High dielectric constant X8R type MLCC medium material and preparation method

A technology of high dielectric constant and dielectric materials, applied in the direction of fixed capacitor dielectric and fixed capacitor components, etc., to achieve the effects of improving dielectric temperature stability, increasing density, and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

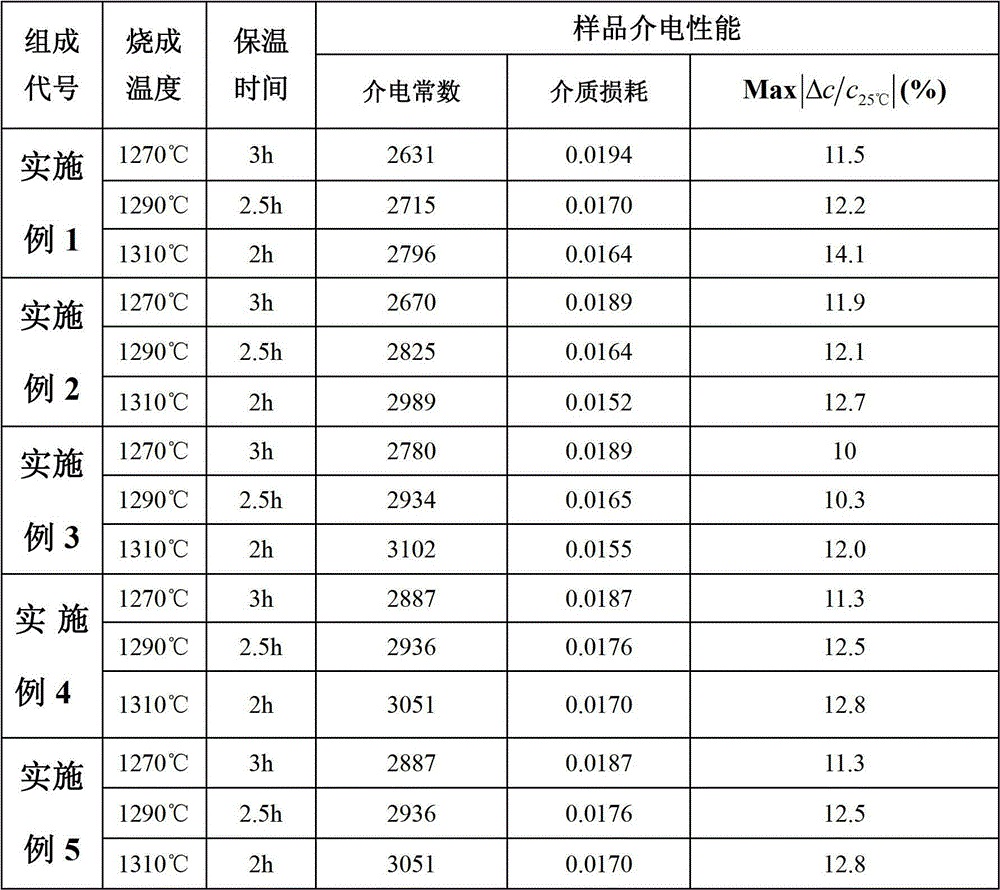

Examples

Embodiment 1

[0030] (1) First take analytically pure Nb 2 o 5 、Co 2 o 3 Accurately weigh 8.28g and 1.72g respectively, mix, sieve and calcinate at 800-900°C, ball mill and dry to obtain the precursor of niobium-cobalt compound;

[0031] (2) Accurately weigh 2.33gTiO 2 , 0.9gNa 2 O and 6.77gBi 2 o 3 Weighing, mixing, sieving, calcining at 800-900°C, ball milling and drying to obtain titanium bismuth sodium compound;

[0032] (3) For 3.13gCaO and 6.87gZrO 2 Weighing, mixing, sieving, calcining at 1150-1200°C, ball milling and drying to obtain zirconium-calcium compound;

[0033] (4) Convert 3.8gBi 2 o 3 , 2.2gZnO, 1gTiO 2 , 0.8H 3 BO 3 , 1gSiO 2Weigh, mix and sieve with 1.2g Ba(OH)2, melt at 1200°C, water quench, grind and sieve to obtain glass powder.

[0034] (5) Accurately weigh 100g of barium titanate synthesized by hydrothermal method, 2.5g of niobium-cobalt compound, BNT0.722, 1.25g of zirconium-calcium compound, 0.1g of manganese carbonate, 0.369g of cerium oxide, and 1...

Embodiment 2

[0036] (1) First take analytically pure Nb 2 o 5 、Co 2 o 3 Accurately weigh 8.31g and 1.69g respectively, mix, sieve and calcinate at 800-900°C, ball mill and dry to obtain the precursor of niobium-cobalt compound;

[0037] (2) Accurately weigh 2.33gTiO 2 , 0.9gNa 2 O and 6.77gBi 2 o 3 Weighing, mixing, sieving, calcining at 800-900°C, ball milling and drying to obtain titanium bismuth sodium compound;

[0038] (3) For 3.13gCaO and 6.87gZrO 2 Weighing, mixing, sieving, calcining at 1150-1200°C, ball milling and drying to obtain zirconium-calcium compound;

[0039] (4) Convert 3.8gBi 2 o 3 , 2.2gZnO, 1gTiO 2 , 0.8H 3 BO 3 , 1gSiO 2 Weigh, mix and sieve with 1.2g Ba(OH)2, melt at 1200°C, water quench, grind and sieve to obtain glass powder.

[0040] (5) Accurately weigh 100g of barium titanate synthesized by hydrothermal method, 2.14g of niobium-cobalt compound, 1.444g of BNT, 1.5g of zirconium-calcium compound, 0.17g of manganese carbonate, 0.8g of cerium oxide, ...

Embodiment 3

[0042] (1) First take analytically pure Nb 2 o 5 、Co 2 o 3 Accurately weigh 8.89g and 1.11g respectively, mix, sieve and calcinate at 800-900°C, ball mill and dry to obtain the precursor of niobium-cobalt compound;

[0043] (2) Accurately weigh 2.33gTiO 2 , 0.9gNa 2 O and 6.77gBi 2 o 3 Weighing, mixing, sieving, calcining at 800-900°C, ball milling and drying to obtain titanium bismuth sodium compound;

[0044] (3) For 3.13gCaO and 6.87gZrO 2 Weighing, mixing, sieving, calcining at 1150-1200°C, ball milling and drying to obtain zirconium-calcium compound;

[0045] (4) Convert 3.8gBi 2 o 3 , 2.2gZnO, 1gTiO 2 , 0.8H 3 BO 3 , 1gSiO 2 Weigh, mix and sieve with 1.2g Ba(OH)2, melt at 1200°C, water quench, grind and sieve to obtain glass powder.

[0046] (5) Accurately weigh 100g of barium titanate synthesized by hydrothermal method, 1.6g of niobium-cobalt compound, 1.805g of BNT, 1.5g of zirconium-calcium compound, 0.25g of manganese carbonate, 1.2g of cerium oxide, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com