Medium-high voltage ceramic dielectric capacitor material with bias characteristic for medium temperature sintering

A container material, medium and high voltage technology, applied in the field of electronic information materials and components, to achieve the effects of good formability, high insulation resistivity and high breakdown voltage, good temperature stability and bias characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

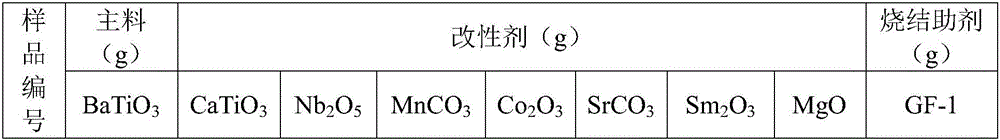

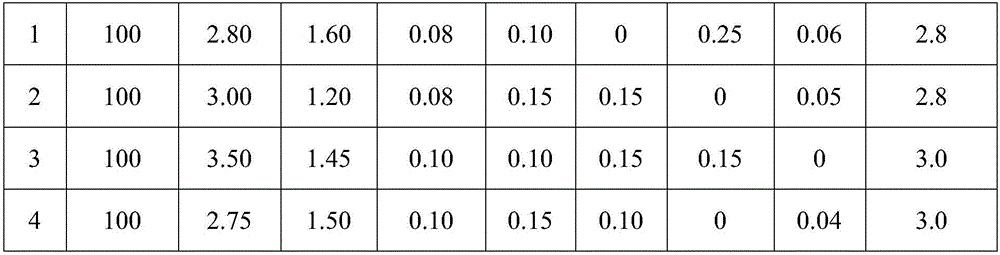

Method used

Image

Examples

Embodiment 1

[0041] It is a medium and high voltage ceramic capacitor material with bias characteristics for medium temperature sintering. It is composed of main materials, modifiers and sintering aids. Among them, the main material is BaTiO with tetragonal crystal structure. 3 , granularity D 50 =0.65 μm, purity ≥99.8wt%.

[0042] CaTiO 3 Preparation: Weigh CaCO according to the molar ratio of 1:1 3 and TiO 2 , using deionized water as the medium, ball milling for 8 hours; drying at 120°C, grinding with an agate mortar, passing through a 100-mesh sieve; calcining at 1060°C for 3 hours to obtain the CaTiO 3 , sealed and stored in a ziplock bag for later use.

[0043] Preparation of sintering aid GF-1: Weigh the raw materials according to the formula, and its mass ratio is 22.7wt%H 3 BO 3 , 68.2wt% ZnO and 9.1wt% SiO 2 ;Choose deionized water as the ball milling medium, the ball milling time is 6 hours; dry at 80°C, the time is 12 hours; after grinding with agate mortar, pass throug...

Embodiment 2

[0057] It is a medium and high voltage ceramic capacitor material with bias characteristics for medium temperature sintering. It is composed of main materials, modifiers and sintering aids. Among them, the main material is BaTiO with tetragonal crystal structure. 3 , granularity D 50 =0.75 μm, purity ≥99.8wt%.

[0058] CaTiO 3 Preparation: Weigh CaCO according to the molar ratio of 1:1 3 and TiO 2 , using deionized water as the medium, ball milling for 8 hours; drying at 120°C, passing through a 100-mesh sieve; calcining at 1060°C for 3 hours to obtain the CaTiO 3 .

[0059] Preparation of sintering aid GF-2: Weigh the raw materials according to the formula, and its mass ratio is 25.6wt%H 3 BO 3 , 2.6wt% CaCO 3 , 64.1wt% ZnO and 7.7wt% SiO 2 ; choose deionized water as the ball milling medium, the ball milling time is 6 hours; dry at 80°C, the time is 12 hours; after grinding with agate mortar, pass through a 100 mesh sieve; calcined at 850°C, the time is 5 hours, Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com