Catalyst used for low steam-to-oil ratio ethylbenzene dehydrogenation to prepare styrene, and preparation method thereof

A catalyst technology for the dehydrogenation of ethylbenzene, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problem of low potassium catalyst activity and low stability problem, achieve the effect of enhancing anti-reduction ability, reducing acidity and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

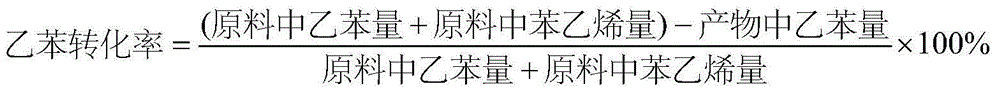

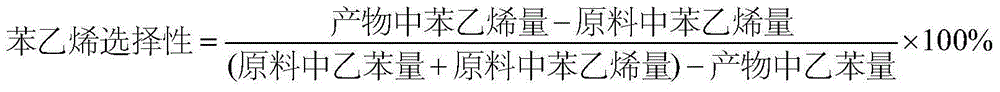

Image

Examples

Embodiment 1

[0030] Weigh 300g iron oxide red, 73.5g potassium carbonate, 5g zinc oxide, 5g manganese dioxide, 5g lead dioxide and dry mix for 1 hour, then roast at 600°C for 2 hours, add 83g cerium oxalate, 28.9g Ammonium tetramolybdate, 25g magnesium oxide, 35.6g calcium carbonate, and 30g carboxymethyl cellulose, dry powder mixed for 2 hours, add 130mL deionized water and knead for about 1 hour to form a dough-like material suitable for extrusion, extrude and cut into pellets into particles with a diameter of about 3 mm and a length of 6-8 mm; aged at room temperature for 12 hours, dried at 120°C for 4 hours, placed in a muffle furnace at a high temperature of 900°C for 6 hours to obtain a catalyst precursor, and measured the precursor with a 500mL measuring cylinder Volume: Prepare a mixed solution consisting of 7.9g rubidium nitrate, 6.9g cesium nitrate and 10g lanthanum nitrate, which has the same volume as the catalyst precursor, and then use the equal volume impregnation method to l...

Embodiment 2

[0032] Weigh 340g iron oxide red, 66.2g potassium carbonate, 2.5g zinc oxide, 2.5g manganese dioxide, 2.5g lead dioxide dry mix for 2 hours, then roast at 750°C for 4 hours, then add 83g cerium oxalate, 17.2 g ammonium tetramolybdate, 10g magnesium oxide, 17.8g calcium carbonate and 30g carboxymethyl cellulose, after mixing the dry powder for 2 hours, add 130mL deionized water and knead for about 1 hour to form a dough-like material suitable for extrusion, extrude and cut into pellets into particles with a diameter of about 3 mm and a length of 6-8 mm; aged at room temperature for 12 hours, dried at 120°C for 4 hours, placed in a muffle furnace at a high temperature of 900°C for 6 hours to obtain a catalyst precursor, and measured the precursor with a 500mL measuring cylinder Volume; prepare rubidium nitrate, cesium nitrate and lanthanum nitrate solutions with a concentration of 0.1mol / L, the dosages are respectively 15.8g of rubidium nitrate, 6.9g of cesium nitrate, and 15g of...

Embodiment 3

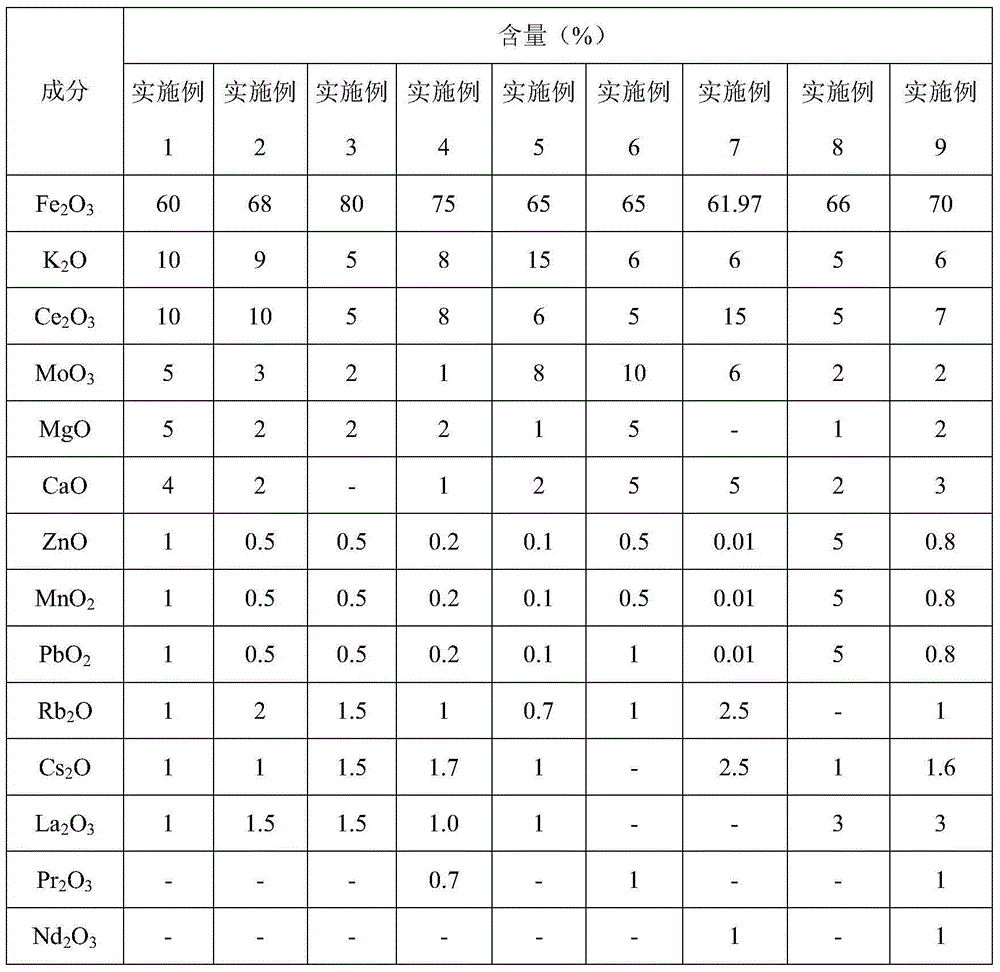

[0034] The preparation method of the catalyst of Examples 3-9 is the same as that of Example 1, and the composition of the catalyst is shown in Table 1. In the preparation process, embodiment 3 does not add porogen, embodiment 4 adds the carboxymethyl cellulose of catalyst weight 5%, adds the polystyrene microsphere of catalyst weight 8% in embodiment 5, adds catalyst weight in embodiment 6 2% graphite, add the carboxymethyl cellulose of catalyst weight 10% in embodiment 7, add the graphite of catalyst weight 1% in embodiment 8, add the carboxymethyl cellulose of catalyst weight 6 in embodiment 9.

[0035] The catalyst composition of table 1 embodiment 1~9

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com