Piston for internal-combustion engine and combination of piston and piston ring for internal-combustion engine

A technology of internal combustion engines and engines, which is applied in the direction of machines/engines, piston rings, engine components, etc., can solve the problems of suppressing and increasing lubricating oil consumption, and achieve the effect of suppressing lubricating oil consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

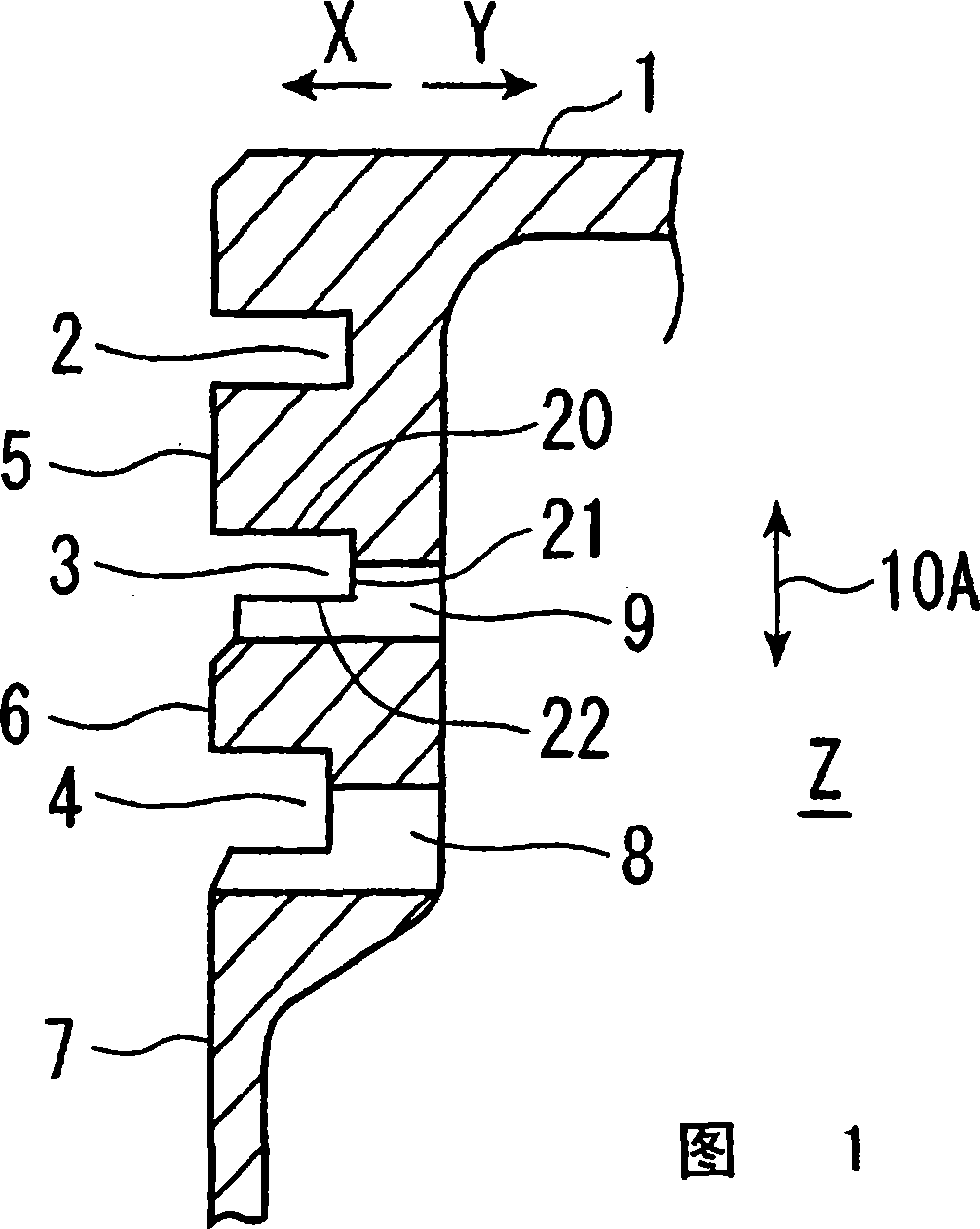

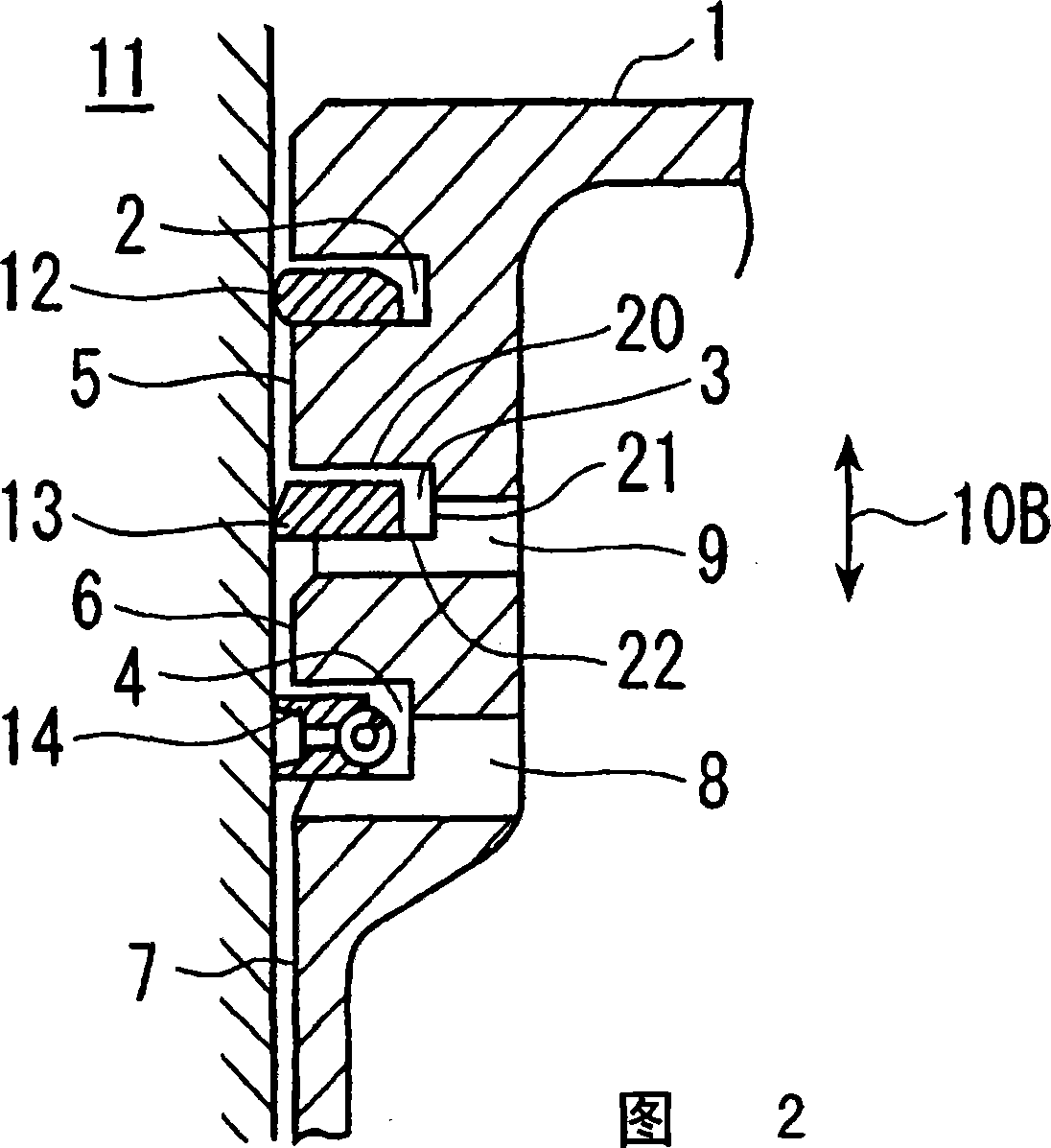

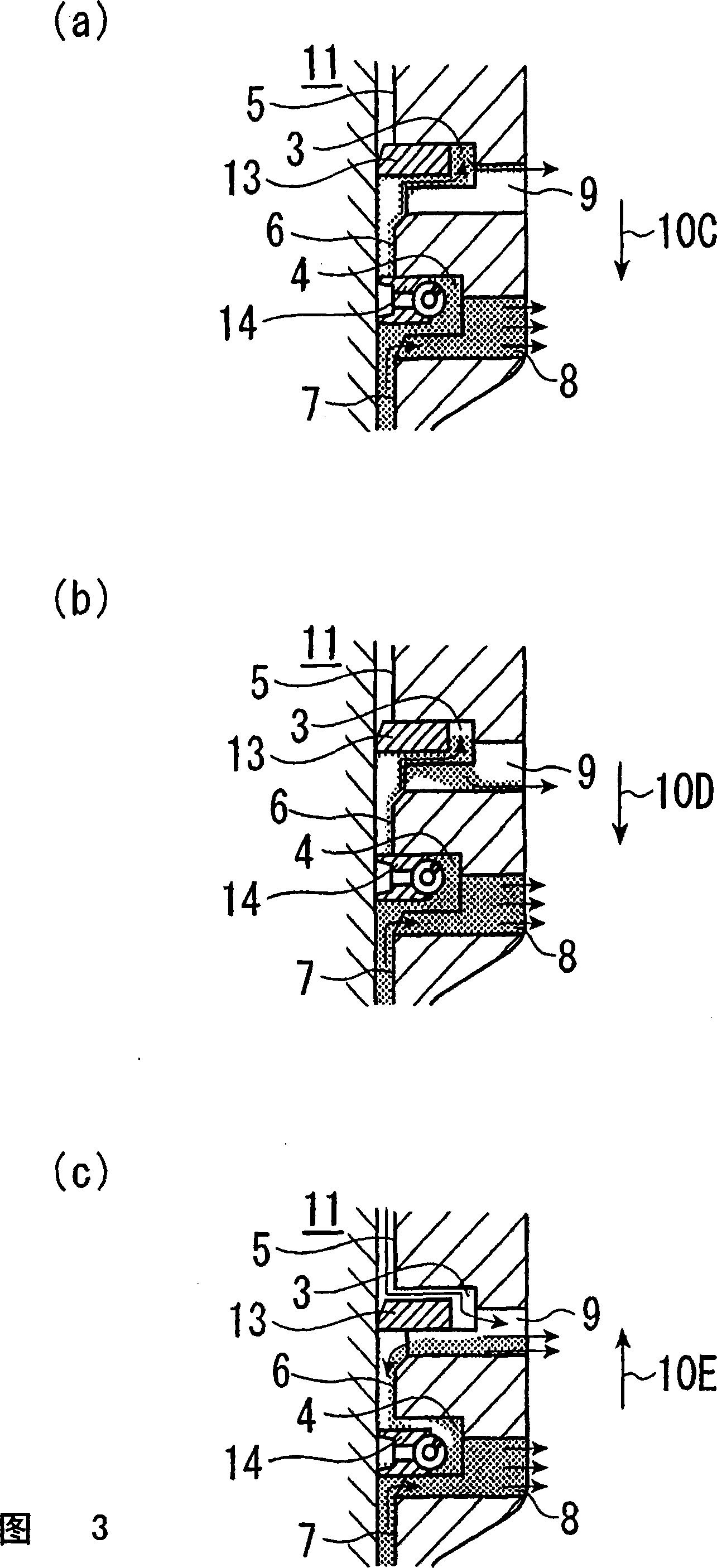

[0098] Use the piston with the three-ring structure shown in Figure 1, install the piston rings with the ring specifications a1, h1, and S1 shown in Table 1, and divide the total tension of the three rings by the total tension of the cylinder diameter The tension ratio was 0.38N / mm, and the amount of lubricating oil consumption and leakage gas during acceleration and deceleration were investigated by assembling it in the cylinder block 11 . Assume that the test engine is a water-cooled four-cycle gasoline engine with a cylinder diameter of 86 mm, a stroke of 86 mm, and a displacement of 1998 cc with 4 cylinders connected in series.

[0099] first ring

second ring

oil ring

ring width

degree h1

ring thickness

degree a1

Close room

Slot S1

ring width

degree h1

ring thickness

degree a1

Close room

Slot S1

ring width

h1

ring thickness

a1

Close room

Slot S1

this invention

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com