Resin emulsion paint special for epoxy pnenolic aldehyde stalloy and preparation thereof

A technology of epoxy phenolic silicon steel and epoxy resin, applied in the field of insulating resin paint, can solve the problems of poor adhesion of silicon steel sheet coating, poor adhesion of coating, and high temperature of punching and painting, and achieves good The effect of high electrical properties, high heat resistance grade and high insulation resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

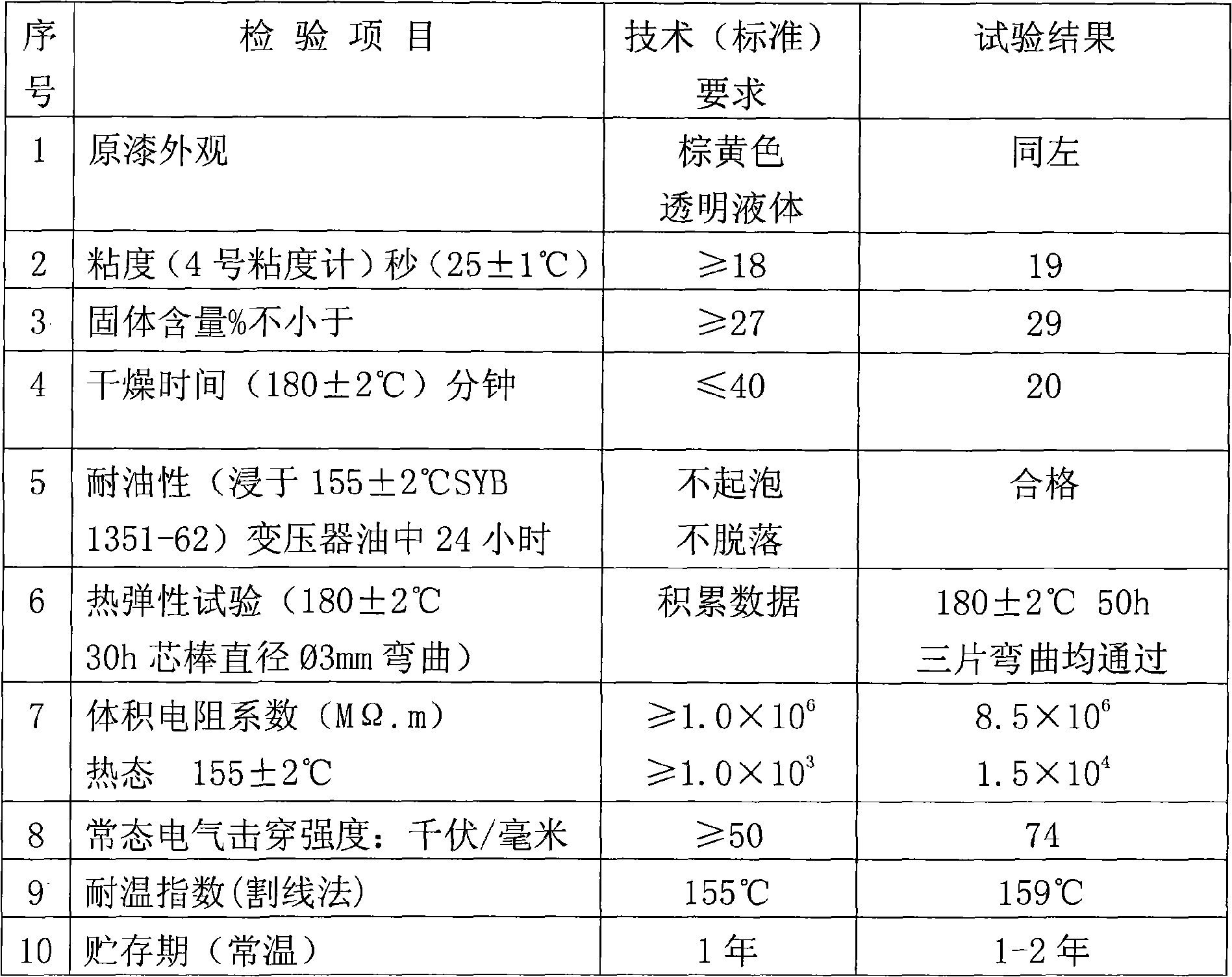

Examples

specific Embodiment approach

[0041] The epoxy phenolic silicon steel sheet special resin paint is made up of polymer 609 epoxy resin, 214 phenolic resin, Z-11 epoxy toughening agent, L-12 leveling agent and thinner, and the thinner is toluene or Ethanol or ethyl acetate, the weight percent of each component is:

[0042] 98~102 parts of polymer 609 epoxy resin;

[0043] 18 parts of 214 phenolic resin;

[0044] 5 parts of Z-11 epoxy toughening agent;

[0045] 7.8 parts of L-12 leveling agent;

[0046] Diluent 2~5 parts.

Embodiment 1

[0047] Embodiment 1: the special resin paint for epoxy phenolic silicon steel sheet is made up of polymer 609 epoxy resin, 214 phenolic resin, Z-11 epoxy toughening agent, L-12 leveling agent and toluene, each component The ratio of parts by weight is:

[0048] 100 parts of polymer 609 epoxy resin;

[0049] 18 parts of 214 phenolic resin;

[0050] 5 parts of Z-11 epoxy toughening agent;

[0051] 7.8 parts of L-12 leveling agent;

[0052] 3 parts of toluene.

[0053] Its preparation method is as follows:

[0054] ①Heat the reaction kettle to 120±10°C, add 100 kg of polymer 609 epoxy resin and 3 kg of diluent, and stir for 4 hours;

[0055] ② Add 5 kg of Z-11 epoxy toughening agent; stir for 4 hours;

[0056] ③ Add 18 kg of 214 phenolic resin, react for 4 hours, and drop to room temperature;

[0057] 4. Add 7.8 kilograms of L-12 leveling agent and stir for 1 hour to get the object of the present invention;

[0058] ⑤ Out of the kettle and into the package, after passing ...

Embodiment 2

[0059] Embodiment 2: the special resin paint for epoxy phenolic silicon steel sheet is made up of polymer 609 epoxy resin, 214 phenolic resin, Z-11 epoxy toughening agent, L-12 leveling agent and ethanol, each component The ratio of parts by weight is:

[0060] 98 parts of polymer 609 epoxy resin;

[0061] 18 parts of 214 phenolic resin;

[0062] 5 parts of Z-11 epoxy toughening agent;

[0063] 7.8 parts of L-12 leveling agent;

[0064] 2 parts ethanol.

[0065] The preparation steps are the same as in Example 1, except that the proportions of the components are different, and ethanol is selected as the diluent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com