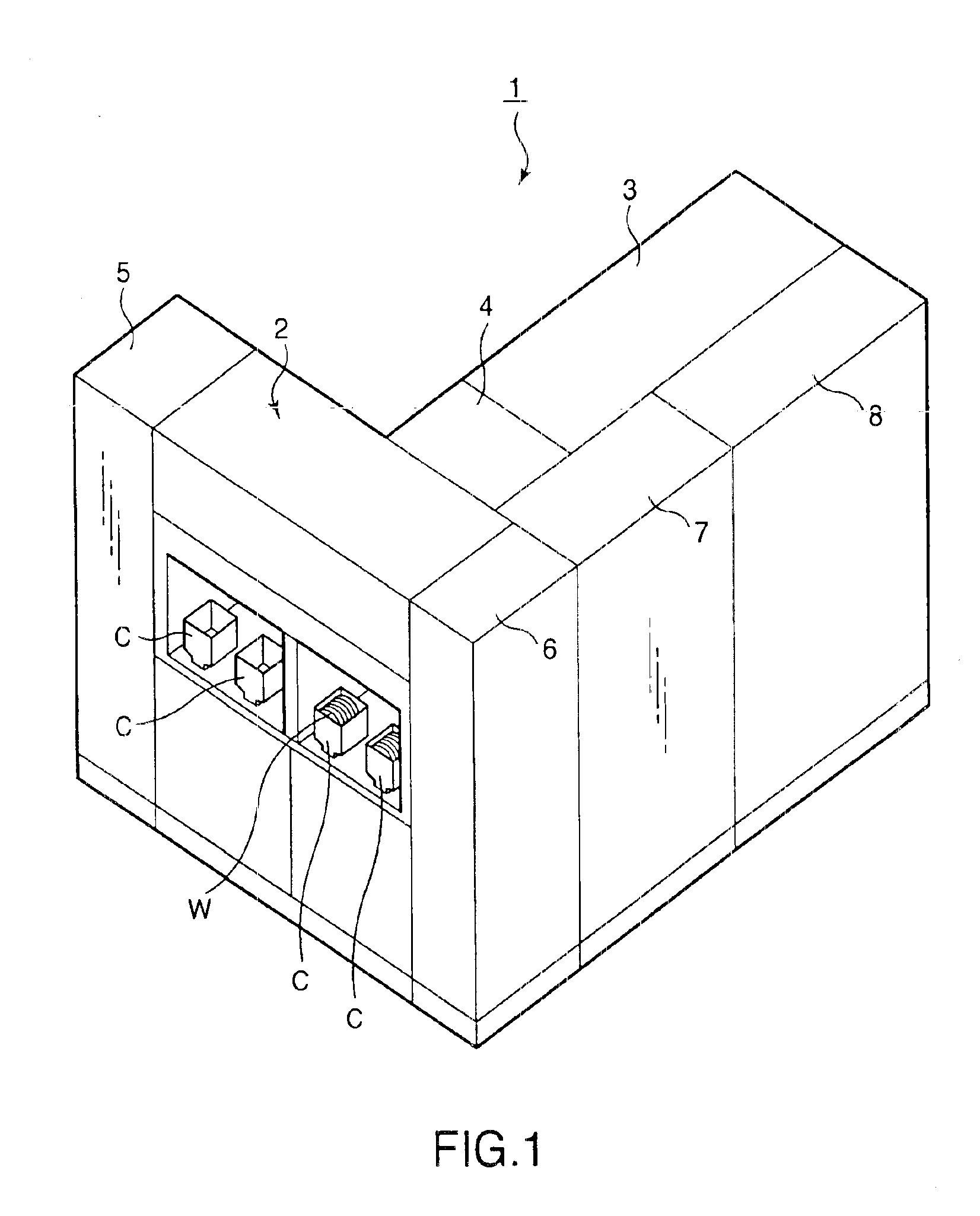

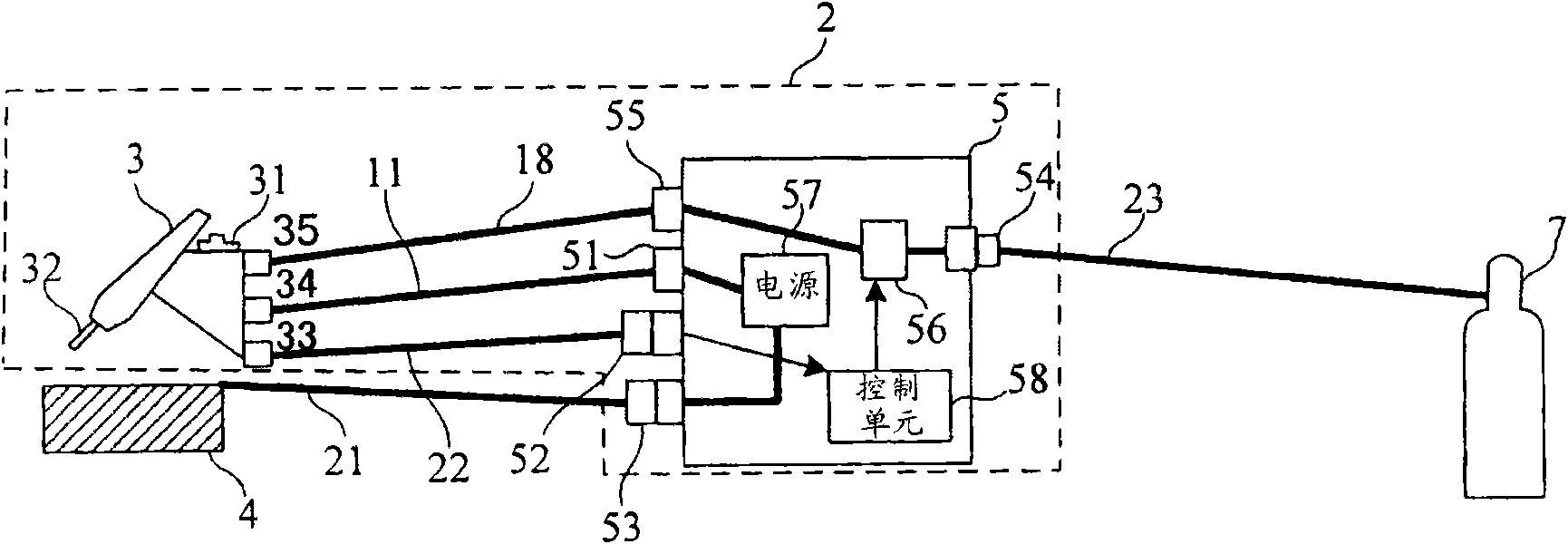

Cleaning processing method and cleaning processing apparatus

InactiveUS6863741B2Curb consumptionLowering water mark generationSemiconductor/solid-state device manufacturingCleaning using liquidsLow speedEngineering

Where a substrate such as a semiconductor wafer held in a process space in a process chamber consisting of an outside chamber and an inside chamber is subjected to a cleaning processing, a chemical agent such as IPA or a solvent having a surfactant added thereto is supplied in the form of a mist or a vapor toward the substrate under the sate that the substrate is stopped or rotated at a low speed after processing with a chemical agent and a subsequent rinsing processing with a pure water. After the supply of the chemical agent is stopped, the substrate is rotated at a rotating speed higher than said low speed so as to centrifugally remove the chemical agent attached to the substrate.

Owner:TOKYO ELECTRON LTD

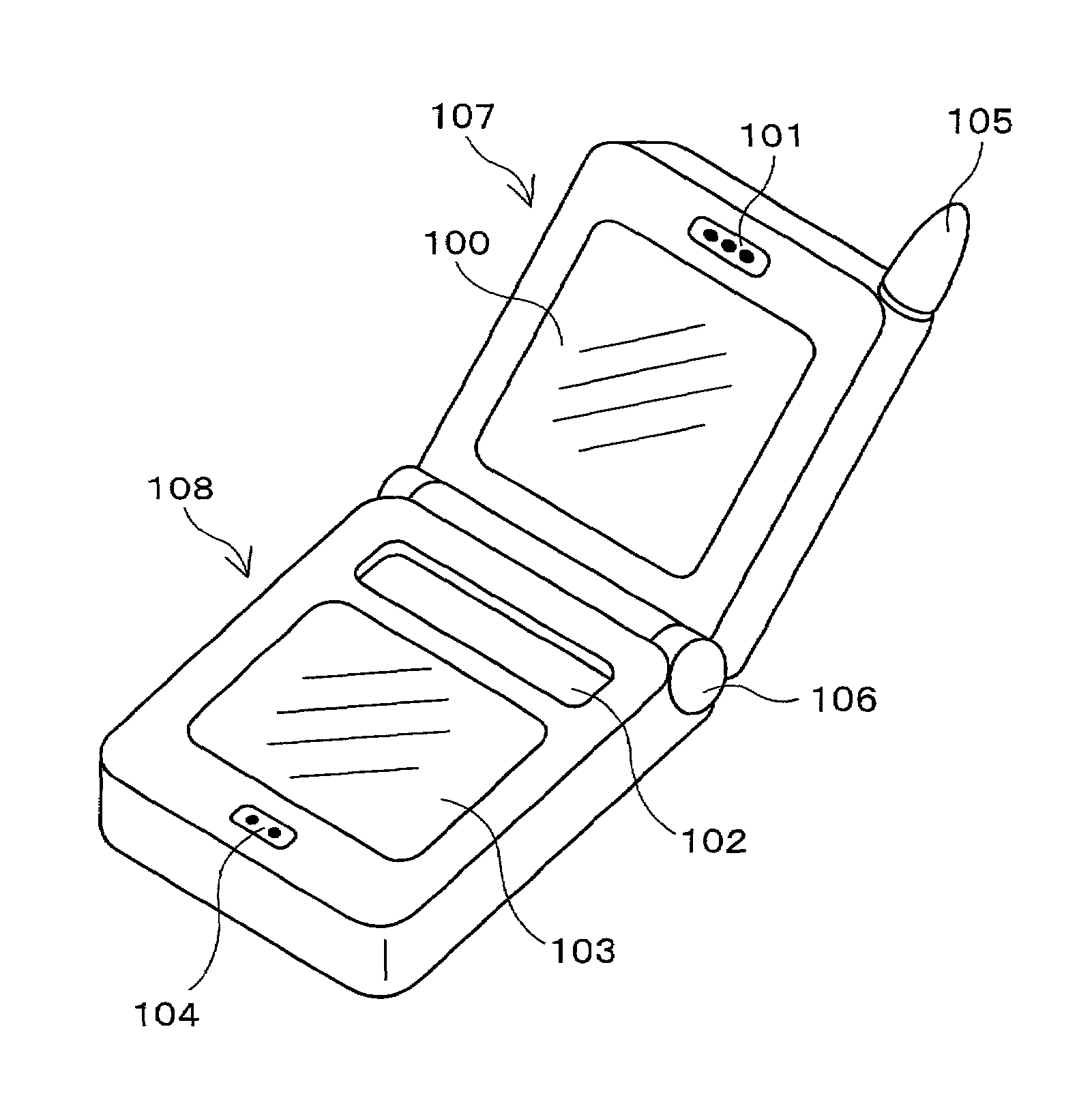

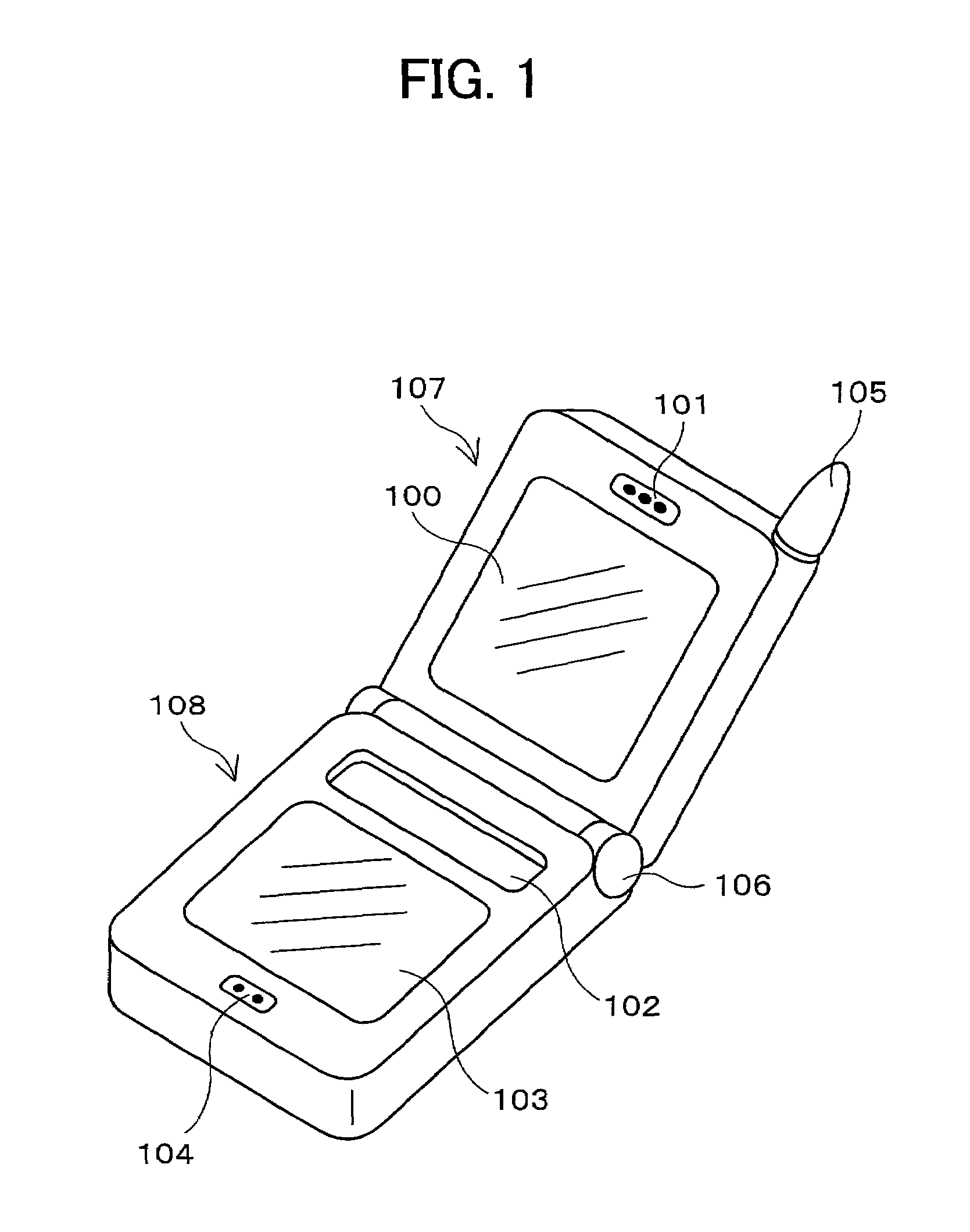

Portable information apparatus for displaying information in a folded state

InactiveUS7016703B2Improve image qualityReduce consumptionPower managementInterconnection arrangementsComputer graphics (images)Imaging quality

Disclosed is a portable information apparatus, which is provided with a display section capable of displaying a color display and a dynamic display in a high image quality, and which consumes less electricity. When the portable information apparatus of a folder type is in a folded state, a display screen 100 is composed of an image display region and a non-image region, so that at least a part of the image display region can be seen via a transparent section 102.

Owner:SHARP KK

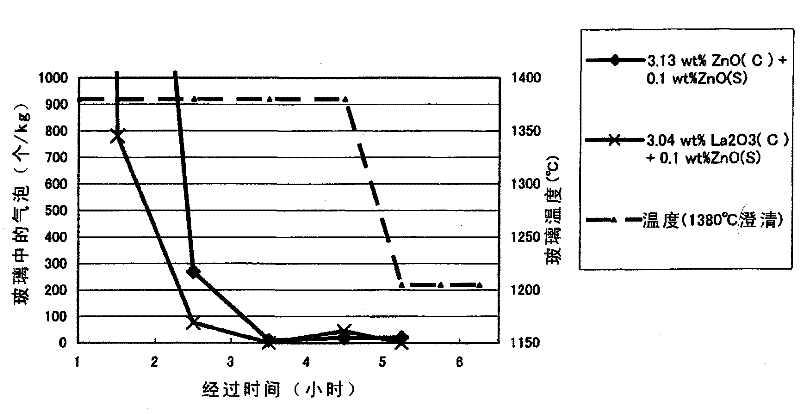

Manufacturing method of glass, optical glass, glass material for press molding, optical element, and their manufacturing method

ActiveCN102272064AReduce erosionReduce volatilityGlass furnace apparatusGlass productionSulfateOptical glass

Disclosed is a method for producing a glass, wherein a molten glass is obtained by melting and refining a glass starting material and the molten glass is molded, thereby producing a glass molded body composed of an optical glass. The method for producing a glass is characterized by comprising preparation of a glass starting material so as to obtain an oxide glass which contains, in cationic percent, 12-65% of B3+, 0-20% of Si4+, 0-6% of Ge4+, 15-50% of La3+, Gd3+, Y3+, Yb3+, Sc3+ and Lu3+ in total, 4-54% of Ta5+, Zr4+, Ti4+, Nb5+, W6+ and Bi3+ in total, 0-35% of Zn2+, 0-9% of Li+, Na+ and K+ in total and 0-15% of Mg2+, Ca2+, Sr2+ and Ba2+ in total, with the sum of all cationic components being 99-100%. The method is also characterized in that the glass starting material contains a carbonate and a sulfate.

Owner:HOYA CORP

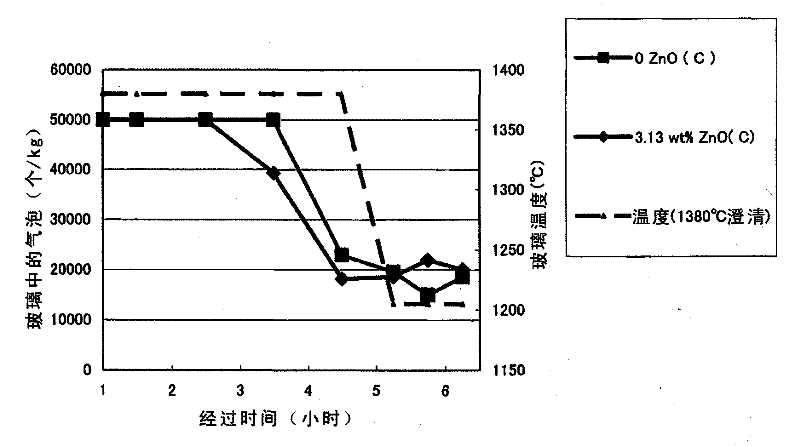

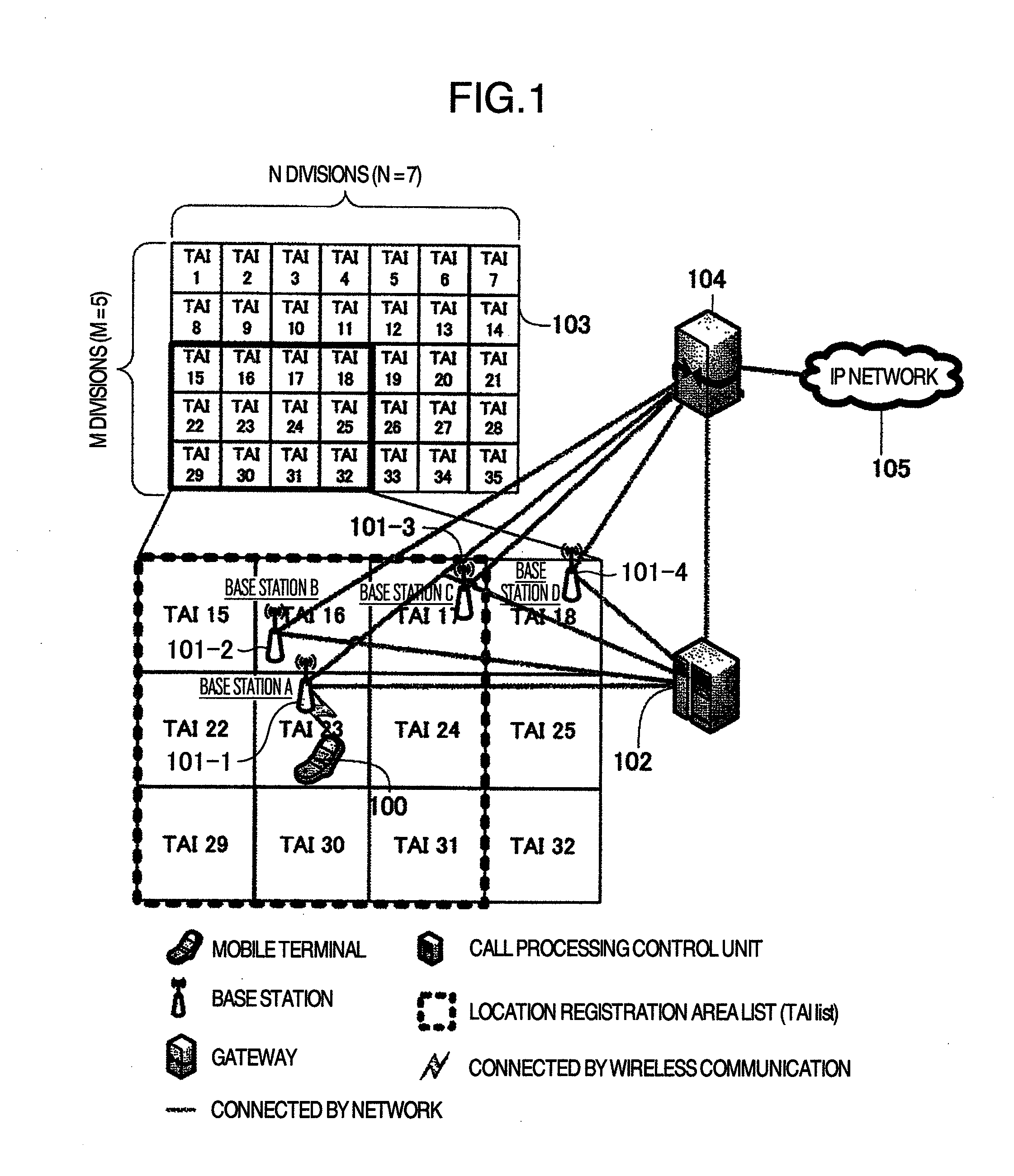

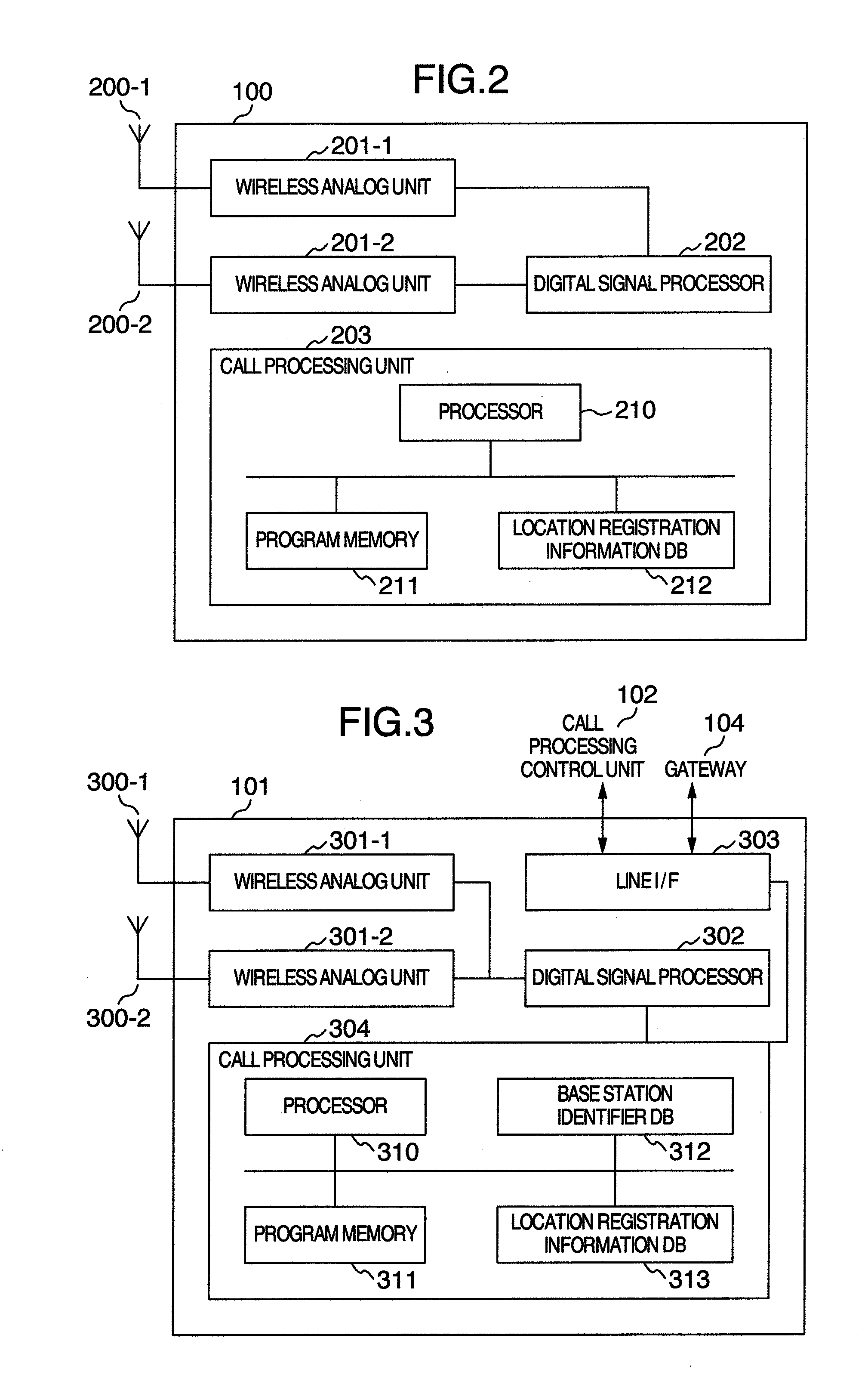

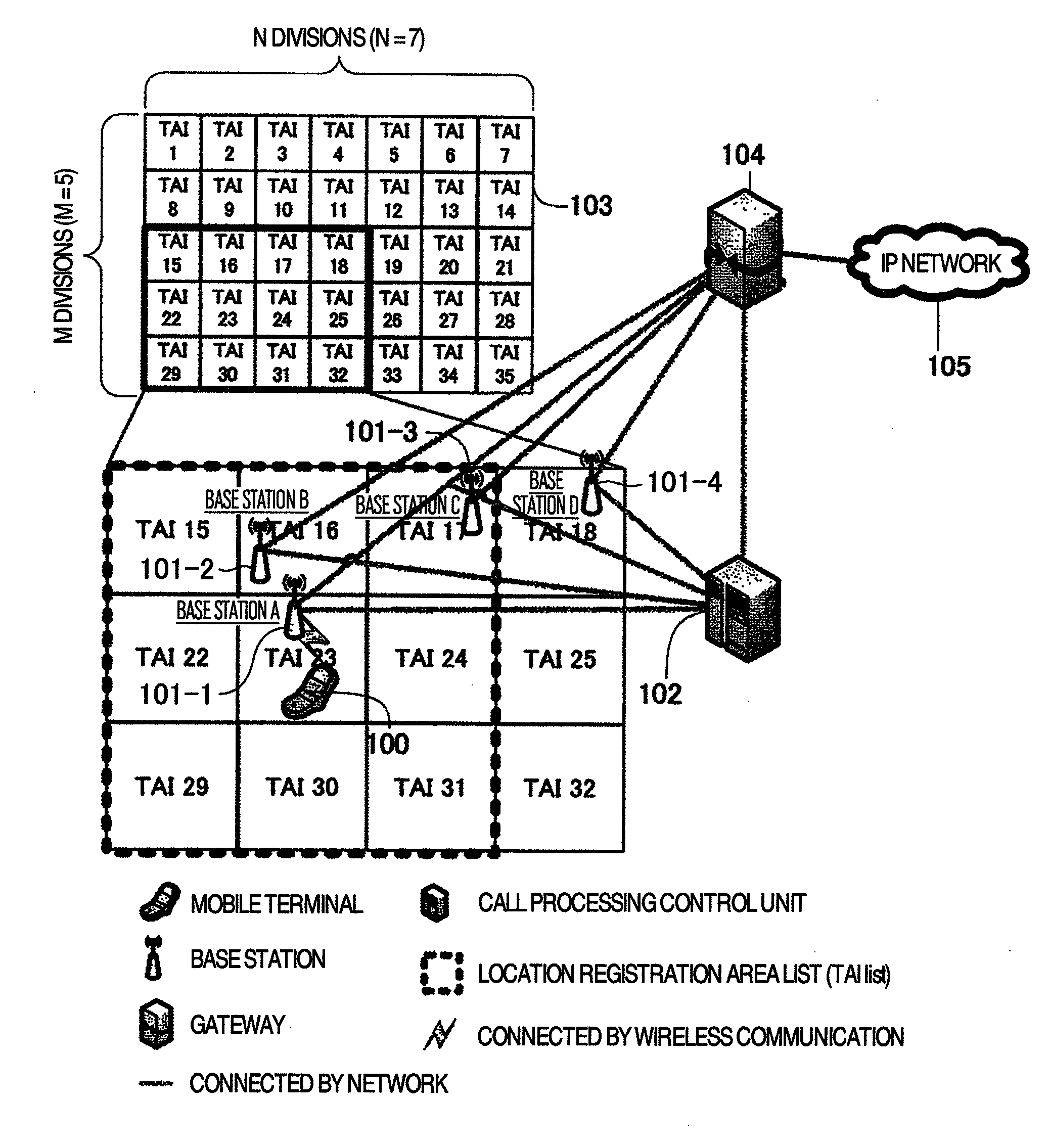

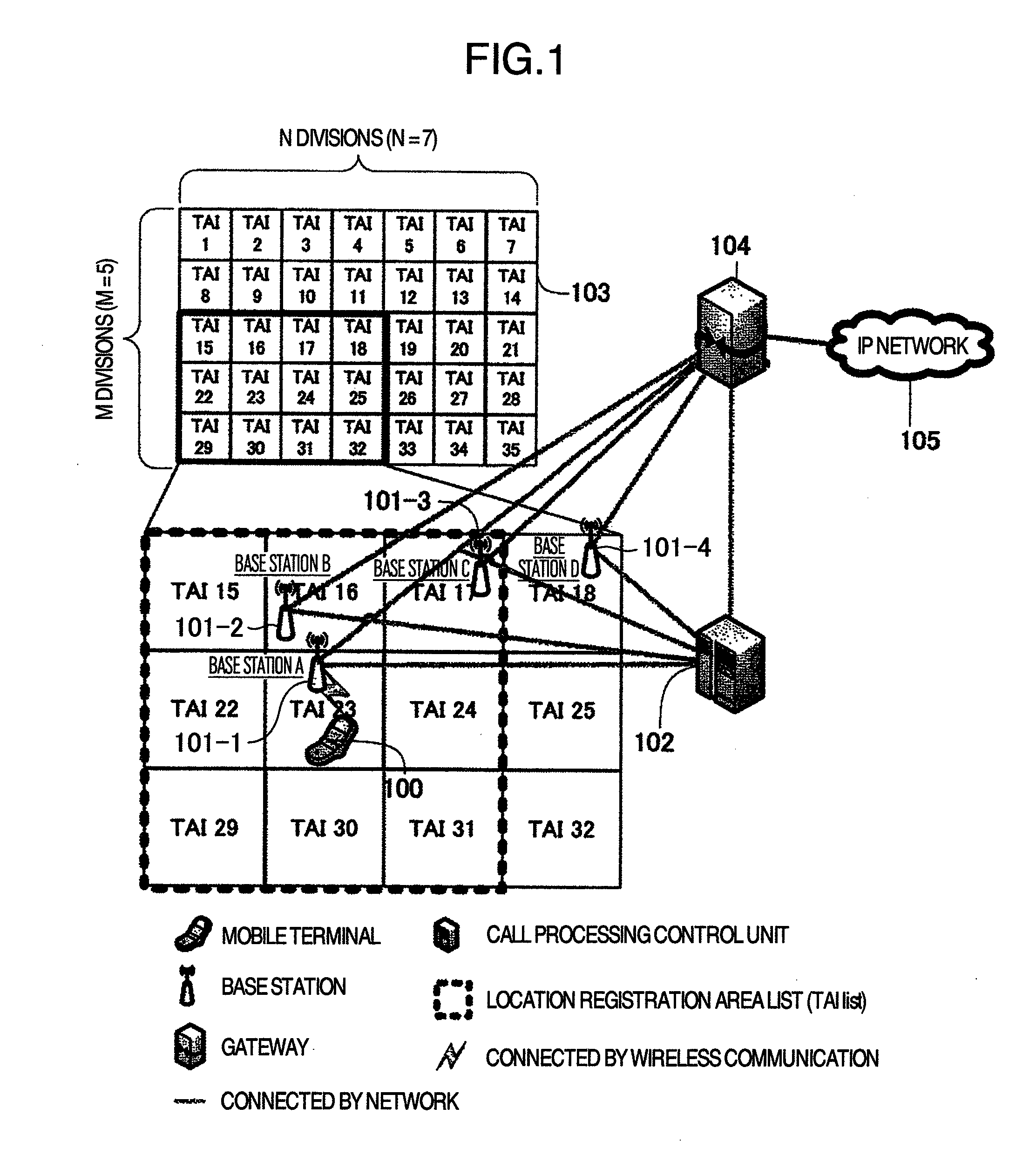

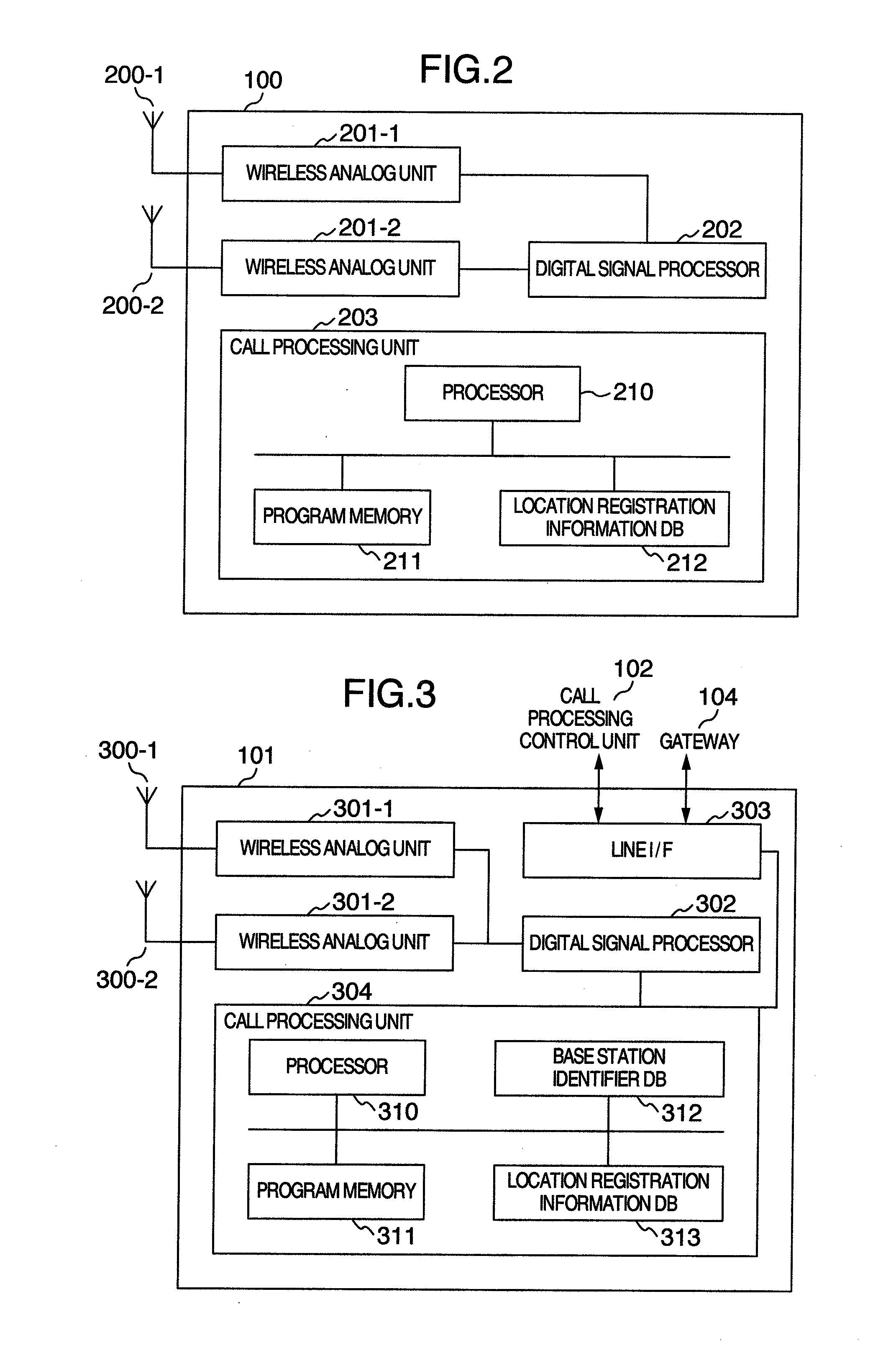

Wireless communication system

ActiveUS20100255841A1Network degradationReduce loadSubstation equipmentWireless commuication servicesCommunications systemControl unit

A wireless communication system including a wireless terminal, a plurality of base stations and a call processing control unit is disclosed. The wireless terminal, upon reception of the notification information from any of the base stations, judges whether the area included in the notification information is contained in the location registration area list stored in a storage unit, and in the case where the particular area is not so contained, sends a location registration request to the call processing control unit. On the other hand, the call processing control unit creates a new location registration area list based on the area included in the notification information and the neighboring areas, and sends the location registration area list to the wireless terminal.

Owner:HITACHI LTD

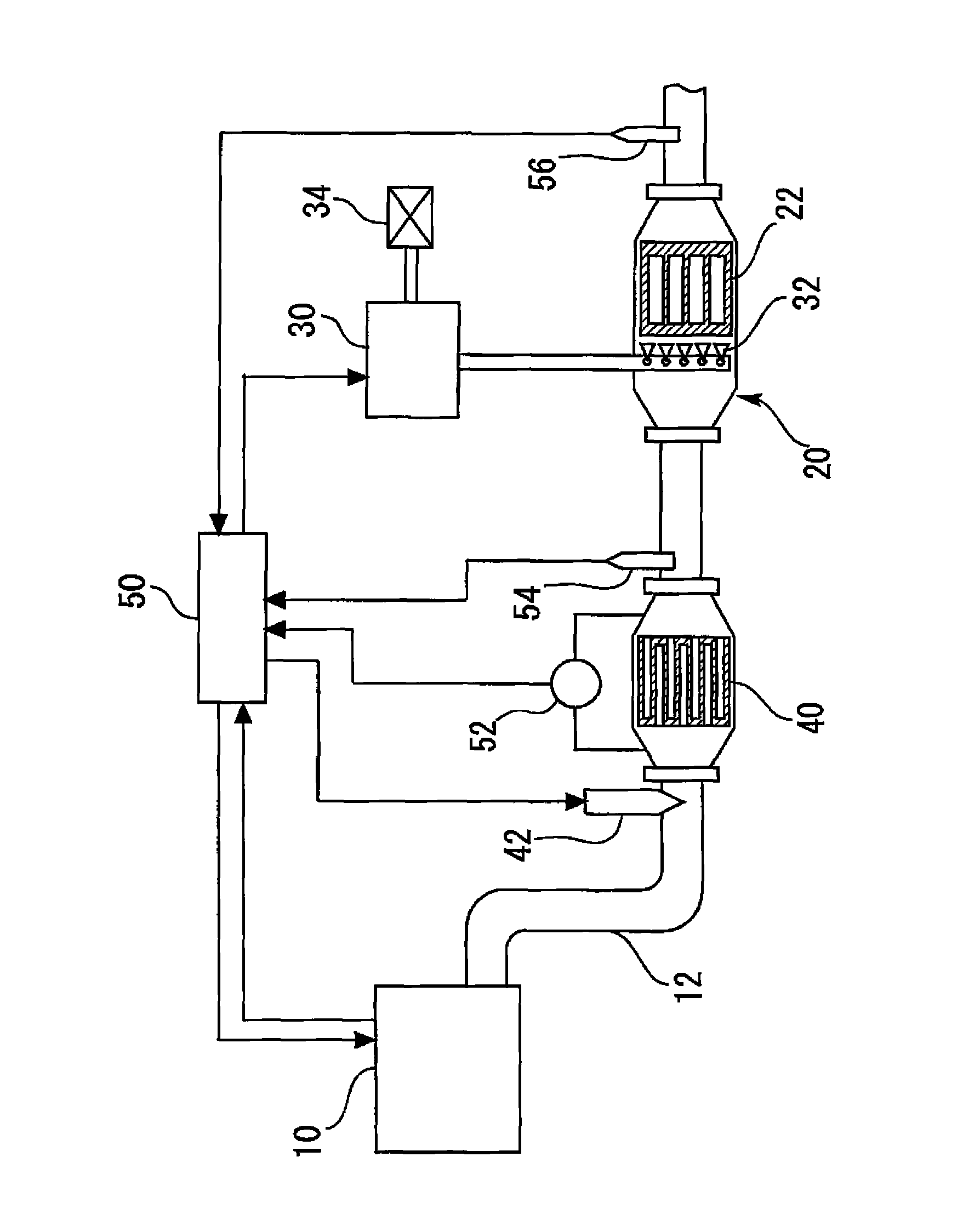

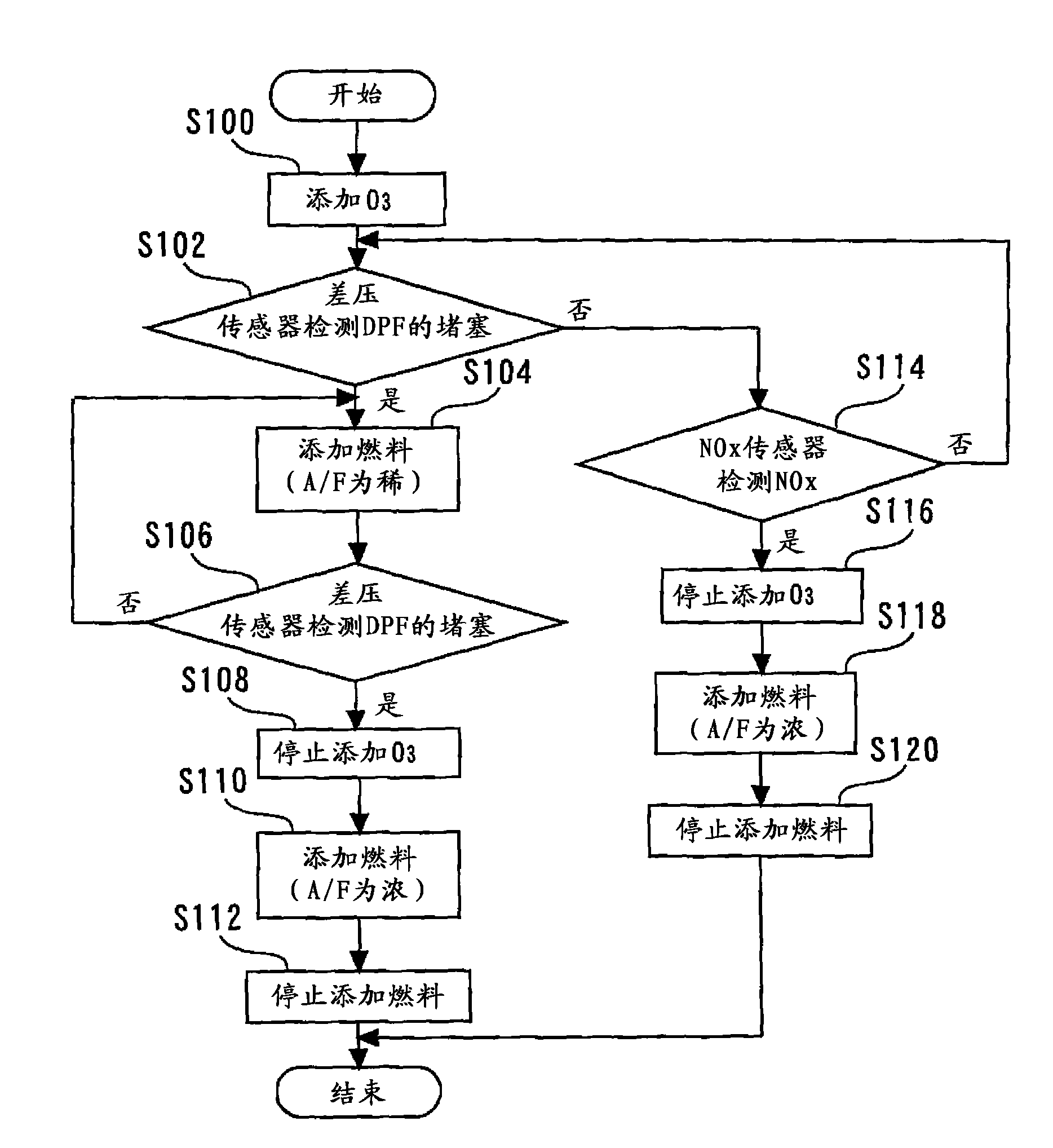

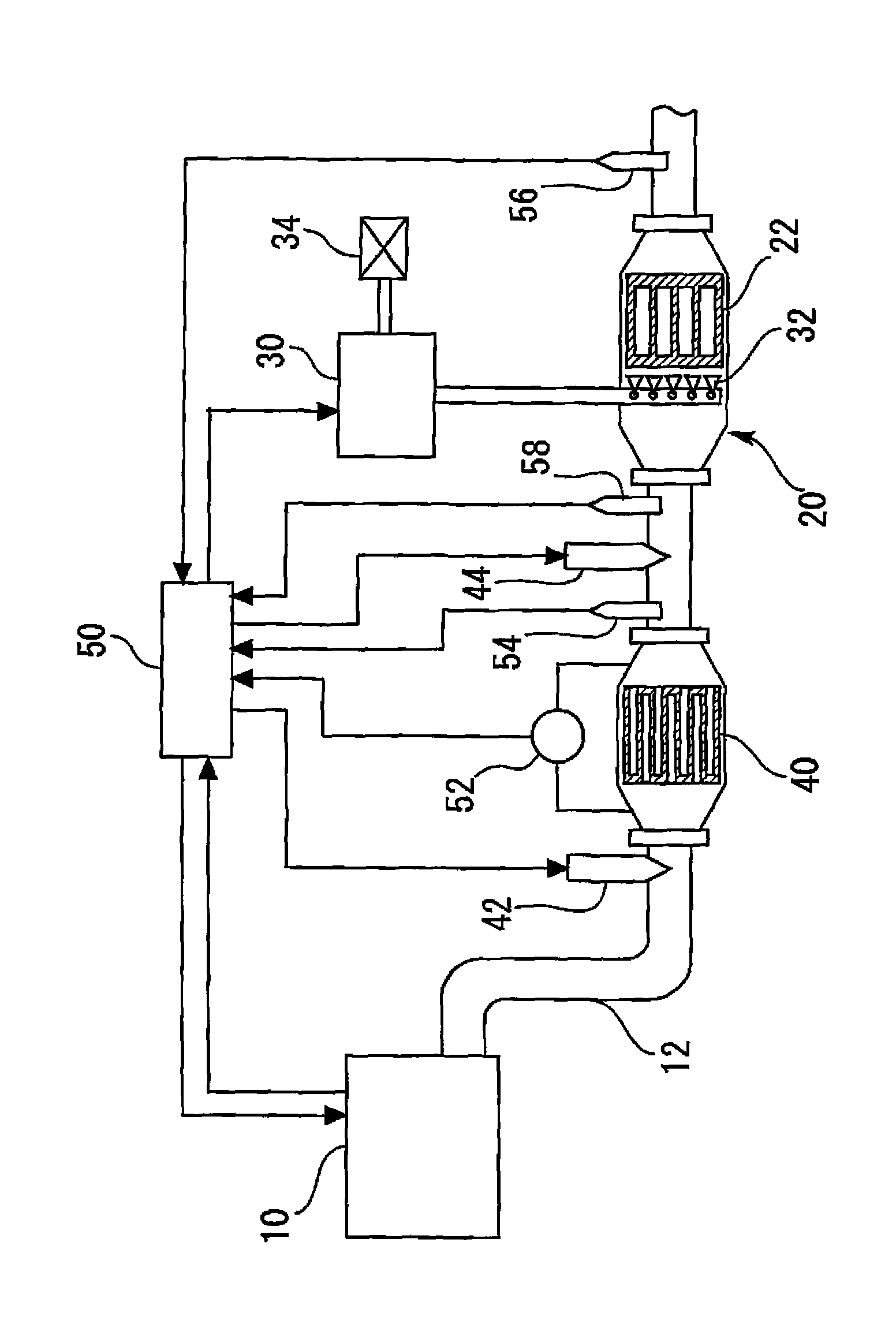

Apparatus for purifying exhaust gas of internal combustion engine

InactiveCN101636565AFacilitate occlusionFacilitate occlusion reactionGas treatmentInternal combustion piston enginesParticulatesExhaust fumes

The invention provides an exhaust gas purifying apparatus comprising a NOx storage reduction catalyst and a particulate filter, wherein the original NOx storage ability of the NOx storage reduction catalyst is sufficiently utilized. Specifically, the exhaust gas purifying apparatus comprises a filter (40) arranged in the upstream of a NOx storage reduction catalyst (22), a fuel supply means (42) for supplying a fuel so that the fuel is mixed with the exhaust gas flowing into the filter (40), and an ozone supply means (30) for supplying ozone in the downstream of the filter (40) so that ozone is mixed with the exhaust gas flowing into the NOx storage reduction catalyst (22).

Owner:TOYOTA JIDOSHA KK

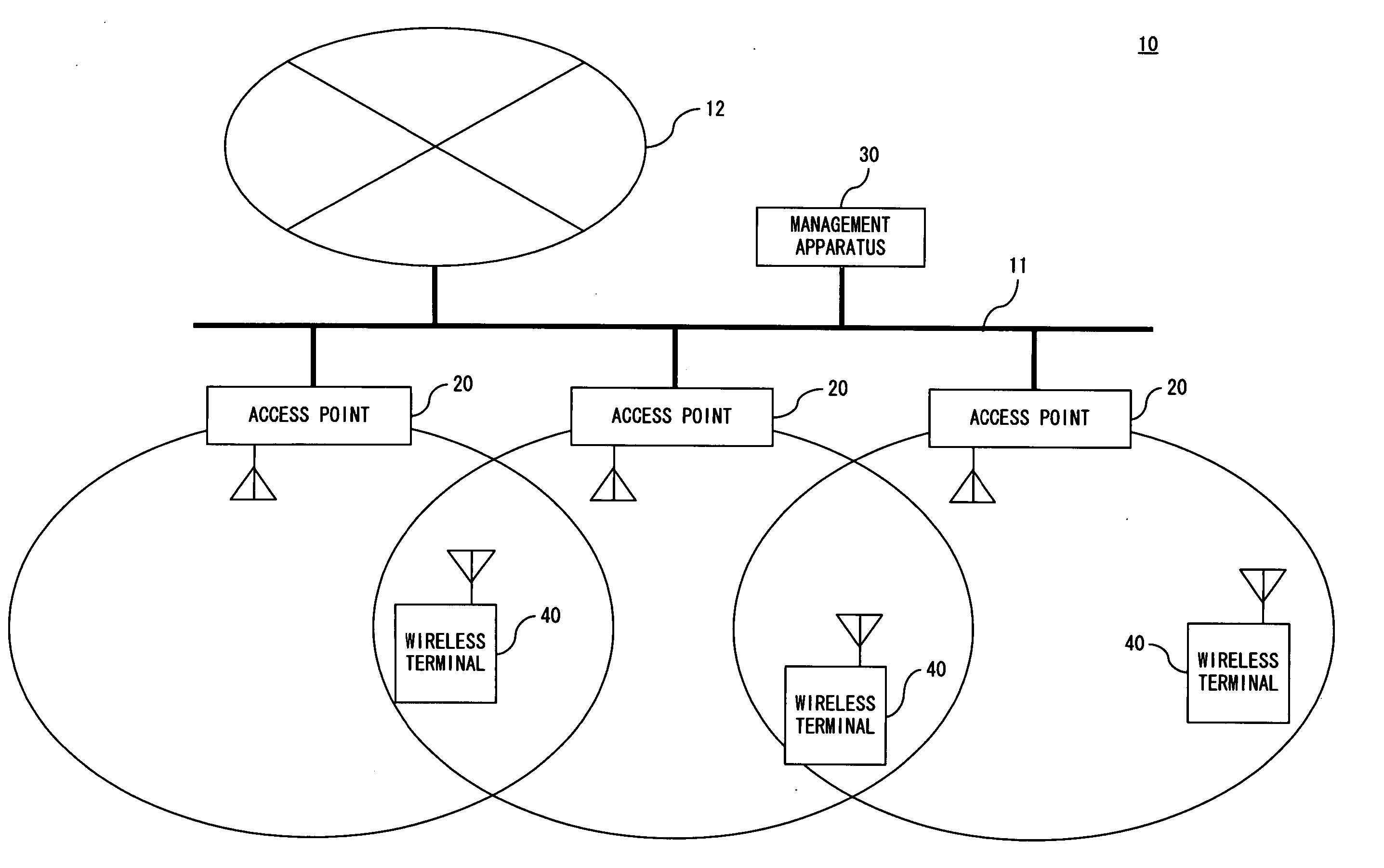

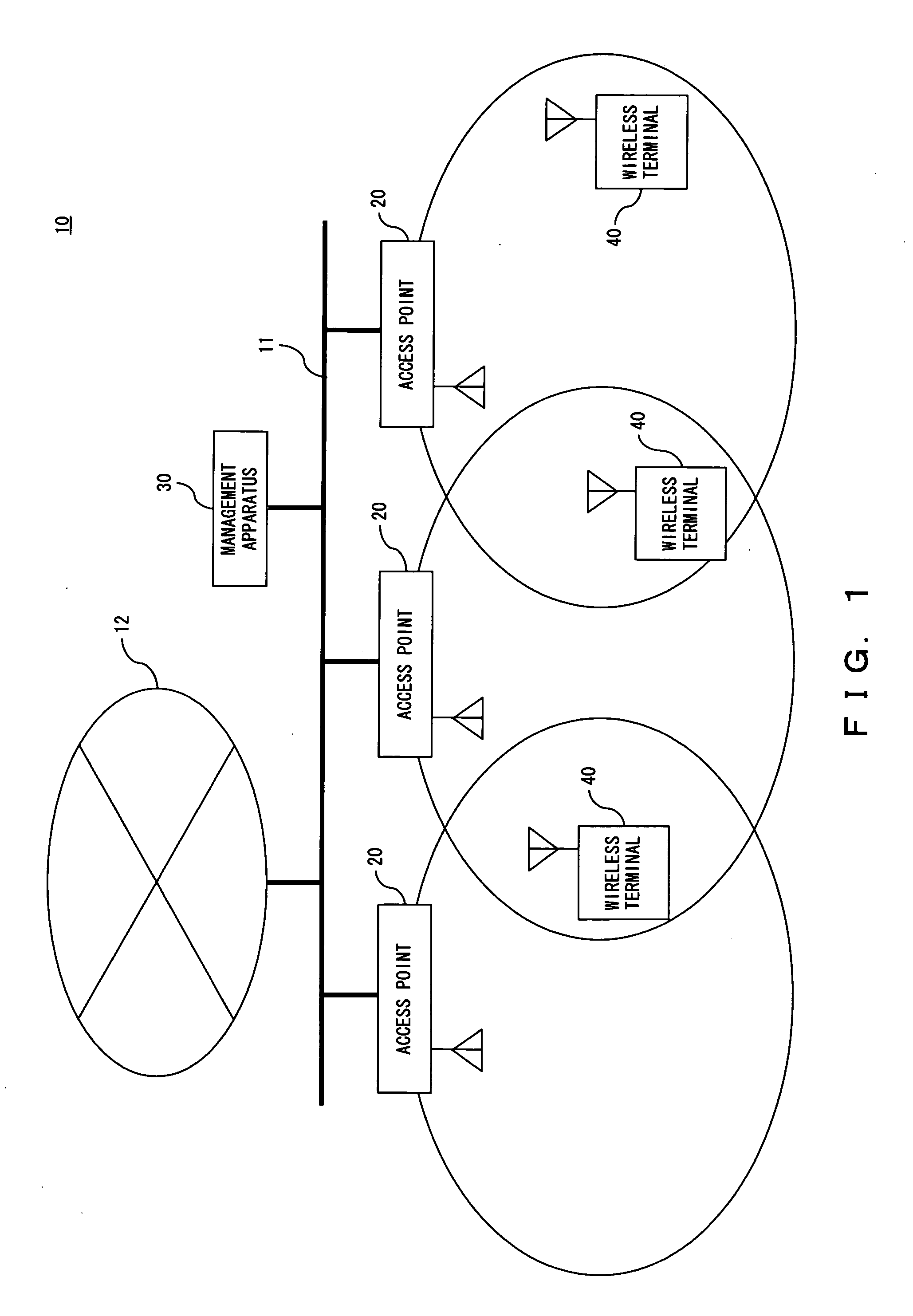

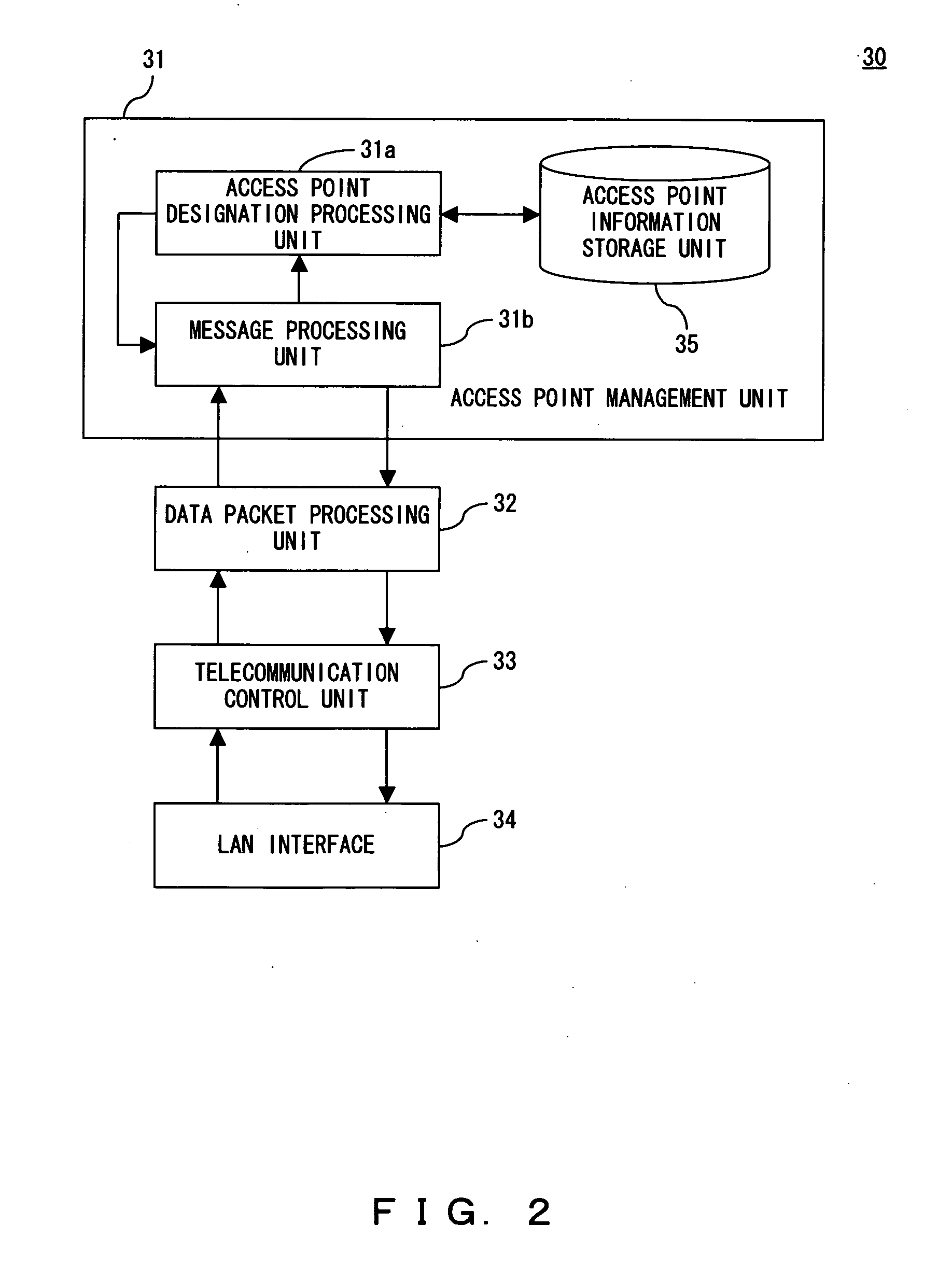

Wireless terminal, management apparatus and wireless LAN control method

InactiveUS20070047480A1Avoid connectionCurb consumptionAssess restrictionNetwork topologiesWireless controlWireless lan

The present invention provides a wireless terminal for constituting a wireless local area network together with a plurality of access points and a management apparatus that manages the access points and carries out a wireless telecommunication with the access points, comprising an access point notification unit for transmitting connection request information, which includes identifier information about a plurality of the access points recognized as communicable and radio wave information about the wireless telecommunication with each of the access points, to the management apparatus by way of one of the access points.

Owner:FUJITSU LTD

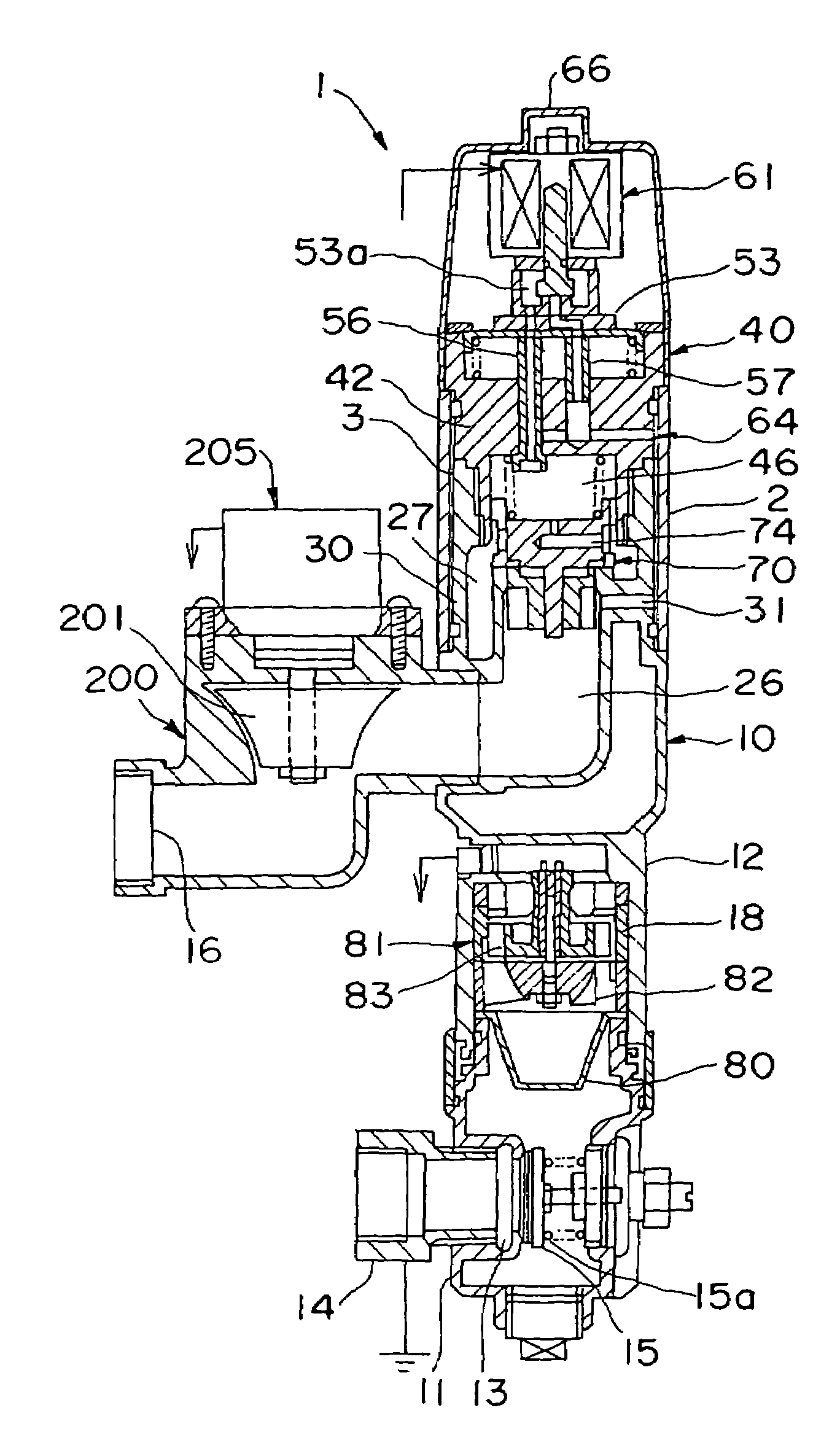

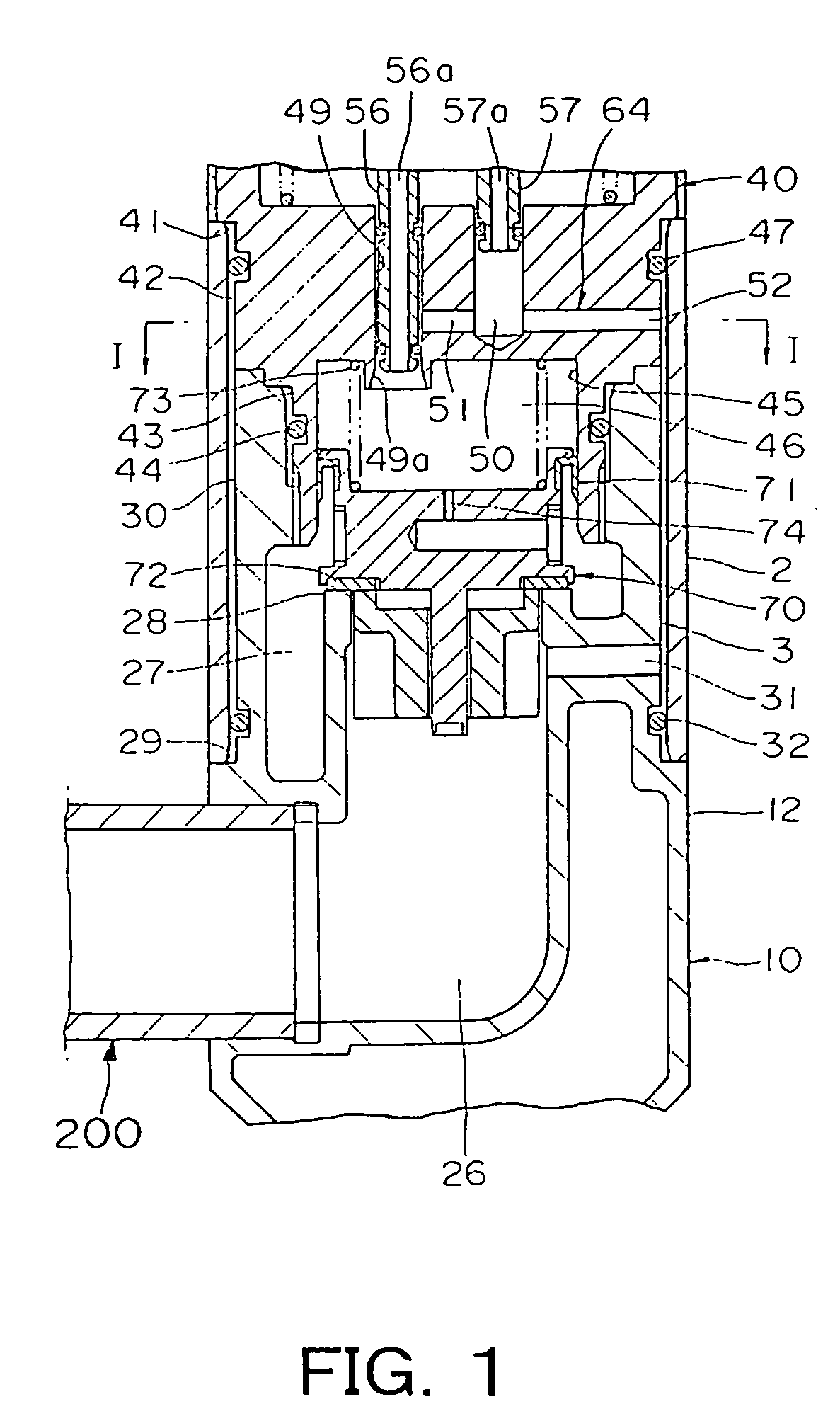

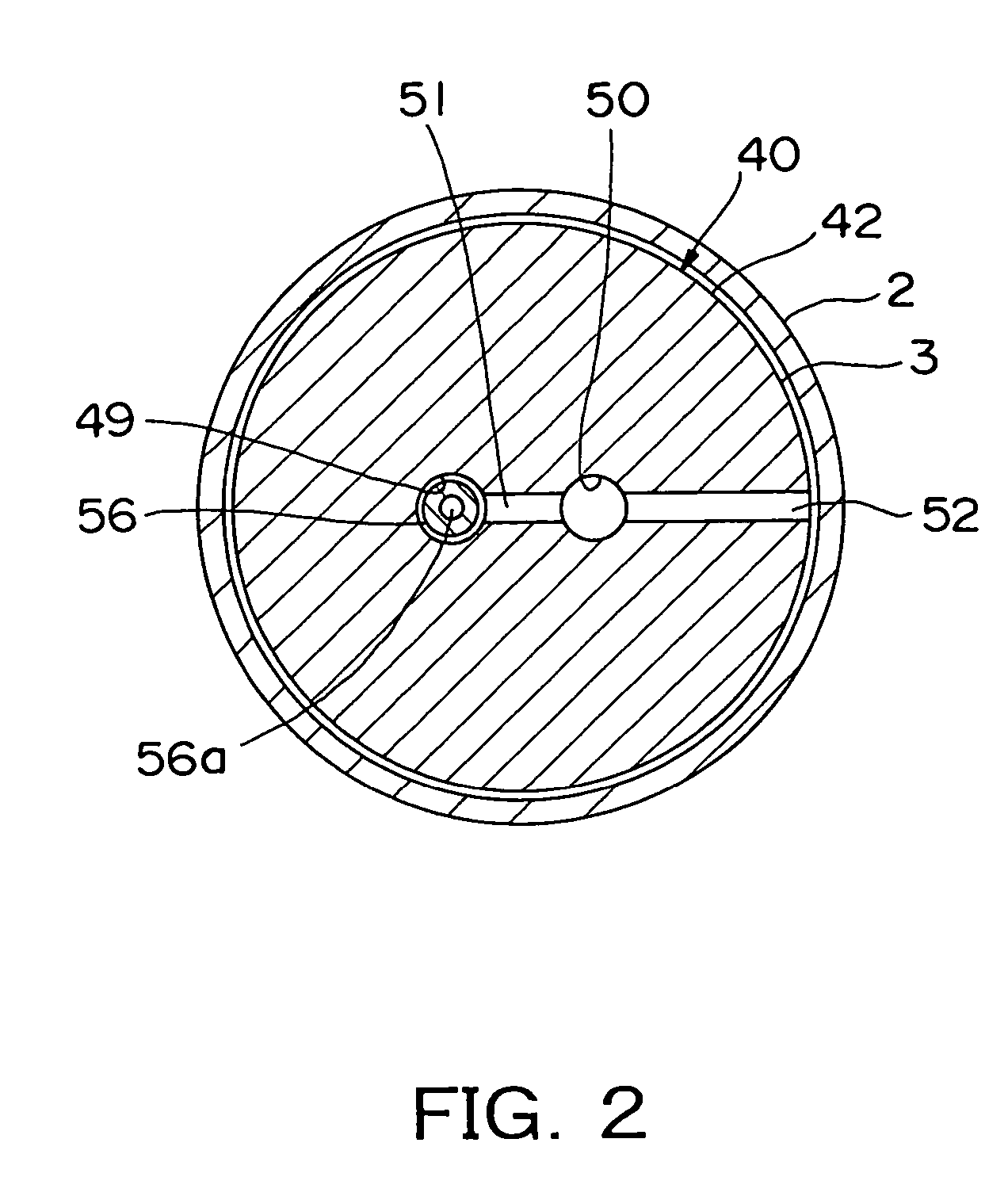

Flow control device

ActiveUS7549439B2Curb consumptionImprove propertiesMeasurement of fluid loss/gain rateOperating means/releasing devices for valvesWater savingEngineering

A flow control device having a power saving effect in addition to a water saving effect. Further, another object is to provide a flow control device easy to install, maintain and manage. The flow control device of the invention comprises a flush valve device having a main control valve in a path leading from an inlet to an outlet, a flowmeter unit for converting the presence or absence of flow of washing water leading from the inlet to the outlet into a pulse signal and outputting the latter, a control device for controlling the opening and closing of the main control valve according to the output of the flowmeter unit, and a power generating unit for generating power by using the flow of the washing water as power, wherein at least part of the power obtained in the power generating unit is supplied to the control device.

Owner:KIMURA GIKEN KK

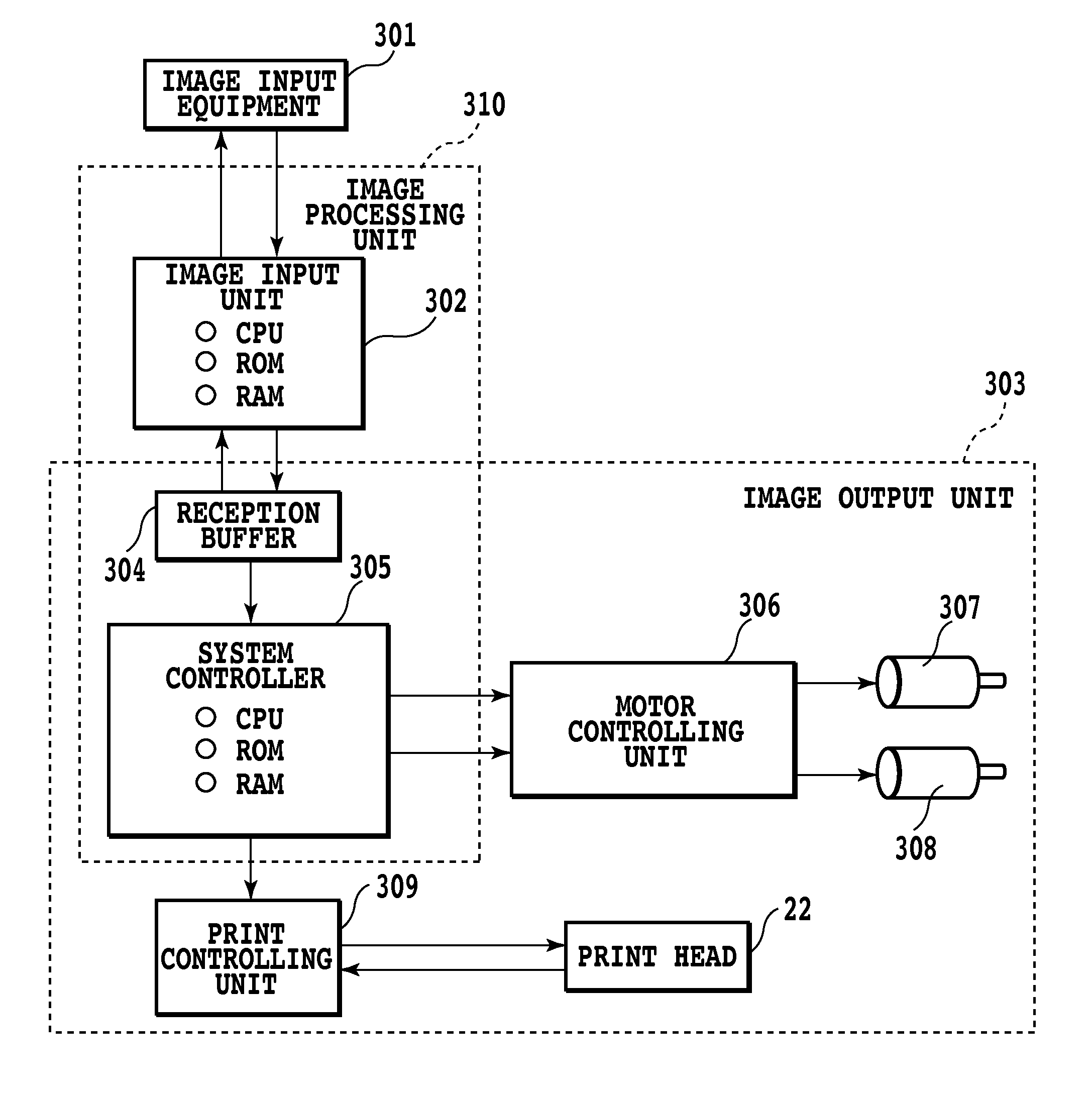

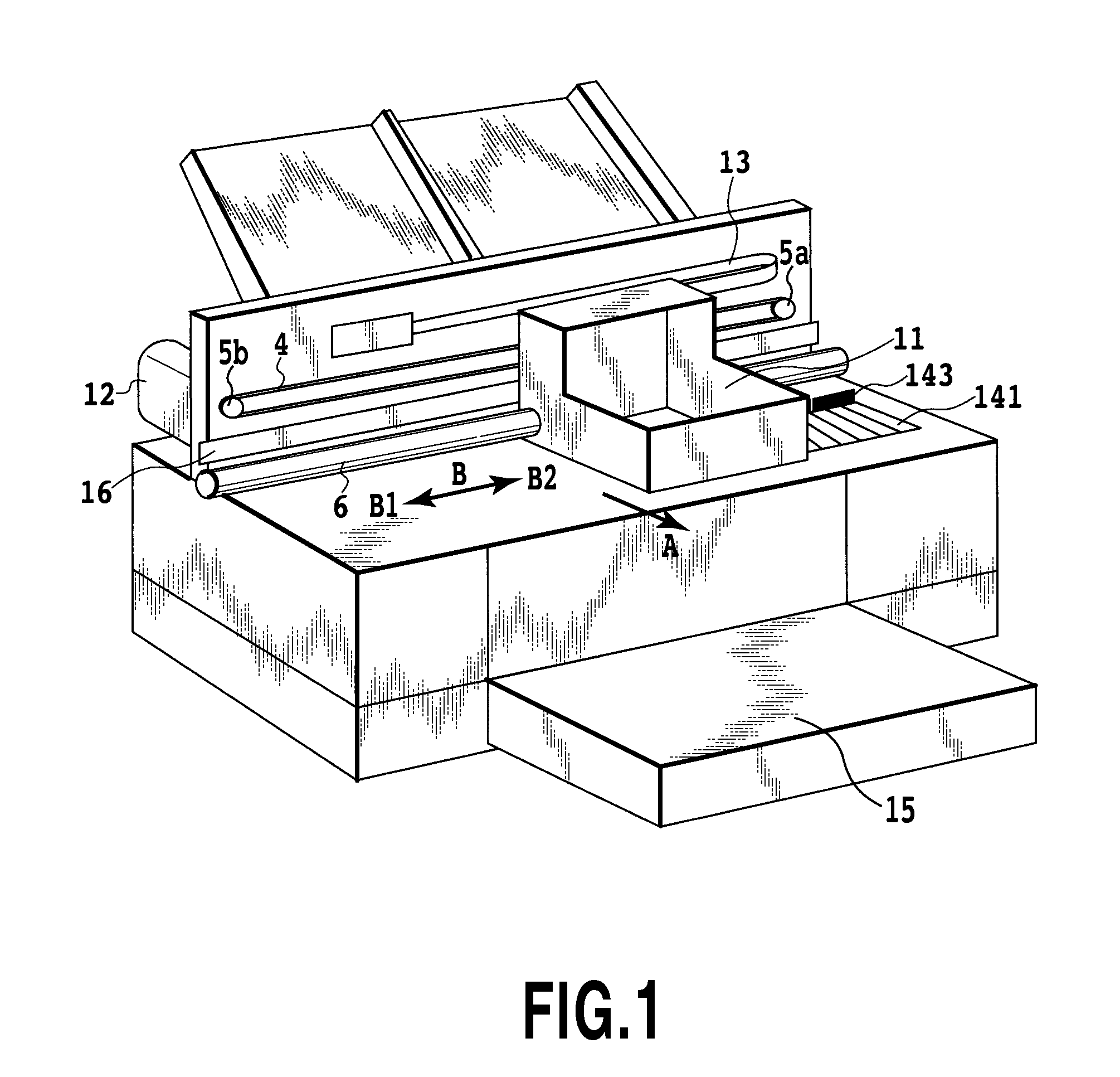

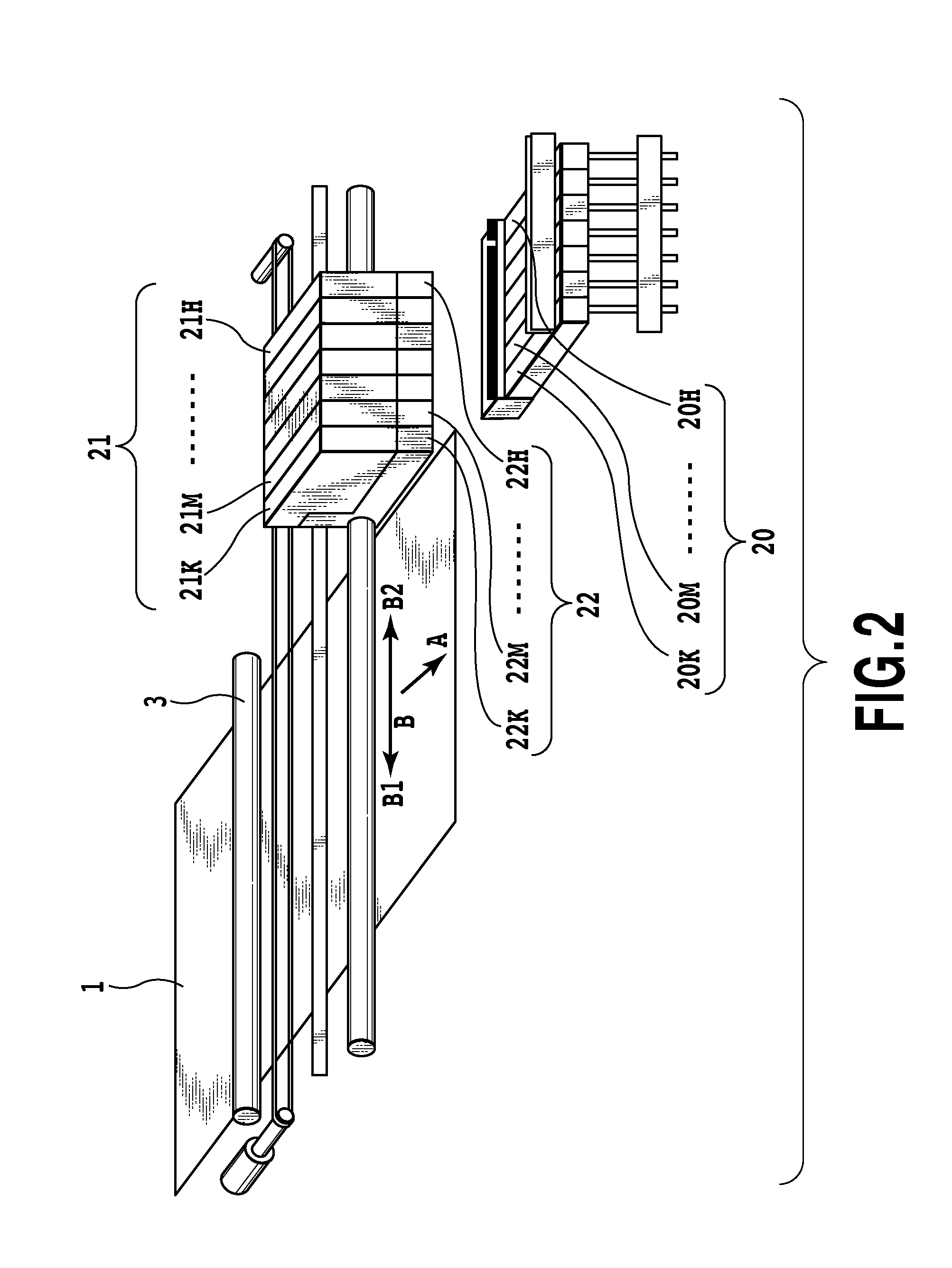

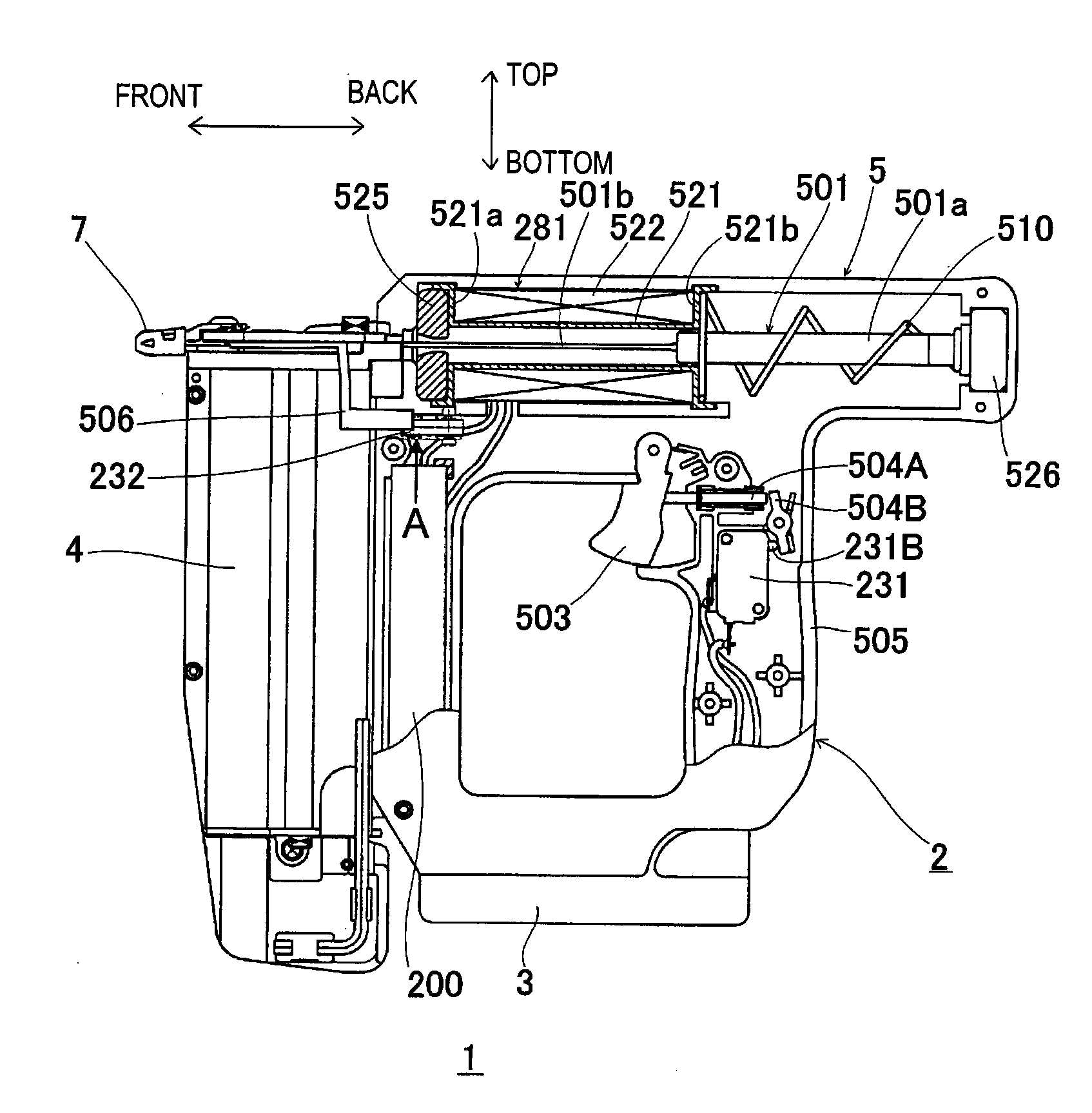

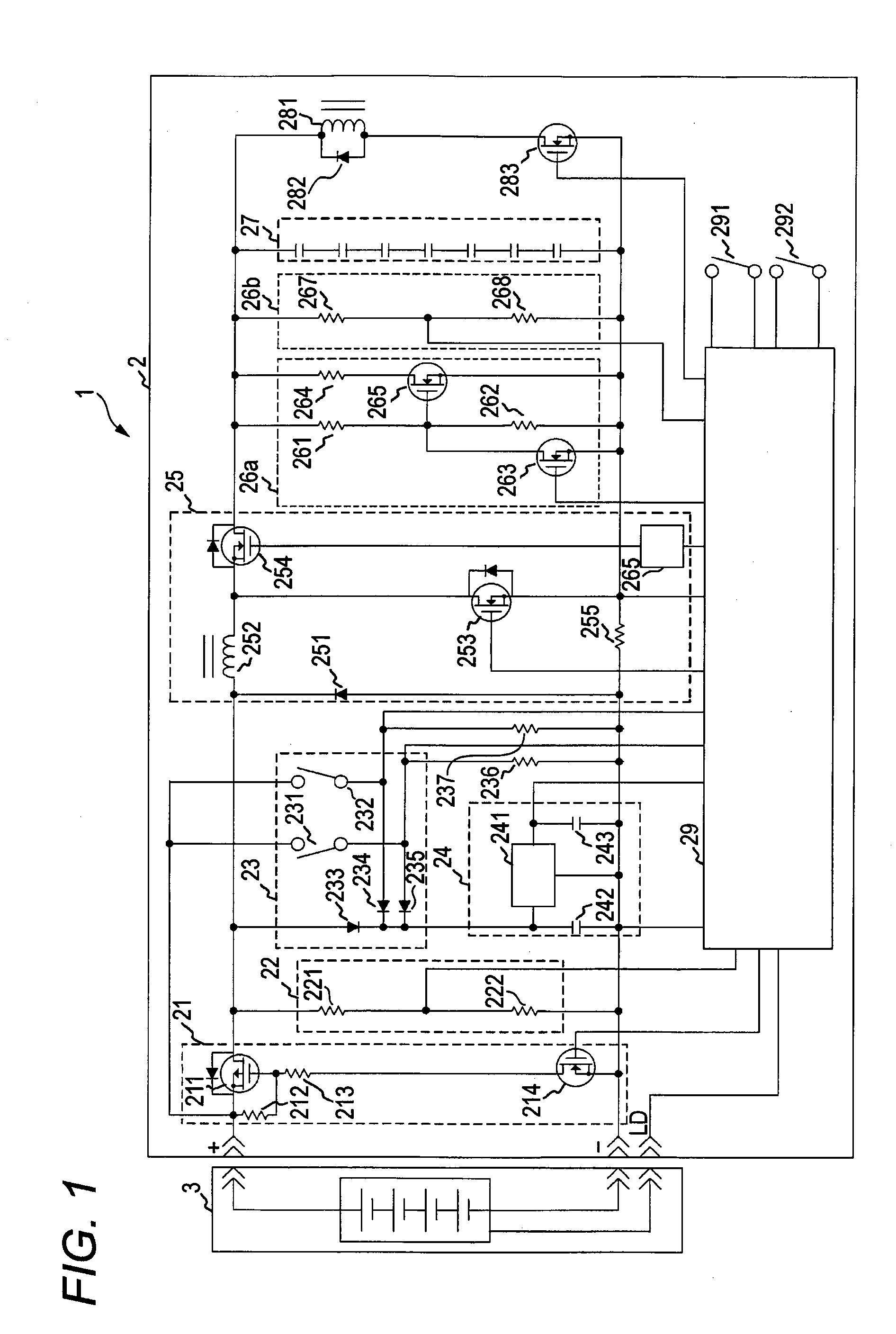

Inkjet printer, inkjet printing method and program

InactiveUS20100328389A1Curb consumptionDegradation of image characteristicSpacing mechanismsVisual presentationEngineeringMechanical engineering

The present invention has an object of providing an inkjet printing apparatus which can improve image performance while restricting an ink consumption amount of a treatment liquid. The present invention generates ejection data for ejecting the plural kinds of the ink and the treatment liquid to each predetermined area of a printing medium in a predetermined order from the print head. The plural kinds of the ink is classified in plurality based upon a minimum application amount of the treatment liquid per a predetermined area required for realizing an effect of the treatment liquid. Ejection data generating unit generates the ejection data in such a manner as to eject the plural kinds of the ink and the treatment liquid from the print head according to the order determined in accordance with the classification of the ink ejected within the predetermined area.

Owner:CANON KK

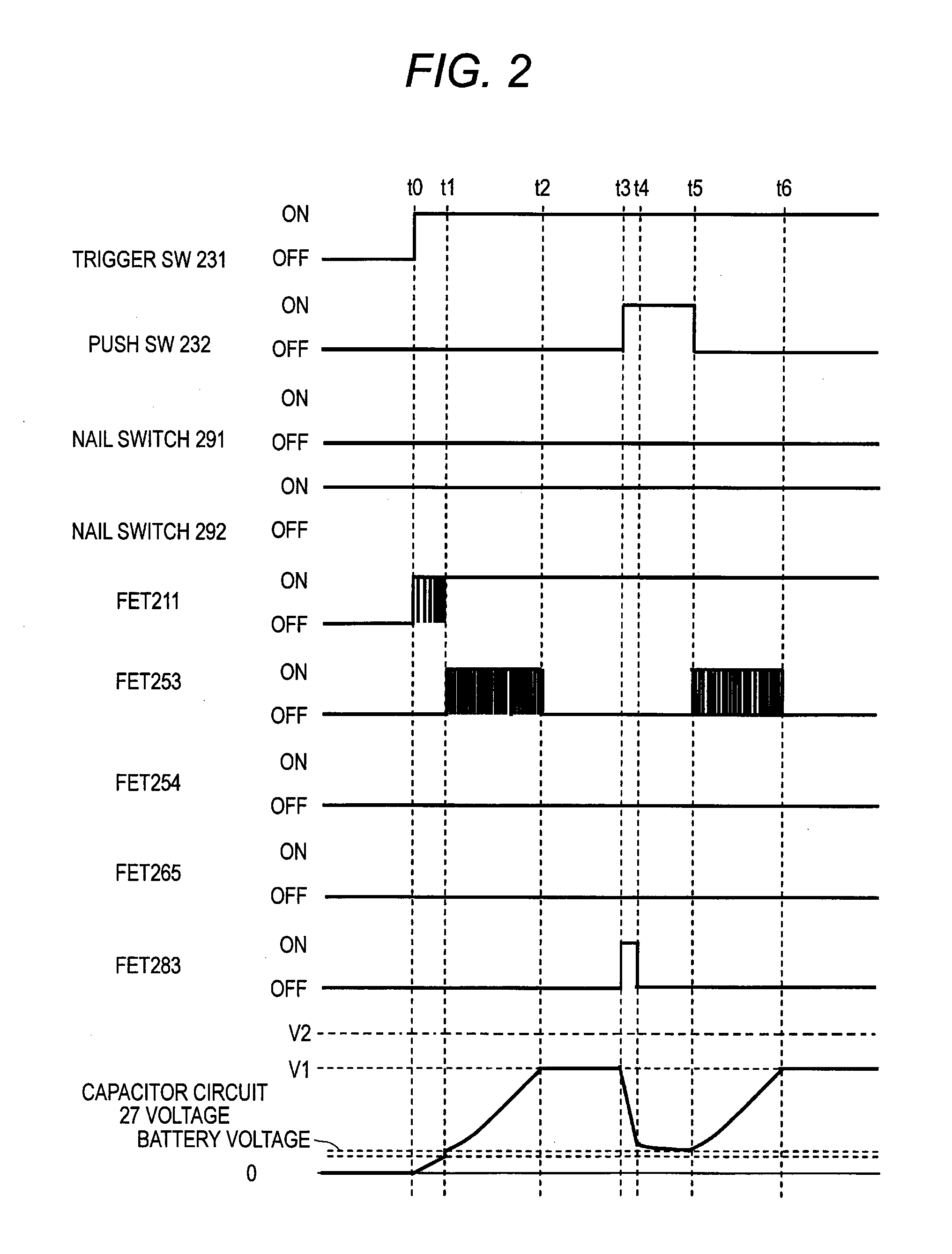

Electric tool and method of driving electric tool

InactiveUS20130334277A1Increase currentReduce stepsStapling toolsMotor/generator/converter stoppersMicrocomputerDriver circuit

When a work stops without driving after a voltage across a capacitor circuit reaches a target boost voltage, a micro-computer switches an FET through a driver circuit. As a result, the voltage charged in the capacitor circuit is charged in a secondary battery through the FET, an inductance, and a parasitic diode of an FET.

Owner:HITACHI KOKI CO LTD

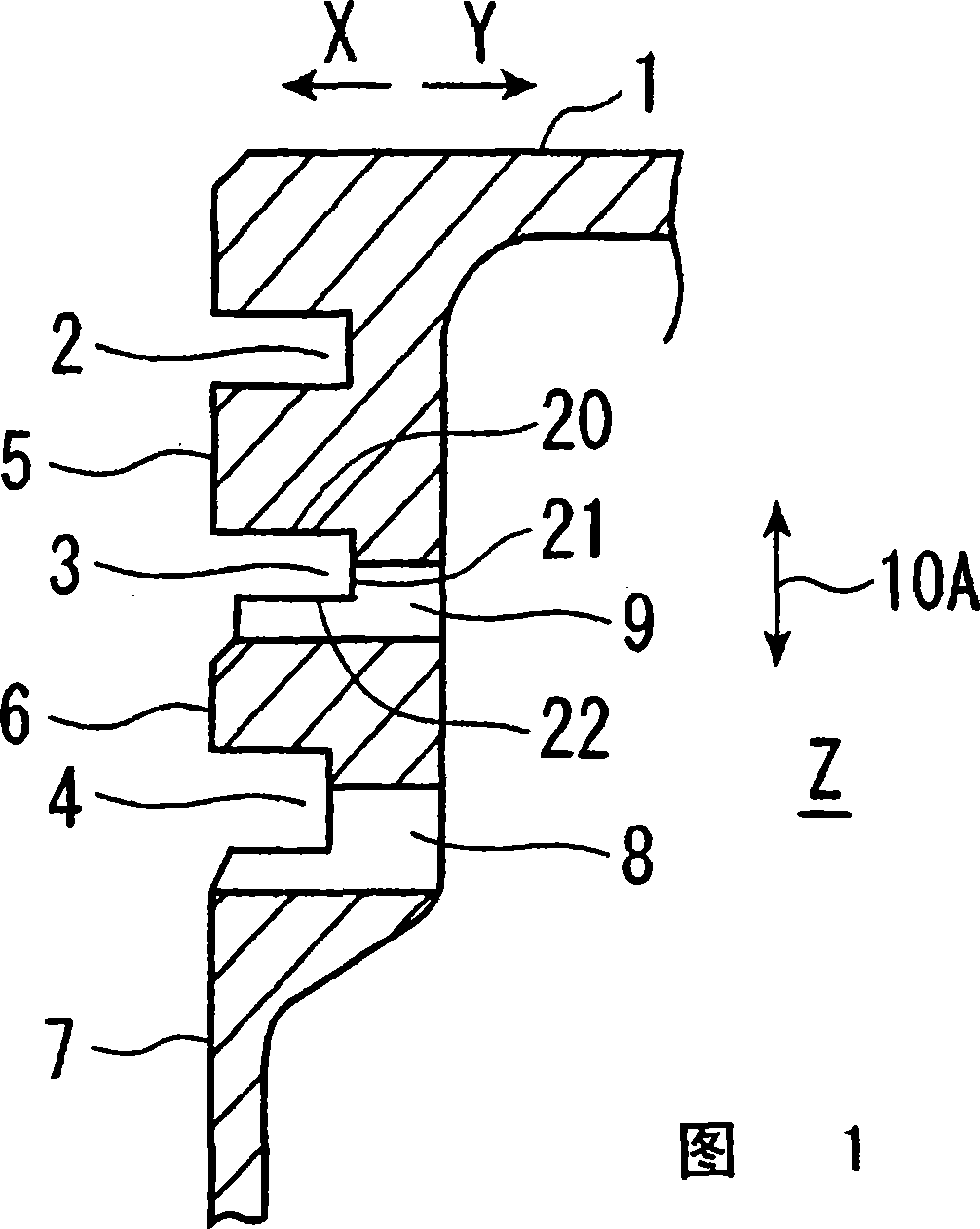

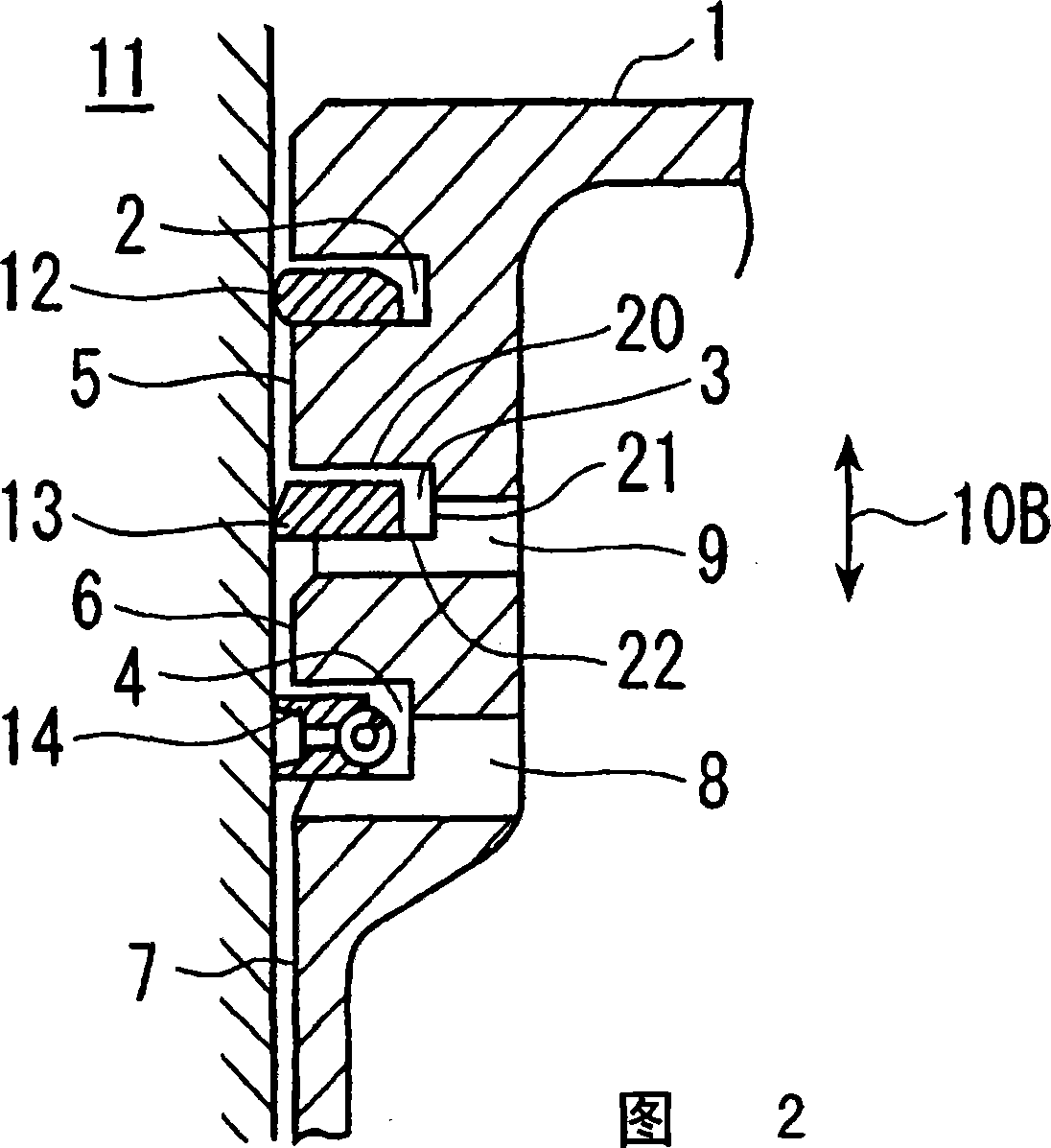

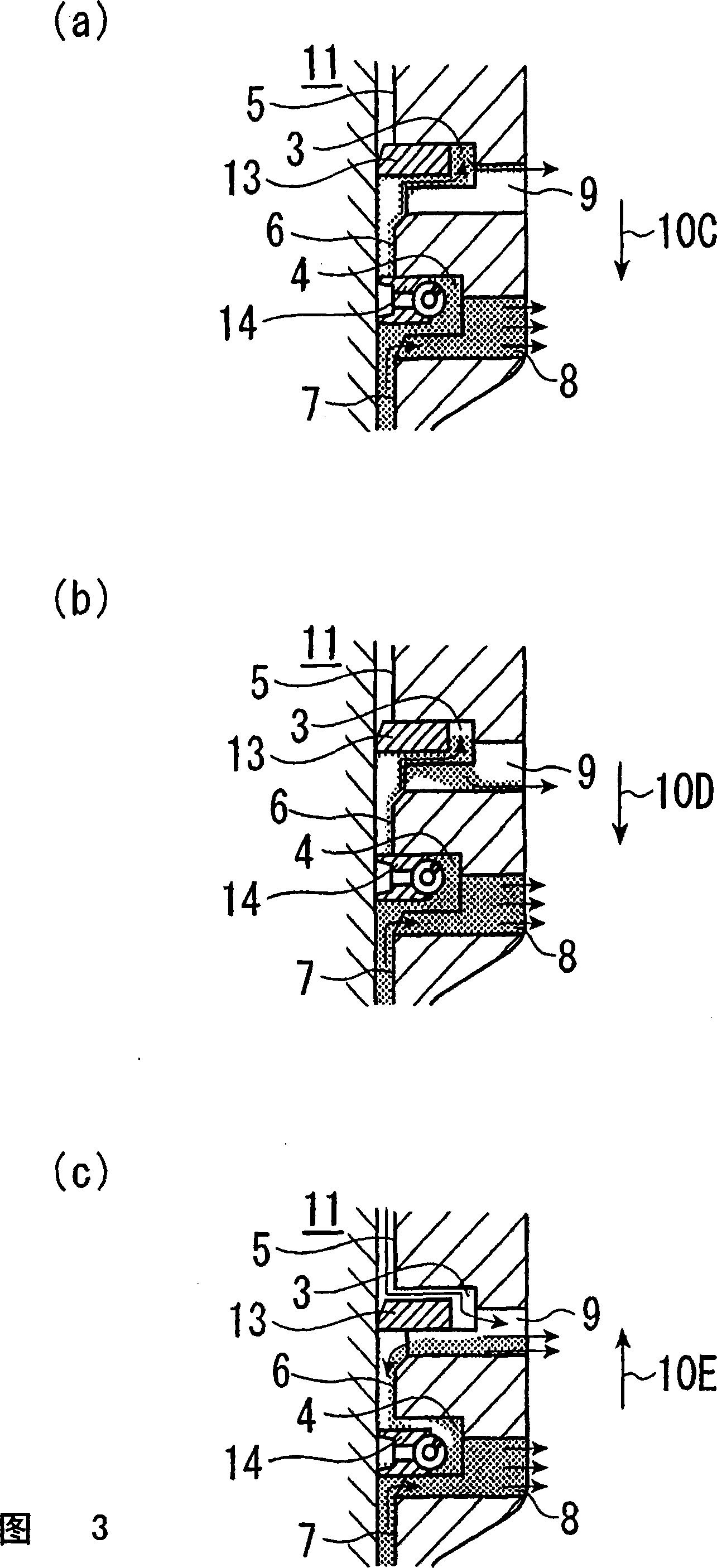

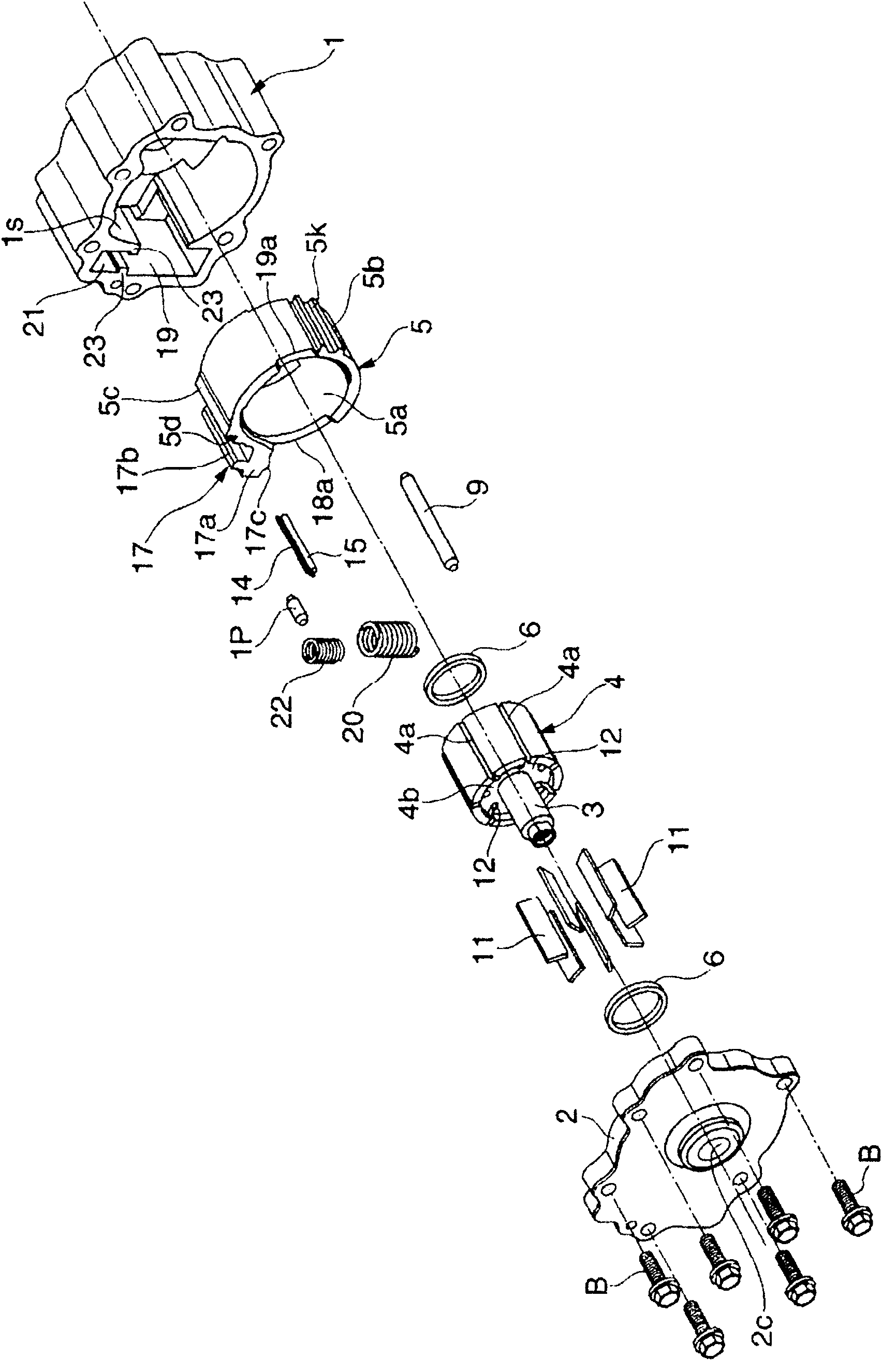

Piston for internal-combustion engine and combination of piston and piston ring for internal-combustion engine

The invention provides a piston of an internal combustion engine and a combination of the piston with three piston rings comprising two pressure rings and one oil ring of the internal combustion engine capable of sufficiently suppressing the consumed amount of a lubricating oil when a combustion chamber is brought into a negative pressure in the intake stroke of the engine and when an engine brake is used. In this piston of the internal combustion engine, a through hole communicating with the internal space of the piston is formed in an oil ring groove to which the oil ring is fitted, and a hole related to a second ring groove is opened in the bottom part of the second ring groove so as to ride over the lower surface of the ring groove from the vertical lower side of the piston to form it as a through hole linearly communicating with the internal space of the piton. In this combination of the piston with the three piston rings of the internal combustion engine, the piston is combined with the pressure rings having closed gaps within a specified range.

Owner:TOYOTA JIDOSHA KK +1

Vacuum suction apparatus

InactiveUS20130082475A1Avoid product qualityCurb consumptionGripping headsSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

Owner:SMC CORP

Microbial enhanced oil recovery methods

ActiveUS8316933B2Promote recoveryCurb consumptionBacteriaUnicellular algaeBiotechnologyMicrobial enhanced oil recovery

Efficient, economical and environmentally safe microbial methods to enhance oil recovery in existing oil reservoirs, as well as microorganisms useful in such methods. The microorganisms are capable of growing in an environment of high salinity, and are deficient in their ability to degrade short chain hydrocarbons of about 12 carbons or less.

Owner:GEO FOSSIL FUELS

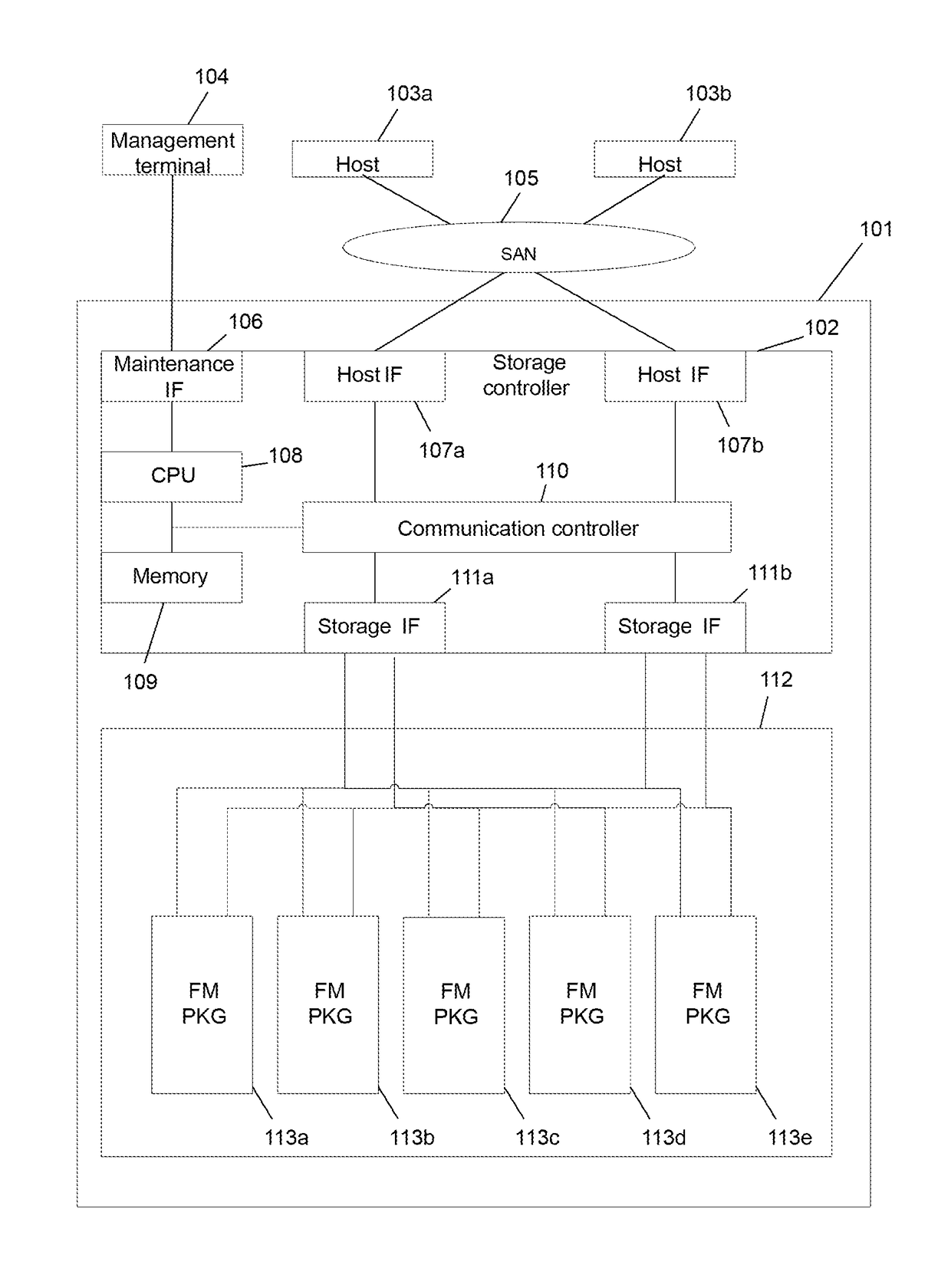

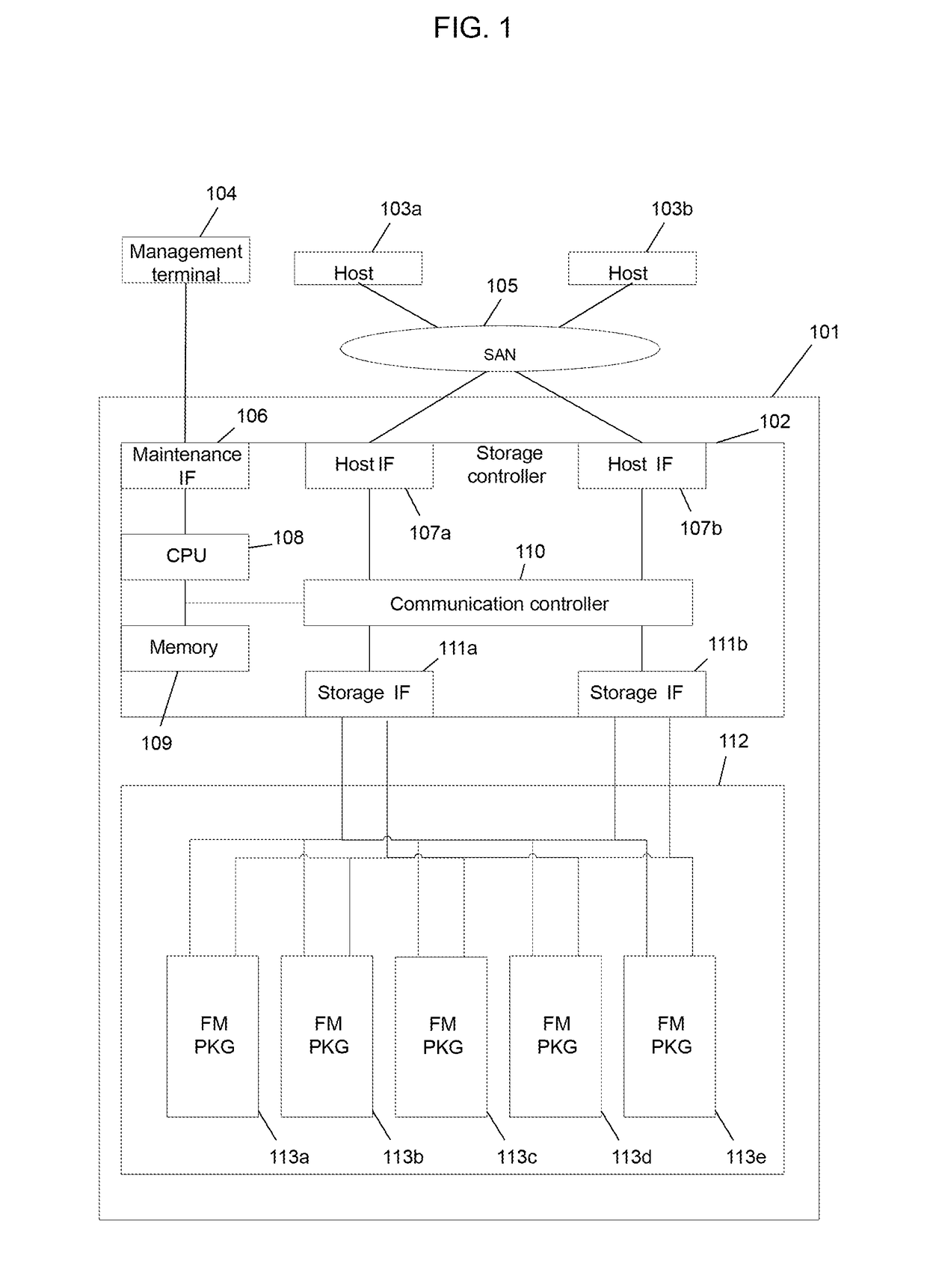

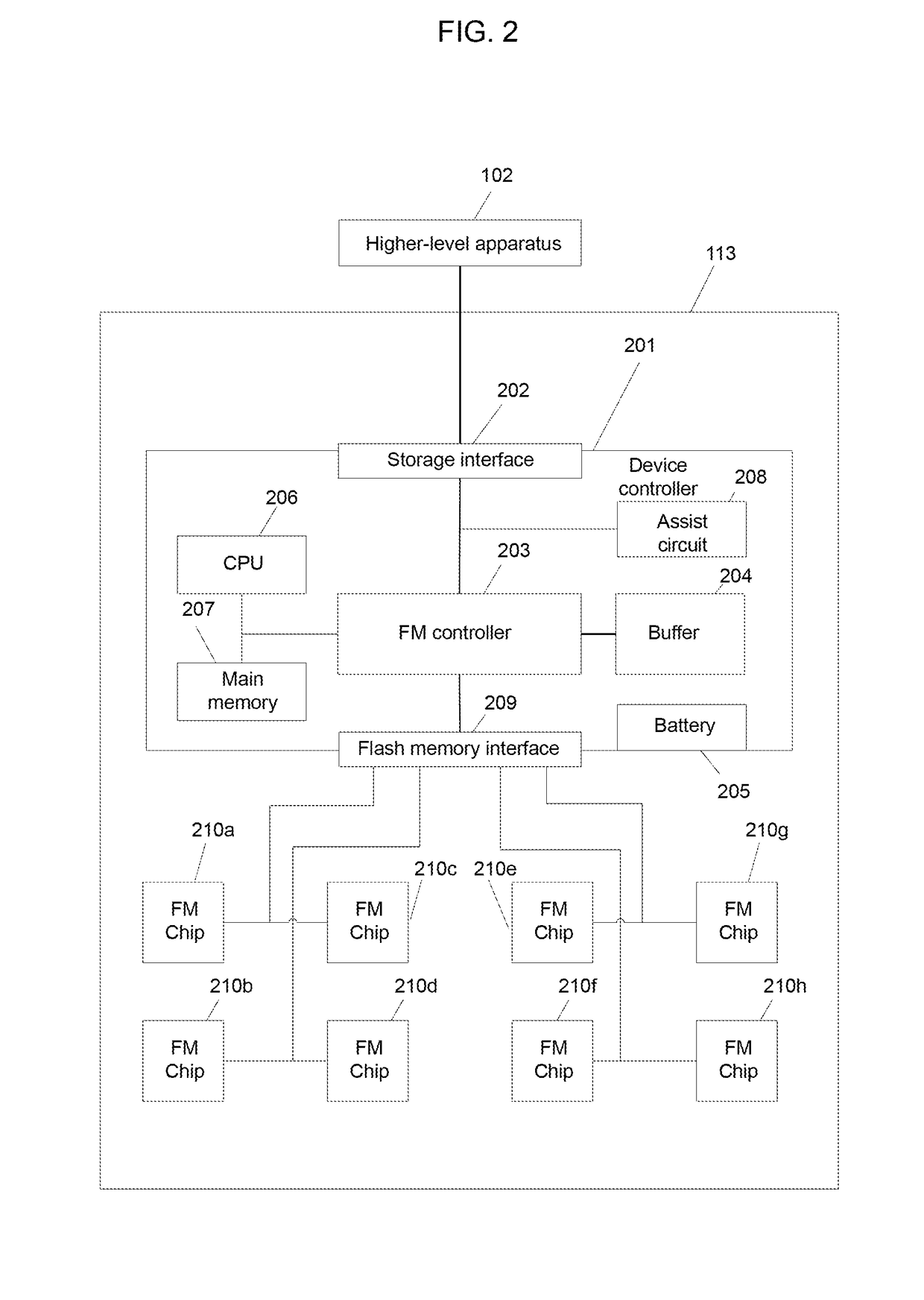

Non-volatile memory device

ActiveUS20180067850A1Curb consumptionMemory architecture accessing/allocationInput/output to record carriersGranularityComputer science

A write frequency of a non-volatile memory is determined at a fine granularity while suppressing consumption of the volatile memory. When it is determined that a copy of specified data from a specified physical storage area to another physical storage area is to be executed, a controller reads the specified data and specified write frequency information, selects a write destination physical storage area group from a plurality of physical storage area groups based on the specified write frequency information and classification information, selects a write destination physical storage area from the write destination physical storage area group, changes the specified write frequency information, writes the specified data to the write destination physical storage area, writes the changed specified write frequency information to the non-volatile memory, and updates translation information based on the write destination physical storage area group and the write destination physical storage area.

Owner:HITACHI LTD

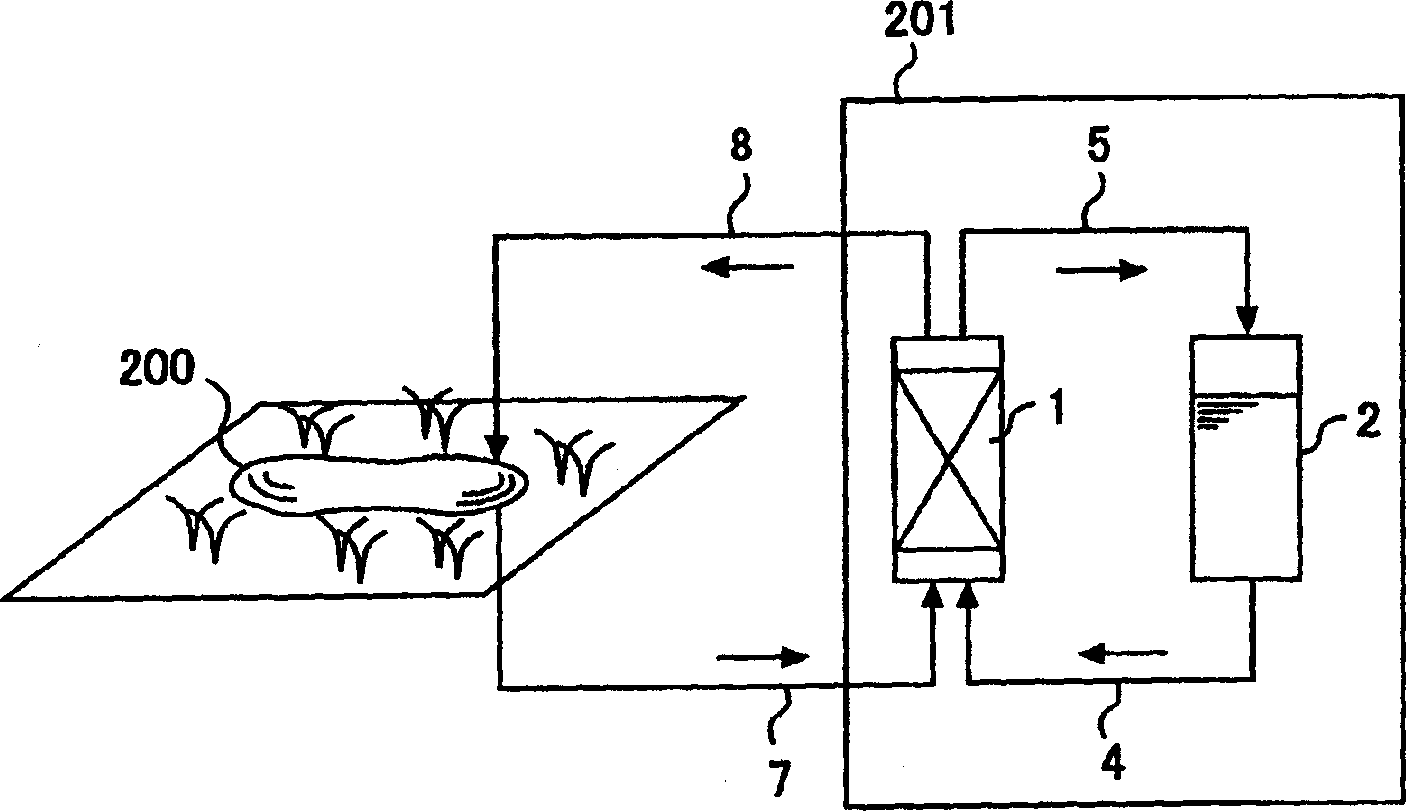

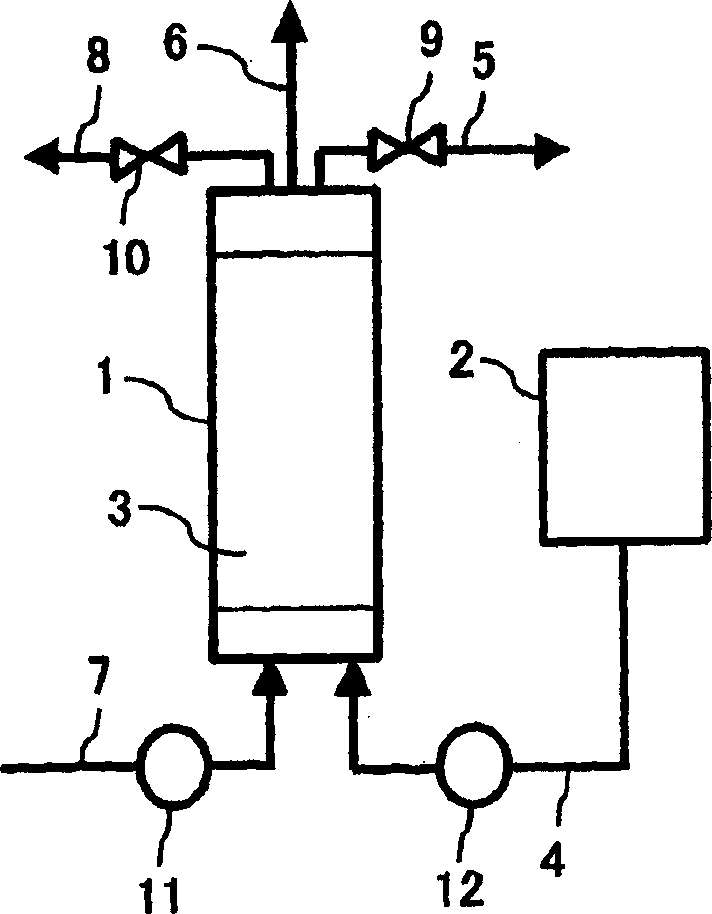

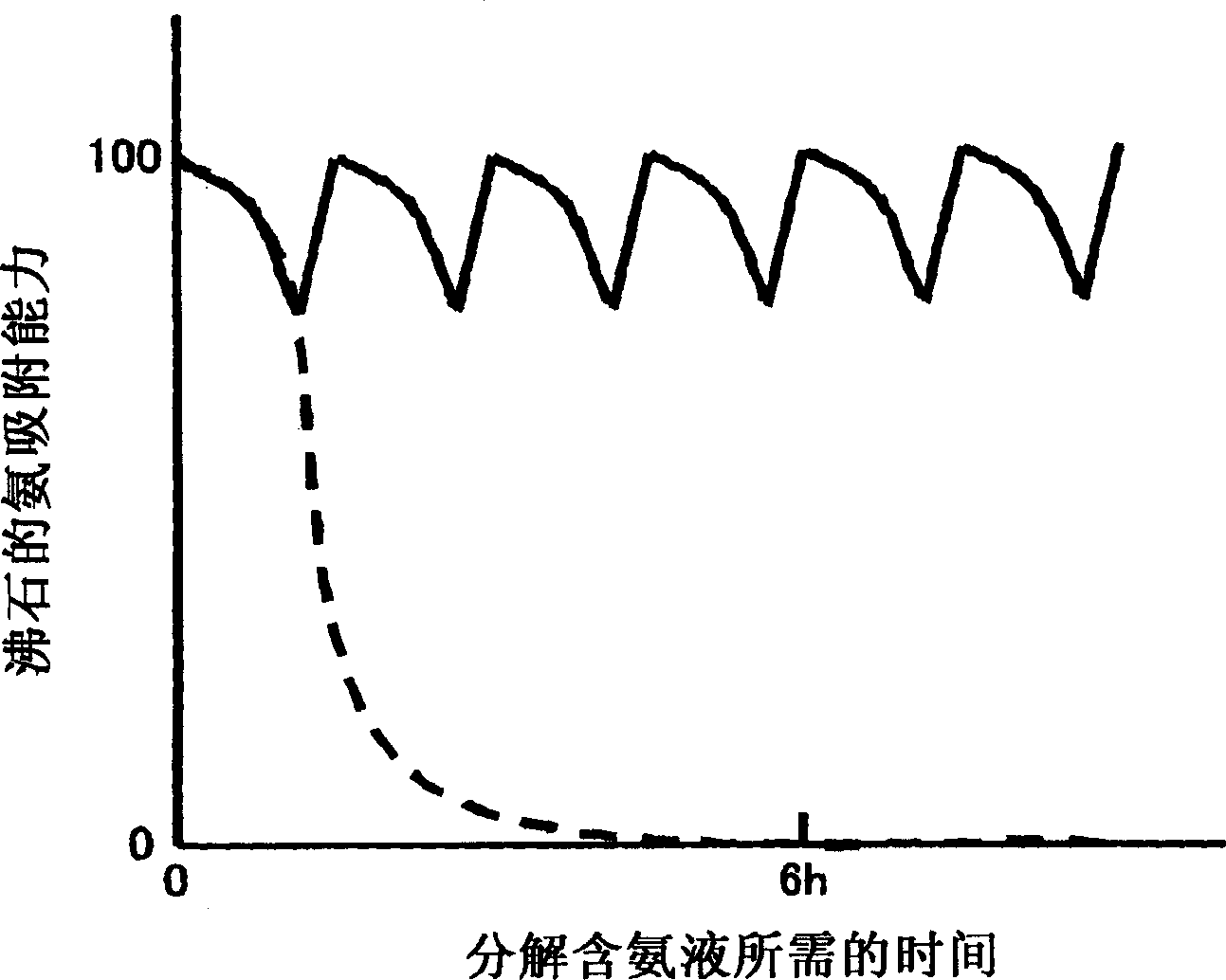

Process and appts. for treating nitrogen compound contg. water

InactiveCN1463253AImprove securityPrevent outflowIon-exchanger regenerationWater contaminantsEutrophicationHypobromous acid

A method of treating water containing a nitrogen compound, and an apparatus of treating water containing a nitrogen compound at high speed without using a biologically unstable treatment causing eutrophication in lakes and swamps. The waste water is introduced into an adsorbing tank that is filled with a zeolite, only nitrogen components are adsorbed by the zeolite, a solution containing hypochlorous acid or hypobromous acid is introduced into the adsorbing tank, and the nitrogen adsorbed in the zeolite is decomposed by the hypochlorous acid or the hypobromous acid.

Owner:MITSUBISHI ELECTRIC CORP

Vacuum suction apparatus

InactiveUS8960749B2Avoid product qualityCurb consumptionGripping headsSemiconductor/solid-state device manufacturingEngineeringBackplane

Owner:SMC CORP

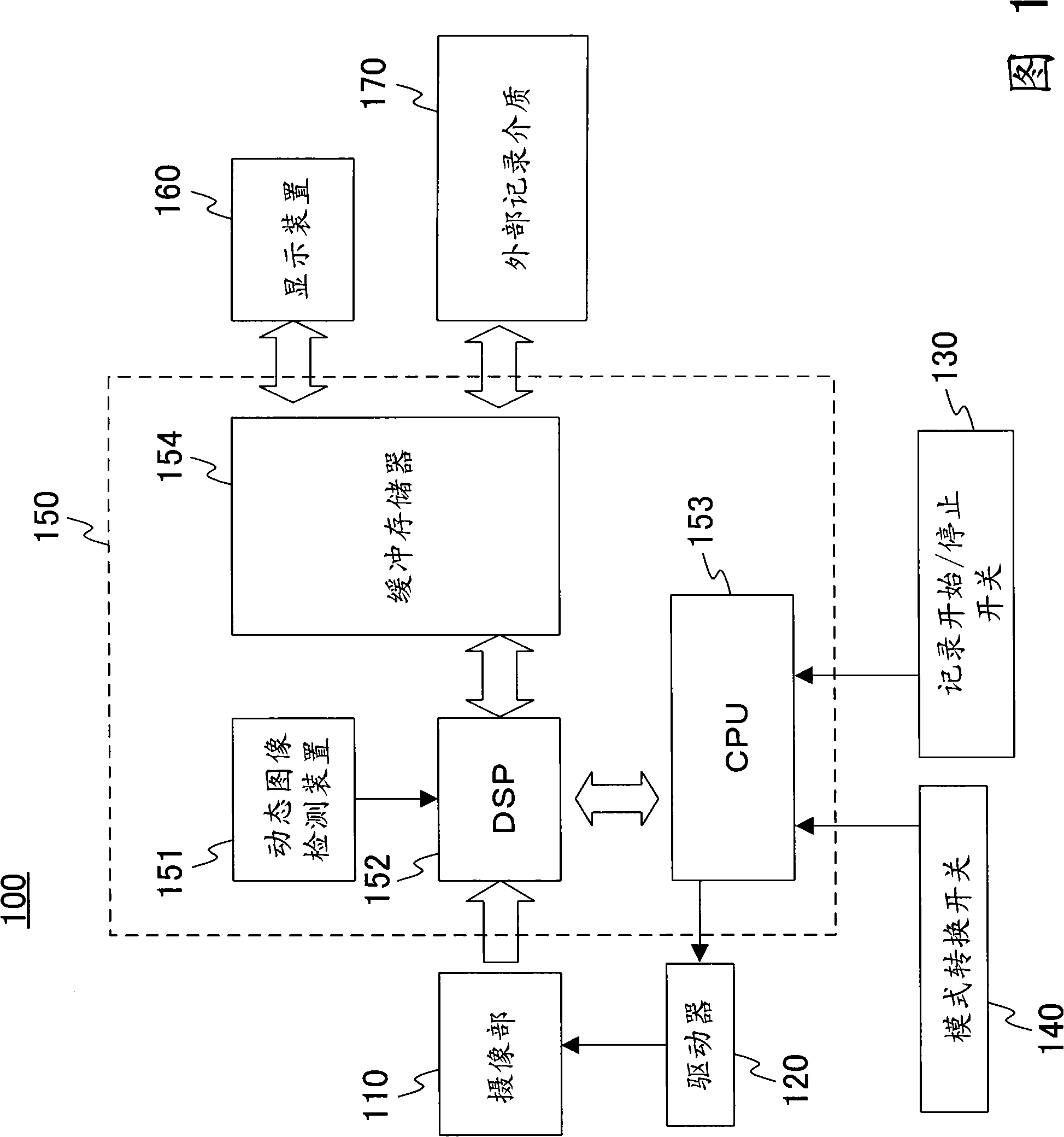

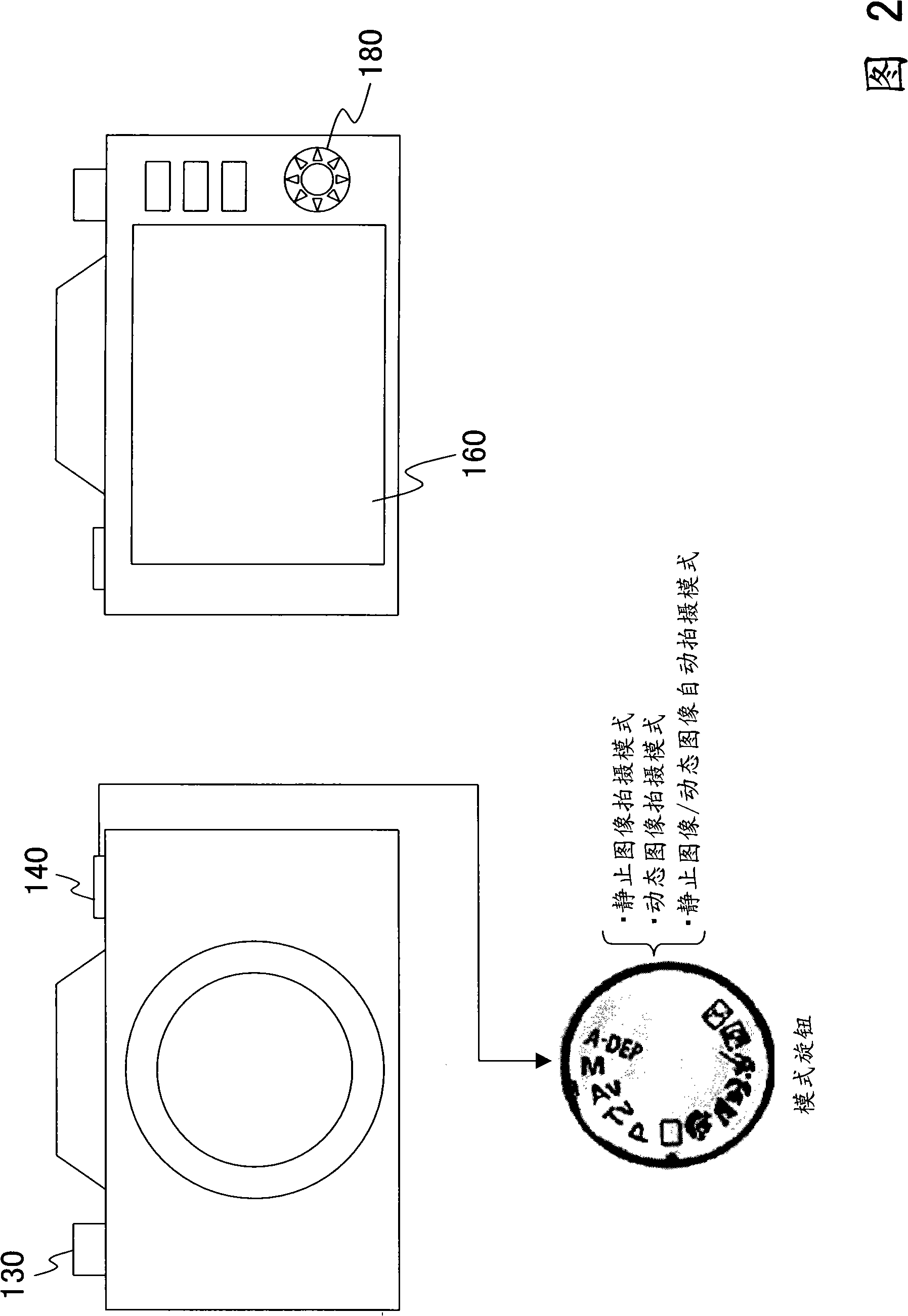

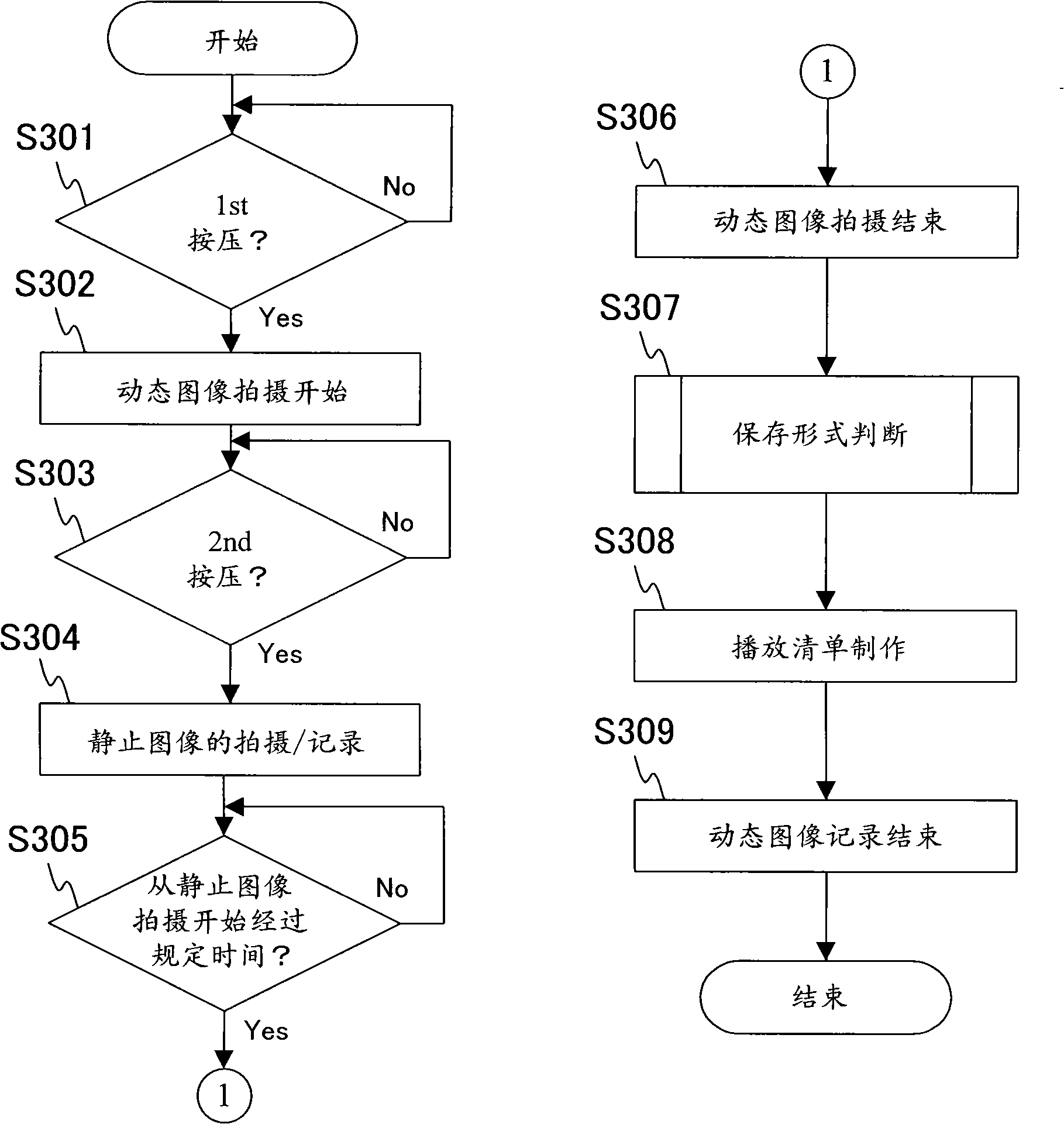

Signal processing circuit and image shooting apparatus

InactiveCN101360210ACurb consumptionTelevision system detailsColor television detailsSignal processing circuitsComputer science

The invention discloses a signal processing circuit and an image shooting apparatus for determining saving format according to set conditions so as to restrain consumption of recording medium and automatically judge user-expected shooting mode when recording dynamic images before and after the static images. The signal processing circuit includes: a buffer memory(154) for temporarily storing a shot image; and a moving-picture detection device(151) for detecting whether or not the shot image is a moving picture. Whether to store the shot image in the buffer memory(154) as a moving memory, as a still picture, or as both a moving picture and a still picture is determined according to the detection result of the moving-picture detection device(151).

Owner:PANASONIC CORP

Wireless communication system

ActiveUS20100255840A1Network degradationEfficiently determinedSubstation equipmentWireless commuication servicesCommunications systemPaging

A wireless communication system including a wireless terminal, a plurality of base stations and a call processing control unit is disclosed. The wireless terminal, upon reception of the notification information from any of the base stations, judges whether the area included in the notification information is contained in the location registration area list stored in a storage unit, and in the case where the particular area is not so contained, sends a location registration request to the call processing control unit. On the other hand, the call processing control unit creates a new location registration area list based on the area included in the notification information and the neighboring areas, and sends the location registration area list to the wireless terminal thereby to execute the paging process.

Owner:HITACHI LTD

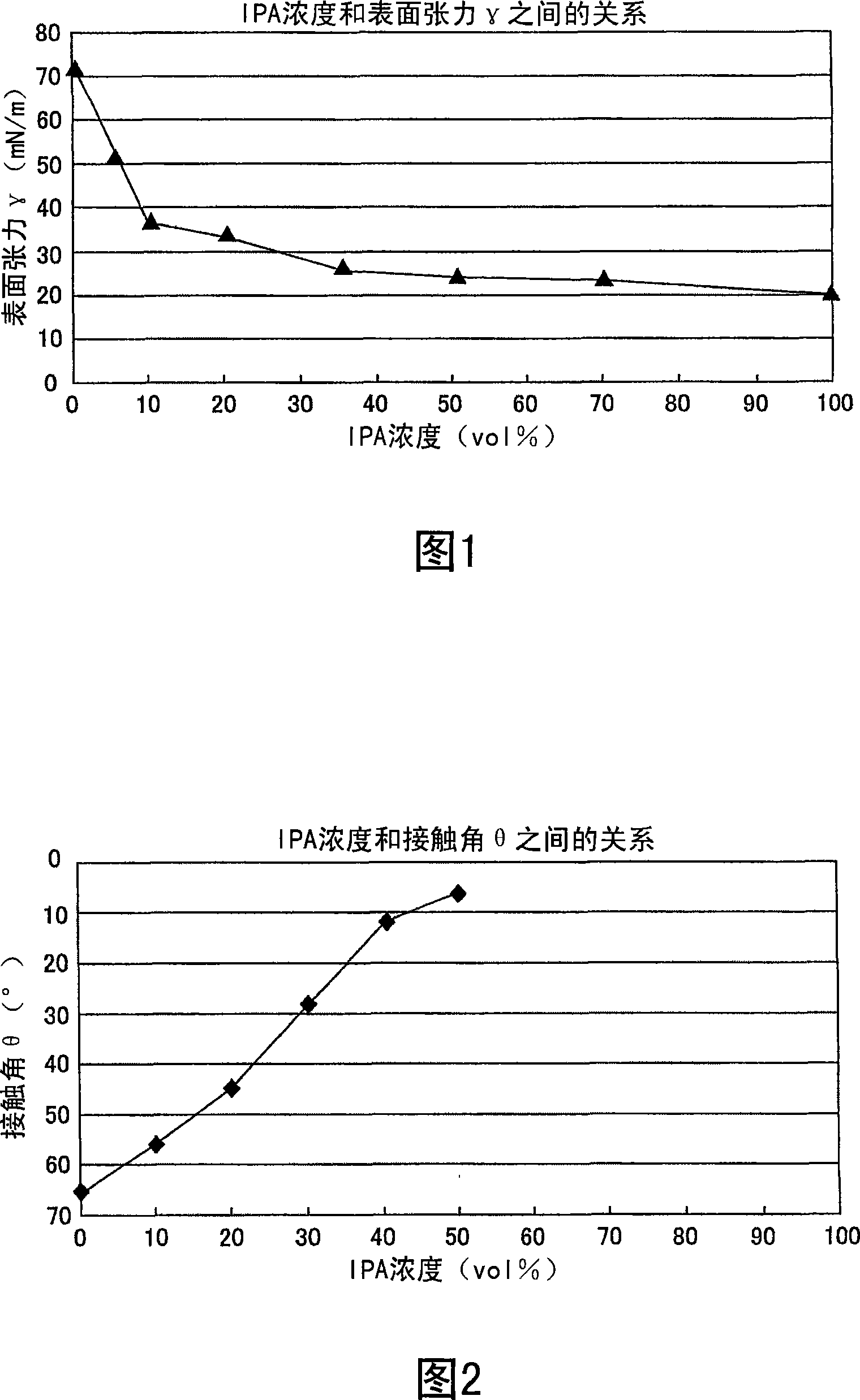

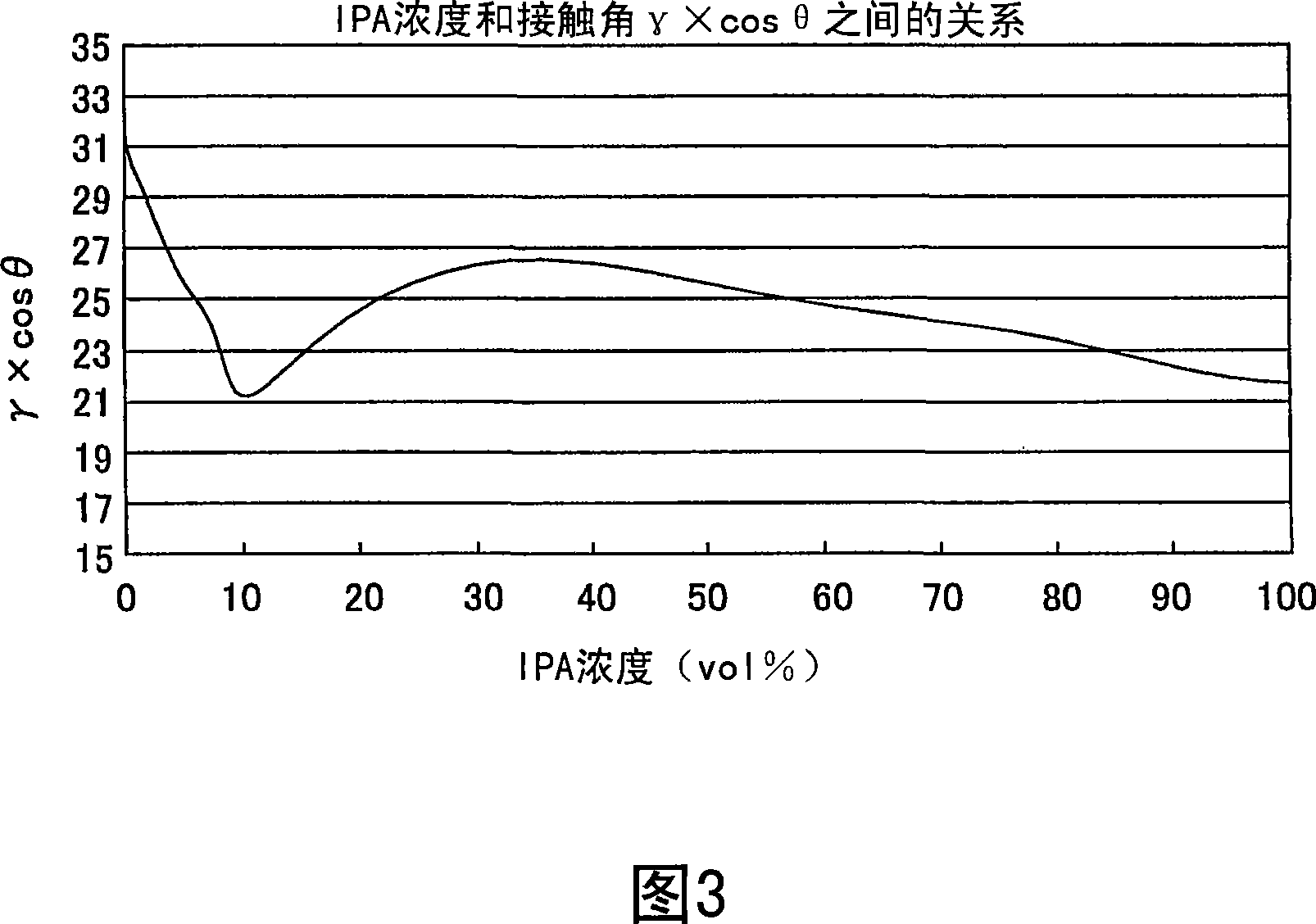

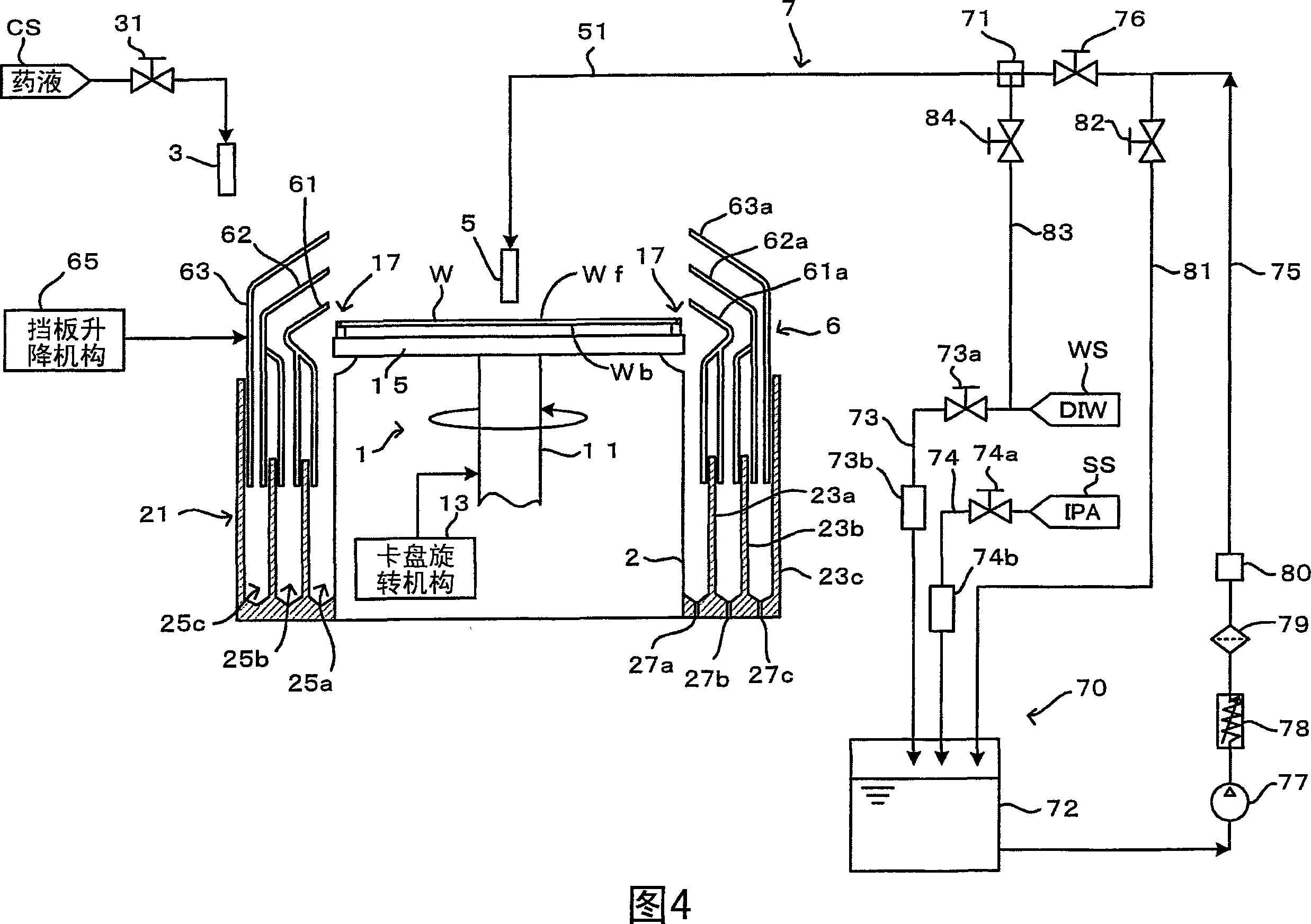

Substrate processing method and substrate processing apparatus

InactiveCN101097837AEfficient entryPrevent collapseSemiconductor/solid-state device manufacturingPhotosensitive material processingOrganic solventSubstrate surface

After rinsing, while rotating a substrate, a front layer part of a rinsing liquid (DIW) adhering to a substrate surface is drained and removed from the substrate surface. This is followed by supply to the substrate surface of a liquid mixture which is obtained by mixing IPA and DIW together. Since a majority of the rinsing liquid on the substrate surface is removed off from the substrate surface, even when micro patterns are formed on the substrate surface, the liquid mixture replaces the liquid component adhering to the gaps between the patterns. Further, the IPA concentration in the liquid mixture supplied to the substrate surface is set to 50% or below. Hence, it is possible to effectively prevent destruction of the patterns while suppressing the consumption amount .

Owner:DAINIPPON SCREEN MTG CO LTD

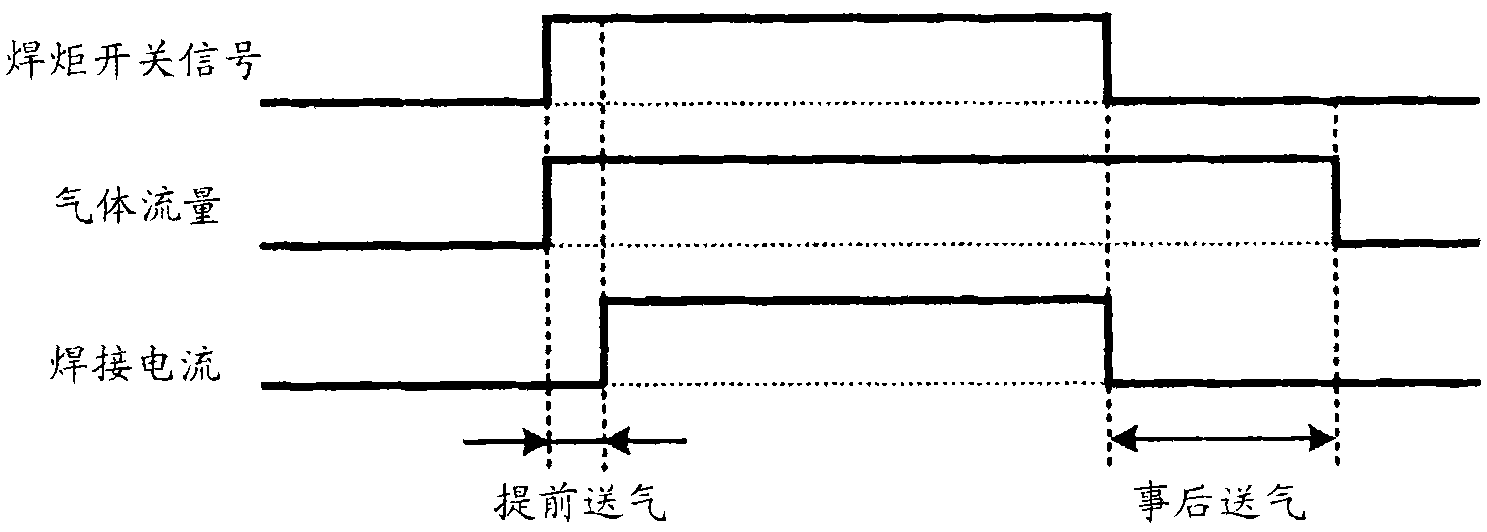

Protection gas controlling device and welding device

InactiveCN101850458AReduce trafficCurb consumptionFlow control using electric meansArc welding apparatusGas cylinderShielding gas

Provided is a protection gas controlling device and welding device which comprehensively inhibits protection gas consumption in a plurality of periods. In a flow path of the protection gas, connecting a storage cylinder (7) and a welding torch (3), an gas valve (56) of a welding machine (56) and an gas valve (107) of a gas control device (9) are serially connected. A gas flow adjustor (108) whichhas the gas flow smaller than that in the gas valve (107) and is in parallel connection with the gas valve (107). In periods before gas feeding in advance and after gas feeding behindhand, gas valves(56, 107) are closed; in periods of gas feeding in advance, the crater period and gas feeding behindhand, the gas valve (56) is opened and the gas valve (107) is closed; and in the welding period (providing the welding current), gas valves (56, 107) are opened. Thereby, the protection gas consumption is inhibited in periods of gas feeding in advance and gas feeding behindhand.

Owner:SANSHA ELECTRIC MFG

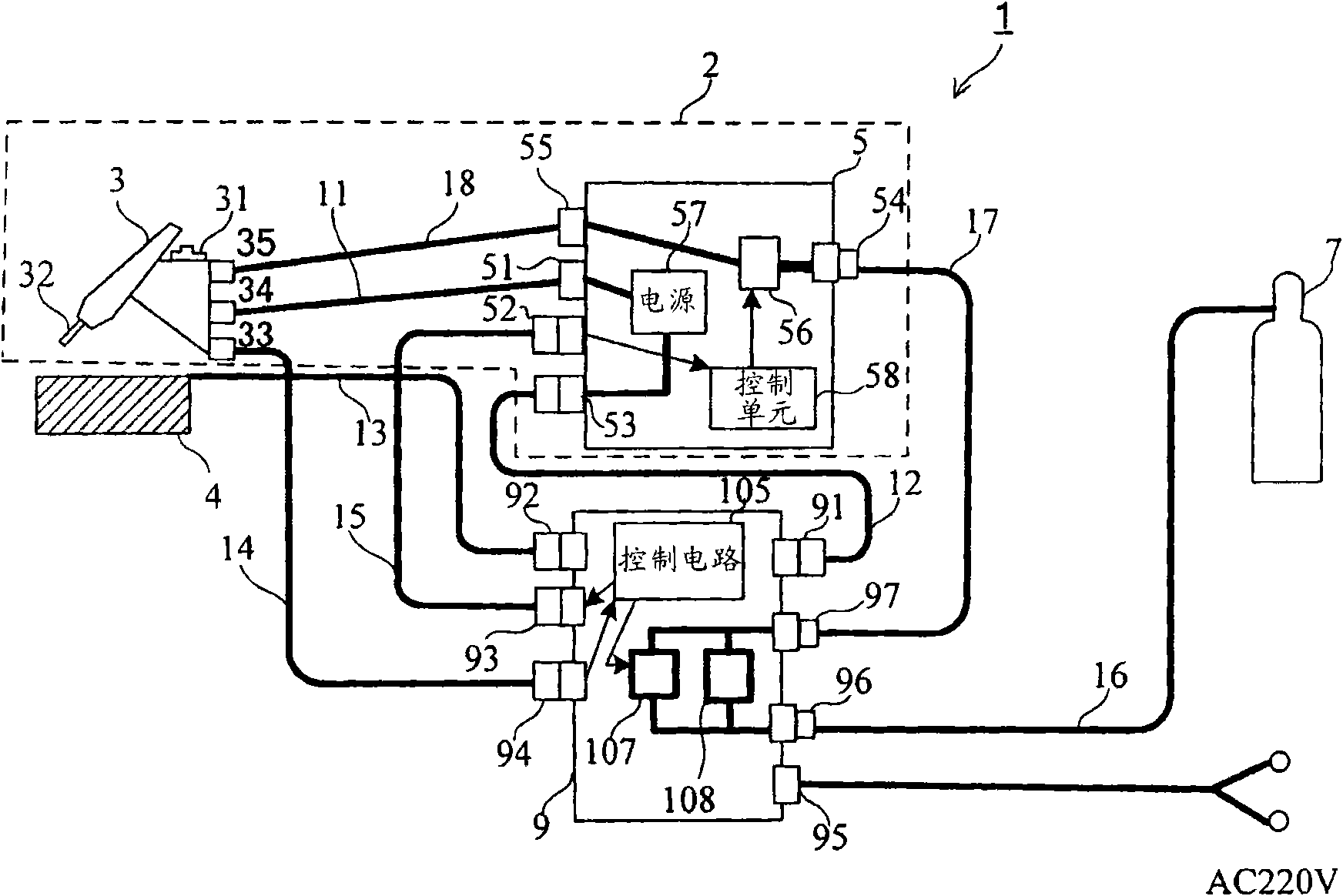

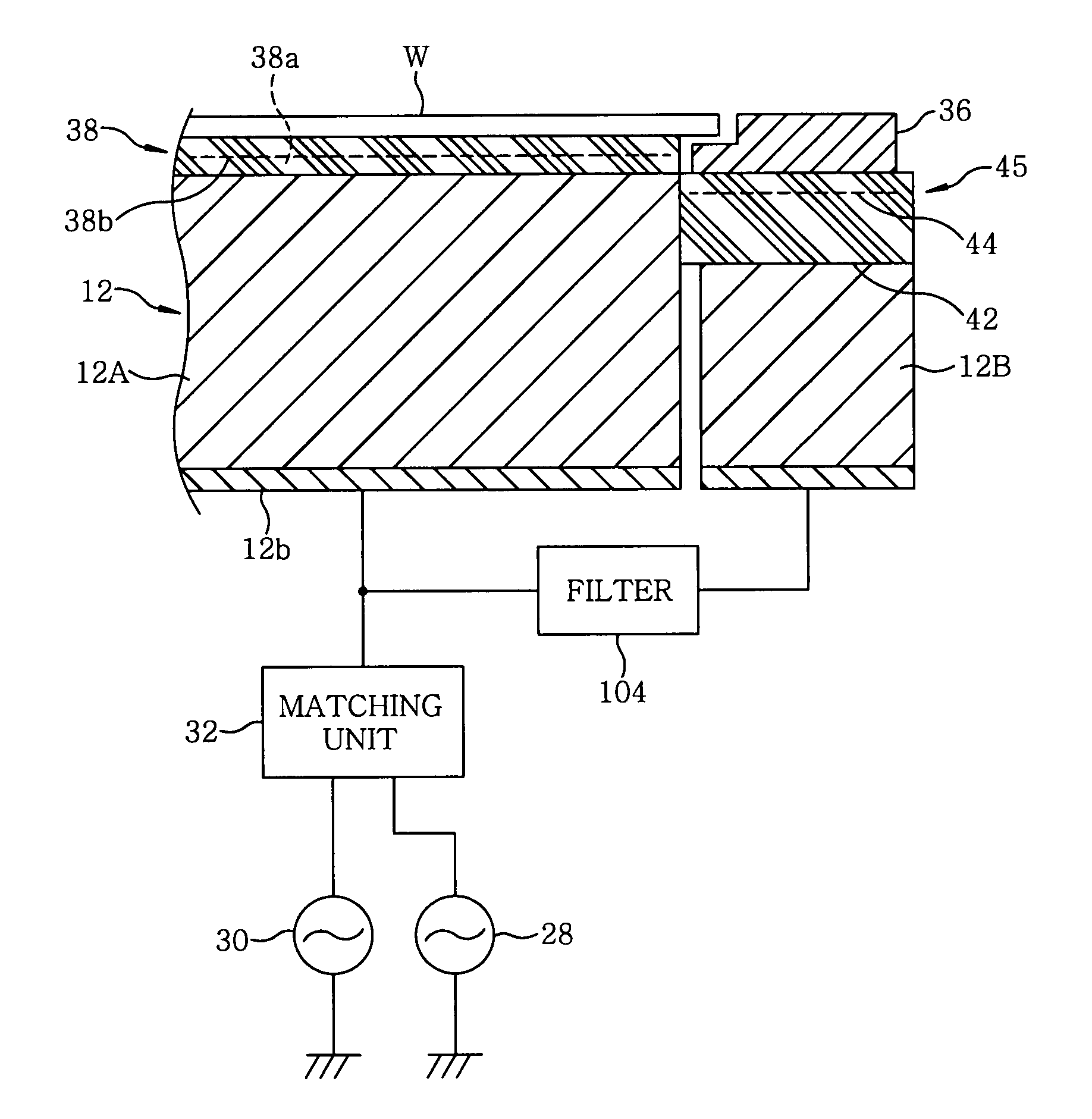

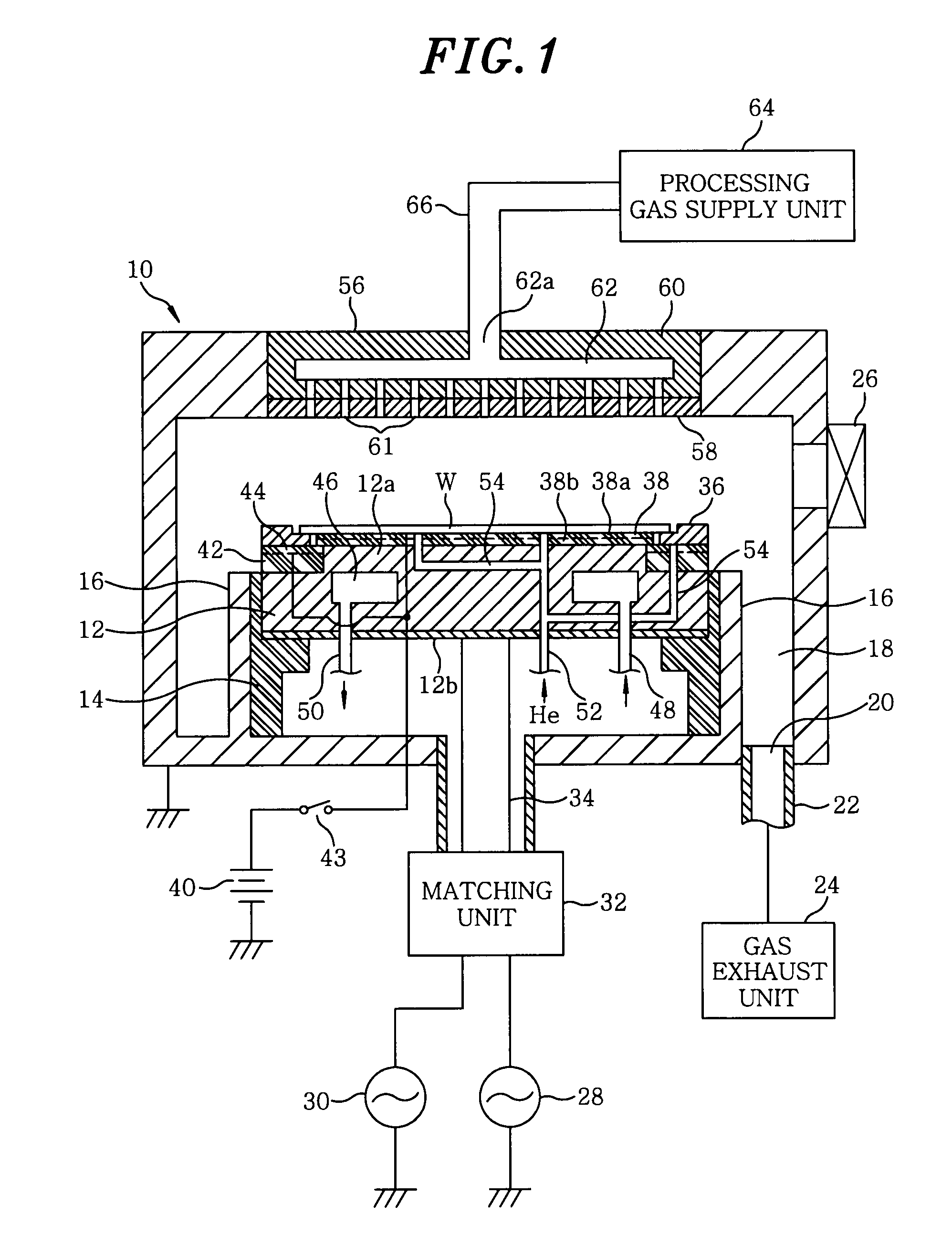

Plasma processing apparatus

ActiveUS8298371B2Effectively suppressing a consumption of a focus ring without substantially affecting processesSmall electrostatic capacitanceElectric discharge tubesSemiconductor/solid-state device manufacturingCapacitanceHigh frequency power

A plasma processing apparatus includes a processing chamber, a first electrode and a second electrode disposed to face each other, a high frequency power supply unit for applying a high frequency power to either the first electrode or the second electrode, a processing gas supply unit for supplying a processing gas to a processing space, and a main dielectric member provided at a substrate mounting portion on a main surface of the first electrode. A focus ring is attached to the first electrode to cover a peripheral portion of the main surface of the first electrode and a peripheral dielectric member is provided in a peripheral portion on the main surface of the first electrode so that an electrostatic capacitance per unit area applied between the first electrode and the focus ring is smaller than that applied between the first electrode and the substrate by the main dielectric member.

Owner:TOKYO ELECTRON LTD

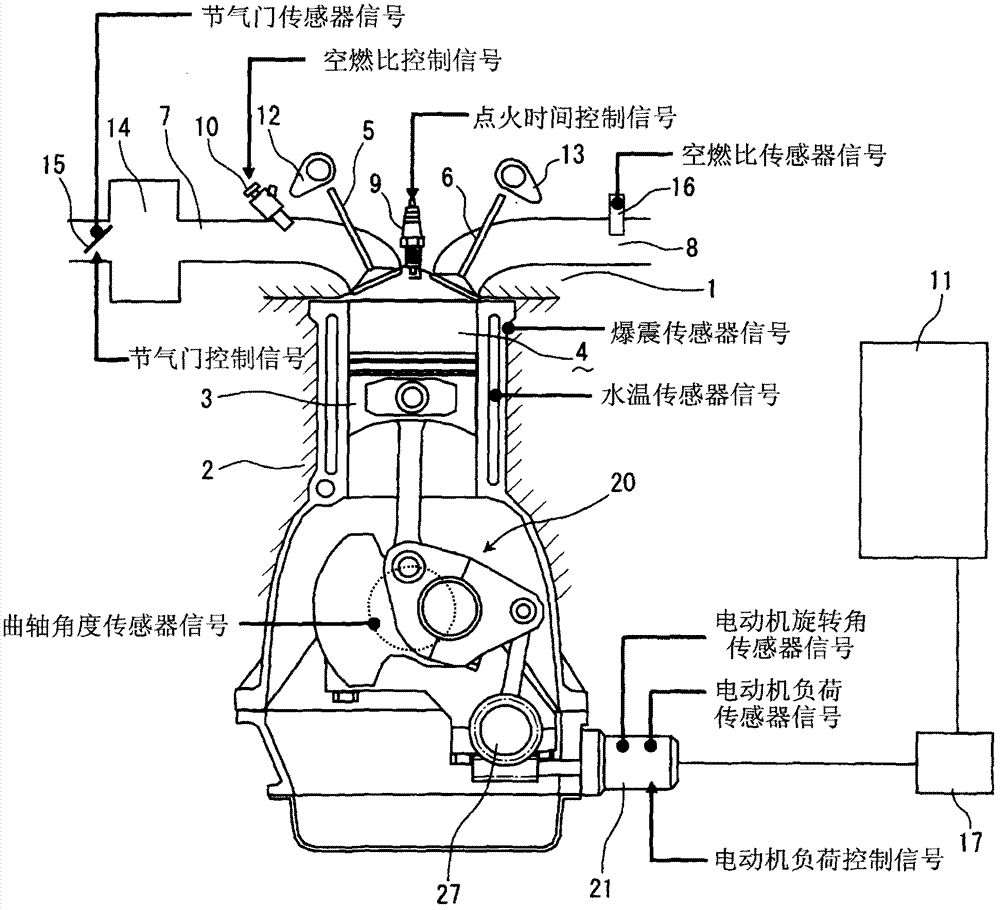

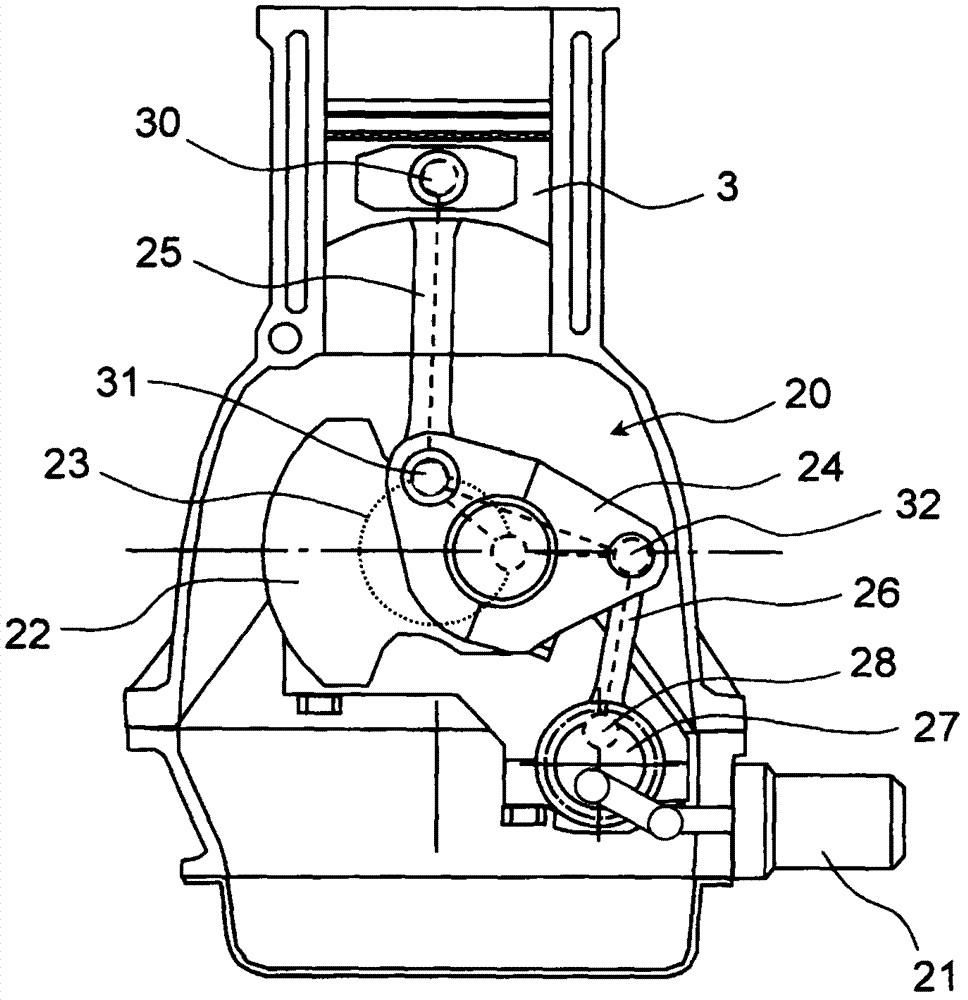

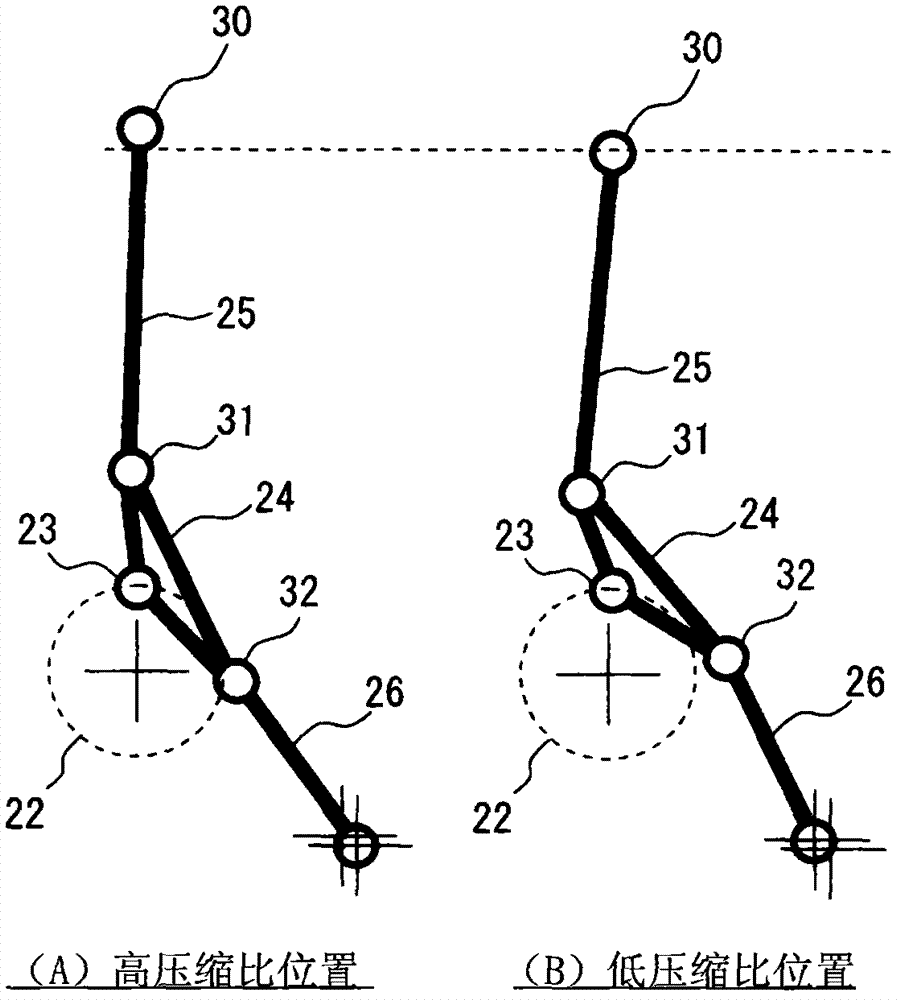

Variable compression ratio engine control apparatus

A variable compression ratio engine control apparatus during a fuel cut operating state in which fuel injection by the fuel injection section is stopped ensures the burning stability when the engine is restarted after the fuel is stopped, and restrains the target compression ratio to be a lower value based on the engine rotational speed, to thereby restrain the compression pressure and improve the fuel consumption performance. The variable compression ratio engine control apparatus includes a variable compression ratio device (20) capable of changing the variable compression ratio of an engine control apparatus, a fuel injection valve (10) injecting fuel into an engine for combustion, and a compression ratio controlling section (11) which sets a target compression ratio according a vehicle running state, controls the engine compression ratio toward the target compression ratio, and sets the target compression ratio based on an engine rotational speed, during a fuel cut operating state in which fuel injection by the fuel injection section is stopped.

Owner:NISSAN MOTOR CO LTD

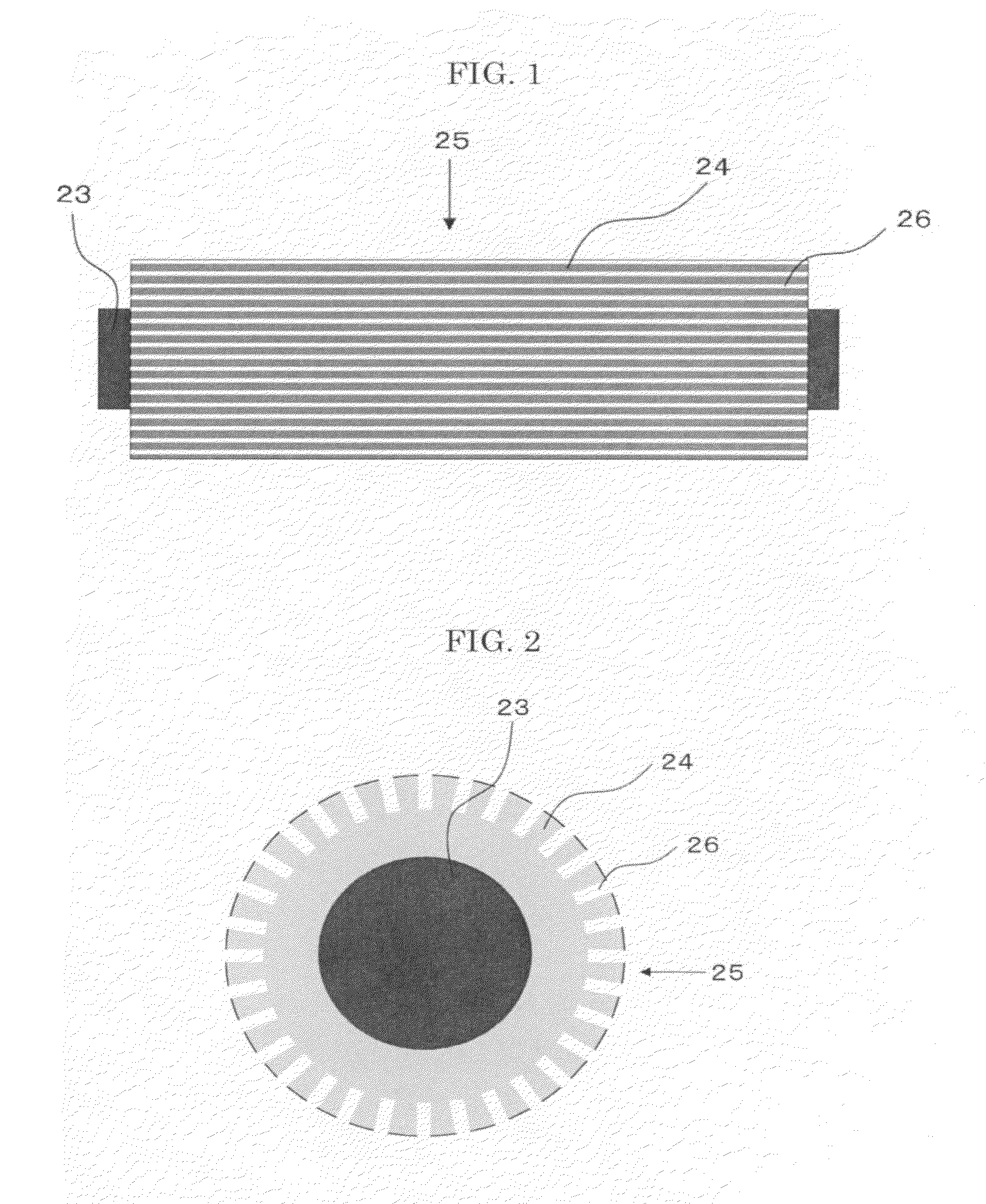

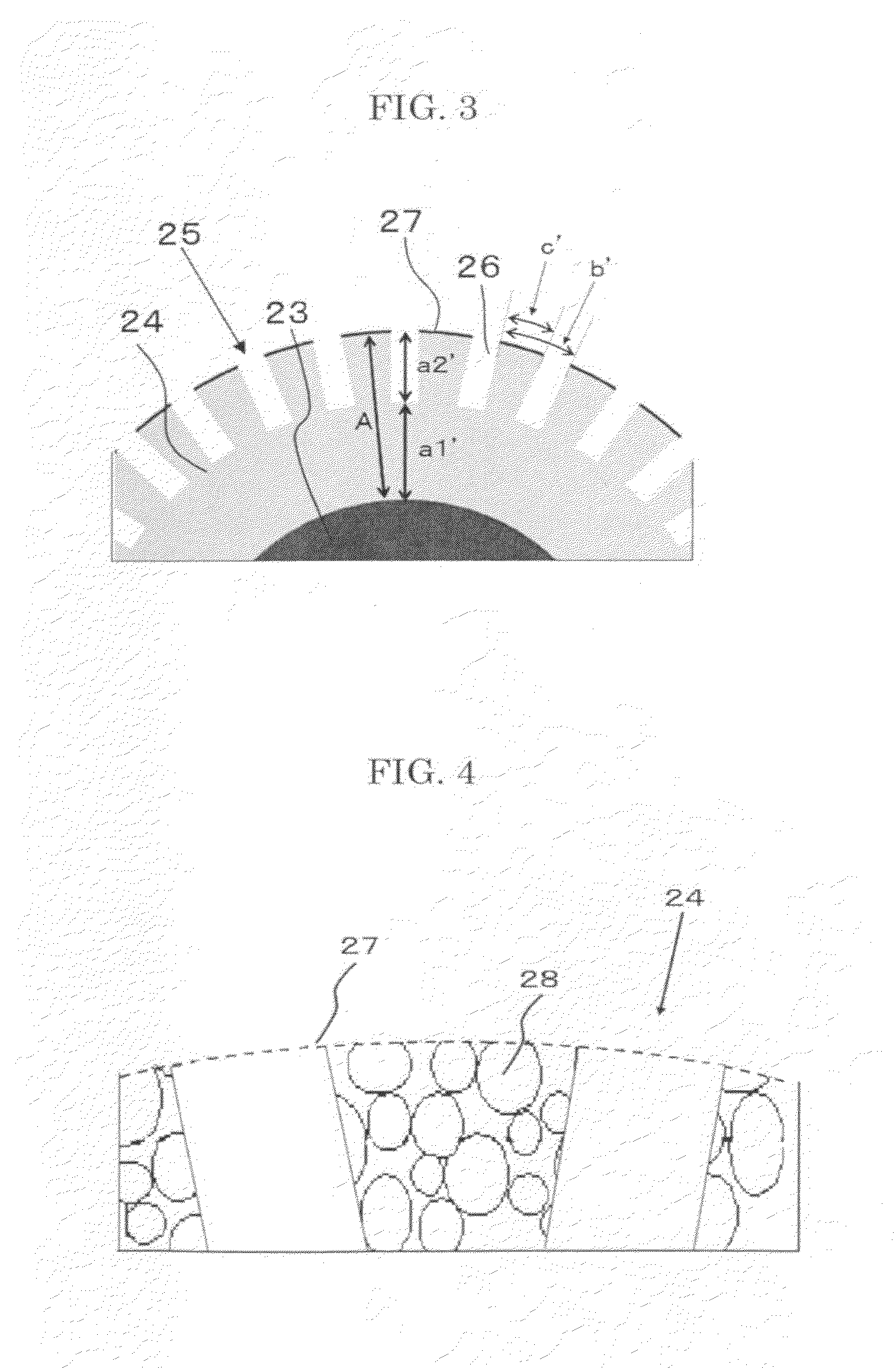

Protecting agent supplying member, protective layer forming device, and image forming apparatus

Owner:RICOH KK

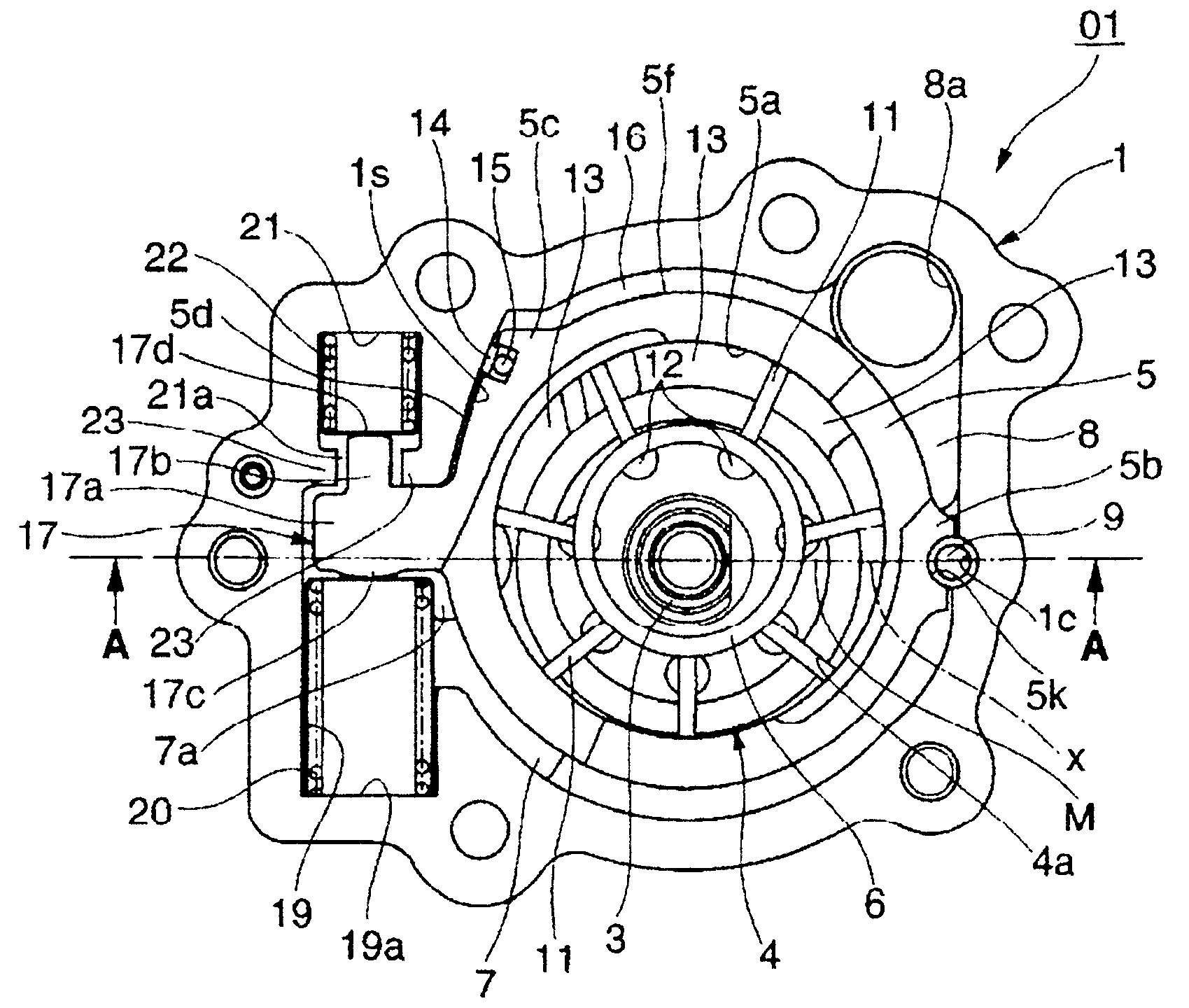

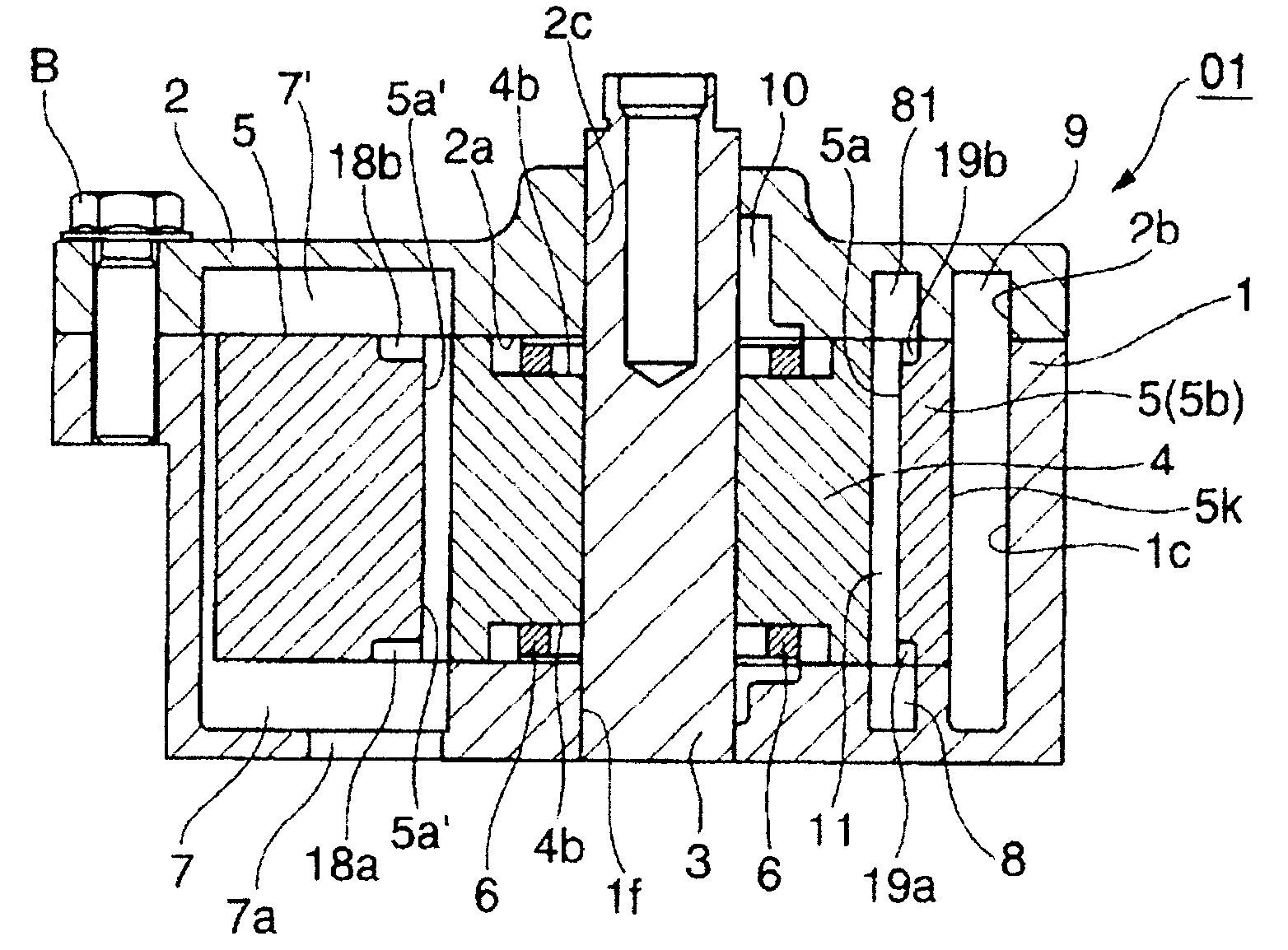

Variable displacement pump, oil jet and lublicating system using variable displacement pump

InactiveCN102146916ACurb consumptionRotary piston pumpsRotary piston liquid enginesPump chamberEngineering

The invention provides a variable displacement pump, which can inhibit the energy consumption in the initial period of the oil discharge. The variable displacement pump has a pump structure which allows discharge of the oil guided to a plurality of pump chambers 13 from an inlet 7 according to the volumn variation of the pump chamber from an outlet 8; when the discharge pressure supplied into a control oil chamber 16 reaches to a first discharge pressure Pf, a cam ring moves a prescribed distance to a direction and when the discharge pressure becomes a second discharge pressure Ps higher than the first discharge pressure Pf, the cam ring moves further to the direction, thereby changing the discharge pressure of the pump. The first discharge pressure is set to the pressure lower than that opening a ball valve 46 through compression deformation of a valve spring 50 of an oil nozzle 30, thereby preventing the energy consumption when the discharge pressure is low.

Owner:HITACHI AUTOMOTIVE SYST LTD

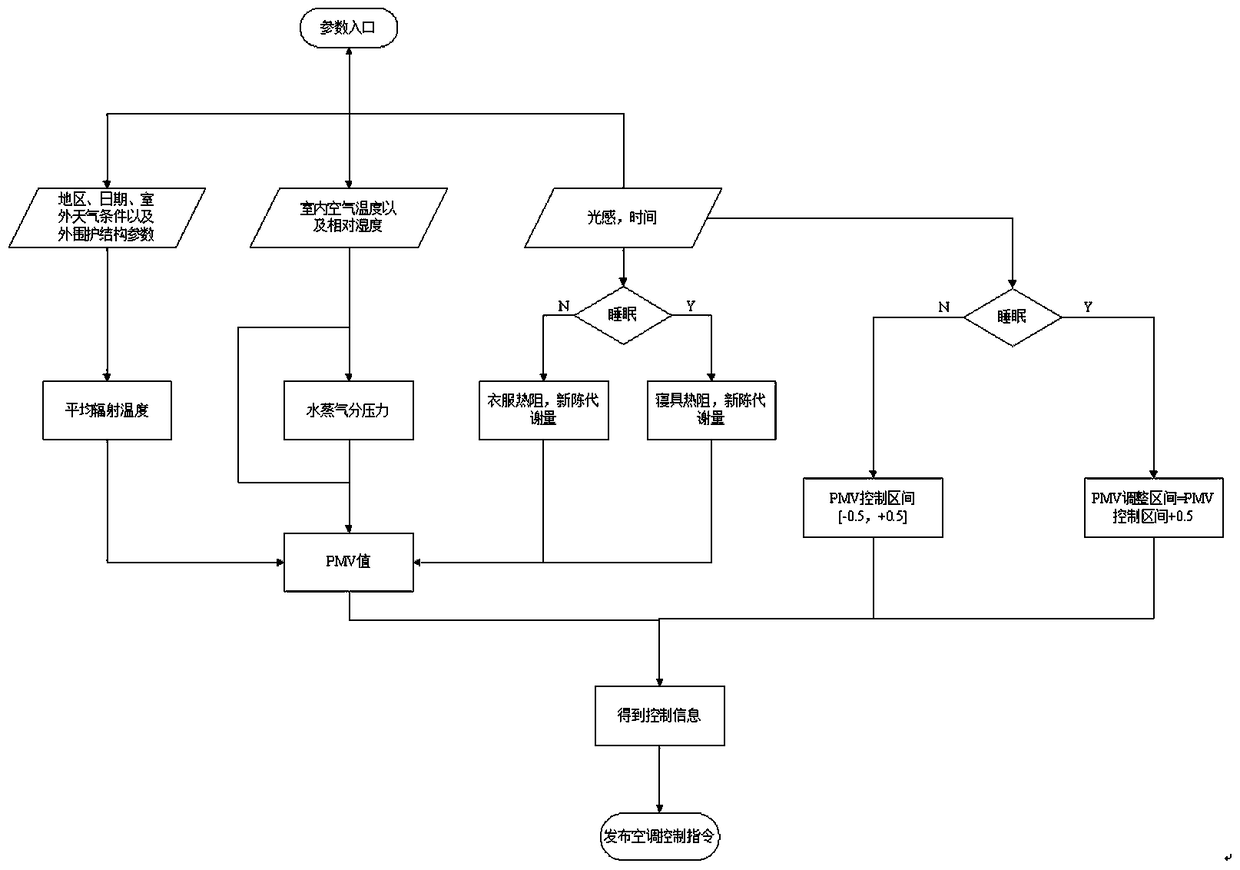

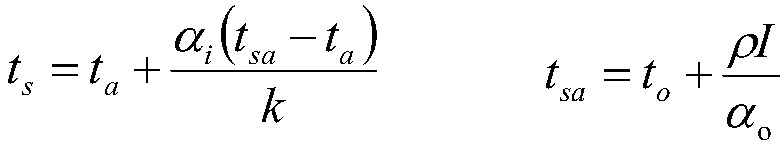

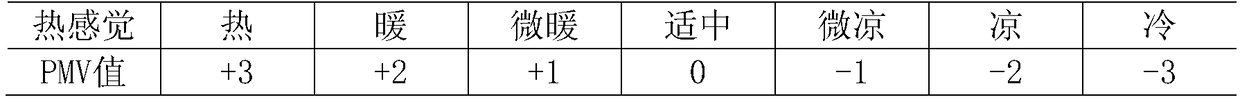

Comfort control method of hotel room air conditioner

InactiveCN108954741ACurb consumptionReduce loadMechanical apparatusLighting and heating apparatusLight perceptionEngineering

The invention specifically relates to a comfort control method of a hotel room air conditioner. The method comprises the following steps of: determining an indoor average radiation temperature according to regions, dates, outdoor weather conditions and peripheral protection structure parameters; determining the metabolic rate of a human body according to light perception and time; calculating a PMV value according to indoor temperature, indoor relative humidity, the average radiation temperature and the metabolic rate of the human body; determining a PMV interval; comparing the PMV value with the PMV interval and issuing an air conditioning control instruction. The PMV target value is set to one side in the hotter direction during indoor refrigeration and to one side in the cooler direction during heating, the PMV control interval is timely adjusted according to different sleep stages after human body sleep, and therefore excessive energy consumption is inhibited within the comfort range, and the reduction of air conditioning load and energy conservation are realized. The PMV control interval is corrected in time to achieve energy-saving comfort control after user intervention isreceived.

Owner:ZHUHAI PILOT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com