Process and appts. for treating nitrogen compound contg. water

A nitrogen compound and treatment method technology, applied in the directions of oxidized water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of complicated operation and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

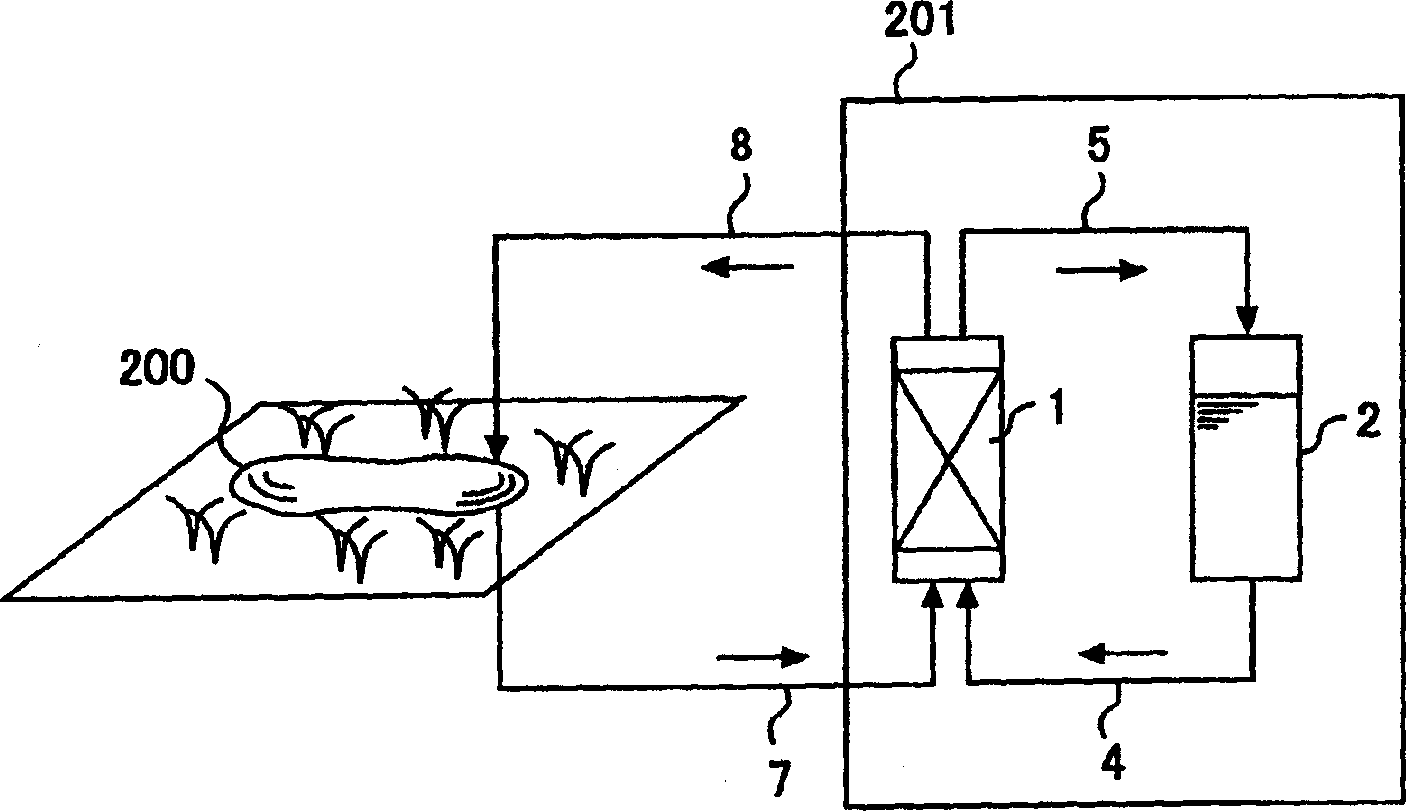

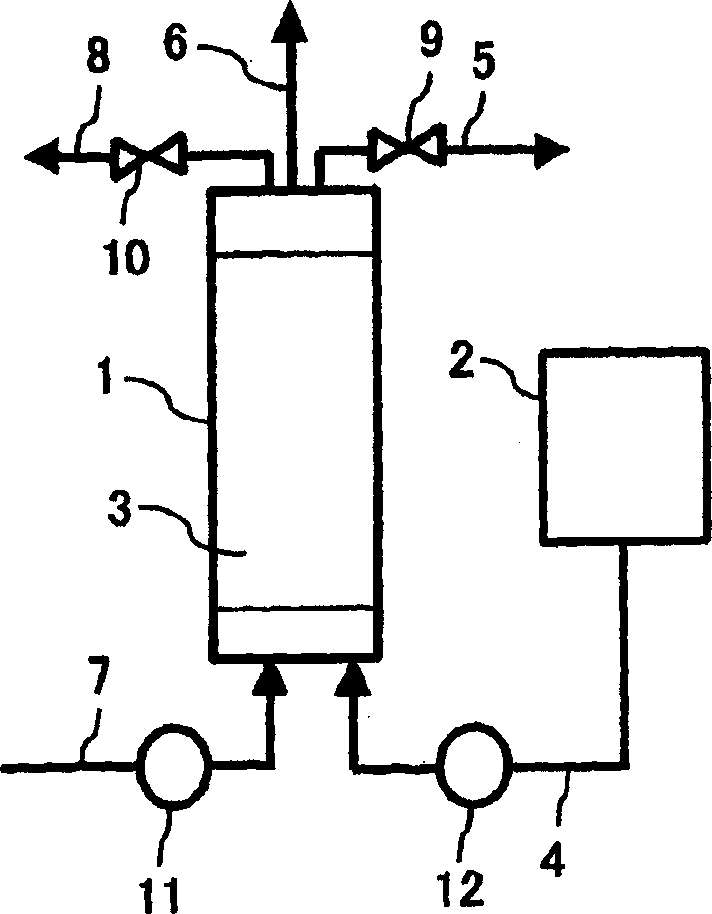

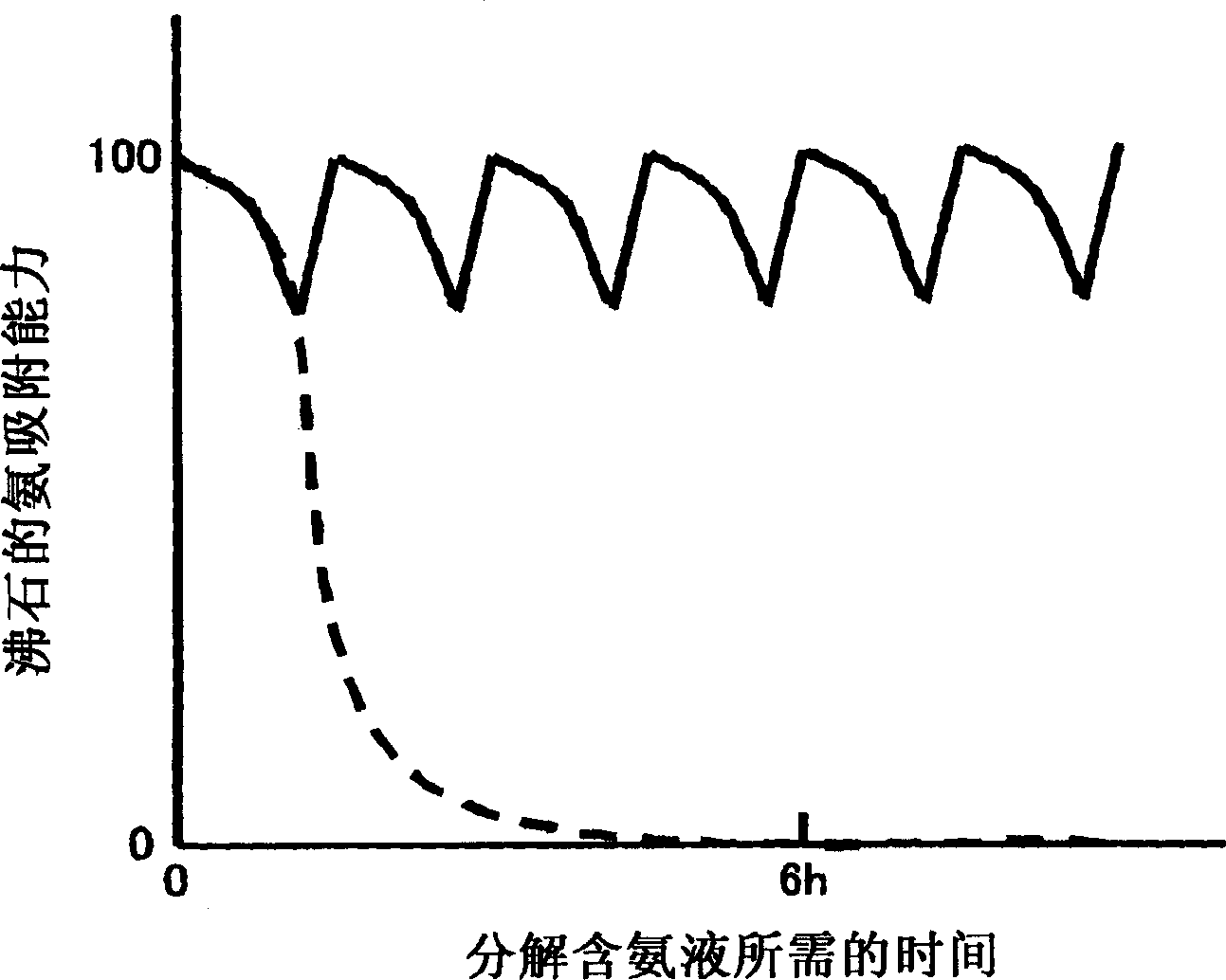

[0035] figure 1It is an explanatory diagram showing the system configuration of the water treatment apparatus related to the nitrogen-containing compound of the present invention. According to the treatment device 201 for water containing nitrogen compounds, the raw water containing nitrogen compounds such as ammonia is introduced from the lake 200 into the adsorption tank 1 through the raw water injection pipe 7, and nitrogen such as ammonia is adsorbed and removed by the adsorbent such as zeolite filled in the adsorption tank 1. Compound, becomes treated water. Though usually contain the nitrogen compound of concentration of tens of mg / L (equivalent to tens of ppm) left and right sides in the drainage, for example according to investigation when the adsorption tank 1 of internal diameter 1 meter fills 100% zeolite (manufactured by Nitto Powder Chemical Co., Ltd., Nitto Zeolite No. 5), if the flow rate leading into the adsorption tank 1 drainage is about 20L / min, the concen...

Embodiment approach 2

[0047] Figure 5 It is an explanatory diagram showing an example of the structure of a water treatment apparatus related to nitrogen-containing compounds according to the present invention. instead of figure 2 The shown device contains a hypobromous acid solution storage tank 2, and is provided with a hypobromous acid generating tank 22, a sodium bromide solution storage tank 18, a sodium bromide solution supply pipeline 19, an ozone generator 20, and an ozone-containing gas supply pipeline 21 And the structure of pumps 23 and 24, this structure can generate hypobromous acid through the reaction of sodium bromide and ozone. With this device, by adding ozone to the sodium bromide solution to generate a solution containing hypobromous acid, it is possible to stably supply chemically unstable and difficult-to-storage hypobromous acid, so that it is possible to realize the treatment of water containing nitrogen compounds with high reliability. device.

[0048] According to thi...

Embodiment approach 3

[0050] Image 6 It is an explanatory diagram showing an example of the structure of a water treatment apparatus related to nitrogen-containing compounds according to the present invention. The composition of this nitrogen-containing water treatment device is in Figure 5 A pH meter 25, a hydrochloric acid storage tank 26, a sodium hydroxide storage tank 27 and a three-way valve 28 have been added to the hypobromous acid generating tank 22 of the device, and a new injection port is provided on the top of the hypobromous acid generating tank 22, through three Pass valve 28 to make it be connected with hydrochloric acid storage tank 26 and sodium hydroxide storage tank 27. In this treatment device of the present invention, the hypobromous acid used as oxidant is stable under acidic and neutral environments, and the hypobromous acid ion dissociates in an alkaline atmosphere, reacts with ozone and changes into bromic acid, so in order to make Nitrogen compounds such as ammonia ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com