Photo-curing and thermal curing heat-resistant conductive adhesive material and preparation method thereof

A heat-curing, conductive adhesive technology, used in conductive adhesives, adhesives, epoxy resin adhesives, etc., can solve the problems of limitation, UV light cannot penetrate, and conductive adhesive materials are not fully cured, so as to reduce the preparation cost, The effect of excellent thermal stability and excellent electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

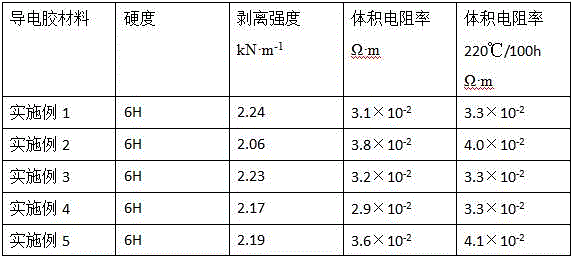

Examples

Embodiment 1

[0024] Embodiment 1: A light-cured and heat-cured heat-resistant conductive adhesive material, including the following raw materials in parts by weight: 20 parts of base adhesive, 70 parts of conductive filler, 6 parts of active monomer auxiliary agent, and 4 parts of thermosetting agent , 1 part of thermal initiator, 1.5 parts of photoinitiator, 5 parts of reactive diluent crosslinking agent, 12 parts of plasticizing modifier, 5 parts of inorganic filler;

[0025] The basic adhesive is difunctional aliphatic polyurethane acrylic resin, polyether acrylic resin and alicyclic epoxy resin, and its mass ratio is 8:3:6; the conductive filler is silver-plated glass microspheres and nano oxide Zinc, its mass ratio is 3:1, and the Ag content of described silver-plated glass microsphere is 12%, and average particle diameter is 20 μ m; Described active monomer auxiliary agent is hexafluorobutyl acrylate and methacrylamide Composite; Described thermal curing agent is triethanolamine; Des...

Embodiment 2

[0030] Embodiment 2: A light-cured and heat-cured heat-resistant conductive adhesive material, including the following raw materials in parts by weight: 10 parts of base adhesive, 50 parts of conductive filler, 3 parts of active monomer auxiliary agent, and 2 parts of thermosetting agent , 0.5 parts of thermal initiator, 1 part of photoinitiator, 3 parts of reactive diluent crosslinking agent, 8 parts of plasticizing modifier, 3 parts of inorganic filler;

[0031] The basic adhesive is difunctional aliphatic polyurethane acrylic resin, polyether acrylic resin and alicyclic epoxy resin, and its mass ratio is 3:1:2; the conductive filler is silver-plated glass microspheres and nano oxide Zinc, its mass ratio is 2:1, and the Ag content of described silver-plated glass microsphere is 12%, and average particle diameter is 20 μ m; Described active monomer auxiliary agent is dipentaerythritol pentaacrylate; Described thermosetting The agent is triethanolamine; the thermal initiator i...

Embodiment 3

[0034] Embodiment 3: A light-curing and heat-curing heat-resistant conductive adhesive material, including the following raw materials in parts by weight: 30 parts of base adhesive, 90 parts of conductive filler, 10 parts of active monomer auxiliary agent, and 6 parts of thermosetting agent , 1.5 parts of thermal initiator, 2 parts of photoinitiator, 8 parts of reactive diluent crosslinking agent, 15 parts of plasticizing modifier, 6 parts of inorganic filler;

[0035]The basic adhesive is difunctional aliphatic polyurethane acrylic resin, polyether acrylic resin and alicyclic epoxy resin, and its mass ratio is 5:2:4; the conductive filler is silver-plated glass microspheres and nano oxide Zinc, its mass ratio is 4:1, and the Ag content of described silver-plated glass microsphere is 12%, and average particle diameter is 20 μ m; Described active monomer assistant is hexafluorobutyl acrylate, methacrylamide and The compound of dipentaerythritol pentaacrylate; The thermal curing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com