High-strength low-water ratio ethylbenzene dehydrogenation catalyst not containing adhesive

A technology of ethylbenzene dehydrogenation and catalyst, which is applied in the direction of catalysts, carbon compound catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of poor catalyst strength and low activity, and achieve increased strength and high activity , Improve the effect of binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

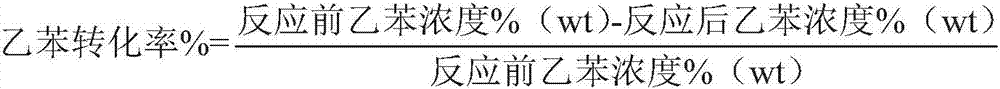

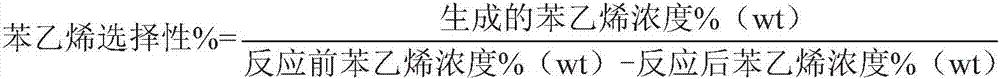

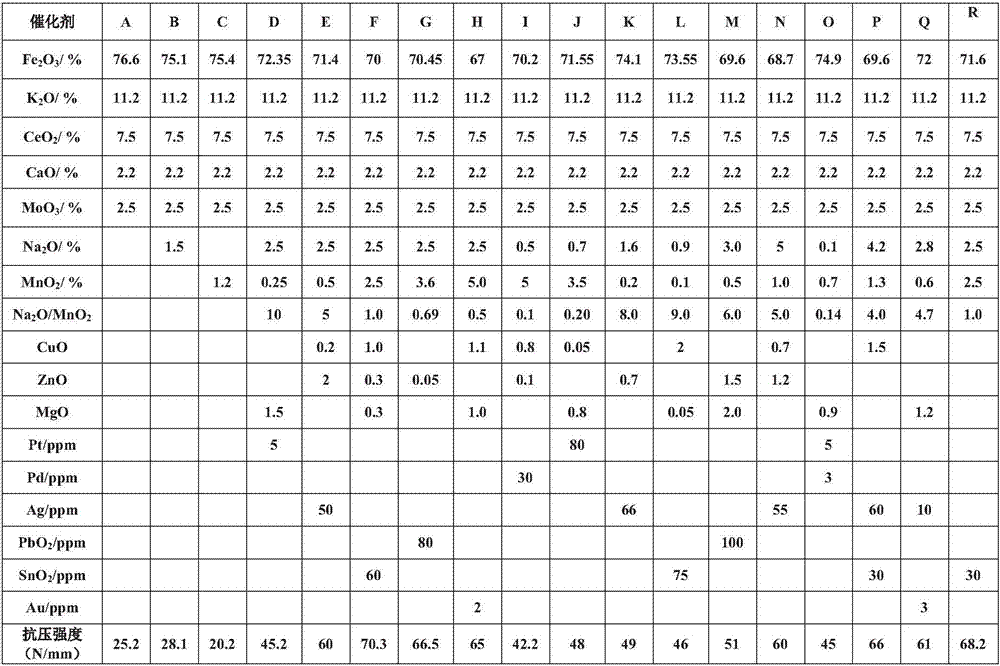

[0058] A series of catalysts DEFGH were prepared by adding different amounts of MnO2, in which the source of cerium in catalyst D was cerium carbonate, the source of cerium in catalyst E was cerium oxalate, and the source of cerium in catalyst F was basic cerium carbonate. The source of cerium in catalyst G is cerium nitrate, the source of cerium in the remaining catalysts is cerium oxide, Pt, Pd, Ag and Au are added in the form of nitrate, and Pb and Sn are added in the form of oxide. The content of sodium oxide in each catalyst was set at 2.5%, and the amount of other raw materials was used according to the composition of the actual oxides shown in Table 1. After making the catalyst, evaluate the activity of the catalyst according to the evaluation method of Example 1, and the test results are shown in Table 2-3

Embodiment 6-14

[0060] Add different amount of MnO 2 and different amounts of Na 2 In the case of O, a series of catalysts I-R were prepared. The amounts of other raw materials were used in accordance with the actual oxide compositions shown in Table 1.

[0061] Table 1 Composition and compression performance of catalysts

[0062]

[0063] It can be seen from Table 1 that adding Na to the catalyst 2 O and MnO 2 , increasing the compressive strength of the catalyst.

[0064] Table 2 is the performance of the catalyst under the condition of water ratio of 0.75.

[0065] Table 2 Catalyst performance under the condition of water ratio 0.75

[0066]

[0067]

[0068] Table 3 shows the performance of the catalyst under the condition of the water ratio of 0.75. In addition, Table 3 shows the decrease value ΔY of the styrene yield when the water ratio is reduced from 1.0 to 0.75.

[0069] Table 3 Catalyst performance under the condition of water ratio 1.0

[0070]

[0071] From th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com