Nano doping dielectric material for preparing base-metal inner-electrode multi-layer ceramic sheet type capacitor

A technology for capacitor dielectrics and multilayer ceramics, which is applied in the direction of fixed capacitor dielectrics, laminated capacitors, and components of fixed capacitors. It can solve problems such as unsuitable for large-scale production, large dielectric temperature coefficient, and unfavorable thinning of the dielectric layer. , to achieve the effects of simple and adjustable formula, small temperature change rate and small dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

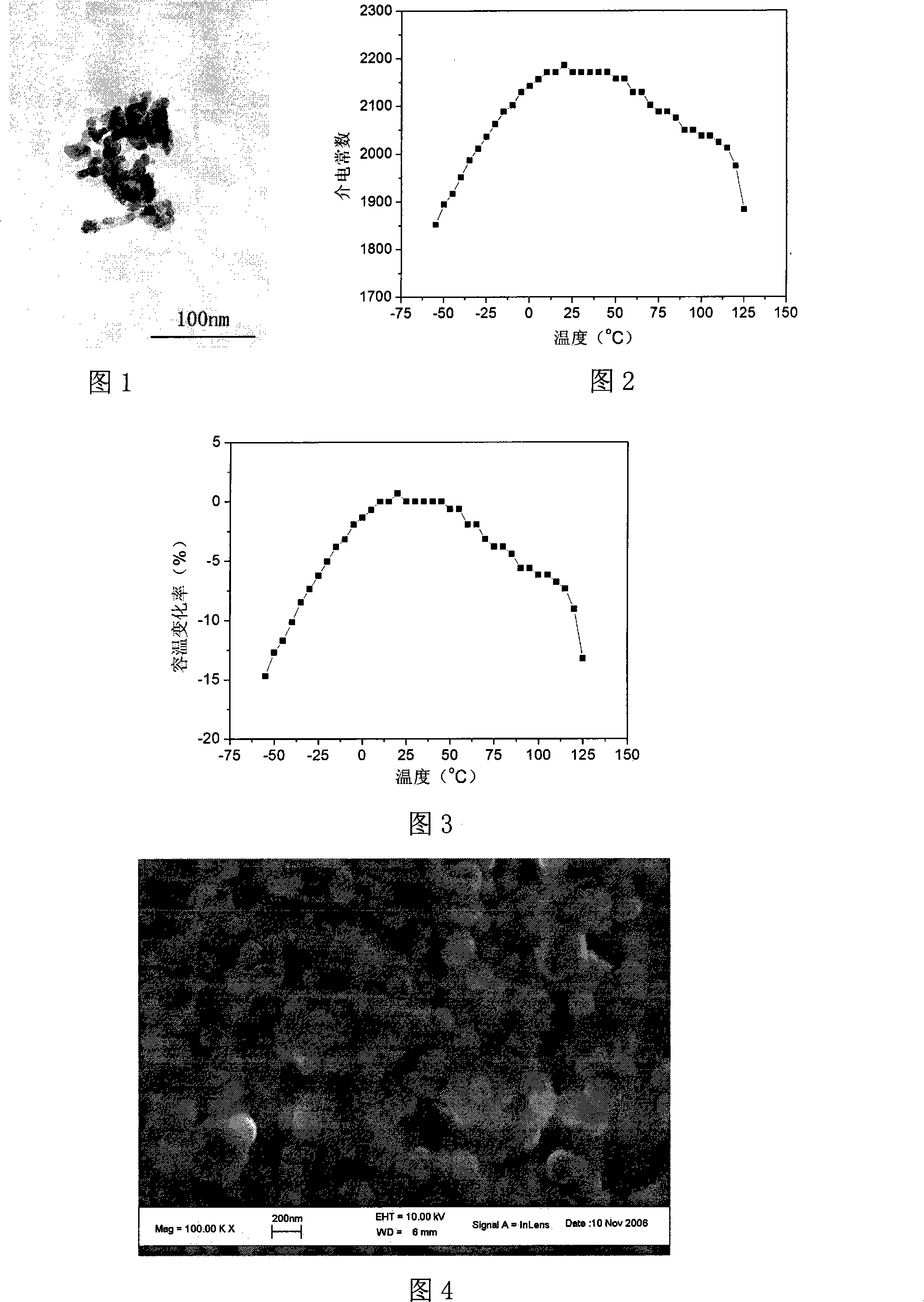

[0062] Embodiment 1 Preparation of nano dopant. According to the molar ratio of Y:Mn:Mg:Si:Ca=5:3:12:7:1, the corresponding weight of soluble salt and ethyl orthosilicate was weighed. According to the sol-gel method nano-dopant preparation process of the present invention, the precursor solution is prepared, firstly dried at 120° C. for 24 hours, and then dried at 140° C. for 6 hours to obtain a xerogel. The obtained xerogel was heat-treated at 800° C. for 3 h, and then ground and sieved to obtain the desired nano-dopant ND1. Figure 1 is a transmission electron micrograph of nano dopants.

Embodiment 2

[0063] Embodiment 2 According to BaTiO 3 : 93mol%; (grain size is respectively 110nm, 125nm, 150nm), nano dopant ND1: 7mol% proportioning. The above materials were mixed, ball milled and then dried. After the ceramic material is pressed into a disc, the N 2 / H 2 (20:1) Under reducing atmosphere, sinter at 1200°C for 2h, and then anneal at 1050°C for 2h under weak oxidation conditions. The surface of the sample was covered with a silver electrode, and the electrical performance test was carried out. The dielectric performance parameters are shown in Table 1. The curve in FIG. 2 shows the characteristic curve of the dielectric constant of sample 1 in Example 2 as a function of temperature, and FIG. 3 shows the curve of the capacitance change rate of sample 1 in Example 2 as a function of temperature. 4 is a scanning electron microscope photo of the surface morphology of sample 1 in Example 2 after sintering. The ceramic grains are spherical and uniform in size, with an avera...

Embodiment 3

[0066] Example 3 Nano-dopants ND2 to ND7 with different components were synthesized according to the sol-gel nano-dopant preparation process provided by the present invention, as shown in Table 2. The doping is performed at 2-10 mol% of the nano dopant relative to the barium titanate, as shown in Table 3. The above materials are mixed, ball milled, and then dried. After the obtained ceramic material is pressed into a disc, the N 2 / H 2 (25:1) Under reducing atmosphere, sinter at 1150-1250°C for 2-3h, then anneal at 1050°C for 3h under weak oxidation conditions. The surface of the sample was covered with a silver electrode, and the electrical performance test was carried out. The dielectric performance parameters are shown in Table 3.

[0067] Table 2

[0068] Dopant No.

Composition (element molar ratio)

ND2

Y: Ce: Mn: Mg: Si: Ca = 4: 1: 3: 12: 5: 2

ND3

Y: Ce: Mn: Mg: Si: Ca = 5: 1: 2.5: 10: 5: 2.5

ND4

Y:Sm:Mn:Mg:Si:Ba=3:1:4.5:10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com