Maleic anhydride modified voltage stabilizer and preparation method and application thereof

A technology of maleic anhydride and voltage stabilization, which is applied in the field of maleic anhydride modified voltage stabilizer and its preparation, can solve the problems of increasing the performance of electric-resistant dendrites, reducing the resistivity, and increasing the dielectric loss tangent value, etc., to achieve increased High resistance to electric properties, prolonging the working life and improving the effect of insulation resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

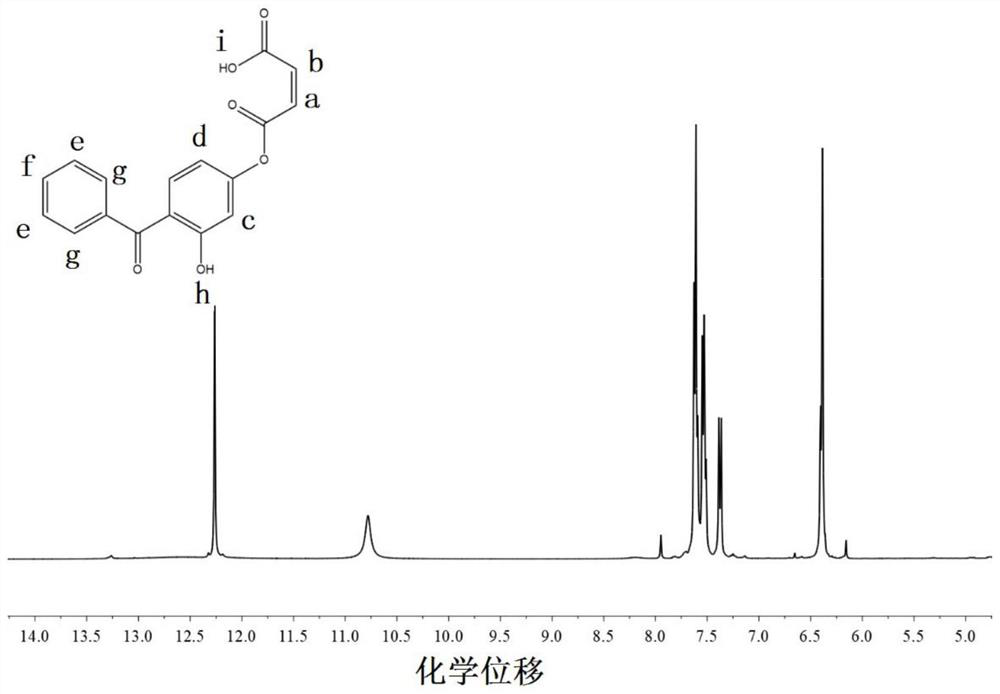

[0037] In the first aspect, this embodiment provides a maleic anhydride modified voltage stabilizer, the structural formula of which is shown in formula 1:

[0038]

[0039] In a second aspect, this embodiment provides a method for preparing a maleic anhydride-modified voltage stabilizer, comprising the following steps:

[0040] (1) dissolving maleic anhydride and 2,4-dihydroxybenzophenone in tetrahydrofuran to obtain a mixture;

[0041] (2) Under nitrogen atmosphere, add concentrated sulfuric acid to the mixture obtained in step (1), stir for 10 hours after stirring, stir at 70°C, add water and centrifuge, and dry the obtained precipitate at 80°C to obtain the Maleic anhydride modified voltage stabilizer;

[0042] Wherein, the molar ratio of dihydroxybenzophenone: maleic anhydride: tetrahydrofuran: catalyst (concentrated sulfuric acid) is 2:1.4:24:0.1.

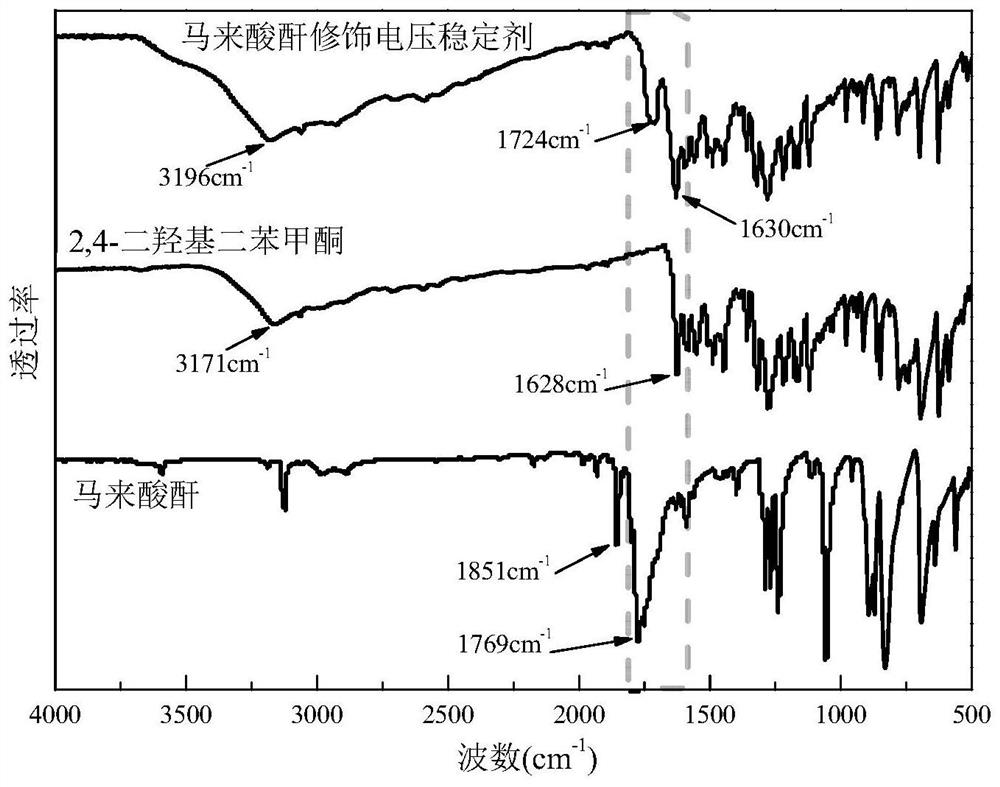

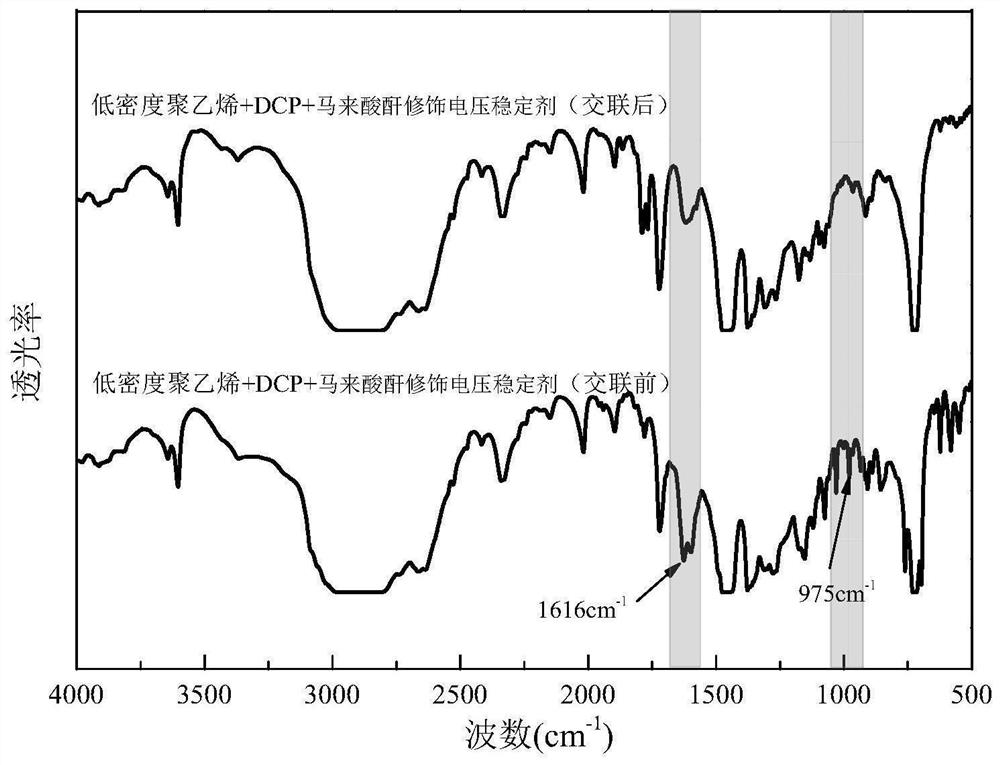

[0043] figure 1 It is the infrared absorption spectrum of the maleic anhydride modified voltage stabilizer. From fi...

Embodiment 2

[0046] In the first aspect, this embodiment provides a maleic anhydride modified voltage stabilizer, the structural formula of which is shown in formula 1:

[0047]

[0048] In a second aspect, this embodiment provides a method for preparing a maleic anhydride-modified voltage stabilizer, comprising the following steps:

[0049] (1) dissolving maleic anhydride and 2,4-dihydroxybenzophenone in tetrahydrofuran to obtain a mixture;

[0050] (2) Under a nitrogen atmosphere, add concentrated sulfuric acid to the mixture obtained in step (1), after stirring, the stirring time is 6 hours, the stirring temperature is 68°C, add water and centrifuge, and the obtained precipitate is dried at 80°C to obtain the obtained Described maleic anhydride modified voltage stabilizer;

[0051] Wherein, the molar ratio of dihydroxybenzophenone: maleic anhydride: tetrahydrofuran: catalyst (concentrated sulfuric acid) is 2:1.7:60:0.5.

Embodiment 3

[0053] In the first aspect, this embodiment provides a maleic anhydride modified voltage stabilizer, the structural formula of which is shown in formula 1:

[0054]

[0055] In a second aspect, this embodiment provides a method for preparing a maleic anhydride-modified voltage stabilizer, comprising the following steps:

[0056] (1) dissolving maleic anhydride and 2,4-dihydroxybenzophenone in tetrahydrofuran to obtain a mixture;

[0057] (2) Under nitrogen atmosphere, add p-benzenesulfonic acid to the mixture obtained in step (1), after stirring, the stirring time is 12 hours, the stirring temperature is 65°C, add water and centrifuge, and the obtained precipitate is dried at 80°C, namely Obtain the maleic anhydride modified voltage stabilizer;

[0058] Wherein, the molar ratio of maleic dihydroxybenzophenone: maleic anhydride: tetrahydrofuran: catalyst (p-benzenesulfonic acid) is 2:2:125:1.2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com