Patents

Literature

60results about How to "High insulation resistivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nano doping dielectric material for preparing base-metal inner-electrode multi-layer ceramic sheet type capacitor

ActiveCN101182201AImprove performanceMeet performance requirementsFixed capacitor dielectricStacked capacitorsBarium titanateCeramic capacitor

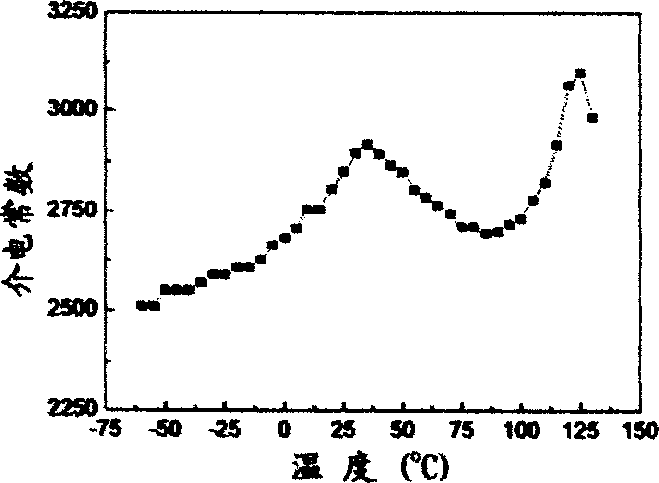

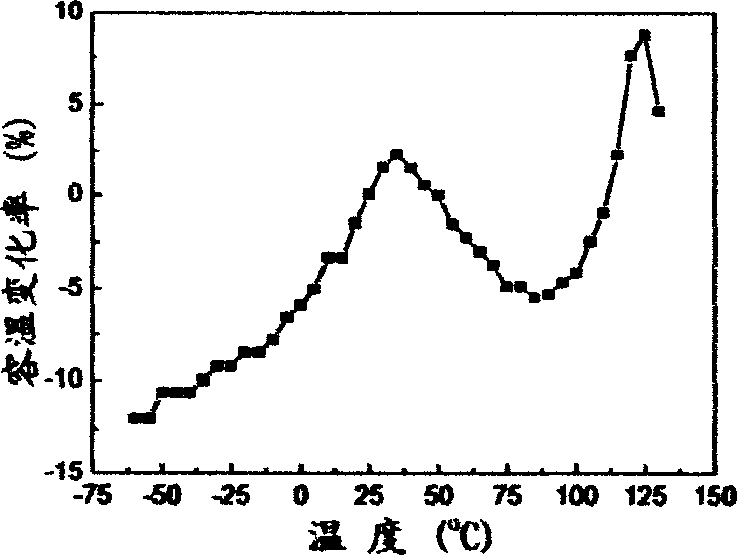

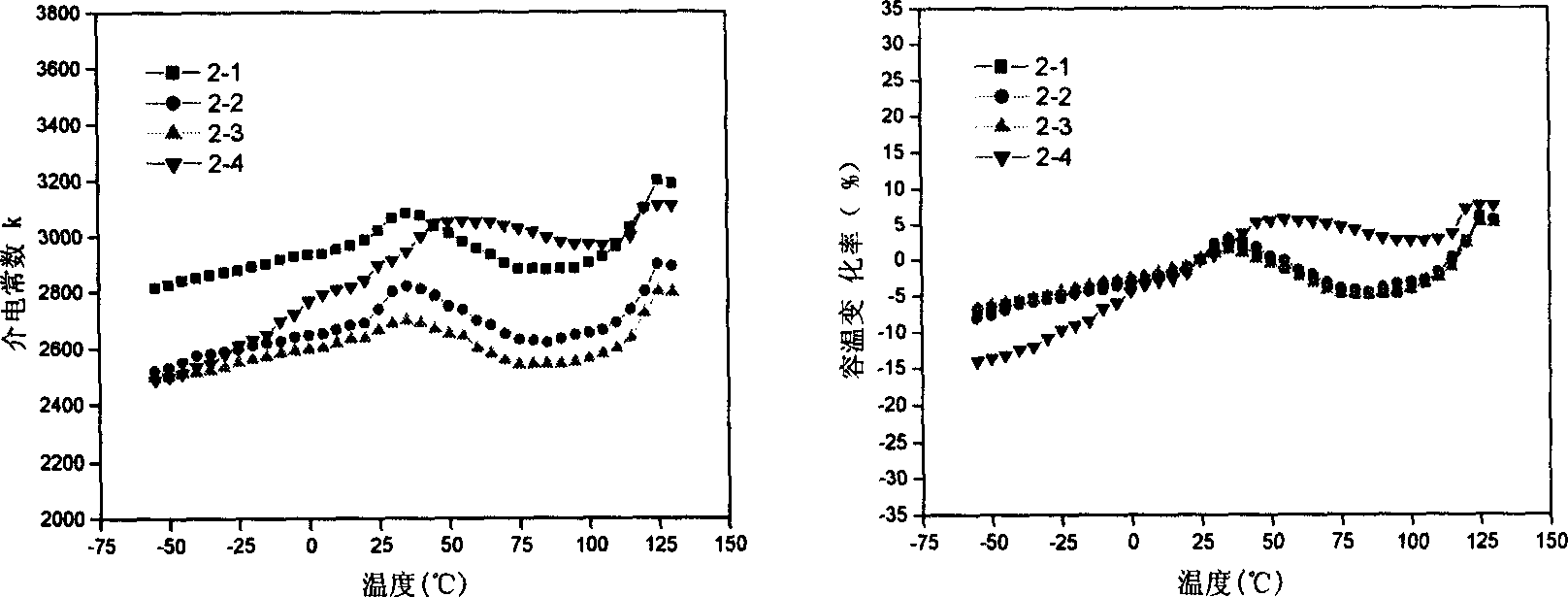

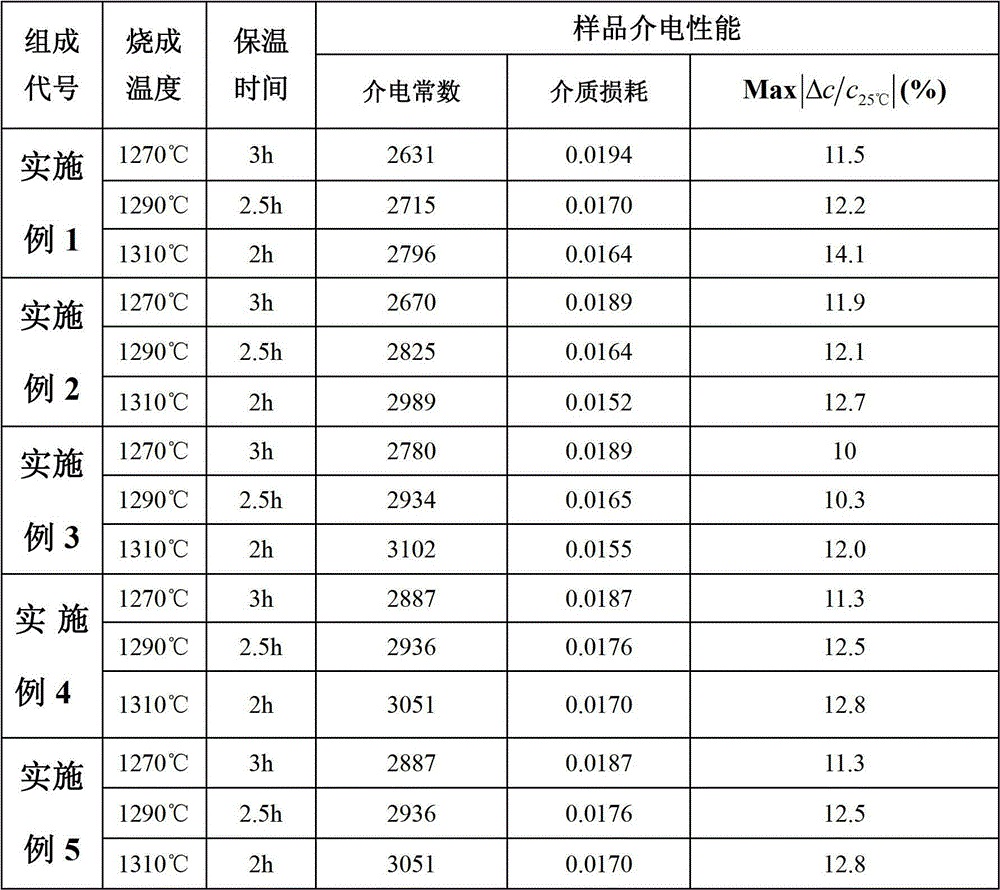

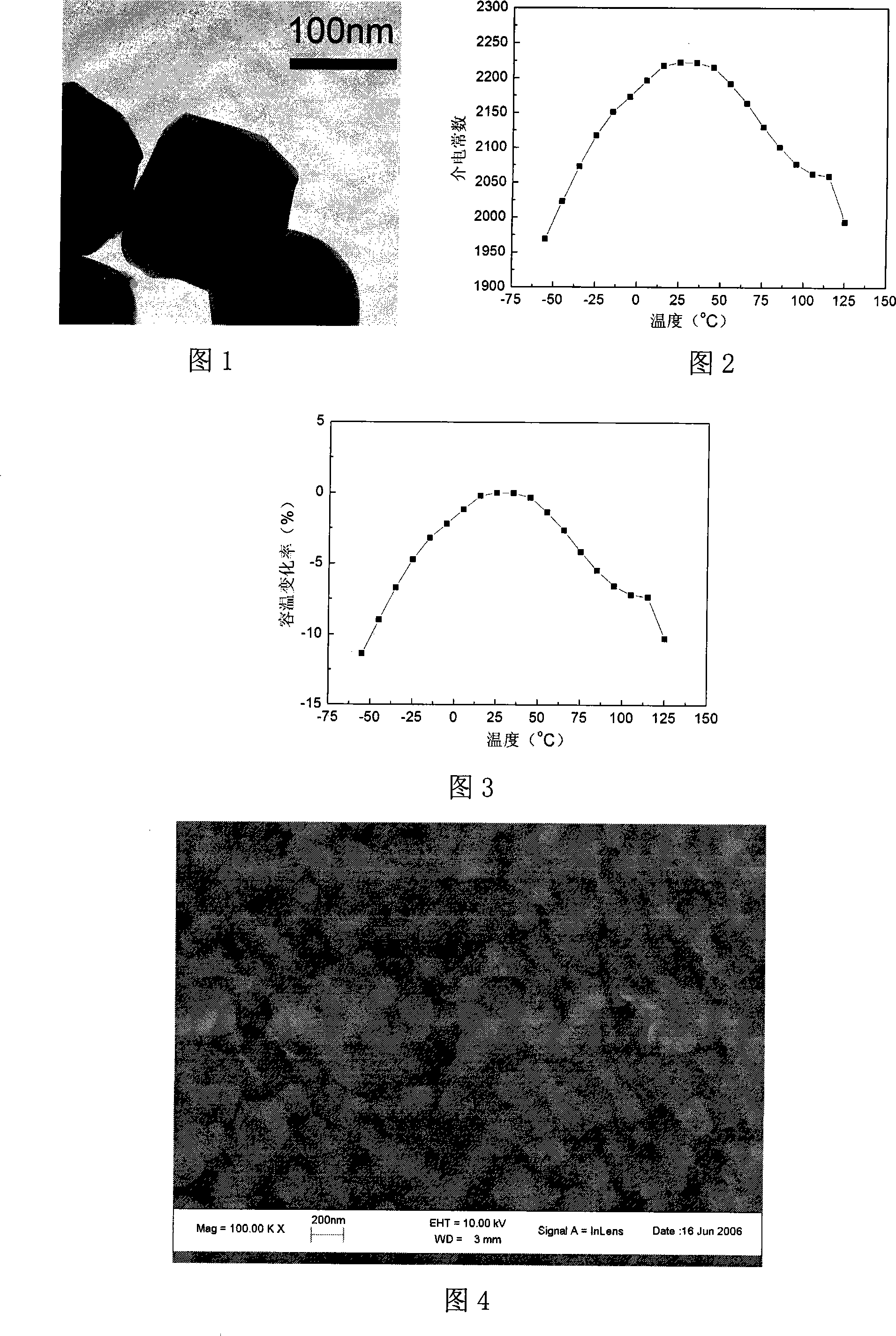

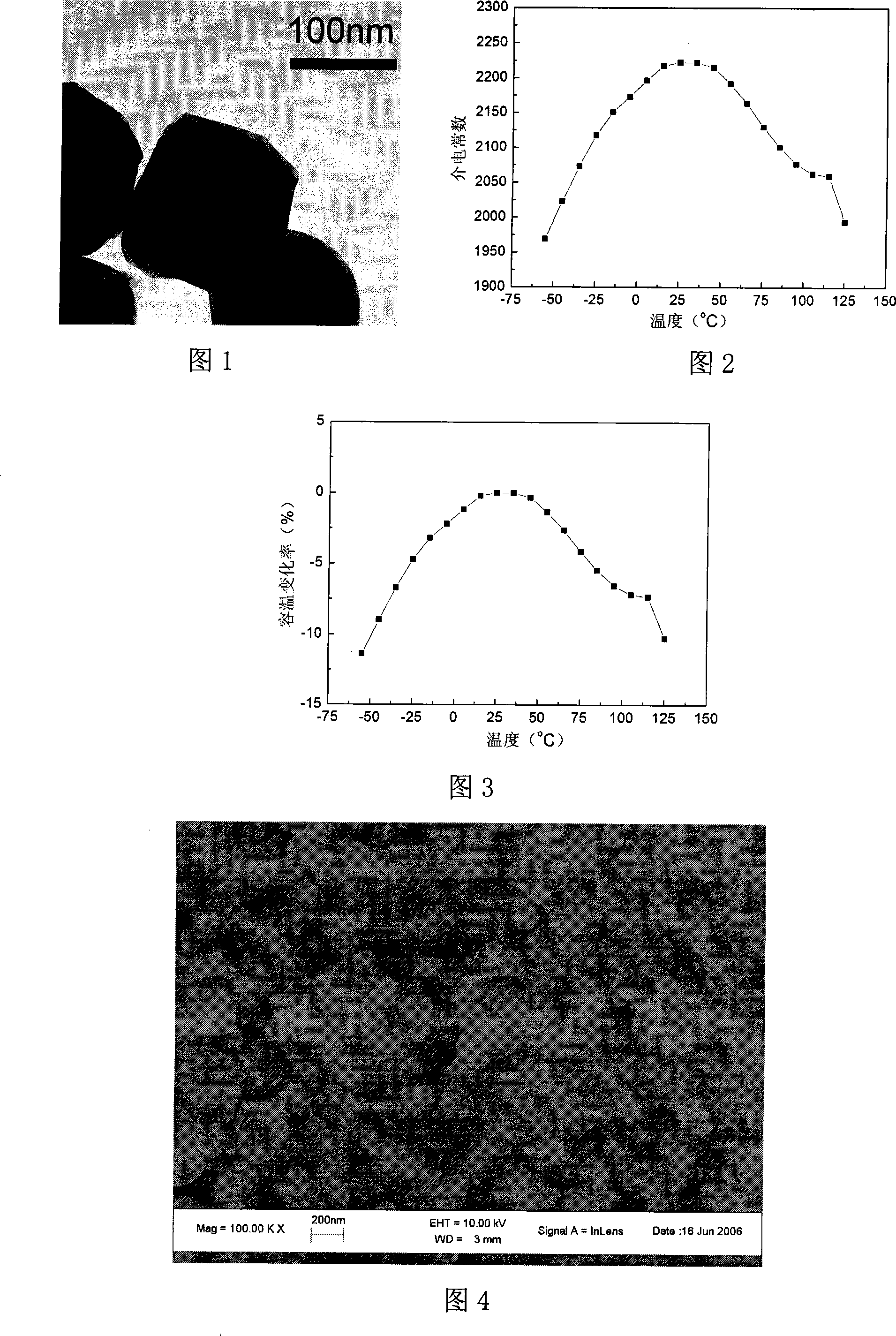

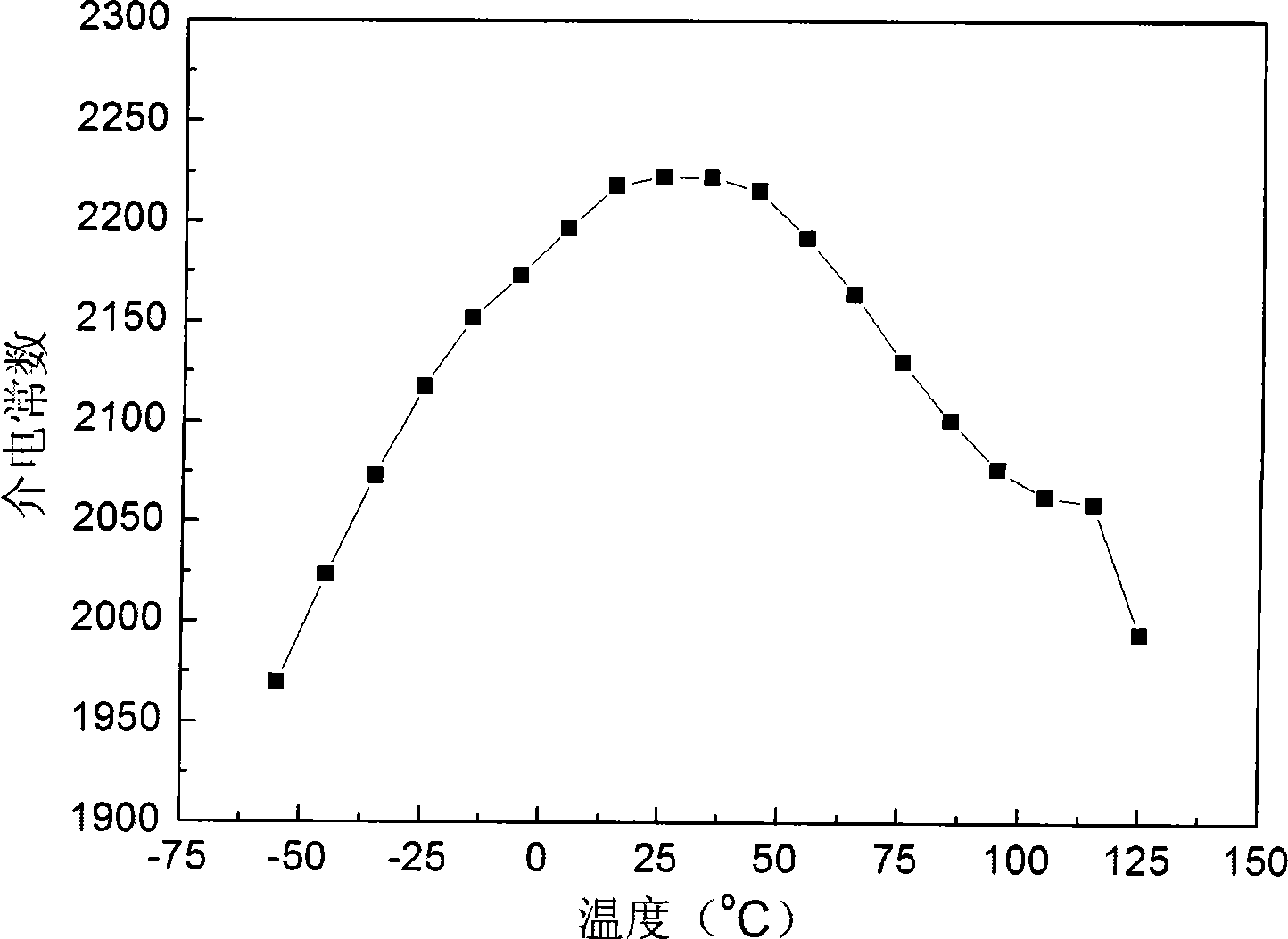

The invention discloses a base metal internal electrode multilayer ceramic chip capacitor dielectric material prepared by nano-doping, which belongs to the technical scope of capacitor material preparation. The ceramic material is composed of barium titanate BaTiO3 as the main material with a mole fraction of 90-98 mol% in the formula and nano dopant accounting for 2-10 mol% of the total material. In a reducing atmosphere, "two-stage" sintering or conventional sintering at a temperature range of 950 ° C to 1250 ° C can obtain X7R / X5R type MLCC materials with excellent performance. The room temperature dielectric constant of the material (wafer sample) can be Controlled at 2000-2600, capacity temperature change rate ≤ ± 15%, dielectric loss at room temperature ≤ 1.5%, ceramic grain size can be controlled at 100-200nm, good uniformity, suitable for production of large capacity, dielectric layer thickness less than Multilayer ceramic capacitors with an ultra-thin dielectric layer of 3 μm, high insulation resistivity, and stable performance.

Owner:TSINGHUA UNIV

Dielectric material for thermostable laminated ceramic capacitor with basic-metal inner electrode

InactiveCN1404080AImprove uniformityImprove performanceFixed capacitor dielectricCeramicsDielectric lossCeramic capacitor

The present invention is material for laminated ceramic capacitor with high temperature stability and basic material inner electrodes. The inner electrode is made of low cost metal, such as Ni, Cu and their alloy. The dielectric material comprises BaTiO3 as main component, and additives in cludes CaO, CaTiO3, BaO, SiO2, SrO2, MnO2, MgO, Co2O3, Co3O4, Fe2O3 and Y2O3 as well as one or more RE oxide and salt in certain proportion and is prepared through mixing, sintering in reducing atmosphere of mixed nitrogen and hydrogen. The dielectric has excellent performance, including room temperature dielectric constant of 2000-3000, etc. The material of the present invention is suitable for producing great capacity superthin laminated ceramic capacity with high insulating resistivity and stable performance.

Owner:TSINGHUA UNIV

Lead-free high-voltage capacitor dielectric ceramic sintered at medium temperature and preparation method thereof

ActiveCN106631005AHigh dielectric constantHigh breakdown strengthBreakdown strengthHigh voltage capacitors

The invention discloses lead-free high-voltage capacitor dielectric ceramic sintered at medium temperature and a preparation method thereof; the lead-free high-voltage capacitor dielectric ceramic is prepared from, by weight, 100 parts of Sr0.78Ca0.20Ba0.02TiO3, 8-20 parts of Bi2O3.2TiO2, 0.05-0.35 part of MnCO3, 0.05-0.30 part of Co2O3, 0.01-0.08 part of MgTiO3, 0-0.20 part of Al2O3, 0-0.10 PART OF Nb2O5, 0-0.08 part of HfO2, and 1-2 parts of a sintering aid, via the steps of ball milling, drying, grinding and screening. The dielectric constant and insulating resistance of the capacitor dielectric ceramic are adjusted mainly by changing the content of Bi2O3.2TiO2, comprehensive performance of the dielectric ceramic is improved by selecting different doping modifying elements, and the finally prepared dielectric ceramic has high dielectric constant, low loss, high insulating resistance and high breakdown strength. The dielectric ceramic is sintered at medium temperature and free of lead, is suitable for the preparation of high-voltage multilayer ceramic capacitors (MLCC), and has great practical value and market value.

Owner:元六鸿远(苏州)电子科技有限公司

Nanometer ceramic-material doping agent, ceramic capacitor media material and production thereof

InactiveCN1854105APromote lowerMeet miniaturizationFixed capacitor dielectricPiezoelectric/electrostrictive/magnetostrictive devicesDopantCeramic capacitor

A nanometer ceramic material dopant, medium material of ceramic capacitor and their production are disclosed. The formula of the dopant consists of aA.bB.cC.dR2 O3.eSiO2; A contains Na2O; B contains one or multiple of MgO and CaO; C contains one or multiple of MnO2 and Co3O4; R contains one of multiple of Y, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb and Lu, among them a, b, c, d and e are coefficient, by computing mol%, 0<=a<=10%, 0<=b<=25%, 0<=c<=15%, 20%<=d<=60%, 10%<=e<=50% and b and c can't be zero at same time. Its advantages include large capacity, adjustable material formula, low sintering temperature, less medium loss, high dielectric constant and better reliability.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

High temperature stable X9R type multilayer ceramic capacitor dielectric material and preparation method thereof

ActiveCN103936414AOvercome the high temperature reduction effectReduce lossBarium titanateCeramic capacitor

The invention discloses a high temperature stable X9R type multilayer ceramic capacitor dielectric material and a preparation method of the high temperature stable X9R type multilayer ceramic capacitor dielectric material. The high temperature stable X9R type multilayer ceramic capacitor dielectric material disclosed by the invention is prepared by the steps of adding a calcium-boron-silicon compound to a barium titanate-sodium bismuth titanate-niobium pentoxide eutectic compound serving as a matrix, compounding one or more of Ce, Nd and La oxides, and compounding one or more of barium-manganese oxide, magnesium oxide and zinc oxide; and the invention provides the preparation method of the high temperature stable X9R type multilayer ceramic capacitor dielectric material. The X9R type multilayer ceramic capacitor dielectric material prepared by using the material and the method provided by the invention has high temperature resistance (above 200 DEG C), and good temperature stability, and enable components and parts such as multilayer ceramic capacitors, tuners and duplexers to be suitable for the application at a high temperature (above 200 DEG C), thus having extremely high industrialization prospect and industrial application value.

Owner:FUJIAN TORCH ELECTRON TECH CO LTD

High dielectric constant X8R type MLCC medium material and preparation method

ActiveCN102718477AImprove medium temperature stabilityHigh Curie temperatureFixed capacitor dielectricRare-earth elementOxygen vacancy

The invention relates to a high dielectric constant X8R type MLCC medium material and a preparation method, the high dielectric constant X8R type MLCC medium material takes 100 weight parts of barium titanate as a base material, and the medium material comprises the following components by weight: 1.6-2.5 parts of niobium cobalt compound, 0.722-1.805 parts of titanium bismuth sodium compound, 1.25-2.0 parts of zirconium calcium compound, 1-3 parts of glass powder, 0.369-1.2 parts of one or a plurality of oxides of Ce, Yb, Dy and Ho and 0.1-0.25 part of manganese carbonate. The key and core of the present invention are characterized in that a proper amount of manganese carbonate, rare earth elements and a zirconium calcium compound are added, the rare earth element can be taken as a donor or an acceptor in the barium titanate dielectric ceramic material for doping and modifying, the movement of the intrinsic oxygen vacancy and the oxygen vacancy brought by other B site donor doping can be inhibited, the insulation resistivity of a material system, the ageing resistance and the reduction resistance of a material system can be increased, and the method provided by the invention can be used for making silver-palladium electrodes and nickel electrodes MLCC.

Owner:FUJIAN TORCH ELECTRON TECH CO LTD

Chemical coating prepared base metal internal electrode multi-layer ceramic chip capacitor dielectric material

ActiveCN101183610AImprove performanceMeet performance requirementsFixed capacitor dielectricCeramicsCapacitanceBarium titanate

The invention discloses a chemical coating prepared dielectric material of base-metal electrode multilayer ceramic capacitor, belonging to the capacitor material preparing technology, which adopts the technical proposal that a plurality of barium titanate grains are coated by the doped elements through chemical coprecipitation; the main ingredient, barium titanate BaTiO3, accounts for 90mol% to 97mol% of the prescription; the amount of nanometer inhibitory coating composite oxide accounts for 3mol% to 10mol% of the total materials. The ceramic material is sintered at a reducing atmosphere controlled by a humidified gas mixture of nitrogen and hydrogen at a temperature between 950 to 1250 DEG C to get a X7R / X5R type MLCC material; wherein the dielectric constant of the material at room temperature is 2000 to 2700; the temperature coefficient of capacitance is less than or equal to positive and negative 15%; the dielectric loss at room temperature is less than or equal to 2%. The ceramic crystal grain under 200nm has low dielectric loss and good material uniformity; the multilayer ceramic capacitor produced with the ceramic crystal grain has the advantages of large capacity, ultrathin dielectric layer and the thickness less than 2um.

Owner:TSINGHUA UNIV

High resistance glass for sealing metal

InactiveCN101186442AHigh insulation resistanceHigh insulation resistivityHigh resistanceAir tightness

High resistance glass for metal seal is provided, which pertains to glass field and relates to insulation material applicable to microelectronics packaging and metal seal, in particular to a metal shell or a seal relay. The invention is characterized in that: the glass contains 35-55 percent of SiO2, 5-20 percent of Al2O3, 10-20 percent of B2O3, 5-15 percent of CaO, 10-25 percent of BaO, 3-8 percent of ZnO and 0-2 percent of Cr2O3, the coefficient of linear expansion is ensured to be 45 multiplied by 10<-7>-54 multiplied by 10<-7> / DEG C; the invention can be sealed with kover or iron-nickel alloy and the sealing piece has high insulation resistance and good gas proofness.

Owner:UNIV OF SCI & TECH BEIJING

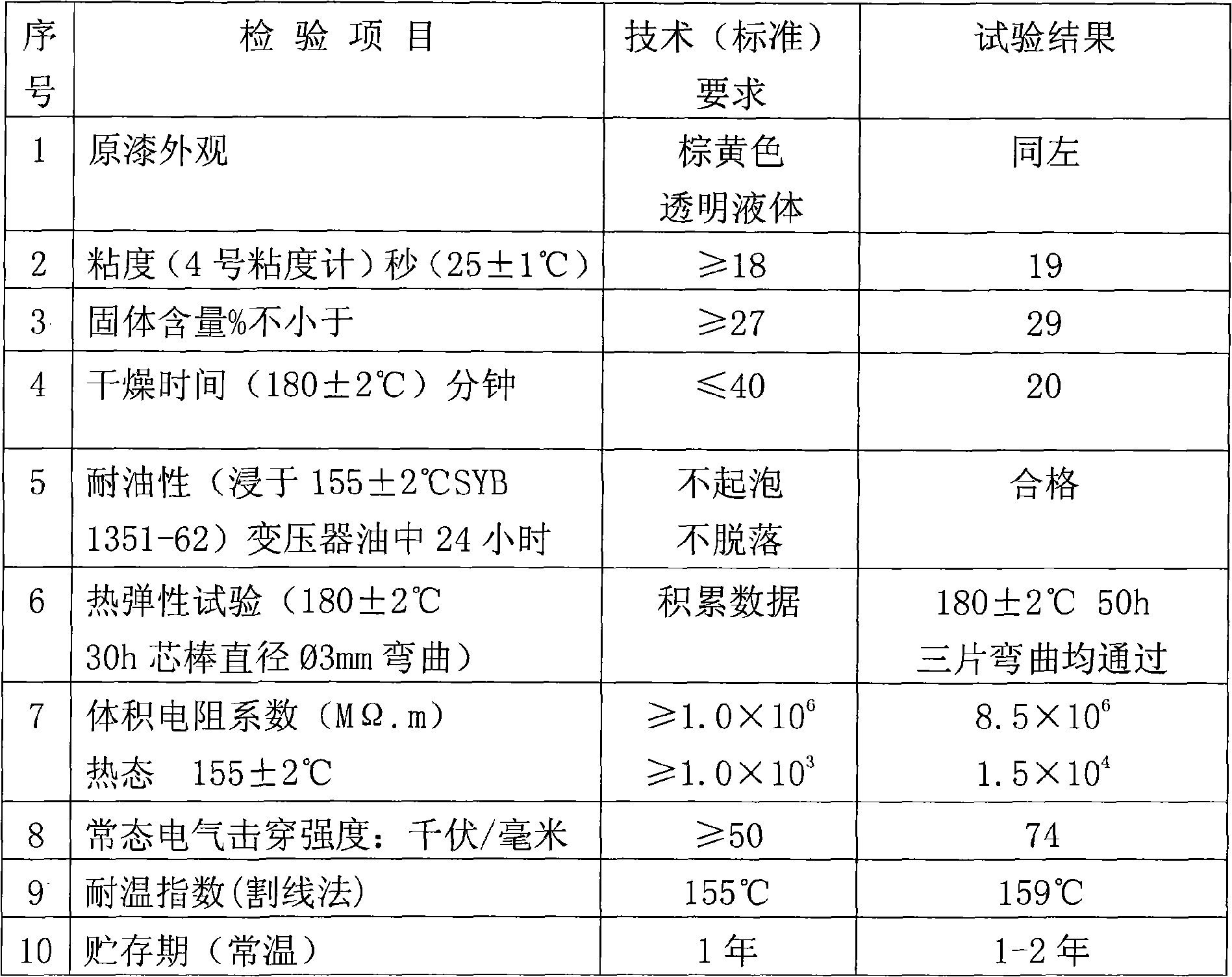

Resin emulsion paint special for epoxy pnenolic aldehyde stalloy and preparation thereof

ActiveCN101314694AExcellent electrical performanceImprove heat resistanceLiquid surface applicatorsEpoxy resin coatingsEpoxyLacquer

The invention discloses resin paint special for epoxy phenol-formaldehyde silicon steel sheet and the preparation method thereof. The resin paint comprises, by weight, polymer 609 epoxy resin 98 to 102 parts, 214 phenol-formaldehyde resin 18 parts, Z-11 epoxy toughener 5 parts, L-12 leveling agent 7.8 parts, and diluting agent 2 to 5 parts. The diluting agent is toluene or ethanol or ethyl acetate. The resin paint has the advantage of excellent performance in resisting heat, moisture, oil, and chemical corrosion, and can be applied at normal temperature and dried rapidly. The resin has good uniformity and arbitrarily adjustable viscosity, and can be uniformly mixed with inorganic filler to achieve good manufacturability. The resin paint has good adhesion with the surface coating of silicon steel sheet, and the coating has good mechanical strength, high heat resistant grade and high insulation resistance coefficient, and can be used for F-grade (155 DEG C) electric products to achieve long storage life.

Owner:JINTAN HUARONG INSULATING MATERIAL CO LTD

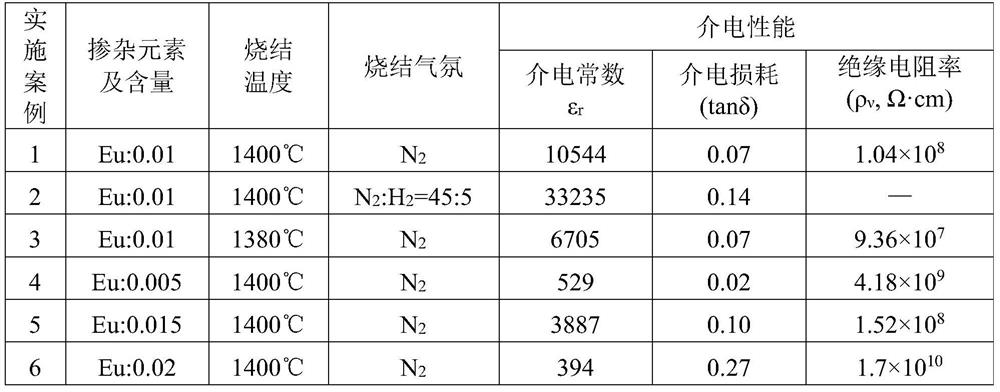

Giant dielectric constant strontium titanate dielectric ceramic and preparation method thereof

InactiveCN113248253ALow dielectric lossHigh insulation resistivityFixed capacitor dielectricStacked capacitorsStrontium titanateDielectric loss

The invention belongs to the technical field of ceramic materials, and discloses a giant dielectric constant strontium titanate dielectric ceramic and a preparation method thereof. The chemical formula of the ceramic is Sr1-xEuxTiO3, wherein x is more than or equal to 0.01 and less than or equal to 0.015. The preparation method comprises the following steps: proportioning SrCO3, Eu2O3 and TiO2, mixing, and carrying out ball milling; drying the ball-milled raw materials, sieving, pre-sintering at 1000 DEG C for 3 hours, and mixing and ball-milling the pre-sintered powder; drying and sieving the ball-milled raw materials, adding a binder into the obtained powder, sieving, granulating, pressing into a green body, and discharging glue; and sintering the blank body after complete glue removal at 1400 DEG C in N2 atmosphere, and preserving heat for 6 hours to obtain the final sample. According to the invention, the Sr1-xEuxTiO3 dielectric ceramic is prepared through doping modification by adopting a traditional solid-phase method, the dielectric constant is improved, the lower dielectric loss is kept, and the dielectric property of the ceramic material is further improved, so that the actual application requirements are better met.

Owner:TIANJIN UNIV

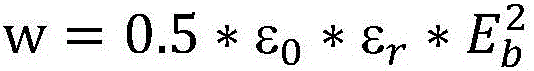

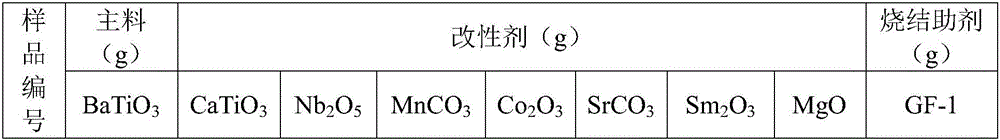

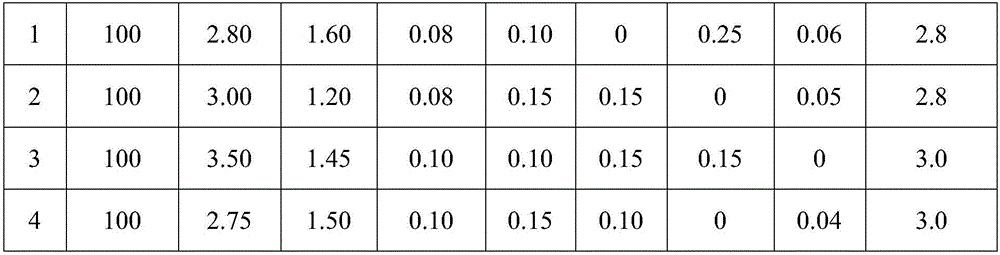

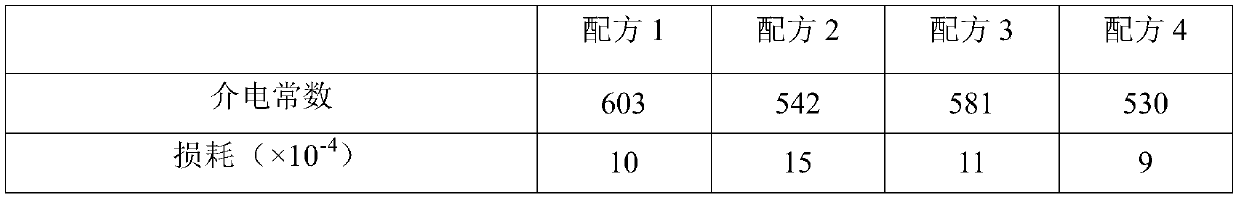

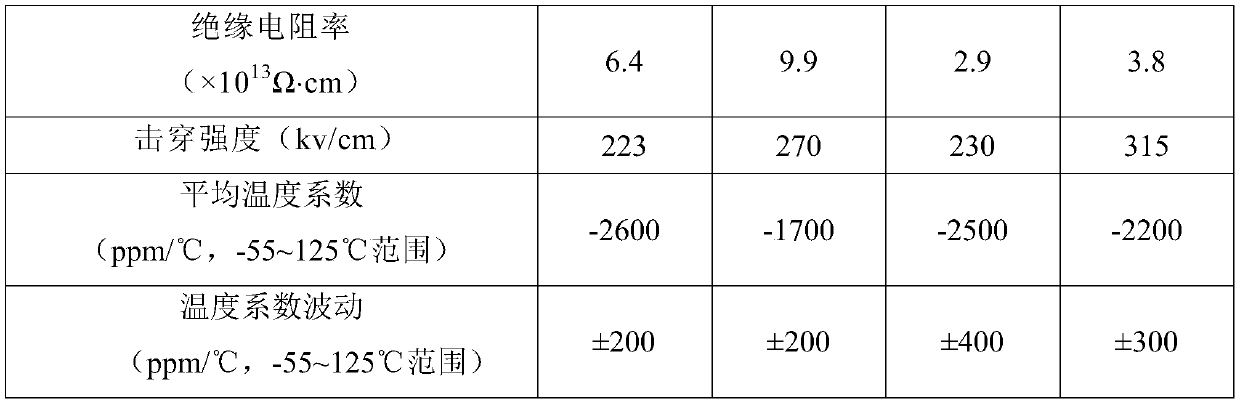

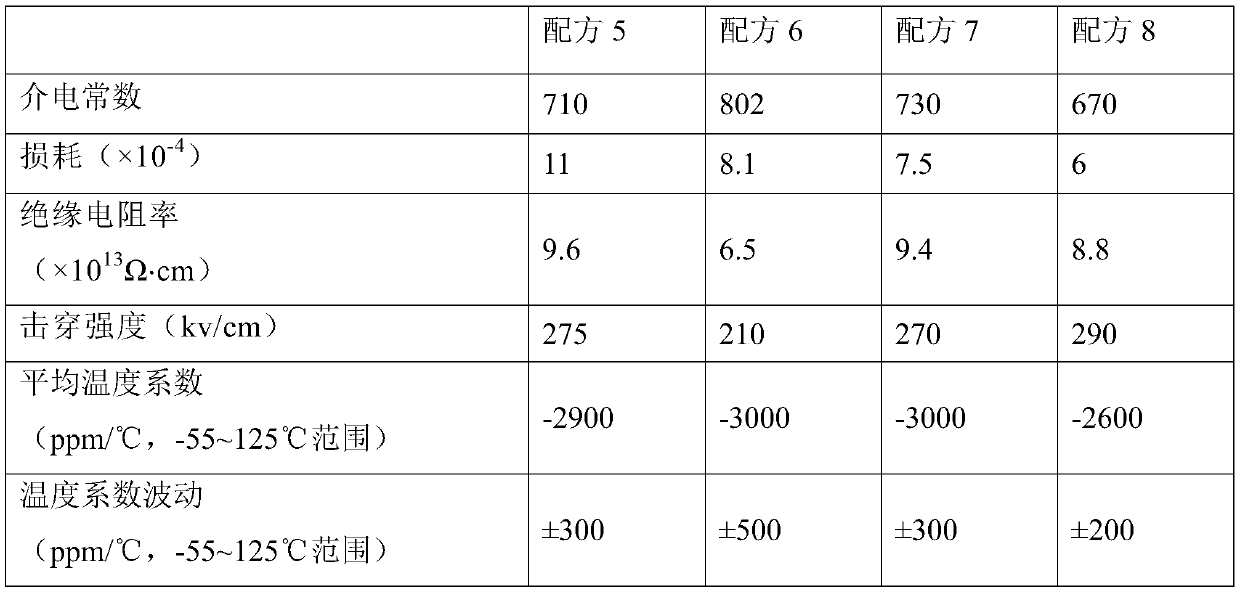

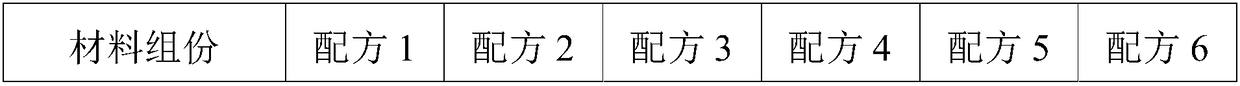

Medium-high voltage ceramic dielectric capacitor material with bias characteristic for medium temperature sintering

The invention relates to a medium-high voltage ceramic dielectric capacitor material with a bias characteristic for medium temperature sintering. A formula of the medium-high voltage ceramic dielectric capacitor material is prepared from the following components in parts by mass: 100 parts of main material BaTiO3, 2.5 to 4.5 parts of modifying agent CaTiO3, 1.0 to 1.8 parts of Nb2O5, 0.05 to 0.35 part of MnCO3, 0 to 0.15 part of CeO2, 0.05 to 0.35 part of SrCO3, 0.05 to 0.30 part of Co2O3, 0 to 0.08 part of MgO, 0 to 0.20 part of Sm2O3, 0 to 0.10 part of Y2O3 and 2.5 to 4.0 percent of sintering aid, wherein the sintering aid contains three or four of ZnO, CaCO3, Li2CO3, H3BO3 and SiO2. The material disclosed by the invention has high breakdown voltage and the bias characteristic under the condition of keeping a high dielectric constant, and is suitable for preparing single-layer and multilayer ceramic dielectric capacitors.

Owner:BEIJING YUANLIU HONGYUAN ELECTRONICS TECH

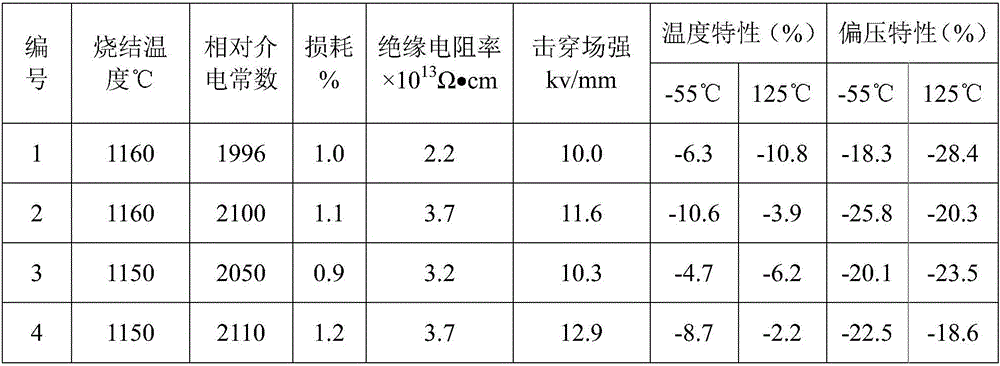

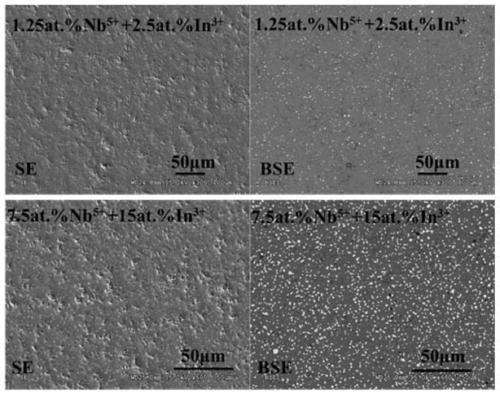

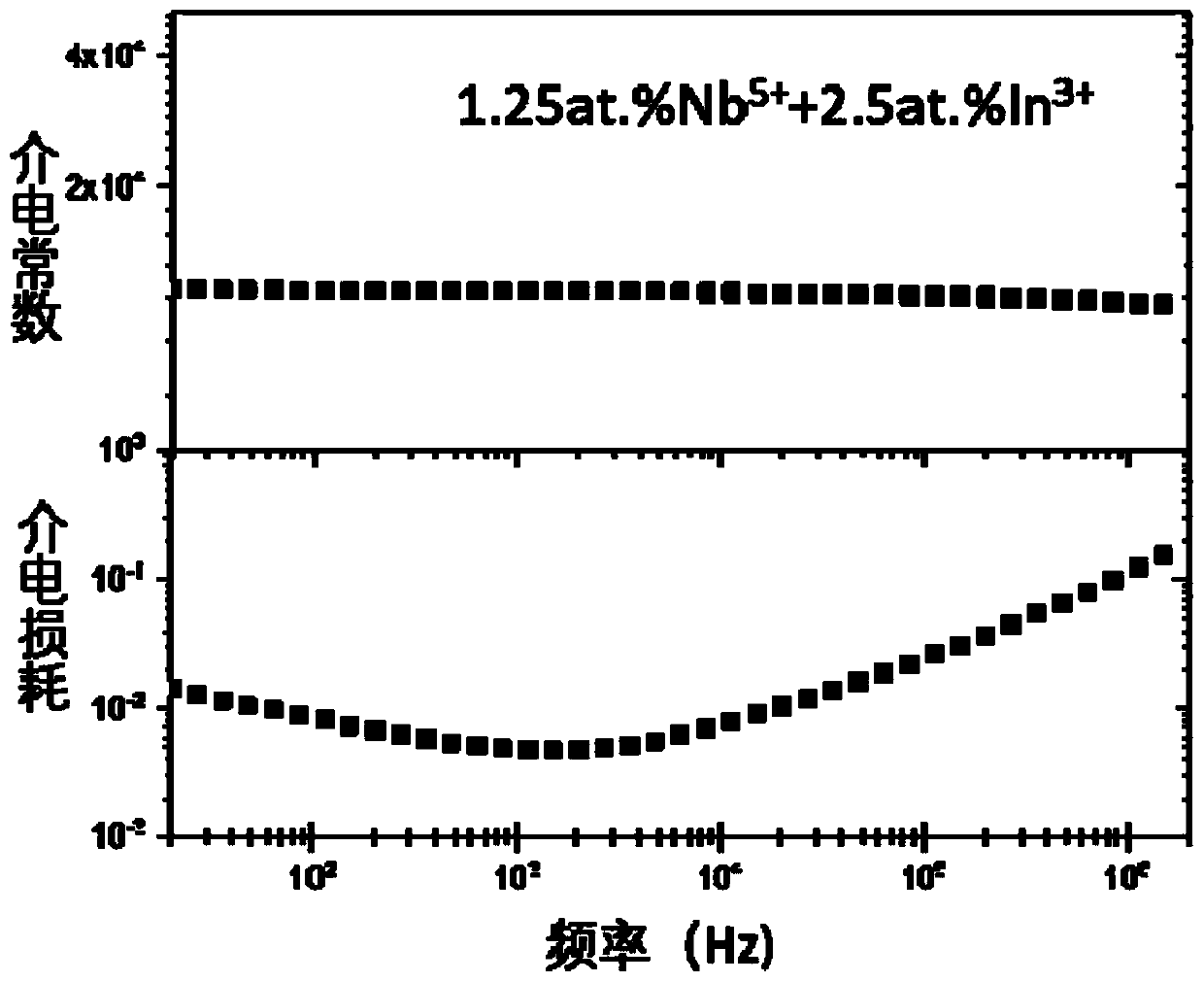

Multiphase giant dielectric ceramic material and preparation method thereof

The invention discloses a multiphase giant dielectric ceramic material. The total component expression of the multiphase giant dielectric ceramic material is AxBnxTi(1-(n+1)xO2, wherein A is selectedfrom at least one of Nb, Ta, V, Mo and Sb, and B is selected from at least one of In, Ga, Al, Co, Cr, Sc, Fe (III) and trivalent rare earth cations; n is the molar ratio of B to A, n is greater than 1and less than or equal to 5, and x is greater than 0 and less than or equal to 0.1. The multiphase giant dielectric ceramic material prepared by the invention has excellent performances of giant dielectric, low loss and good frequency and temperature stability, has high insulation resistivity and high-voltage breakdown resistance, has insulation resistivity higher than 1011 [ohm]cm, and can be applied to high-energy storage devices and supercapacitors. The invention also discloses a preparation method of the multiphase giant dielectric ceramic material.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

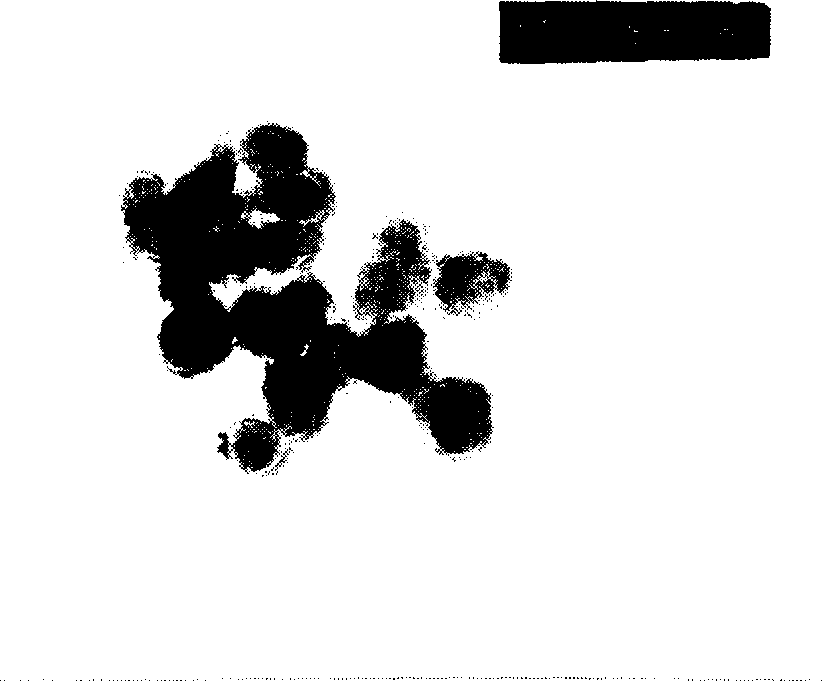

Strontium, bismuth and titanium base energy storage medium material for medium temperature sintering and preparation method

ActiveCN109970446AStable temperature coefficientHigh dielectric constantFixed capacitor dielectricDielectricStrontium

The invention discloses a strontium bismuth and titanium base energy storage medium material for medium temperature sintering and a preparation method. The medium material is prepared from a base material, a modifying agent and sintering auxiliaries; the base material is SrO-xBi2O3-(1+3x)TiO2, wherein 0.04<=x<=0.11; the modifying agent includes one or more of MnCO3, Mg(OH)2, Co2O3, SiZrO3, CeO2 and Y2O3; the sintering auxiliaries include two or more of H3BO3, ZnO, CaCO3 and SiO2. The SrO-xBi2O3-(1+3x)TiO2 base material is prepared by adopting a solid phase method, and the adjustable energy storage dielectric material with the high dielectric constant, disruptive strength and insulation resistivity, low consumption and sintering temperature and stable temperature coefficient is obtained byadding the modifying agent and the sintering auxiliaries.

Owner:BEIJING YUANLIU HONGYUAN ELECTRONICS TECH

Temperature-stable X8R MLCC (multiplayer ceramic chip capacitor) medium material with low-temperature sintering effect

ActiveCN108083795AUniform particle size distributionGood dispersionFixed capacitor dielectricStacked capacitorsBarium titanateManganese

The invention discloses a temperature-stable X8R MLCC (multiplayer ceramic chip capacitor) medium material with low-temperature sintering effect. The temperature-stable X8R MLCC medium material is sintered by a main material, auxiliary materials, modifiers and a sintering additive, wherein the main material is BaTiO3 (barium titanate); the auxiliary materials comprise Na0.5Ni0.5TiO3 and CaTiO3 (calcium titanate); the modifiers comprise Nb2O5 (niobium pentoxide), MnCO3 (manganese carbonate), Co2O3 (cobalt oxide) and MgO (magnesium oxide). By adopting the technical scheme, the temperature-stableX8R MLCC medium material has the advantages that the dielectric property is good, the loss is lower, the insulation resistivity is higher, and the X8R temperature stability is good; the cost of the raw materials is low, the production technology is simple, the sintering technology is easy to control, the environment-friendly requirement is met, and the good application value and market prospect are realized.

Owner:BEIJING YUANLIU HONGYUAN ELECTRONICS TECH

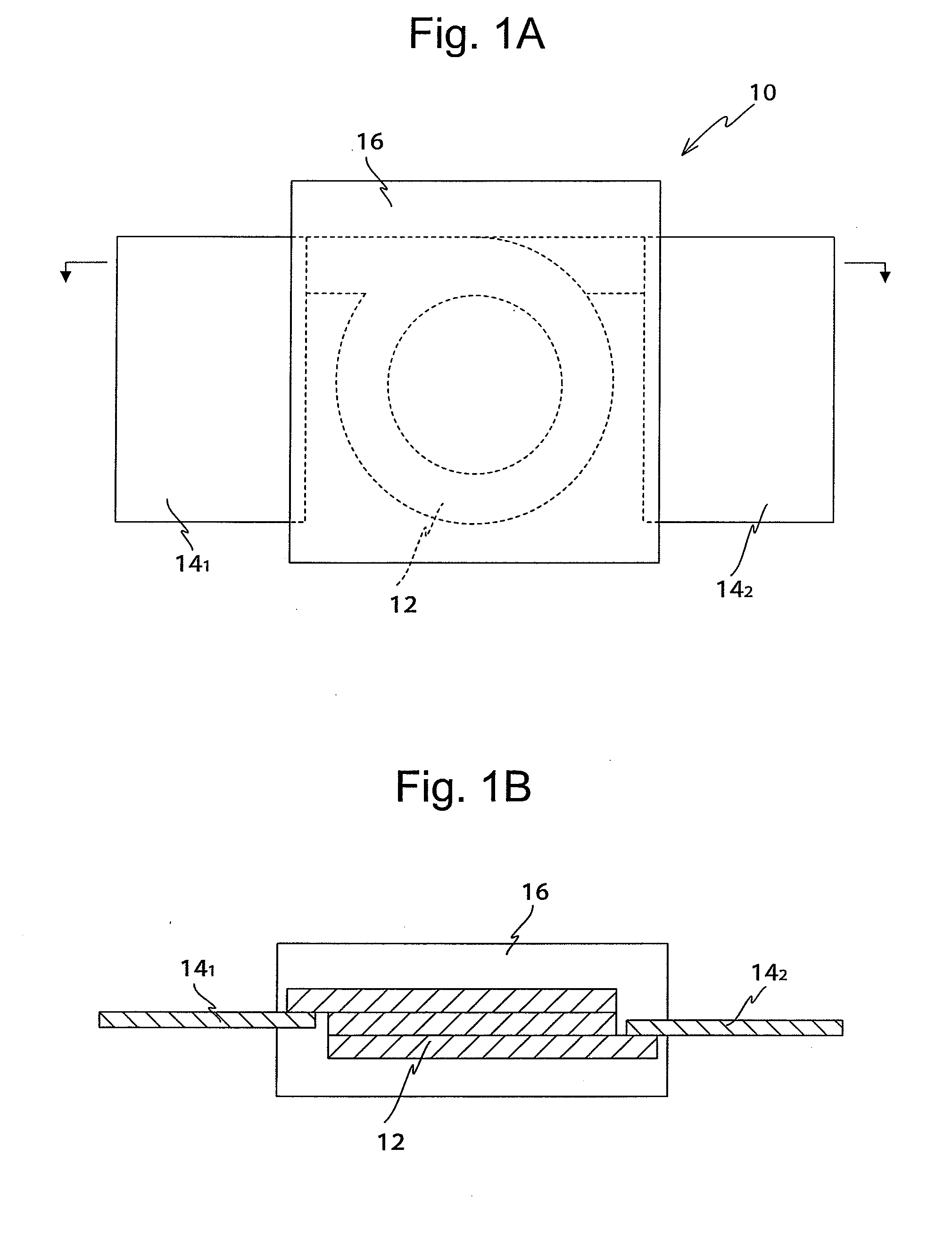

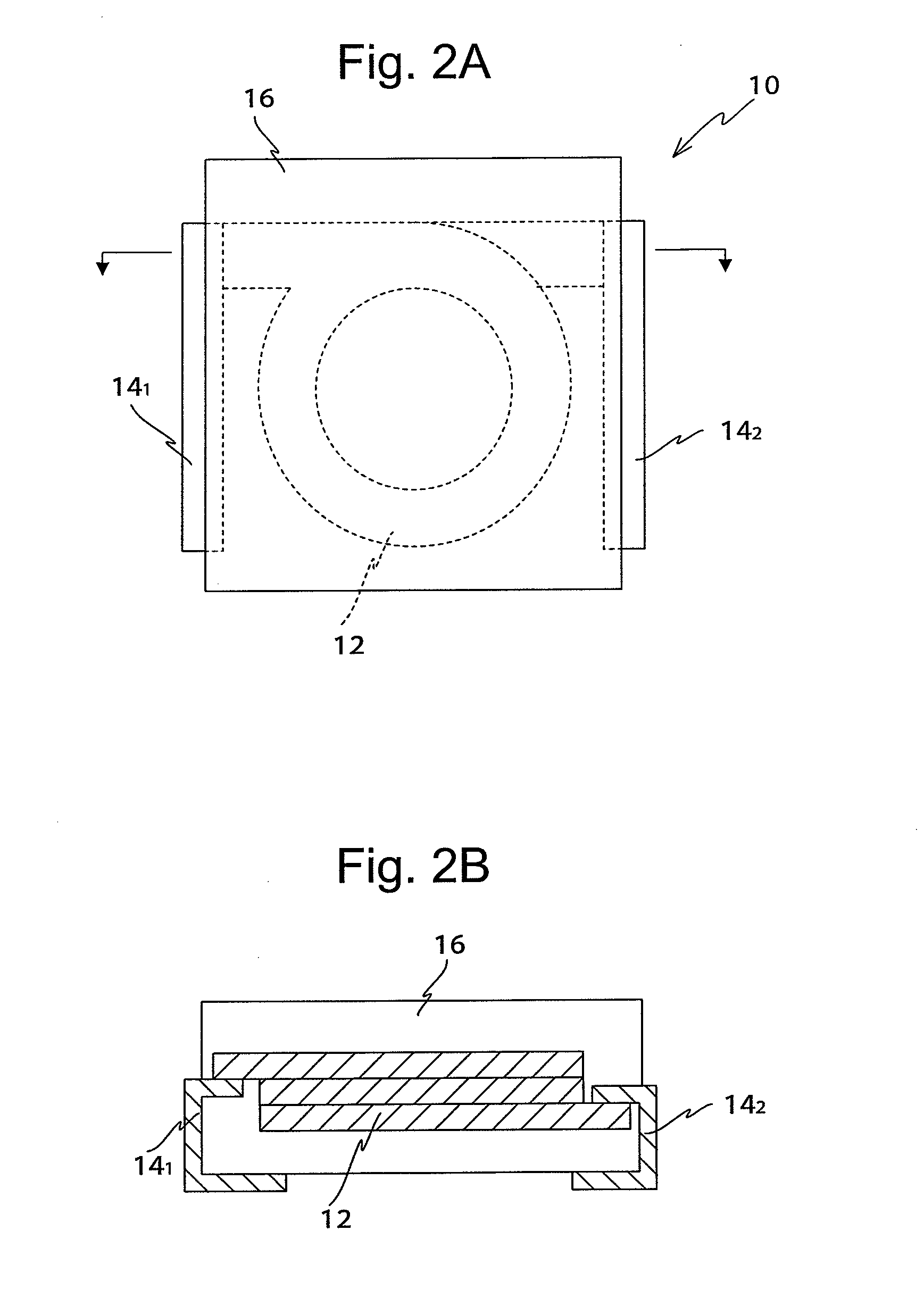

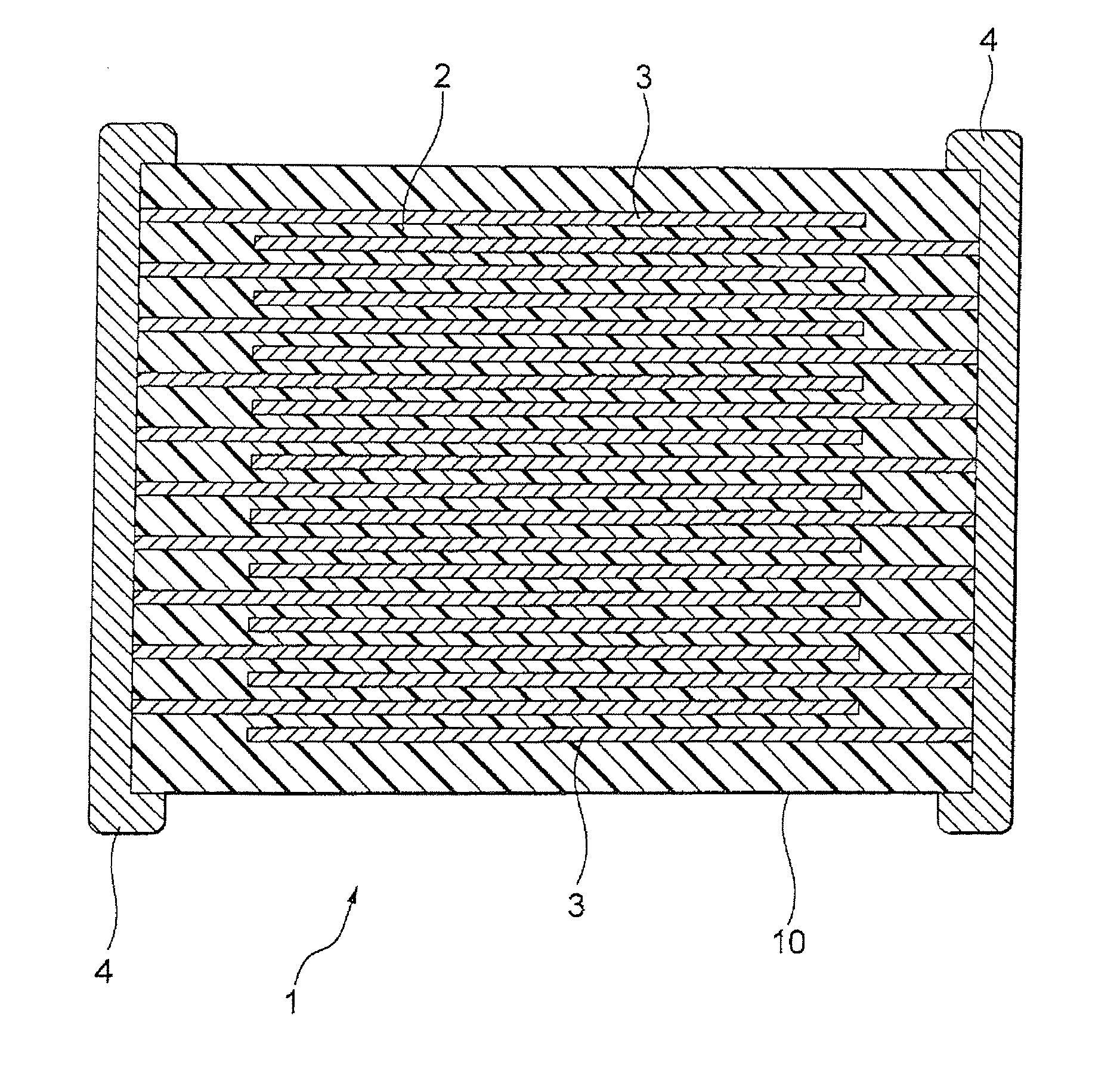

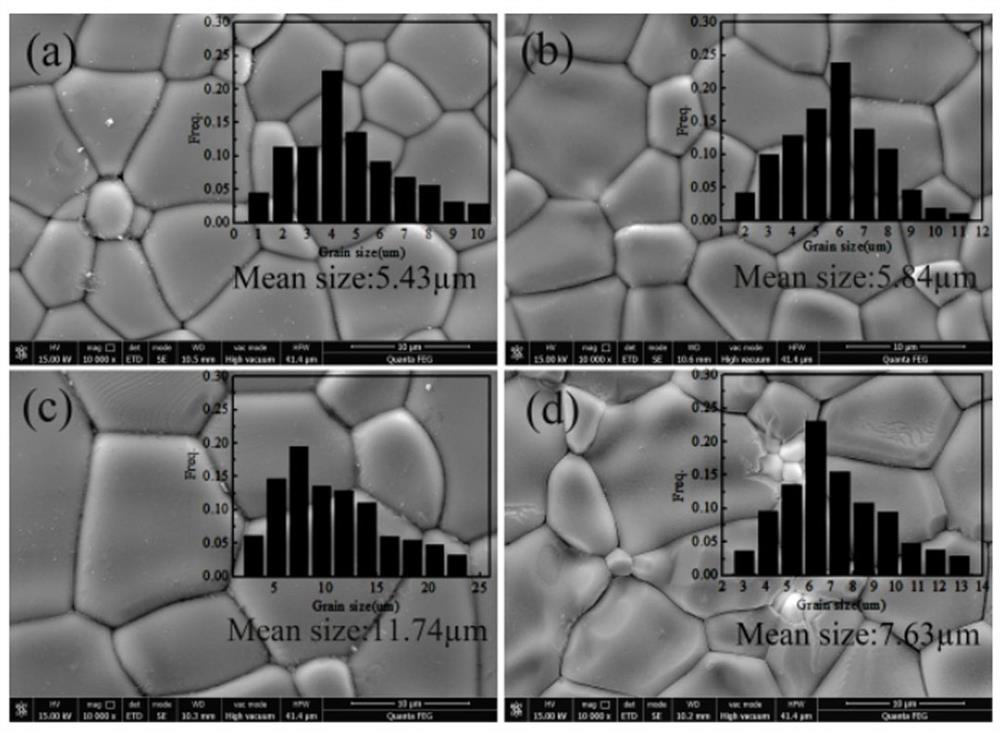

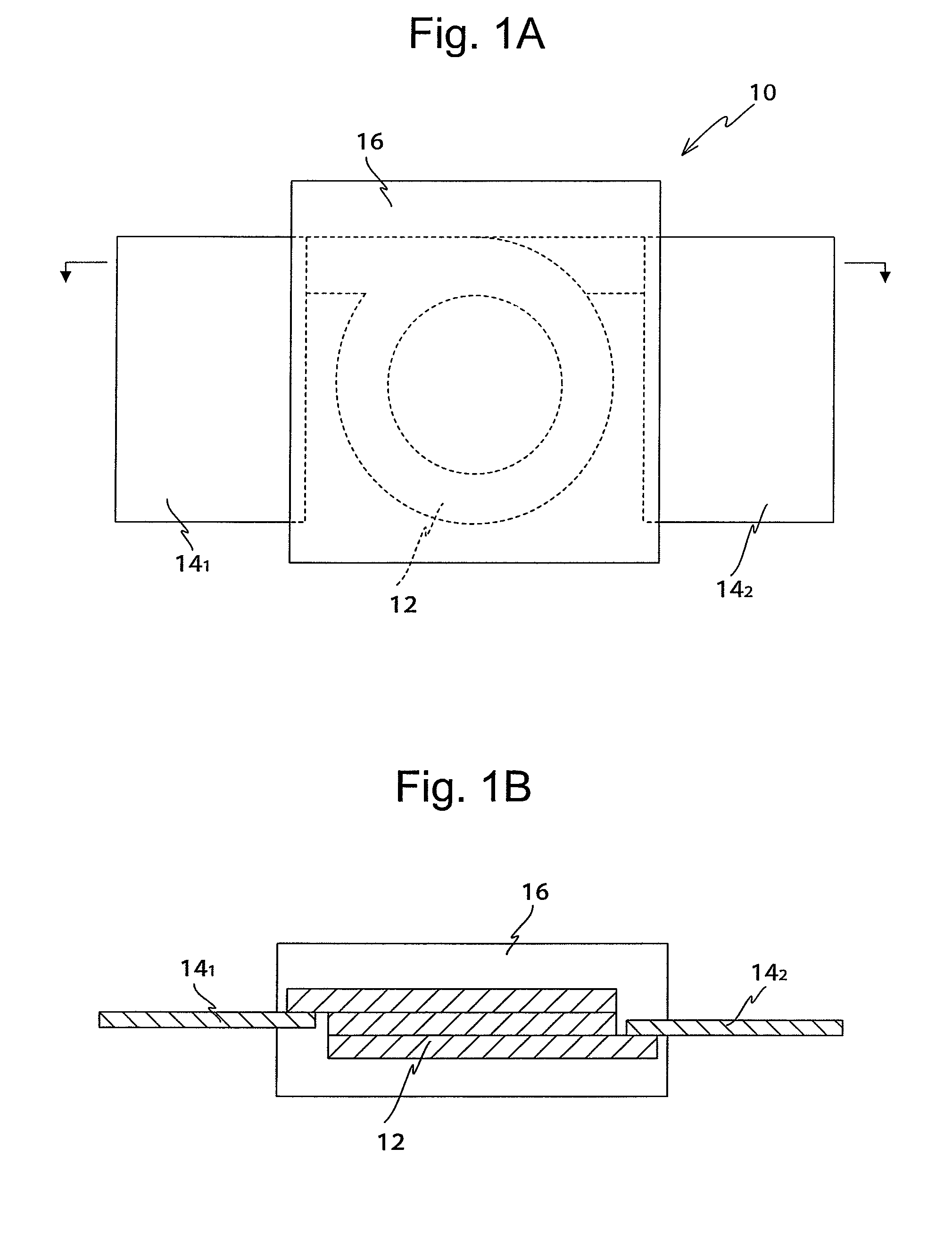

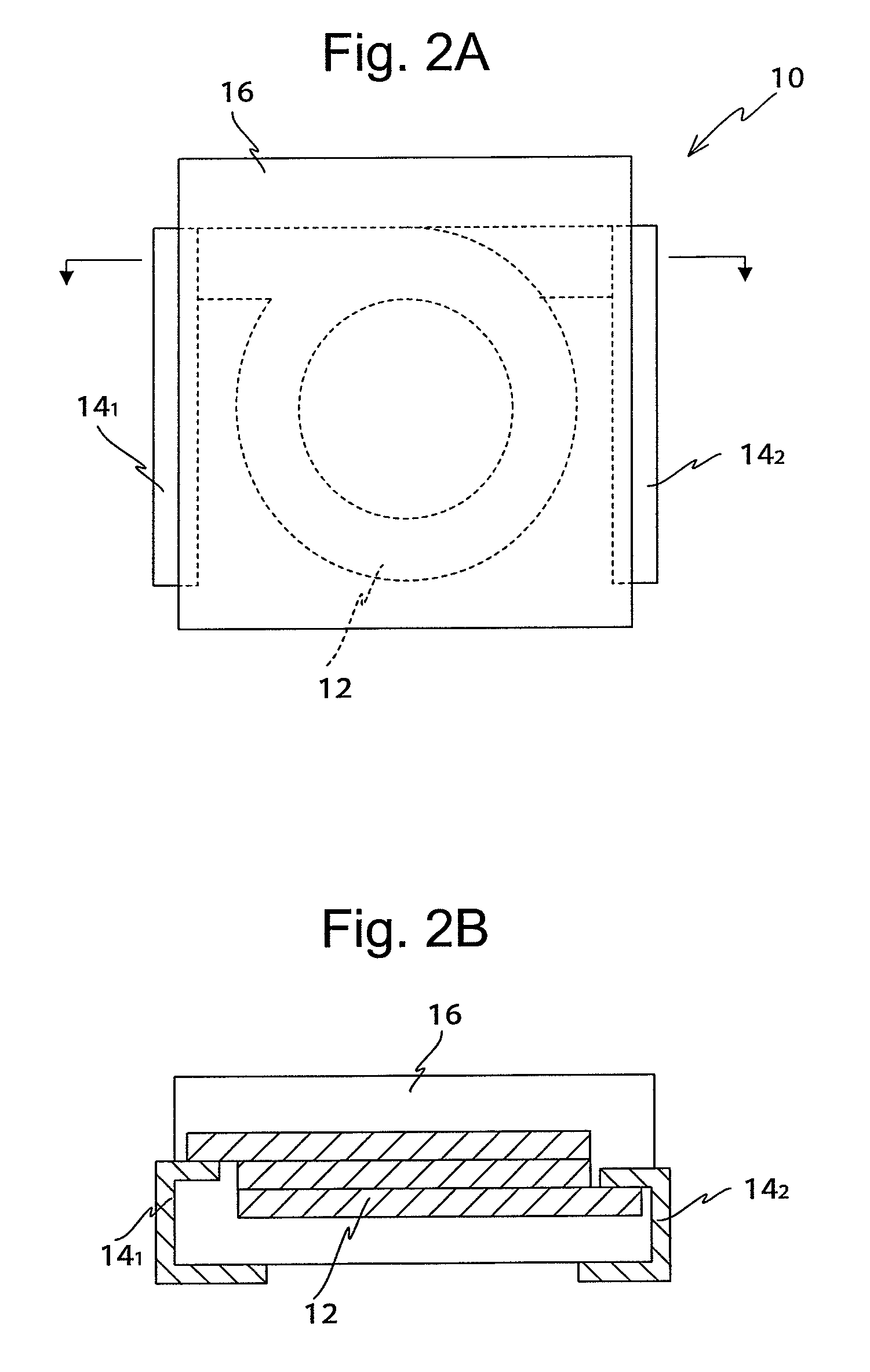

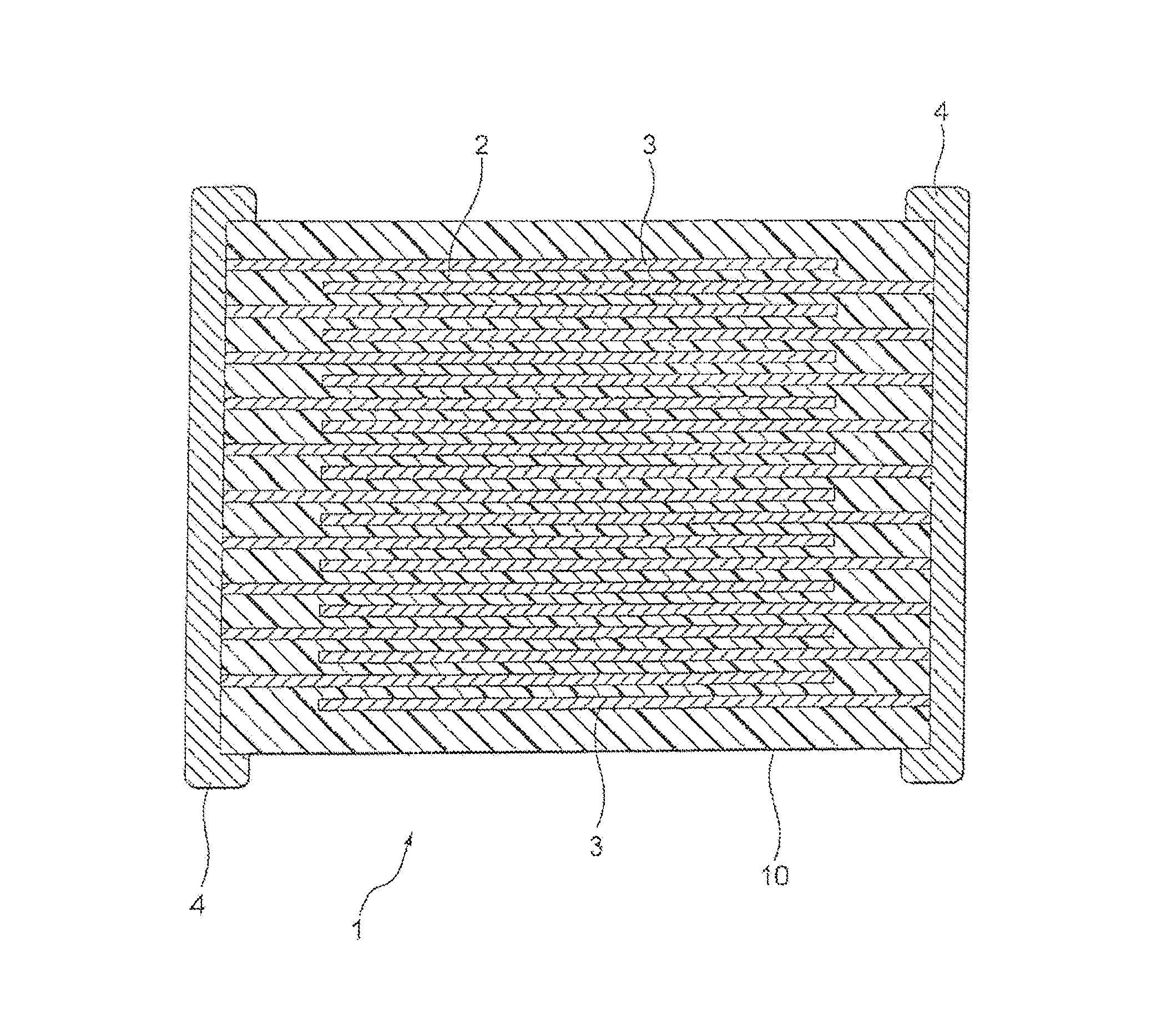

Composite magnetic material and magnetic element

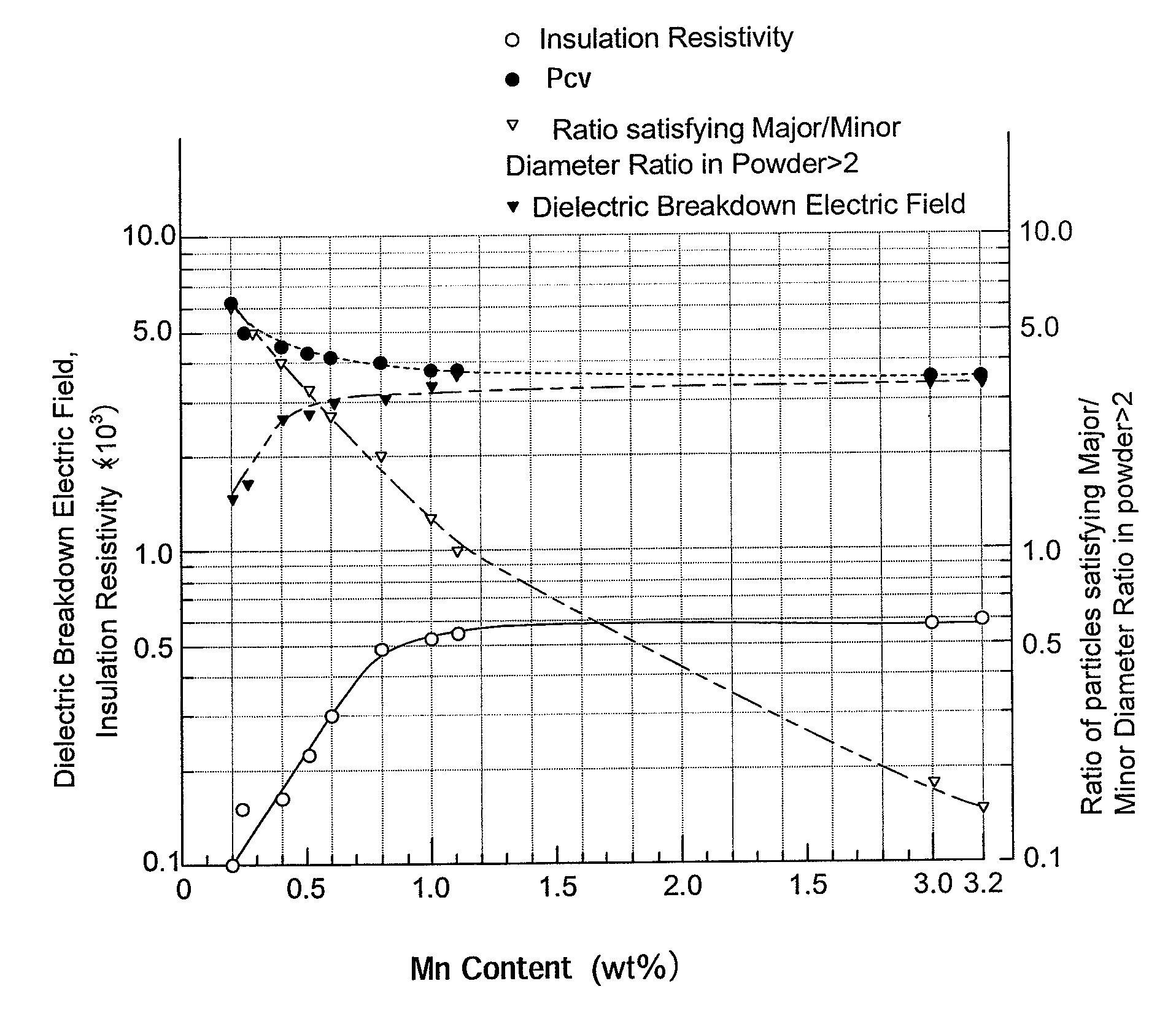

ActiveUS20110168939A1High insulation resistivityLow core lossTransportation and packagingMetal-working apparatusMetallurgyCompound (substance)

The object of the present invention is to provide a composite magnetic material having well-balanced magnetic properties and chemical properties, and a magnetic element using thereof. Concretely, the present provides the composite magnetic material comprising a binder and a magnetic powder contains followings: Mn not less than 0.25 wt % and not larger than 3 wt %, Si not less than 1 wt % and not larger than 7 wt %, Cr not less than 2 wt % and not larger than 8 wt %, and the rest of Fe and inevitable impurities with respect to the total weight of a magnetic powder material, and a ratio of powder particles having the major / minor axis is not less than 2 is not larger than 5% of the total powder particles.

Owner:SUMIDA CORP

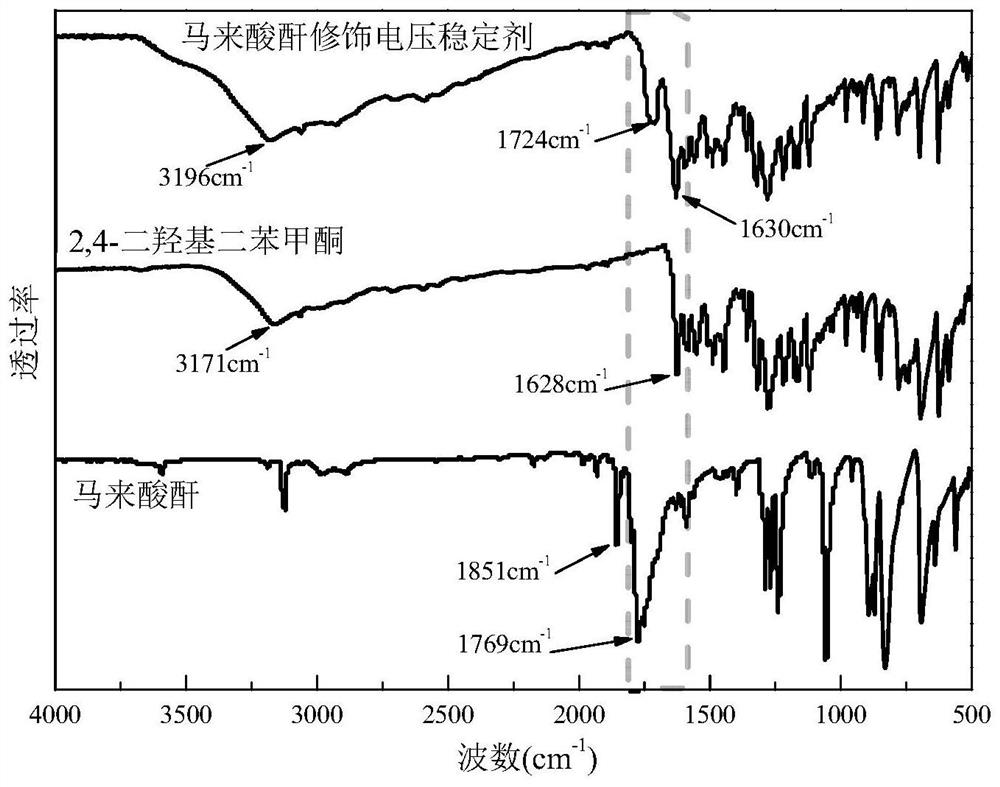

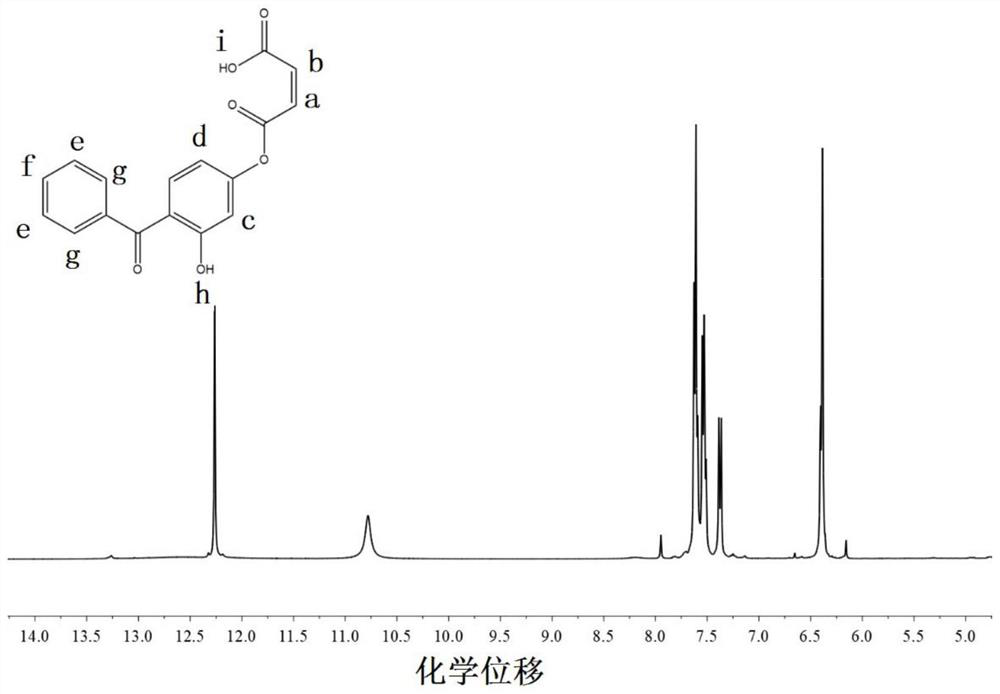

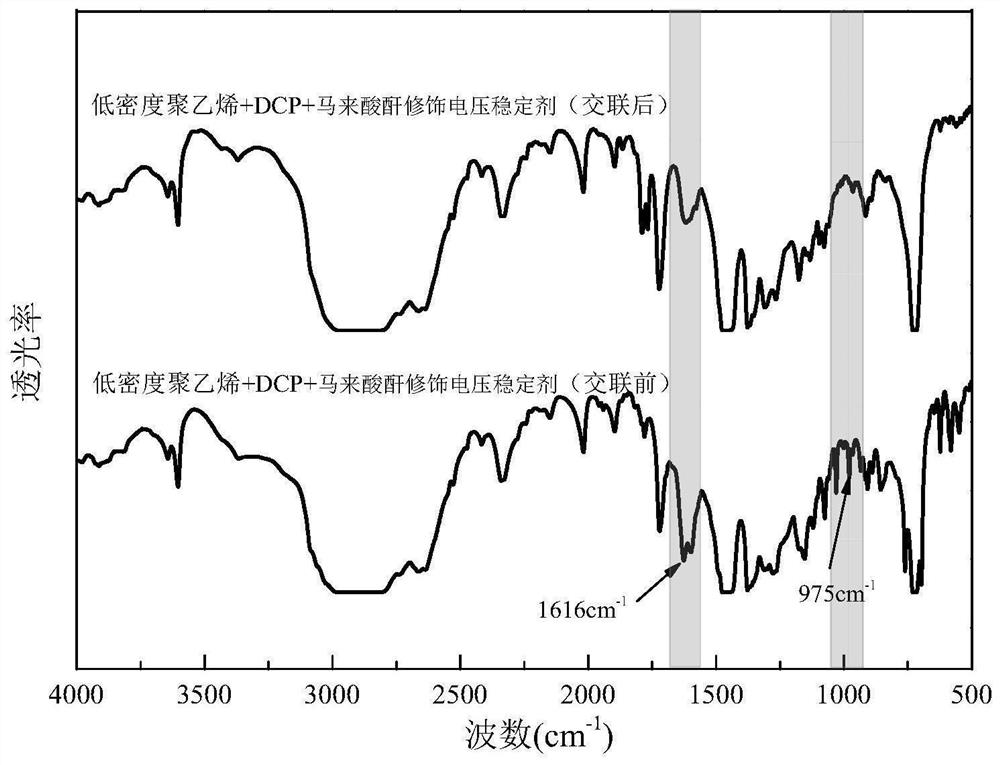

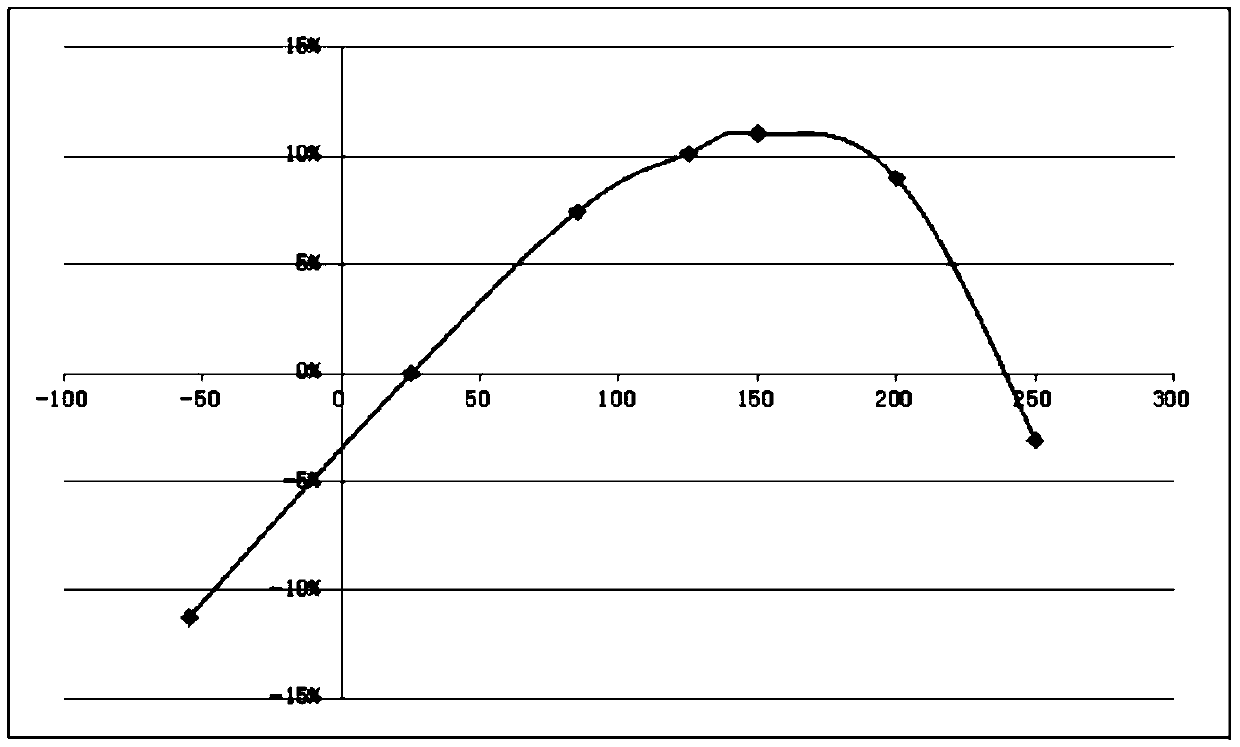

Maleic anhydride modified voltage stabilizer and preparation method and application thereof

ActiveCN113831247AIncrease the performance of electricity-resistant branchesExtend working lifeOrganic compound preparationCarboxylic acid esters preparationPolymer sciencePtru catalyst

The invention discloses a maleic anhydride modified voltage stabilizer and a preparation method and application thereof, and belongs to the technical field of high voltage and insulation. The invention discloses a maleic anhydride modified voltage stabilizer as shown in a formula 1 and a preparation method thereof, and the preparation method comprises the following steps: (1) dissolving maleic anhydride and 2, 4-dihydroxybenzophenone in tetrahydrofuran to obtain a mixture; and (2) in a protective gas atmosphere, adding a catalyst into the mixture obtained in the step (1), stirring, adding water, centrifuging, and drying the obtained precipitate to obtain the maleic anhydride modified voltage stabilizer. The invention also provides an application of the maleic anhydride modified voltage stabilizer in a crosslinked polyethylene insulating material of a high-voltage alternating-current cable.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD +1

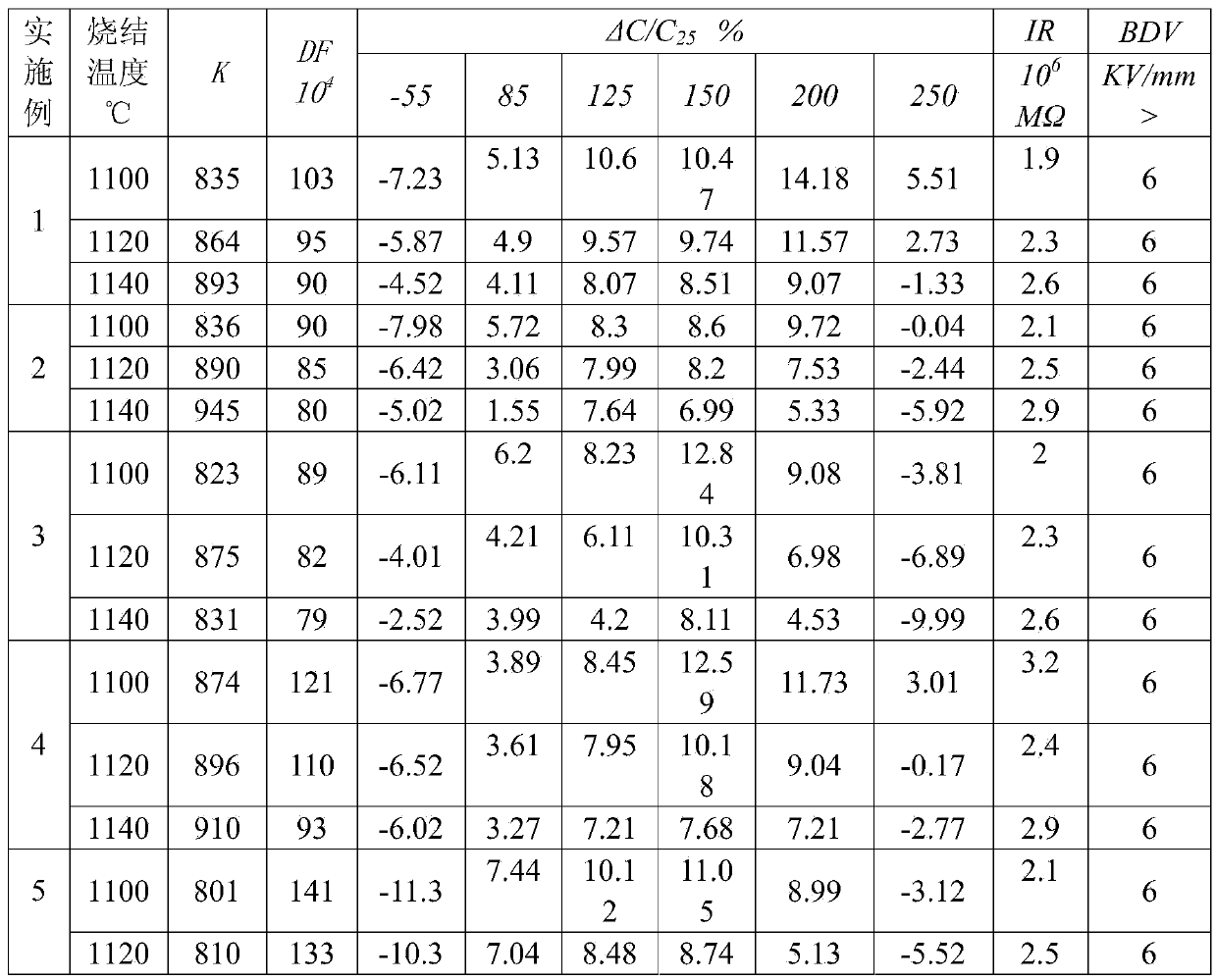

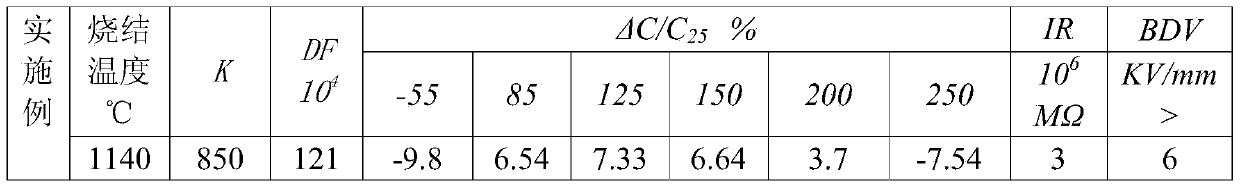

High-temperature ceramic capacitor dielectric material and preparation method thereof

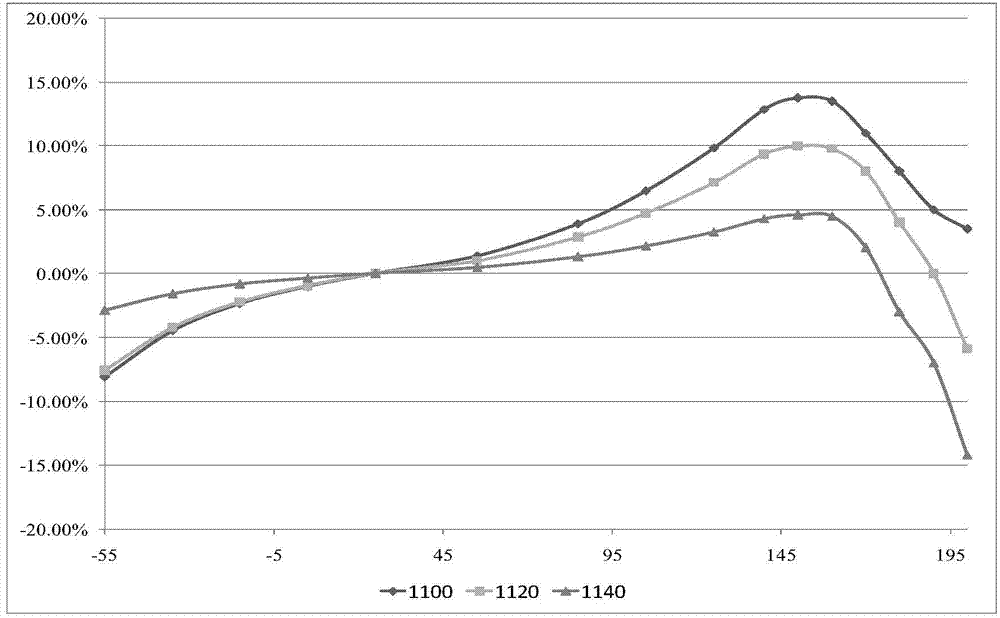

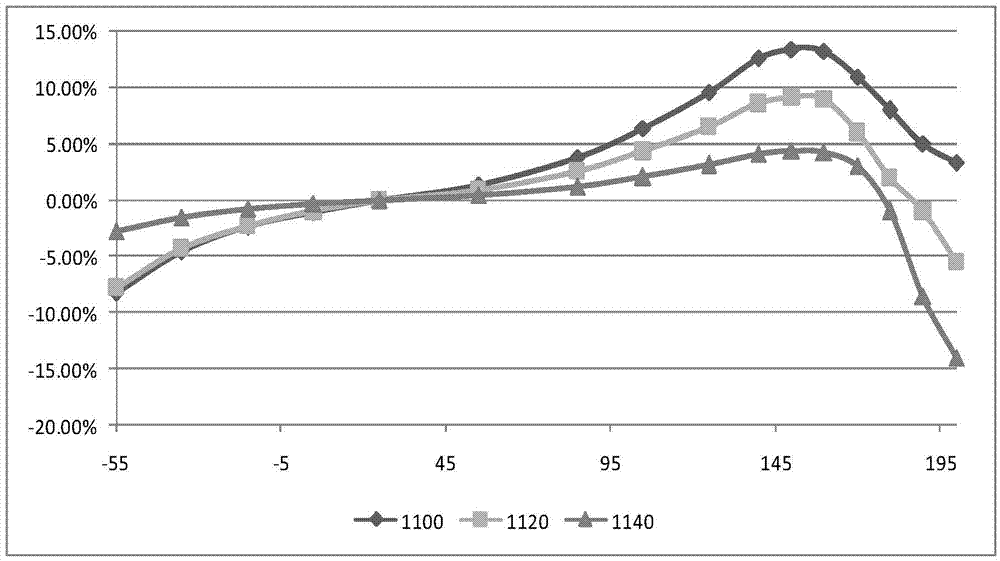

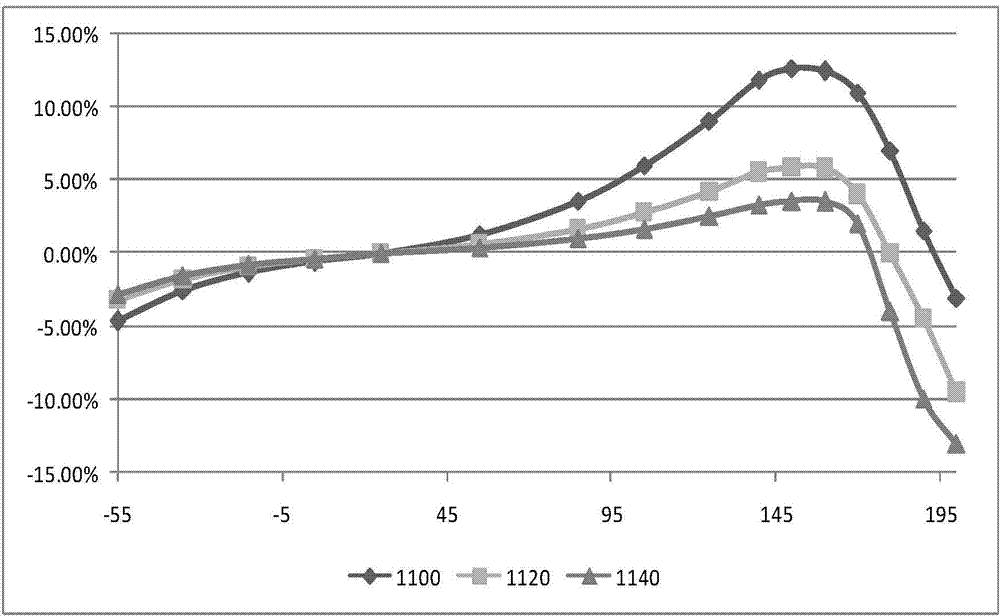

The invention discloses a high-temperature ceramic capacitor dielectric material and a preparation method thereof. A ceramic capacitor prepared from the material works at the temperature of -55 DEG C to 250 DEG C. The dielectric material is prepared from, by weight, 100 parts of [(1-x)BaTiO3-xBiyNazTiO3], 4-6 parts of NbO, 0.1-0.5 part of RE2O3, 0.05-0.15 part of MnO2 and 2-4 parts of CaSiB2O6, wherein x ranges from 0.08-0.20, y ranges from 0.4-0.6, z ranges from 0.4-0.6, the mole ratio of BaTiO3 to BiyNazTiO3 in [(1-x)BaTiO3-xBiyNazTiO3] is (1-x) to x, NbO is niobium-containing oxide including one or more of MgNb2O6, ZnNb2O6, Ca(Mg1 / 3,Nb2 / 3)O3 and Ba(Mg1 / 3,Nb2 / 3)O3, and RE is one or more of Y, Nd and Er. The high-temperature ceramic capacitor dielectric material has the advantages that the dielectric constant is larger than or equal to 800, dielectric loss is low, and temperature stability (-15%<=deltaC / C<=15%) is high.

Owner:FUJIAN TORCH ELECTRON TECH CO LTD

Ferrite manganese-magnesium-zinc material for power-type inductors, and application thereof

ActiveCN101521072BReduce manufacturing costHigh magnetic flux densityInorganic material magnetismCurie temperatureInductor

Owner:南通大东电子有限公司

Dielectric ceramic composition and electronic device

ActiveUS20130222974A1Improve featuresIncrease the electric field strengthFixed capacitor dielectricStacked capacitorsPhysical chemistryDielectric ceramics

Dielectric ceramic composition comprising a compound shown by a general formula {A1−x(RE)2x / 3}y-B2O5+y and has a tungsten bronze-type structure. In the formula, “A” is at least one selected from a group comprising Ba, Ca, Sr and Mg, “B” is at least one selected from Nb and Ta, “RE” is at least one selected from Sc, Y, La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb and Lu, and said “x” and “y” satisfies 0<x<1 and y>1.000, respectively. The dielectric ceramic composition further comprises an oxide of at least one selected from V, Mo, Fe, W, Mn and Cr.

Owner:TDK CORPARATION

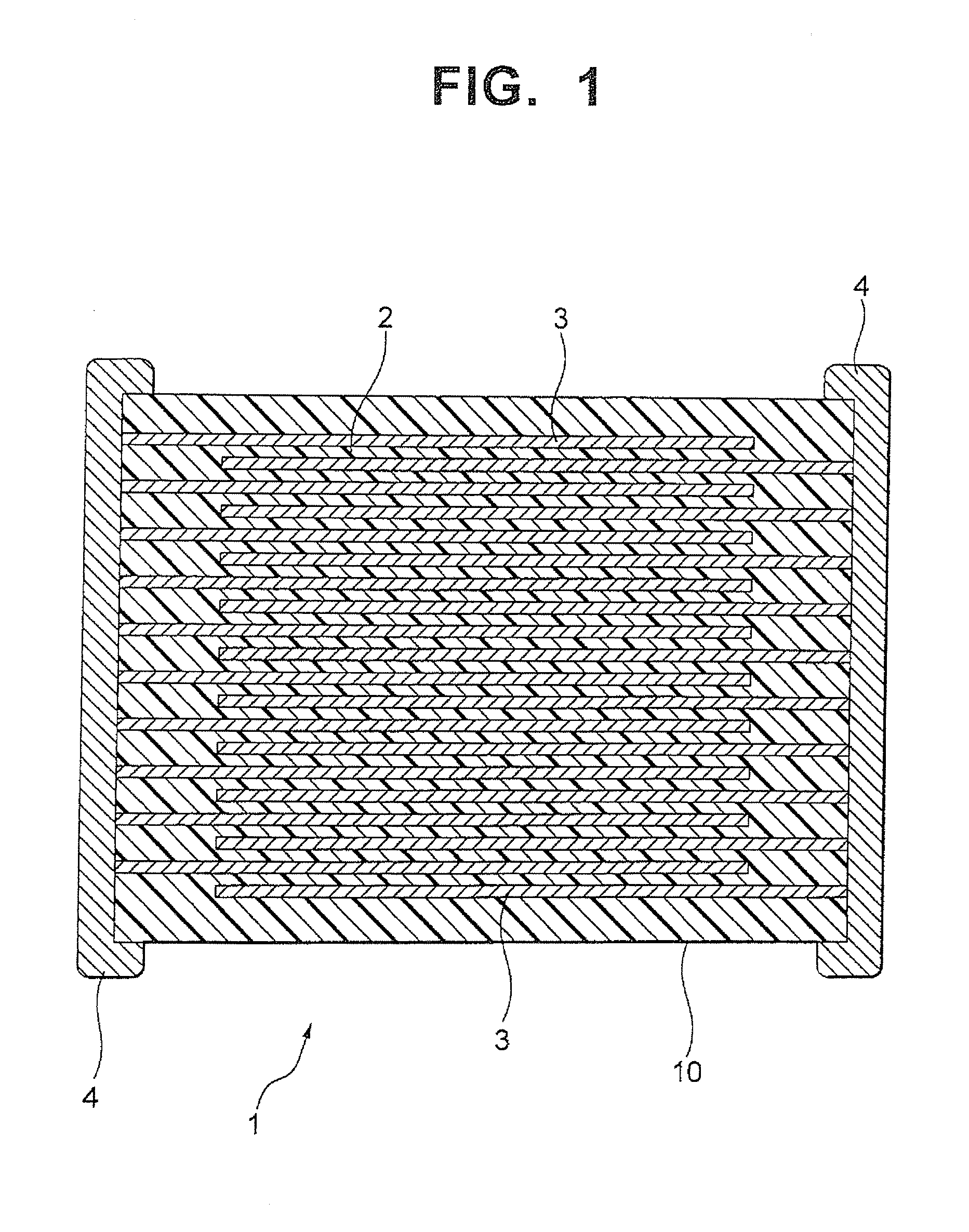

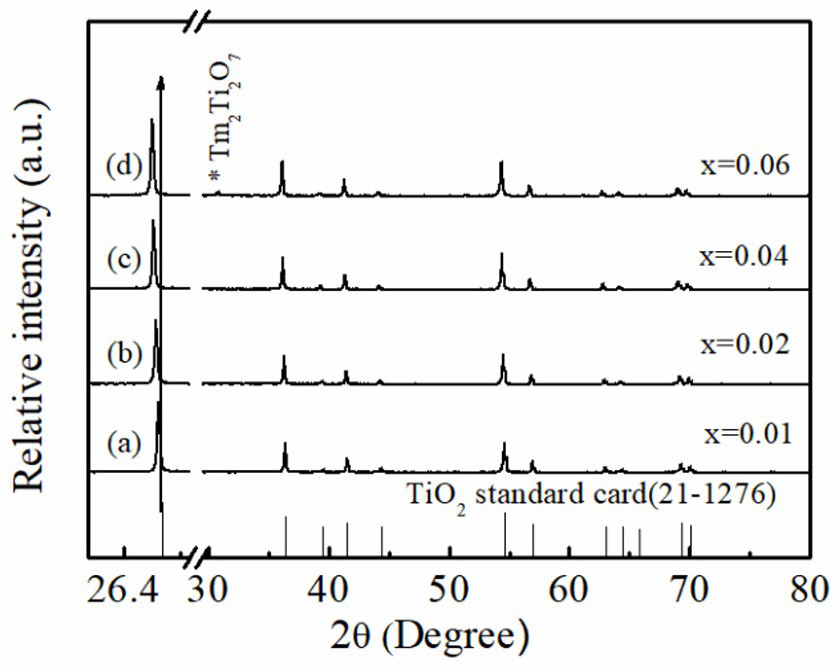

Titanium dioxide-based giant dielectric ceramic material and preparation method thereof

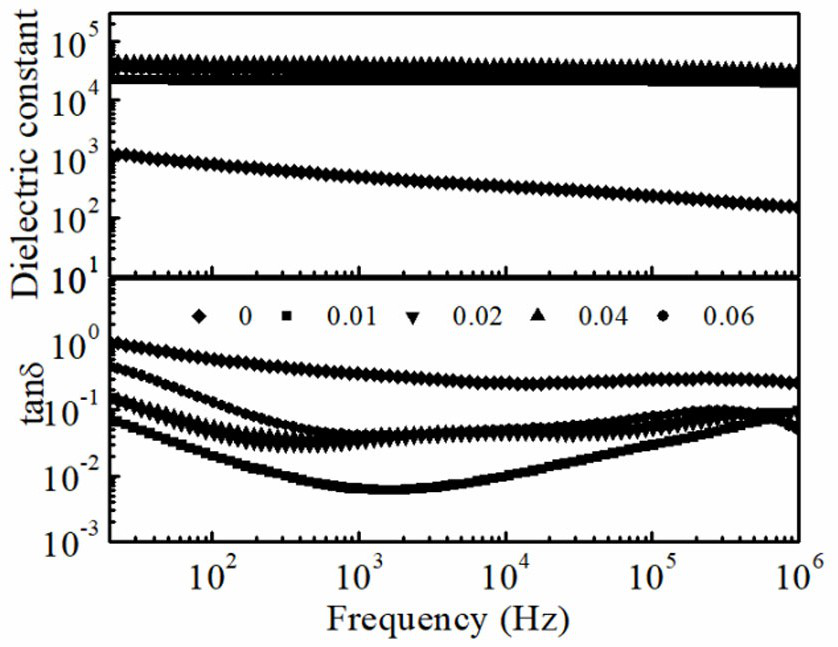

PendingCN113563064AHigh dielectric constantHigh insulation resistivityDielectric ceramicsDielectric permittivity

The invention discloses a method for preparing a titanium dioxide-based giant dielectric ceramic material by adopting a solid-phase sintering method. The general formula of the titanium dioxide-based giant dielectric ceramic material is (Tm0.5Nb0.5)x(Ti<1-y>By)<1-x>O2 (x is equal to 0 to 0.1, y is equal to 0 to 0.1), and B represents Zr, Sn, Hf or Ge. The method is a solid-phase sintering method, the method is simple, the repeatability is good, the yield is high, the frequency stability of the obtained titanium dioxide-based giant dielectric ceramic material within the range of 20 Hz-1 MHz is good, the dielectric constant is 104-105, and the insulation resistivity is 108-1013 [omega]cm. In addition, the material has excellent temperature stability at the temperature ranging from -150 DEG C to 260 DEG C. The titanium dioxide-based giant dielectric ceramic material has practical application value in various electronic devices such as capacitors and dynamic memories.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

High temperature resistant liquid anhydride curing agent and preparation method thereof

The invention discloses a high-temperature-resistant liquid anhydride curing agent, comprising the following components in parts by weight: 45-55 parts of maleic anhydride, 5-15 parts of phenyl hydroxide, 33-35 parts of diethylene glycol, 4-6 parts of triethanolamine and 1-1.2 parts of concentrated sulphuric acid. The raw materials are mixed according to requirements and react to generate the curing agent disclosed by the invention, then the curing agent disclosed by the invention can cure epoxy resin at the high temperature of 150 DEG C after being subjected to glue mixing with epoxy resin, the cured epoxy resin has high toughness and excellent mechanical strength, working temperature can resist 200 DEG C, insulation resistance is more than 1012 Omega, and the curing agent is applicable to filling and sealing constructions on a dry type transformer, a mutual inductor, a relay, a temperature sensor and various integrated circuits.

Owner:舒城金泽信环保材料有限公司

Chemical coating prepared base metal internal electrode multi-layer ceramic chip capacitor dielectric material

ActiveCN101183610BImprove performanceMeet performance requirementsFixed capacitor dielectricCeramicsCapacitanceBarium titanate

Owner:TSINGHUA UNIV

Composite magnetic material and magnetic element

ActiveUS8277679B2High insulation resistivityLow core lossTransportation and packagingMetal-working apparatusMetallurgyCompound (substance)

The object of the present invention is to provide a composite magnetic material having well-balanced magnetic properties and chemical properties, and a magnetic element using thereof. Concretely, the present provides the composite magnetic material comprising a binder and a magnetic powder contains followings: Mn not less than 0.25 wt % and not larger than 3 wt %, Si not less than 1 wt % and not larger than 7 wt %, Cr not less than 2 wt % and not larger than 8 wt %, and the rest of Fe and inevitable impurities with respect to the total weight of a magnetic powder material, and a ratio of powder particles having the major / minor axis is not less than 2 is not larger than 5% of the total powder particles.

Owner:SUMIDA CORP

Medium-temperature and quickly-cured colorless transparent epoxy resin curing agent and preparation method thereof

InactiveCN102344545AImprove toughnessHigh insulation resistivityOther chemical processesEthylene diaminePolymer science

The invention discloses a medium-temperature and quickly-cured colorless transparent epoxy resin curing agent, which comprises the following components in part by weight: 55-65 parts of trolamine, 25-35 parts of propene carbonate and 10-15 parts of ethylene diamine. The three raw materials are mixed and reacted to generate the curing agent. The obtained curing agent and the epoxy resin are subjected to glue mixing according to the proportion so as to be heated and quickly cured and generate colorless transparent high-tenacity epoxy resin curing plastic. The medium-temperature and quickly-cured colorless transparent epoxy resin curing agent can be widely applied to perfusion sealing or high-temperature bonding repair of electronic and non-electronic products.

Owner:舒城金泽信环保材料有限公司

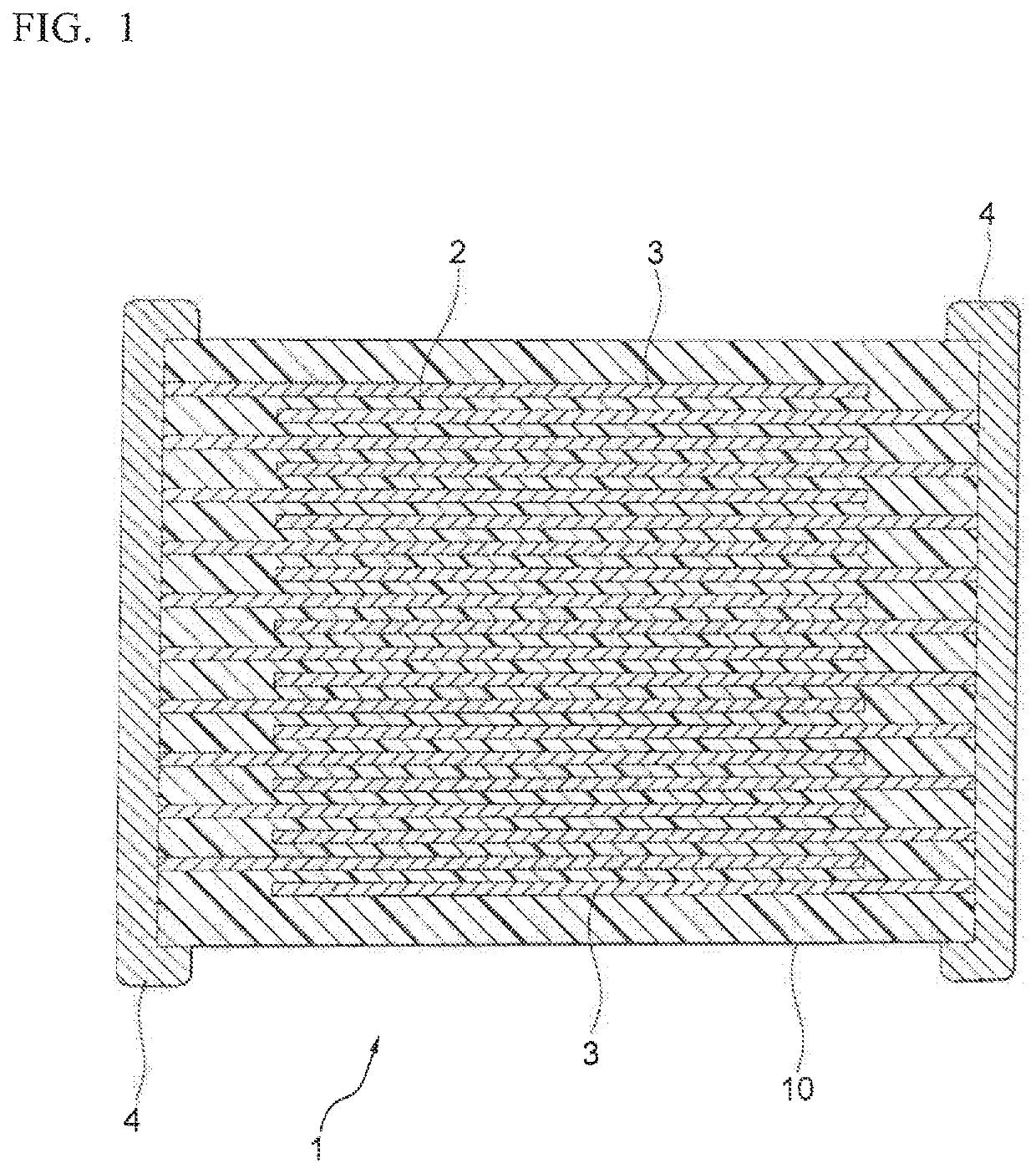

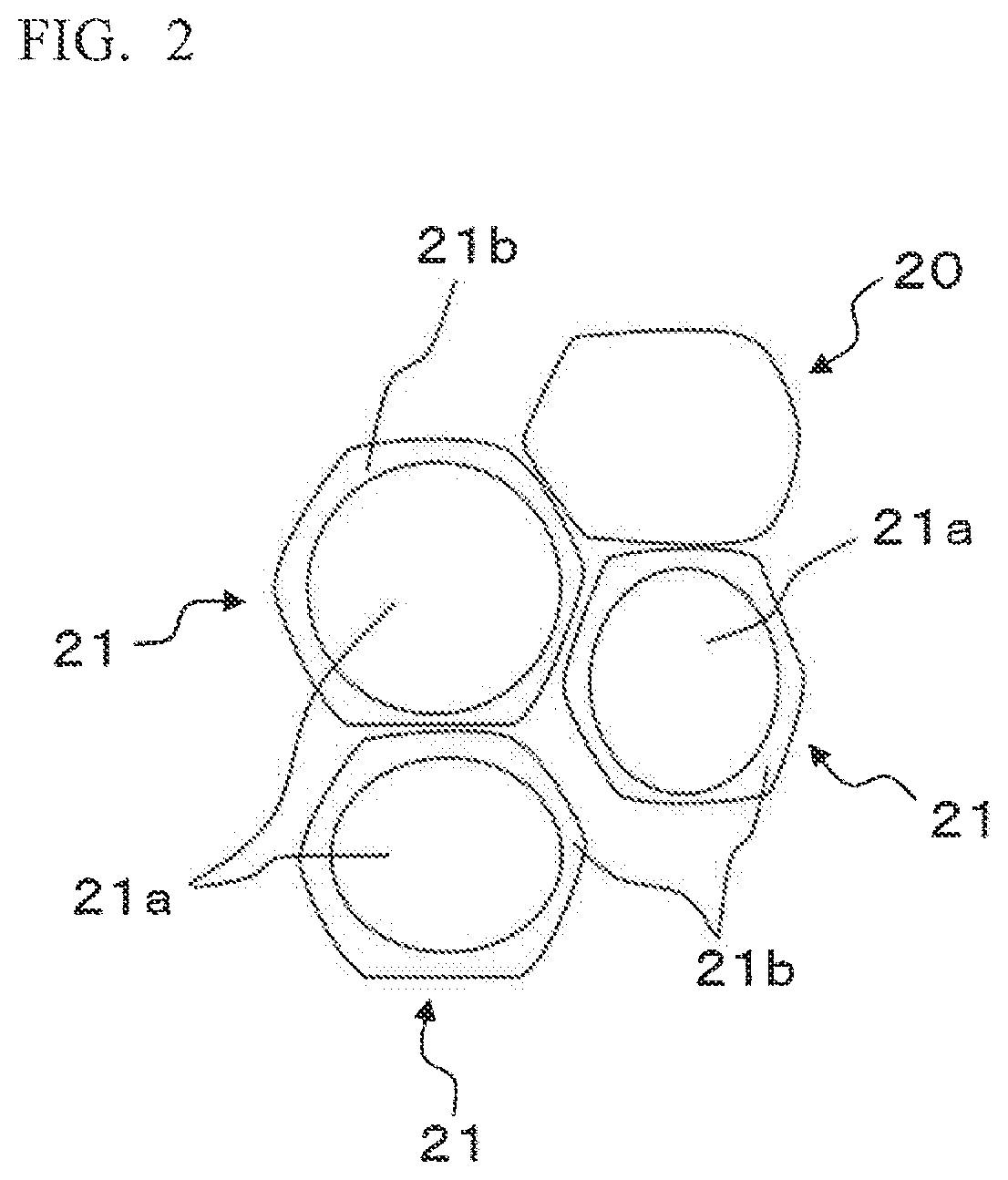

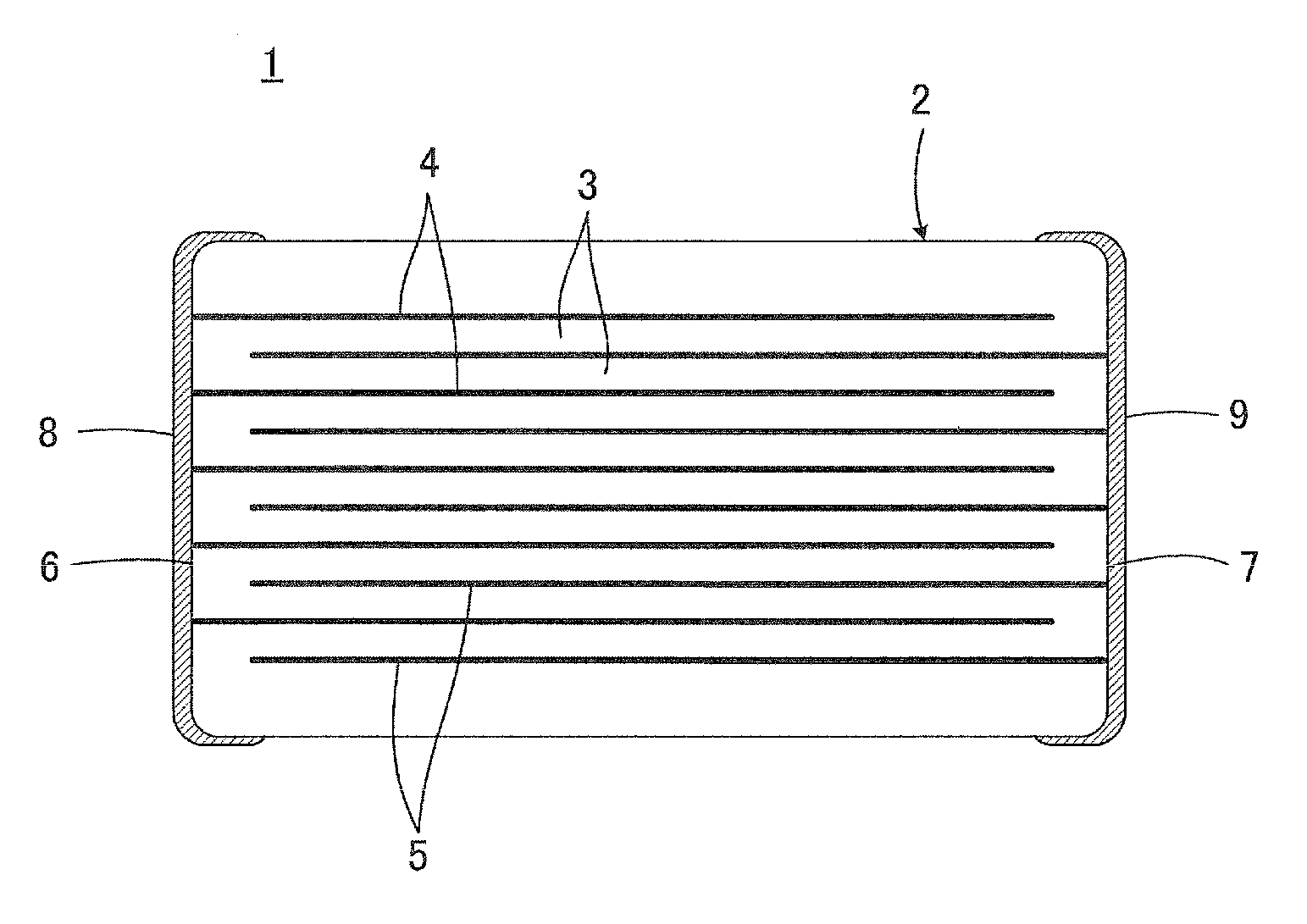

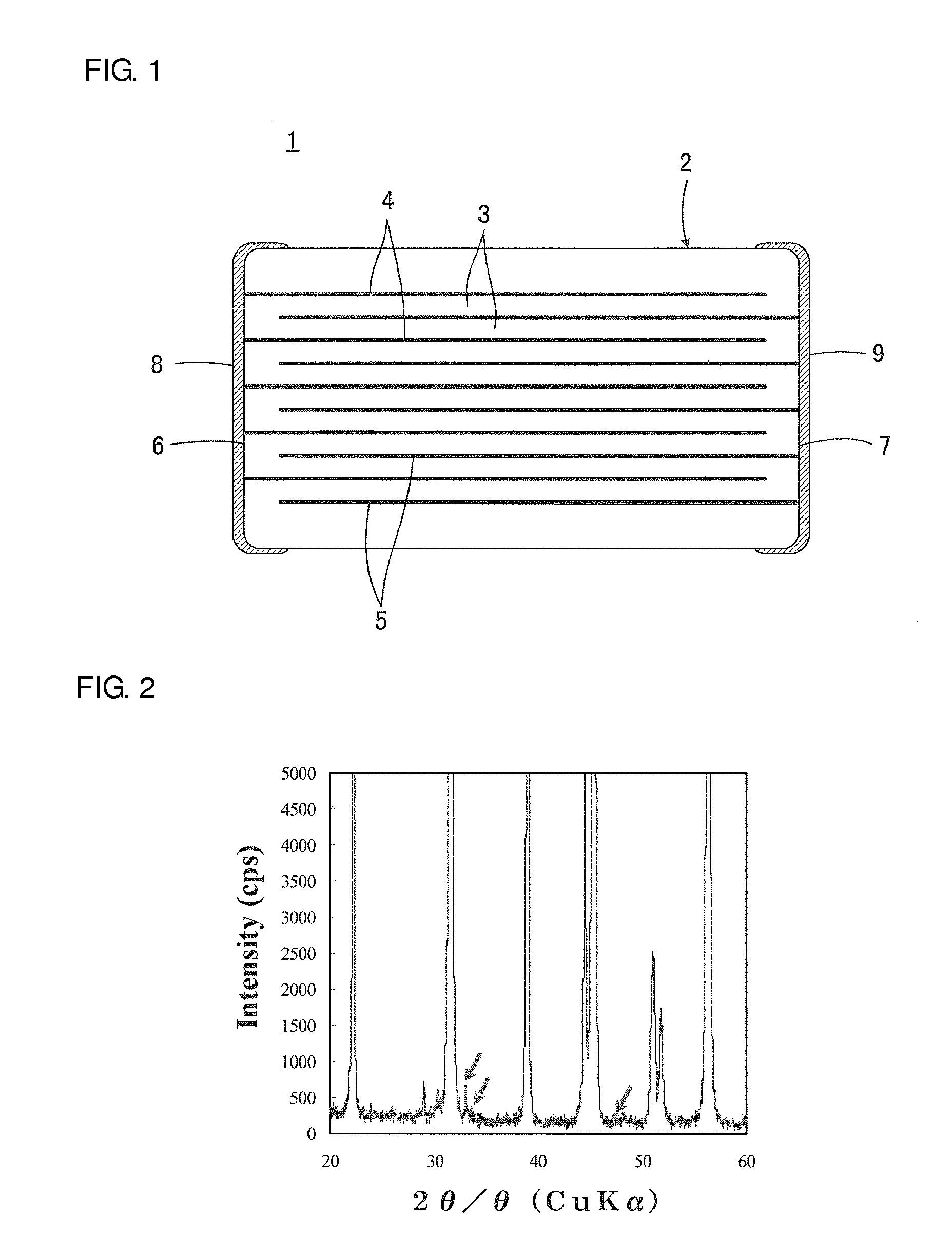

Dielectric ceramic composition and multilayer ceramic electronic component

ActiveUS20200039887A1Extended service lifeImprove uniformityFixed capacitor electrodesFixed capacitor dielectricRare-earth elementDielectric ceramics

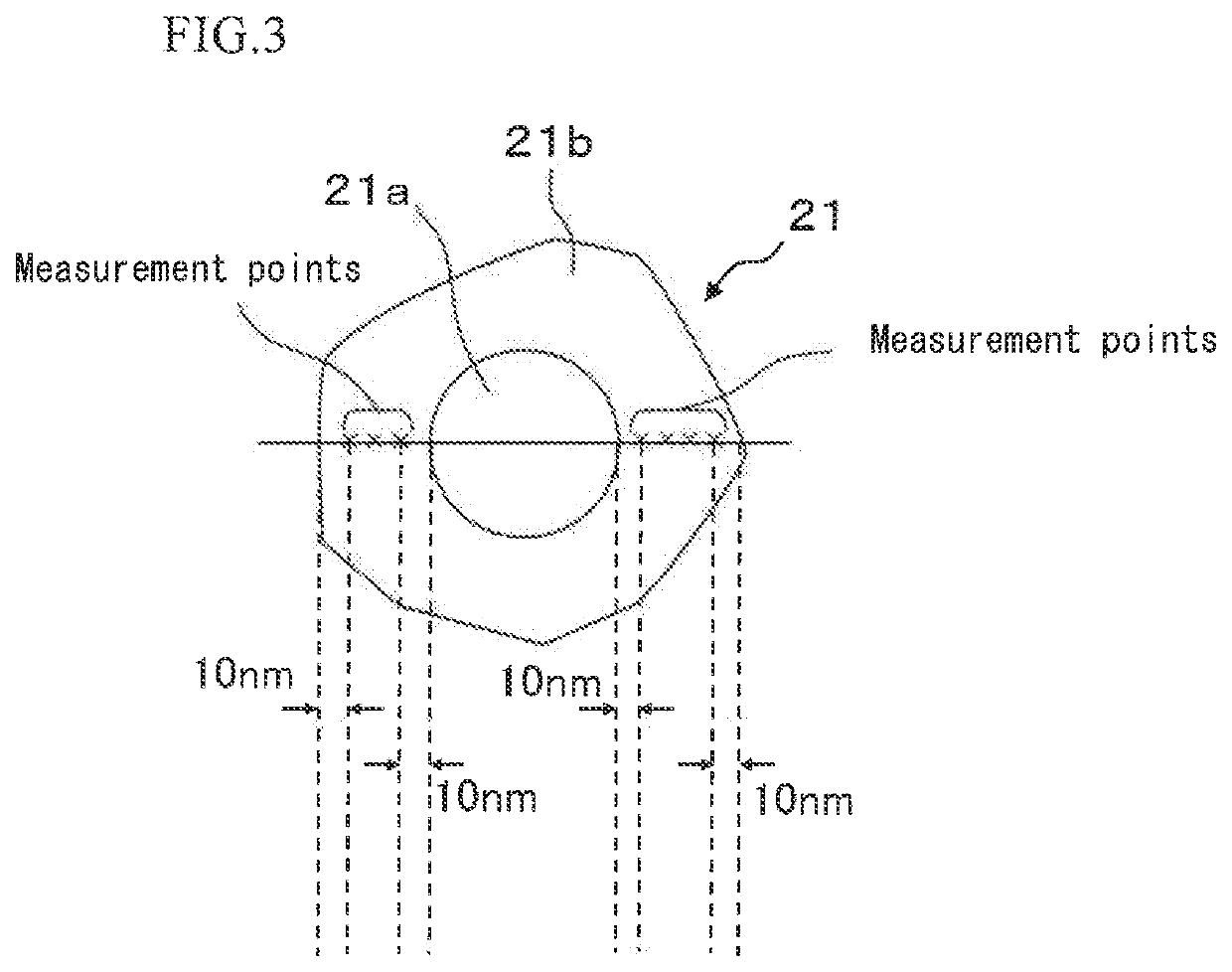

The object of the present invention is to provide a dielectric ceramic composition having even improved insulation specific resistance and highly accelerated lifetime. A dielectric ceramic composition comprising a dielectric particle having a core-shell structure including a main component expressed by a general formula ABO3 (A is Ba and the like; and B is Ti and the like) and a rare earth element component R, in whicha shell part of the core-shell structure has an average rare earth element concentration C of 0.3 atom % or more, anda rare earth element concentration gradient S is −0.010 atom % / nm≤S≤0.009 atom % / nm or a rare earth element concentration variation satisfies σ / C≤0.15 (a is a standard deviation of a rare earth element concentration and C is an average rare earth element concentration).

Owner:TDK CORPARATION

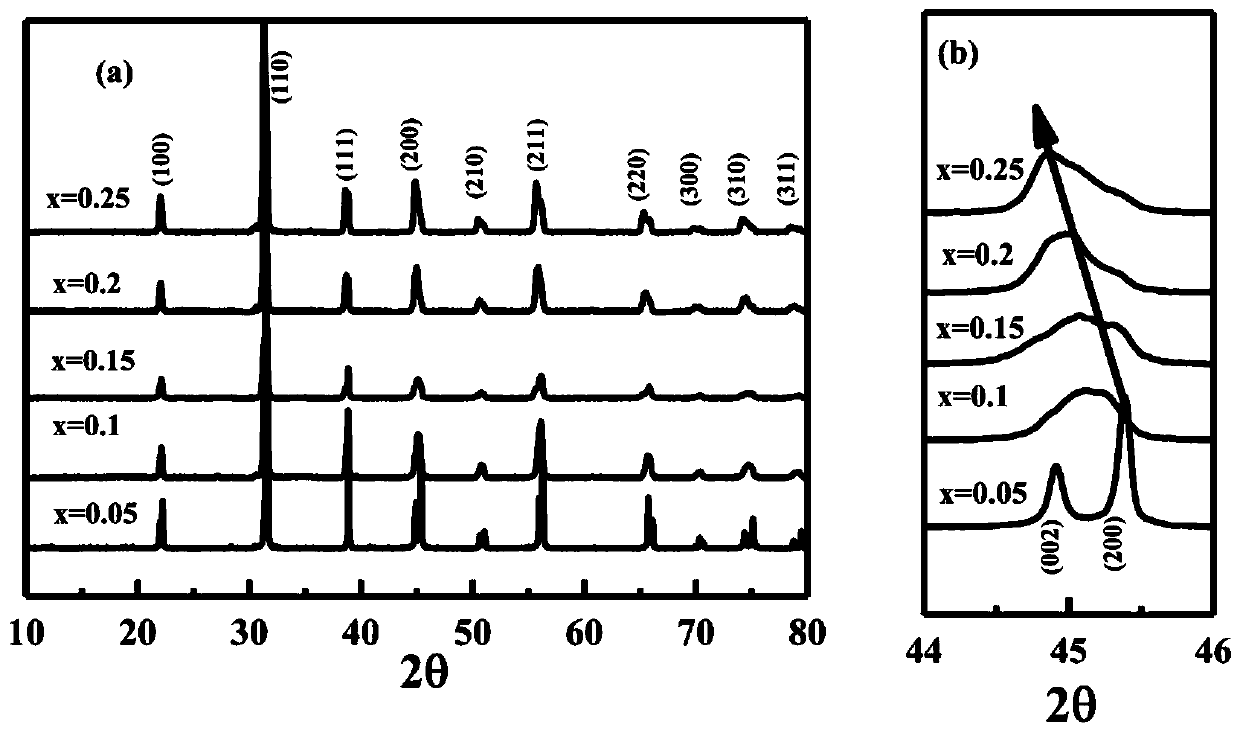

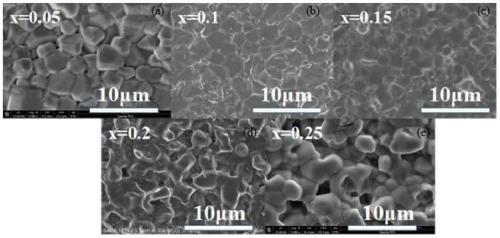

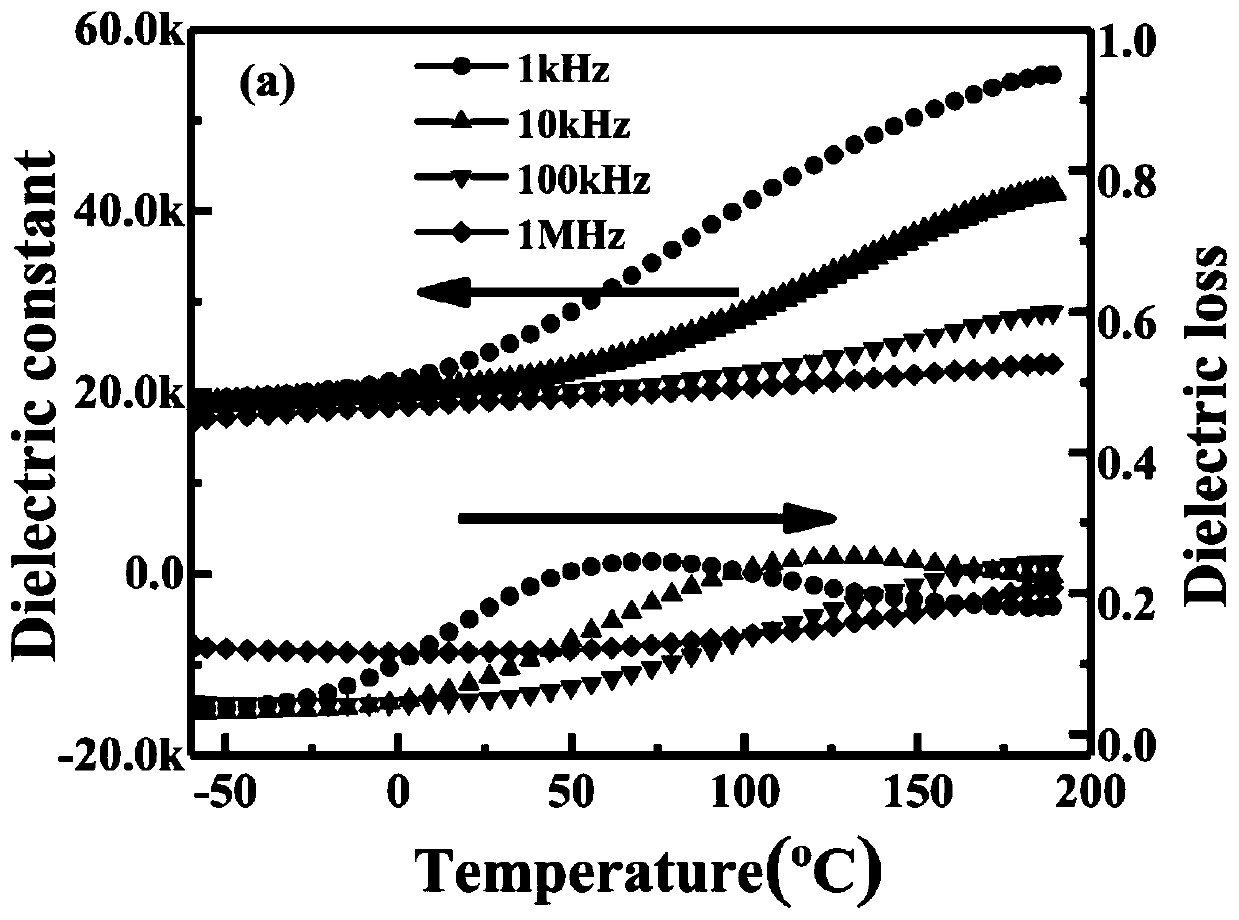

Anti-reduction BaTiO3-based dielectric ceramic and preparation method thereof

ActiveCN110304916AExcellent anti-reduction performanceHigh insulation resistivityInsulation resistanceMuffle furnace

The invention relates to an anti-reduction BaTiO3-based dielectric ceramic and a preparation method thereof. The chemical formula of the dielectric ceramic is (1-x) BaTiO3-xBi (Zn1 / 2Y1 / 2) O2.75, wherein x= 0.05-0.25. The preparation method comprises the following steps: (1) taking BaTiO3, Bi2O3, ZnO and Y2O3 as raw materials, and proportioning the raw materials according to the stoichiometric ratio of metal atoms in the chemical formula; (2) uniformly ball-milling and mixing the raw materials, drying, and presintering the raw materials in a muffle furnace to obtain ceramic powder; (3) carryingout secondary ball milling on the ceramic powder obtained by presintering, drying, then granulating and pressing to obtain a ceramic green body; and (4) after adhesive discharge of the ceramic greenbody, introducing reducing gas into a tube furnace for sintering to obtain the anti-reduction BaTiO3-based dielectric ceramic. The dielectric ceramic is sintered in a reducing atmosphere and has the characteristics of excellent insulating property and dielectric property, low production cost, stable dielectric property in a wide temperature range and the like, particularly when x = 0.15, the dielectric ceramic has the insulation resistivity which reaches up to 5.5* 1012 omega.cm, and the dielectric temperature stability meets the X8R standard.

Owner:WUHAN UNIV OF TECH

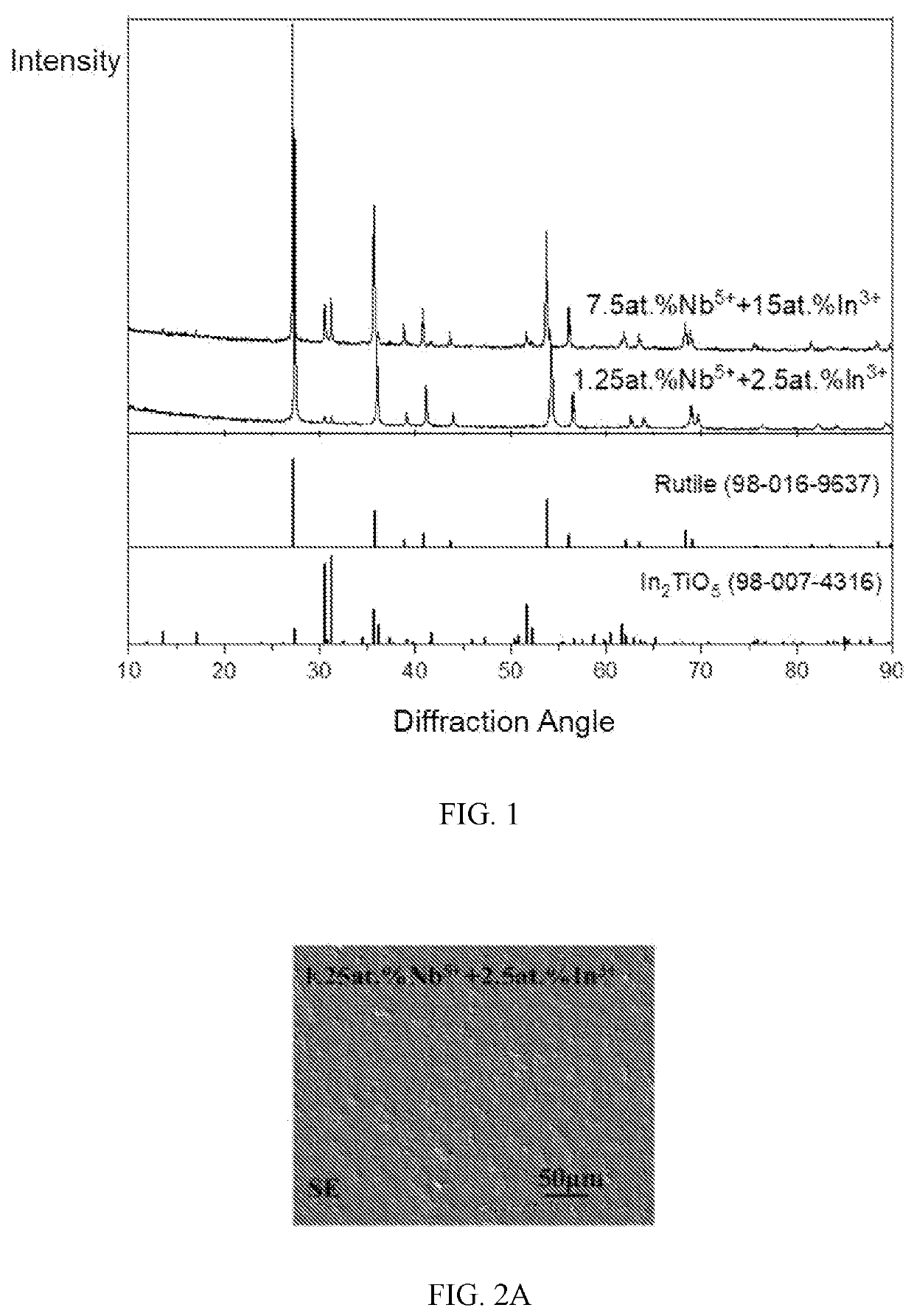

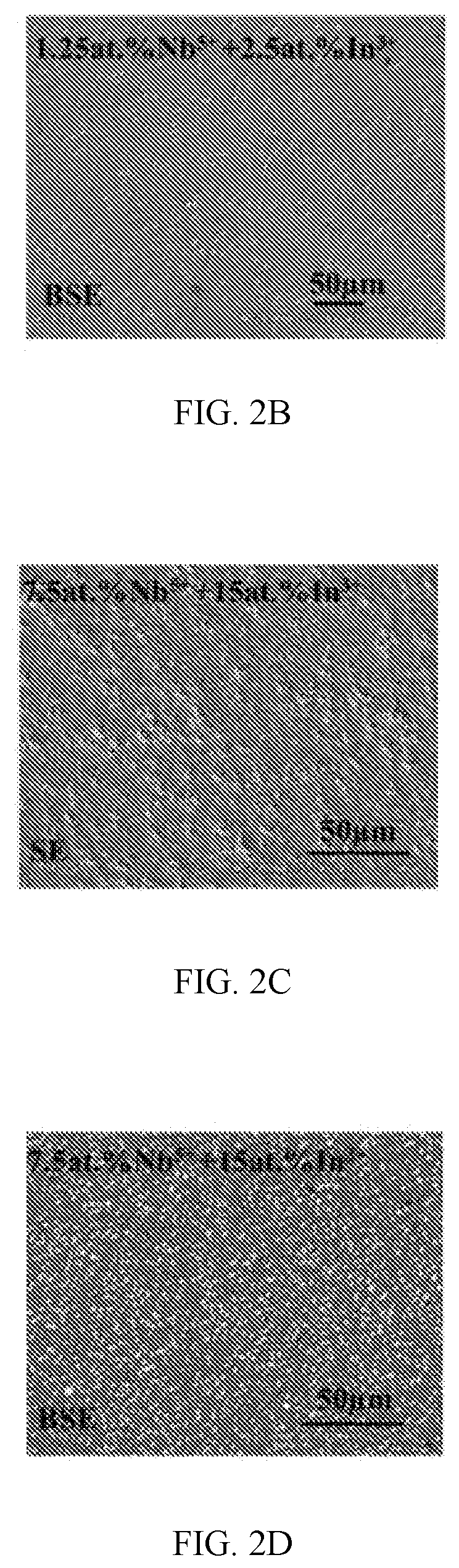

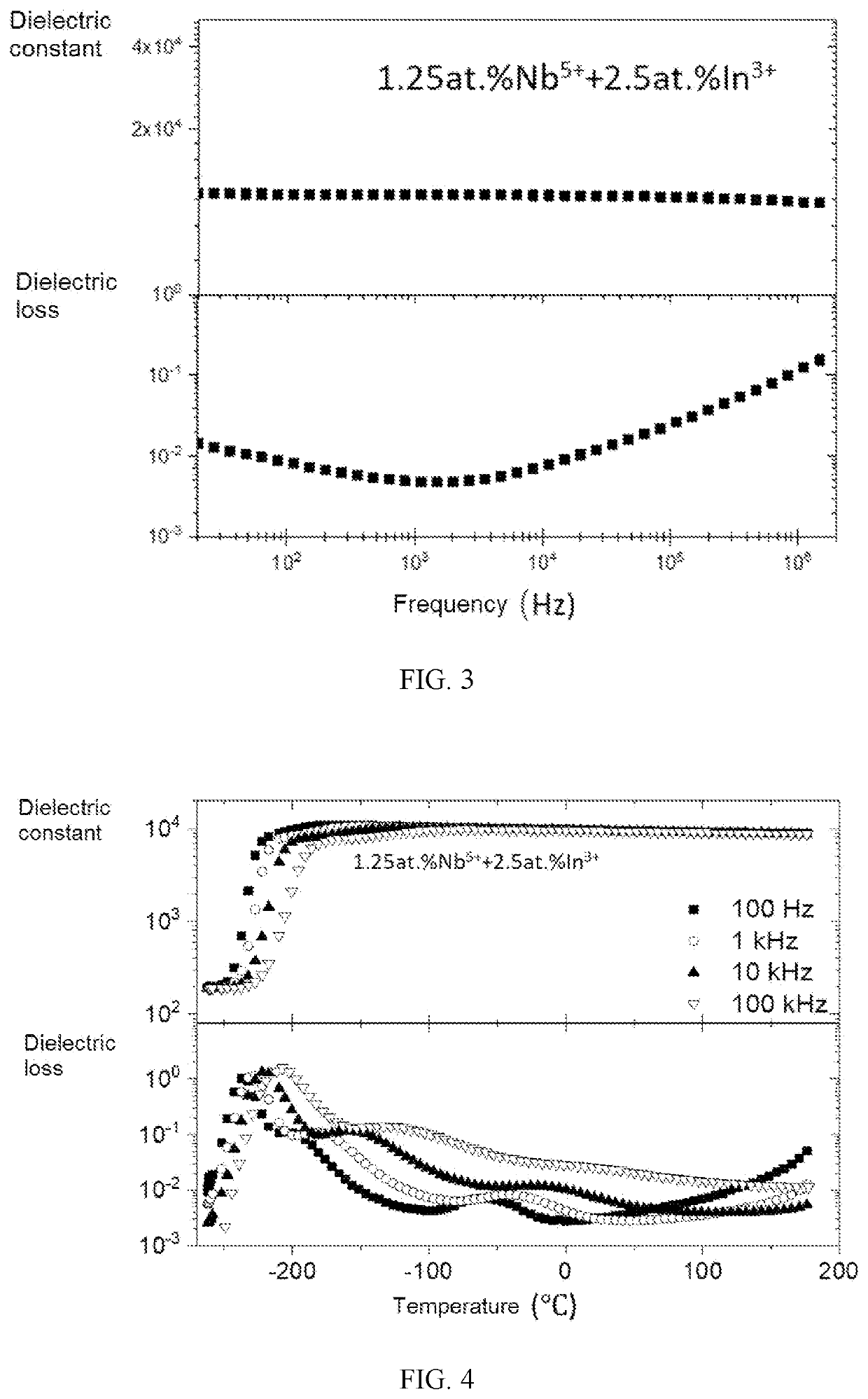

Multiphase ceramic material with giant dielectric constant, and preparation method thereof

PendingUS20220127197A1Excellent dielectric propertiesLow dielectric lossCeramicsDielectric lossHigh energy

The present invention discloses a multiphase ceramic material with a giant dielectric constant, wherein the multiphase ceramic material has a general formula of AxBnxTi1−(n+1)xO2; wherein A is at least one selected from the group consisting of Nb, Ta, V, Mo, and Sb, B is at least one selected from the group consisting of In, Ga, Al, Co, Cr, Sc, Fe (III), and a trivalent rare-earth cation; n is a molar ratio of B to A, 1<n≤5 , 0<x≤0.1. The multiphase ceramic material possesses outstanding properties including a giant dielectric constant, a low dielectric loss, and excellent frequency- and temperature-stability. In particular, it exhibits a high insulation resistivity of higher than 1011 Ω·cm and a high breakdown voltage, which implies it can be applied in high-energy storage devices and supercapacitors. This invention also provides a method to synthesize the multiphase ceramic material.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

Silicon resin powder

InactiveCN102964996ALow halogen contentHigh insulation resistivityConjugated diene hydrocarbon coatingsPowdery paintsWater basedEpoxy

The invention provides silicon resin powder which is prepared from the following components in parts by weight: 15-35 parts of methyl vinyl polysiloxane, 10-15 parts of diphenyl trichlorosilane, 5-10 parts of acrylic polymer powder, 5-10 parts of calcium oxide, 10-20 parts of silicon carbide, 5-15 parts of water-based amino resin, 5-10 parts of novolac epoxy resin, 10-20 parts of nitrile-butadiene rubber and 2-5 parts of molybdenum disulfide. The silicon resin powder provided by the invention has favorable adhesive force, solvent resistance, heat-resistance temperature and storage stability.

Owner:QINGDAO HANHE PHARMA

Dielectric ceramic composition and electronic device

ActiveUS8841224B2Improve featuresIncrease the electric field strengthFixed capacitor dielectricStacked capacitorsBronzeMaterials science

Dielectric ceramic composition comprising a compound shown by a general formula {A1−x(RE)2x / 3}y-B2O5+y and has a tungsten bronze-type structure. In the formula, “A” is at least one selected from a group comprising Ba, Ca, Sr and Mg, “B” is at least one selected from Nb and Ta, “RE” is at least one selected from Sc, Y, La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb and Lu, and said “x” and “y” satisfies 0<x<1 and y>1.000, respectively. The dielectric ceramic composition further comprises an oxide of at least one selected from V, Mo, Fe, W, Mn and Cr.

Owner:TDK CORPARATION

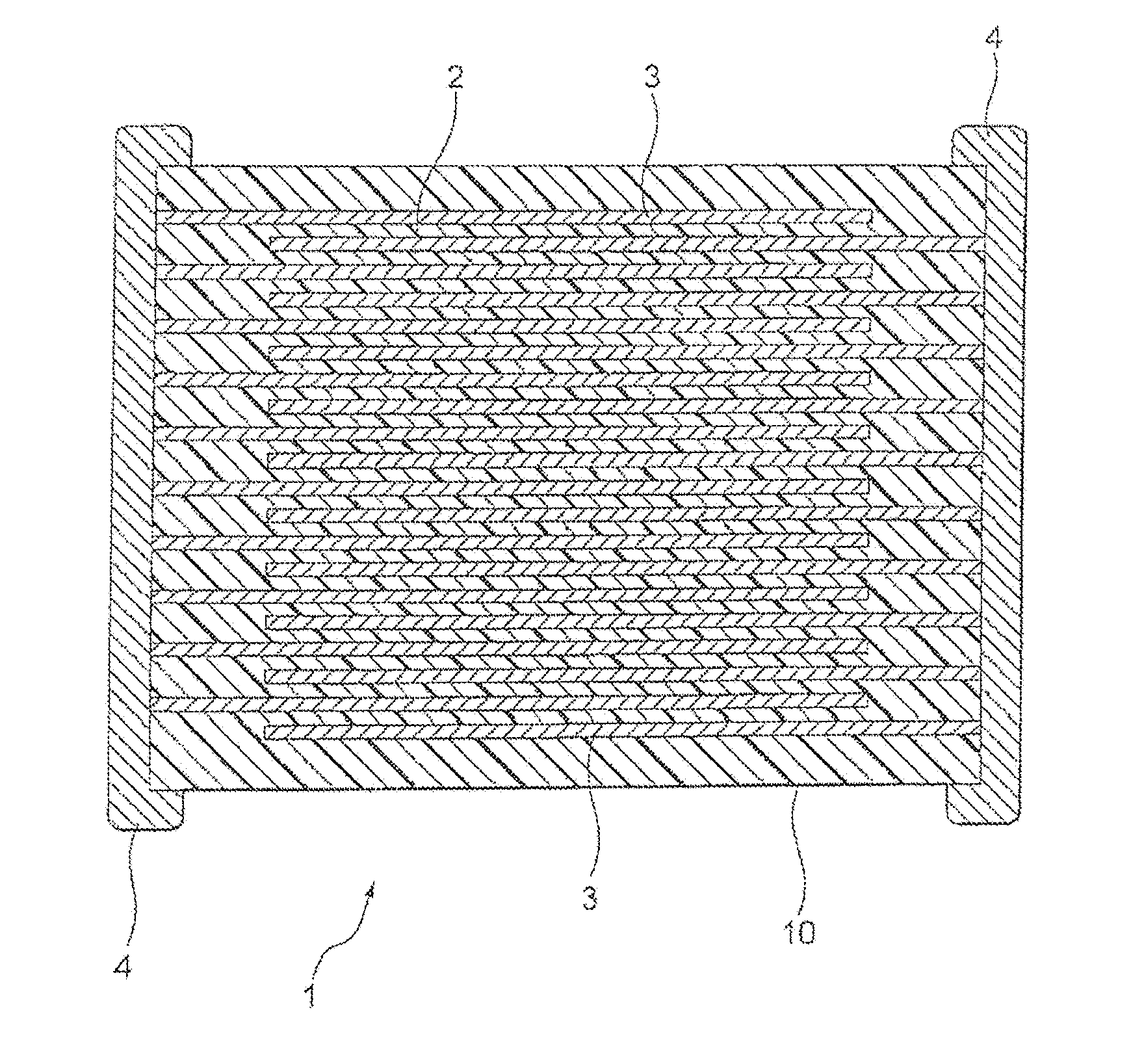

Dielectric ceramic and laminated ceramic capacitor

ActiveUS20120170169A1Improve reliabilityReduce variationStacked capacitorsCeramicsDielectricCeramic capacitor

A dielectric ceramic which is suitable for use in a laminated ceramic capacitor under a high-temperature environment, such as encountered in, for example, automobile use has a composition represented by the composition formula: (1−x) (Ba1-yCay)mTiO3+xCaTiO3+aRe2O3+bMgO+cMnO+dV2O3+eSiO2 in which Re is Gd, Dy, Y, Ho, and / or Er), 0.001≦x≦0.02, 0.08≦y≦0.20, 0.99≦m≦1.05, 0.01≦a≦0.04, 0.005≦b≦0.035, 0≦c≦0.01, 0≦d≦0.01, 0.01≦e≦0.04 when a, b, c, d, and e are each expressed in terms of parts by mol with respect to 1 mol of (1−x) (Ba,Ca)TiO3+xCaTiO3. This dielectric ceramic can constitute the dielectric ceramic layers of a laminated ceramic capacitor.

Owner:MURATA MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com