Strontium, bismuth and titanium base energy storage medium material for medium temperature sintering and preparation method

A strontium-bismuth-titanium-based storage and dielectric material technology is applied in the direction of fixed capacitor dielectrics, fixed capacitor parts, electrical components, etc. Loss, effect of high breakdown voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] A method for preparing a strontium-bismuth-titanium-based energy storage medium material for medium-temperature sintering according to the invention, comprising:

[0048] Step 1, prepare base material:

[0049] Weigh analytically pure SrCO at a molar ratio of 1:x:(1+3x) 3 、Bi 2 o 3 and TiO 2 Raw materials, wherein 0.04≤x≤0.11; put the weighed raw materials into a ball mill jar equipped with zirconia balls, and conduct mixed ball milling with deionized water as the medium, which lasts 7 to 9 hours; dry in an oven, dry The temperature is 110°C-120°C, and the drying time is 6-8 hours; calcined in a muffle furnace at 1100°C-1200°C for 2-3 hours to obtain SrO-xBi 2 o 3 -(1+3x)TiO 2 Powder.

[0050] Step 2. According to the ratio of the above-mentioned base material, modifier and sintering aid, weigh the base material, modifier and sintering aid, put them into a ball mill tank equipped with zirconia balls, add deionized water ball mill 5 hours, dried at 120°C for 6 ho...

Embodiment 1

[0054] The invention provides a strontium-bismuth-titanium-based energy storage medium material for medium-temperature sintering, including a base material, a modifier and a sintering aid; wherein:

[0055] SrO-xBi 2 o 3 -(1+3x)TiO 2 To analyze pure SrCO 3 、Bi 2 o 3 and TiO 2 As a raw material, weigh SrCO with a molar ratio of 1:0.04:1.12 3 、Bi 2 o 3 and TiO 2 Raw materials, put the weighed raw materials into a ball mill tank equipped with zirconia balls, and carry out mixed ball milling with deionized water as a medium for 9 hours; then dry them in an oven at a drying temperature of 110°C for 8 hours ; Calcined at 1200°C for 2 hours in a muffle furnace to obtain SrO-0.04Bi 2 o 3 -1.12TiO 2 Powder.

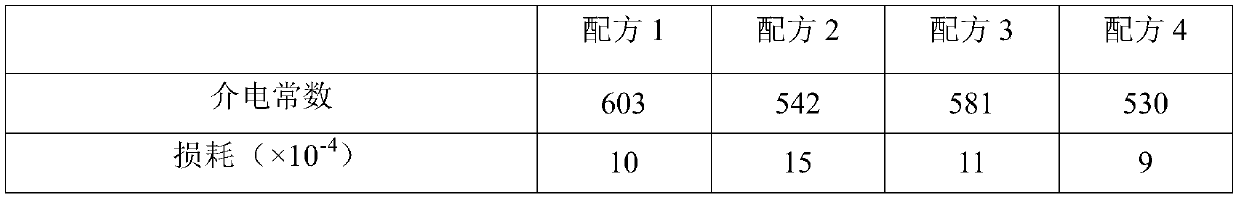

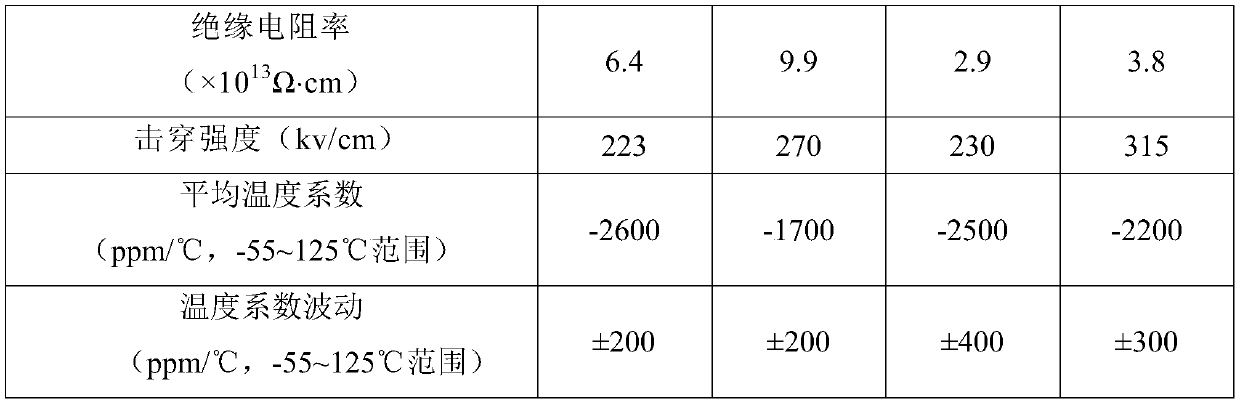

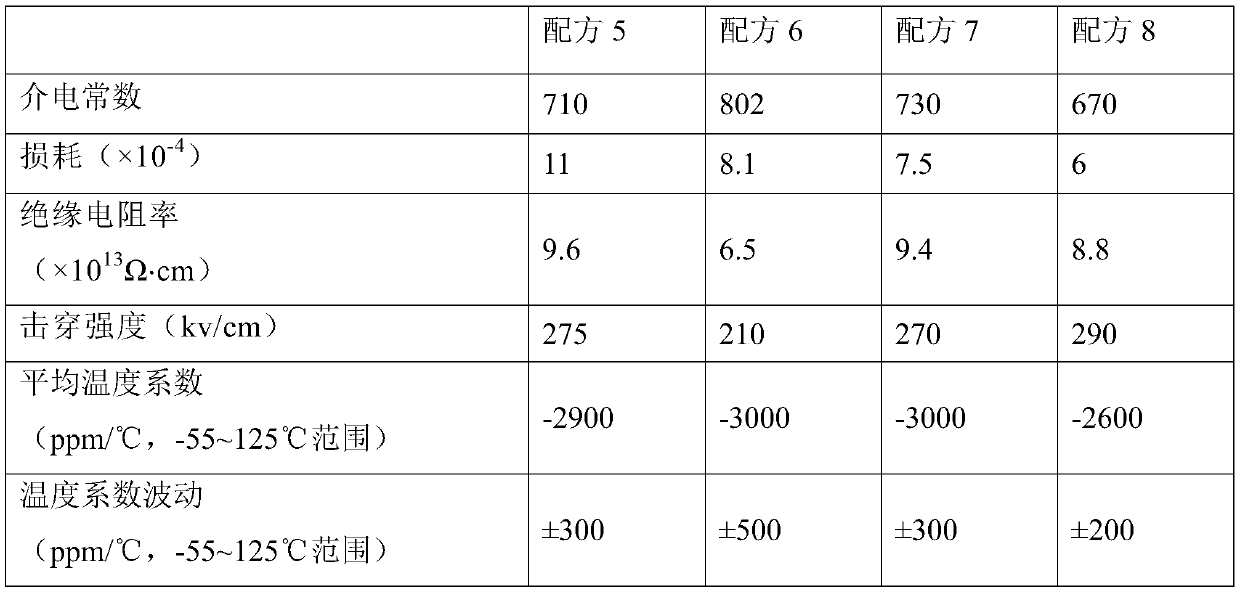

[0056] Weigh the base material, modifier and sintering aid according to the weight ratio in Table 1 (unit: gram), use deionized water as the medium, ball mill and mix for 5 hours, dry at 120°C for 6 hours, and take out the ceramic powder After grinding and passing th...

Embodiment 2

[0064] The invention provides a strontium-bismuth-titanium-based energy storage medium material for medium-temperature sintering, including a base material, a modifier and a sintering aid; wherein:

[0065] SrO-xBi 2 o 3 -(1+3x)TiO 2 To analyze pure SrCO 3 、Bi 2 o 3 and TiO 2 As a raw material, weigh SrCO with a molar ratio of 1:0.11:1.33 3 、Bi 2 o 3 and TiO 2 Raw materials, put the weighed raw materials into a ball mill tank equipped with zirconia balls, and carry out mixed ball milling with deionized water as a medium for 7 hours; then dry them in an oven at a temperature of 120°C, and dry The time is 6 hours; then calcined in a muffle furnace at 1100°C for 3 hours to obtain SrO-0.11Bi 2 o 3 -1.33TiO 2 Powder.

[0066] Weigh the base material, modifier and sintering aid according to the weight ratio in Table 3 (unit: gram), use deionized water as the medium, ball mill and mix for 5 hours, dry at 120°C for 6 hours, and take out the ceramic powder After grinding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com