Titanium dioxide-based giant dielectric ceramic material and preparation method thereof

A technology of titanium dioxide and ceramic materials, which is applied in the field of titanium dioxide-based giant dielectric ceramic materials and its preparation, can solve the problems of insufficient comprehensive dielectric properties and restrictions on the development of the electronic material industry, and achieve excellent temperature and frequency stability, large Practical value, effect of improving insulation resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

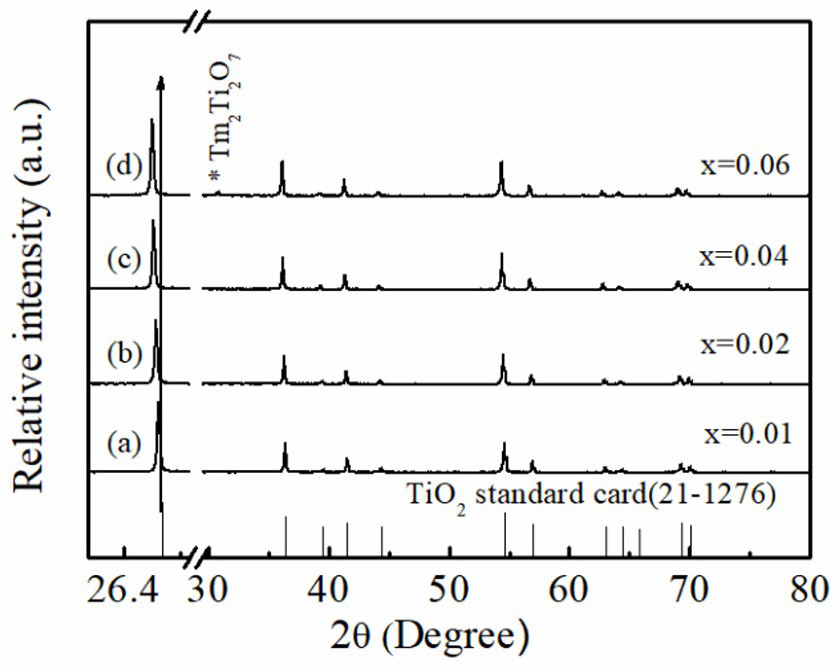

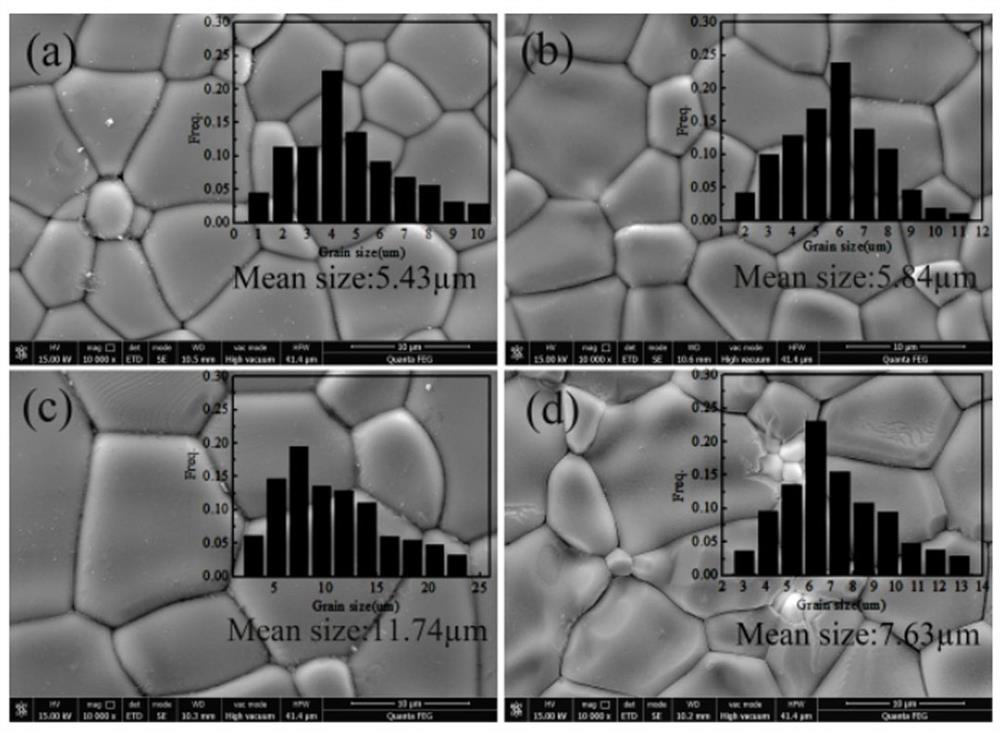

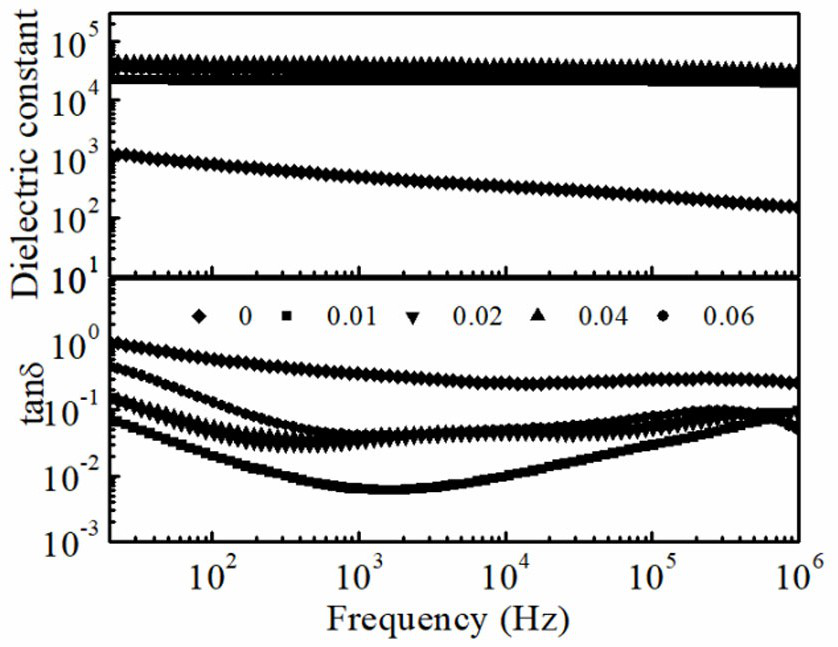

[0026] (1) (Tm 0.5 Nb 0.5 ) x (Ti 1-y B y ) 1-x o 2 (x=0.01, y = 0) Processing of raw material powder: thulium oxide (Tm 2 o 3 ), niobium oxide (Nb 2 o 5 ), titanium oxide (TiO 2 ) was dried at 150°C for 5 hours;

[0027] (2) Weighing and batching: Press (Tm 0.5 Nb 0.5 ) 0.01 Ti 0.99 o 2 Stoichiometric ratio Weighing Tm processed in step (1) 2 o 3 (99.999%) 2.3435g, TiO 2 (99.99%)96.0421g, Nb 2 o 5 (99.99%) 1.6144g raw material powder;

[0028] (3) Ball milling and mixing: Add the weighed raw materials into the ball milling tank, use zirconia balls as the balls and absolute ethanol as the ball milling medium, and the mass ratio of raw material mixture to zirconia balls and absolute ethanol is 1:3 : 2, fully ball milled for 24 hours, separated the zirconia balls, put the raw material mixture into a drying oven and dried at 75°C to obtain (Tm 0.5 Nb 0.5 ) 0.01 Ti 0.99 o 2 ceramic powder;

[0029] (4) (Tm 0.5 Nb 0.5 ) 0.01 Ti 0.99 o 2 Synthesis o...

Embodiment 2

[0038] (1) (Tm 0.5 Nb 0.5 ) x (Ti 1-y B y ) 1-x o 2 (x=0.02, y = 0) Processing of raw material powder: thulium oxide (Tm 2 o 3 ), niobium oxide (Nb 2 o 5 ), titanium oxide (TiO 2 ) was dried at 150°C for 5 hours;

[0039] (2) Weighing and batching: Press (Tm 0.5 Nb 0.5 ) 0.02 Ti 0.98 o 2 Stoichiometric ratio Weighing Tm processed in step (1) 2 o 3 9(9.999%) 4.5511g, TiO 2 (99.99%)92.3138g, Nb 2 o 5 (99.99%) 3.1351g raw material powder;

[0040] (3) Ball milling and mixing: Add the weighed raw materials into the ball milling tank, use zirconia balls as the balls and absolute ethanol as the ball milling medium, and the mass ratio of raw material mixture to zirconia balls and absolute ethanol is 1:3 : 2, fully ball milled for 24 hours, separated the zirconia balls, put the raw material mixture into a drying oven and dried at 75°C to obtain (Tm 0.5 Nb 0.5 ) 0.02 Ti 0.98 o 2 ceramic powder;

[0041] (4) (Tm 0.5 Nb 0.5 ) 0.02 Ti 0.98 o 2 Synthesis o...

Embodiment 3

[0049] (1) (Tm 0.5 Nb 0.5 ) x (Ti 1-y B y ) 1-x o 2 (x=0.04, y = 0) Processing of raw material powder: thulium oxide (Tm 2 o 3 ), niobium oxide (Nb 2 o 5 ), titanium oxide (TiO 2 ) was dried at 150°C for 5 hours;

[0050] (2) Weighing and batching: Press (Tm 0.5 Nb 0.5 ) 0.04 Ti 0.96 o 2 Stoichiometric ratio Weighing Tm processed in step (1) 2 o 3 (99.999%) 8.6031g, TiO 2 (99.99%)85.4706g, Nb 2 o 5 (99.99%) 5.9263g raw material powder;

[0051](3) Ball milling and mixing: Add the weighed raw materials into the ball milling tank, use zirconia balls as the balls and absolute ethanol as the ball milling medium, and the mass ratio of raw material mixture to zirconia balls and absolute ethanol is 1:3 : 2, fully ball milled for 24 hours, separated the zirconia balls, put the raw material mixture into a drying oven and dried at 75°C to obtain (Tm 0.5 Nb 0.5 ) 0.04 Ti 0.96 o 2 ceramic powder;

[0052] (4) (Tm 0.5 Nb 0.5 ) 0.04 Ti 0.96 o 2 Synthesis of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com