Variable displacement pump, oil jet and lublicating system using variable displacement pump

A fuel injector and capacity technology, applied to parts, pumps, pump components, etc. of pumping devices used for elastic fluids, can solve problems such as energy consumption, and achieve the effect of suppressing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

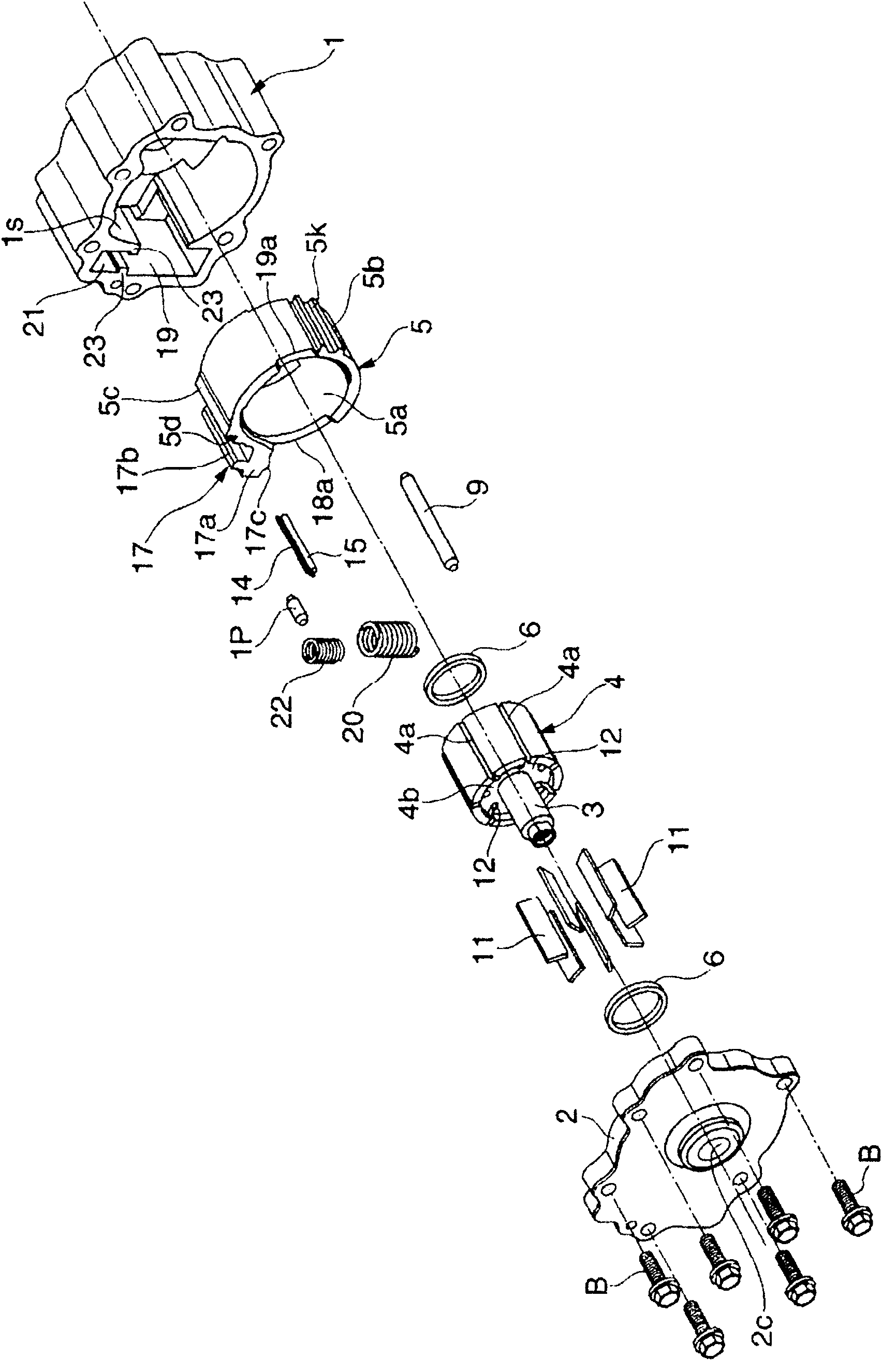

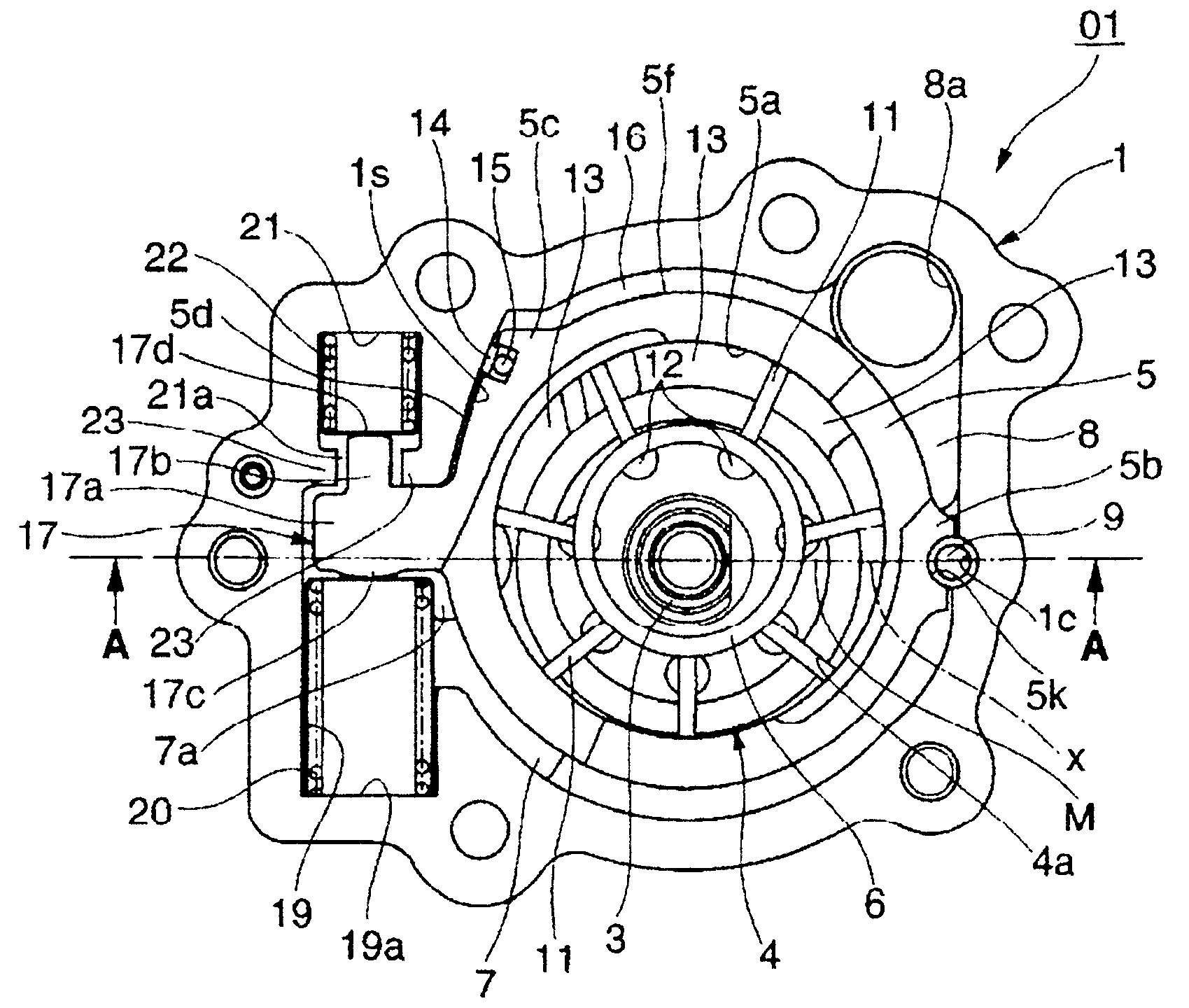

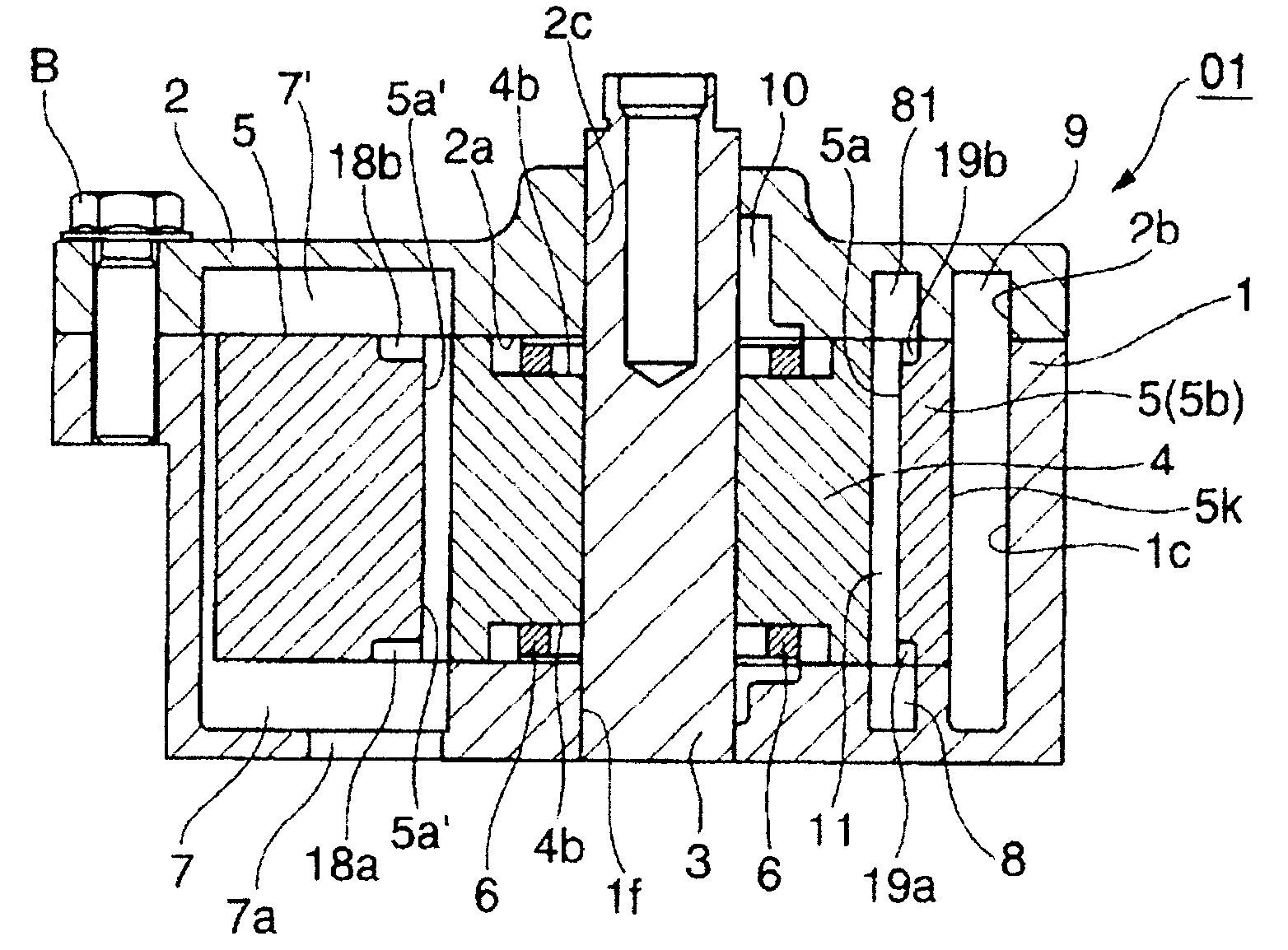

[0082] Such as Figure 1 ~ Figure 3 As shown, the variable displacement pump 01 includes: a bottomed cylindrical pump casing 1 provided at the front end of a cylinder block of an internal combustion engine and having one end opening closed by a cover member 2; The drive shaft 3 that is driven by the crankshaft of the engine, the rotor 4 that is rotatably accommodated inside the pump housing 1 and is connected to the drive shaft 3 at the center, and the movable shaft that is swingably arranged on the outer peripheral side of the rotor 4 The cam ring 5 and a pair of small-diameter vane rings 6 , 6 are slidably arranged on both side surfaces of the inner peripheral portion of the rotor 4 .

[0083] The above-mentioned pump casing 1 is integrally formed of an aluminum alloy material, such as Figure 4 As shown, since the concave bottom surface 1a slides on one axial side of the cam ring 5, the flatness and surface roughness of the bottom surface 1a are processed with high precisi...

no. 2 approach

[0193] Figure 20 The second embodiment is shown. The basic structure such as the pump structure is the same as that of the first embodiment, but two pilot oils are arranged above and below the pivot pin 9 in the figure to push the cam ring 5 so that the eccentricity increases. Room 16.

[0194] That is, assuming that the control oil chamber of the first embodiment is the first control oil chamber 16a, a substantially L-shaped groove 24 is formed in the lower portion of the pump housing 1 on the side of the pivot pin 9, and the groove 24 constitutes the second control oil chamber 16a. Control oil chamber 16b. In addition, a second sealing surface 24 a is formed at a lower portion of the groove 24 , and the second sealing surface 24 a is formed in an arc shape whose radius is centered on the axis of the pivot pin 9 .

[0195] On the other hand, a substantially triangular convex portion 25 is integrally provided at a portion of the cam ring 5 facing the inside of the groove 24...

no. 3 approach

[0201] Figures 21-29 The third embodiment showing the variable displacement pump 01 has some differences in structure from the variable displacement pump 01 of the first and second embodiments, but there are also common points, so details of the common points will be omitted. illustrate.

[0202] That is, the variable displacement pump 01 includes: a pump housing 111 having a pump housing chamber 113 with a U-shaped cross section; a cover member 112 for closing one end opening of the pump housing 111; The drive shaft 114 driven by the crankshaft of the engine; the rotor 115 which is rotatably accommodated in the pump housing chamber 113 and whose central part is connected to the drive shaft 114; The seven blades 116 that can advance and retreat freely in each slot 115a; the cam ring 117 that can be arranged eccentrically (swingable) relative to the rotation center of the rotor 115 inside the pump casing 111; A single coil spring 118 is a urging member that urges the cam rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com