Chemical coating prepared base metal internal electrode multi-layer ceramic chip capacitor dielectric material

A technology for capacitor dielectrics and multilayer ceramics, which is applied in the direction of fixed capacitor dielectrics, ceramics, and parts of fixed capacitors. It can solve the problem of dielectric constant reduction and other problems, and achieve low dielectric loss, uniform particle size, and high insulation resistivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

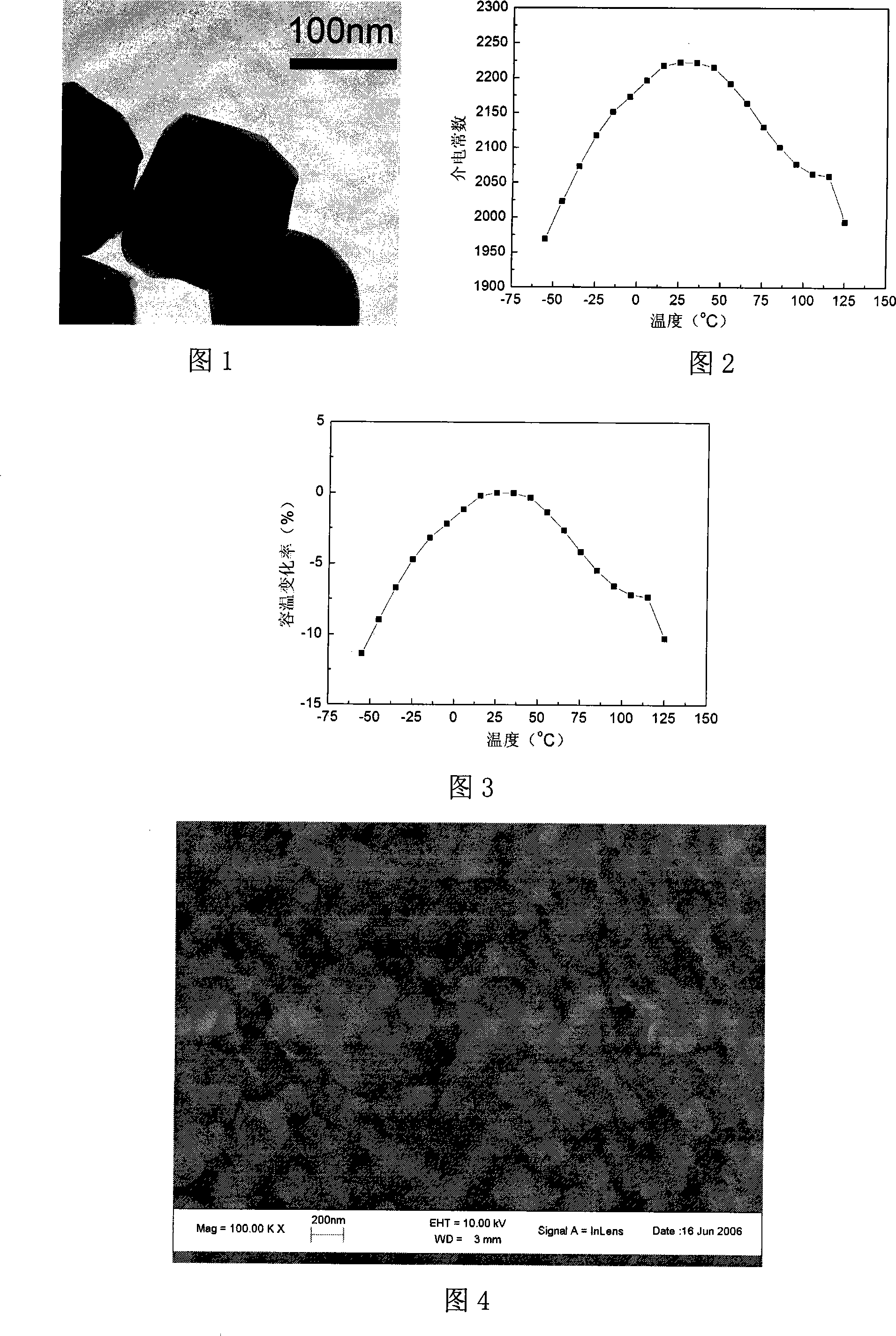

[0063] Example 1 Preparation of coated barium titanate powder. The barium titanate (grain size is 120nm) was ball-milled with ethanol as the medium for 12h, according to barium titanate (BaTiO 3 ) and the cladding layer composite oxide (CL) 96:4 and Y:Ce:Mn:Mg:Si:Ca=4:1:3:12:5:2 (both in molar ratio), weigh the corresponding weight of Soluble salts and ethyl orthosilicate. The coated barium titanate particle suspension is prepared by the chemical coating method of the present invention, and the coated barium titanate powder is obtained after drying. The obtained powder was heat-treated at 500°C for 2 hours, and then sieved to obtain the desired medium material. Figure 1 is a transmission electron microscope photograph of coated barium titanate particles.

Embodiment 2

[0064] Embodiment 2 The coated barium titanate powder is prepared by the chemical coating method of the present invention, wherein the barium titanate grain size is respectively 120nm, 135nm, 150nm, and the molar ratio of each element in the composite oxide coating layer is Y: Ce:Mn:Mg:Si:Ca=3:2:3:12:4:2. barium titanate (BaTiO) 3 ) to the cladding complex oxide (CL) in a molar ratio of 95:5. After the ceramic material is pressed into a disc, in N 2 / H 2 (30:1) Under reducing atmosphere, sintered at 1200℃ for 2h, and then annealed at 1050℃ for 2h under weak oxidizing conditions. The surface of the sample was covered with silver electrodes, and the electrical properties were tested. The dielectric properties are shown in Table 1. The curve of FIG. 2 shows the characteristic curve of the dielectric constant of the sample 1 of the present embodiment as a function of temperature, and FIG. 3 shows the curve of the change of the capacitance of the sample 1 as a function of tempe...

Embodiment 3

[0067] Example 3 The chemical coating method of the present invention was adopted, barium titanate powders with different initial particle sizes were selected, and oxide layers with different types and contents of elements were coated. The compositions of various coating layers are shown in Table 2. The total content of various oxides accounts for 3-10 mol% of barium titanate, as shown in Table 3. After the porcelain material is pressed into discs, the 2 / H 2 (35:1) Under reducing atmosphere, sinter at 1150-1250℃ for 2-3h, and then anneal at 1050℃ for 3h under weak oxidizing conditions. The surface of the sample was covered with silver electrodes, and the electrical properties were tested. The dielectric properties are shown in Table 3.

[0068] Table 2

[0069] Cladding Number

Composition (element molar ratio)

CL1

Y:Mn:Mg:Si:Ca=4:3:12:4:1

CL2

Y:Ce:Mn:Mg:Si:Ca=5:1:3:10:5:2

CL3

Dy:Sm:Mn:Mg:Si:Ba=5:1:4:12:5:1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com