Dielectric ceramic composition and method of production and electronic device of the same

一种介电陶瓷、制造方法的技术,应用在电子部件领域,能够解决难以确认等问题,达到加速寿命提高、抑制低频率介电分散、优异容量温度特性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

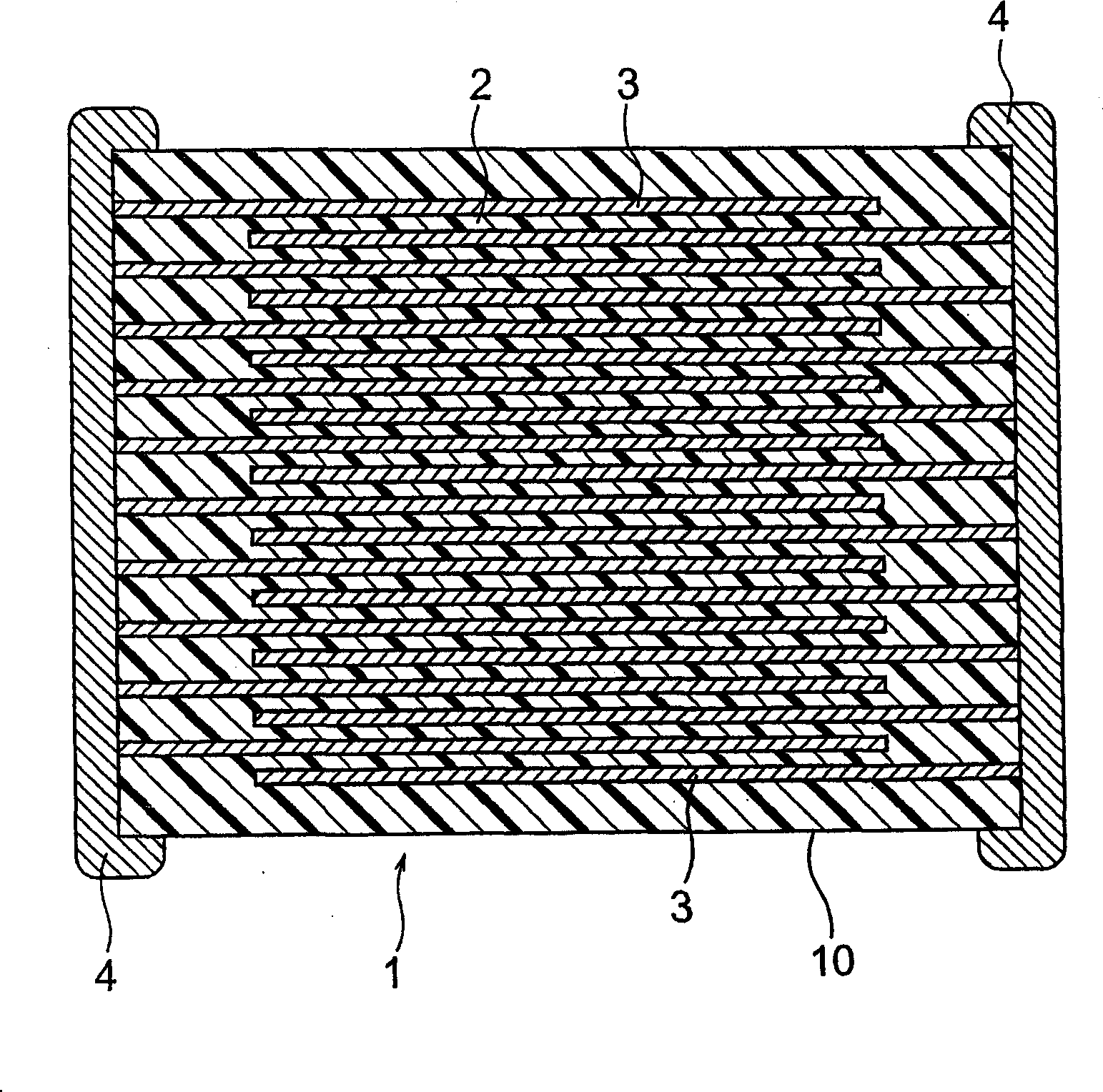

[0115] In this example, samples of laminated ceramic capacitors were produced according to the following procedure.

[0116] Preparation of various pastes

[0117] First, starting materials (SrCO 3 , CaCO 3 、TiO 2 , ZrO 2 ) and the 1st to 4th subcomponent raw materials. In this example, carbonate was used as the MnO raw material (the third subcomponent: MnCO 3 ), other raw materials use oxides (1st subcomponent: V 2 o 3 , the second subcomponent: Al 2 o 3 , the fourth subcomponent: (Ba 0.6 Ca 0.4 ) SiO 3 (in the table, denoted as BCG)). In addition, (Ba 0.6 Ca 0.4 ) SiO 3 was produced as follows: BaCO 3 , CaCO 3 and SiO 2 Wet mixing for 16 hours, drying, sintering in the air at 1000-1300°C, and wet pulverization with a ball mill for 100 hours.

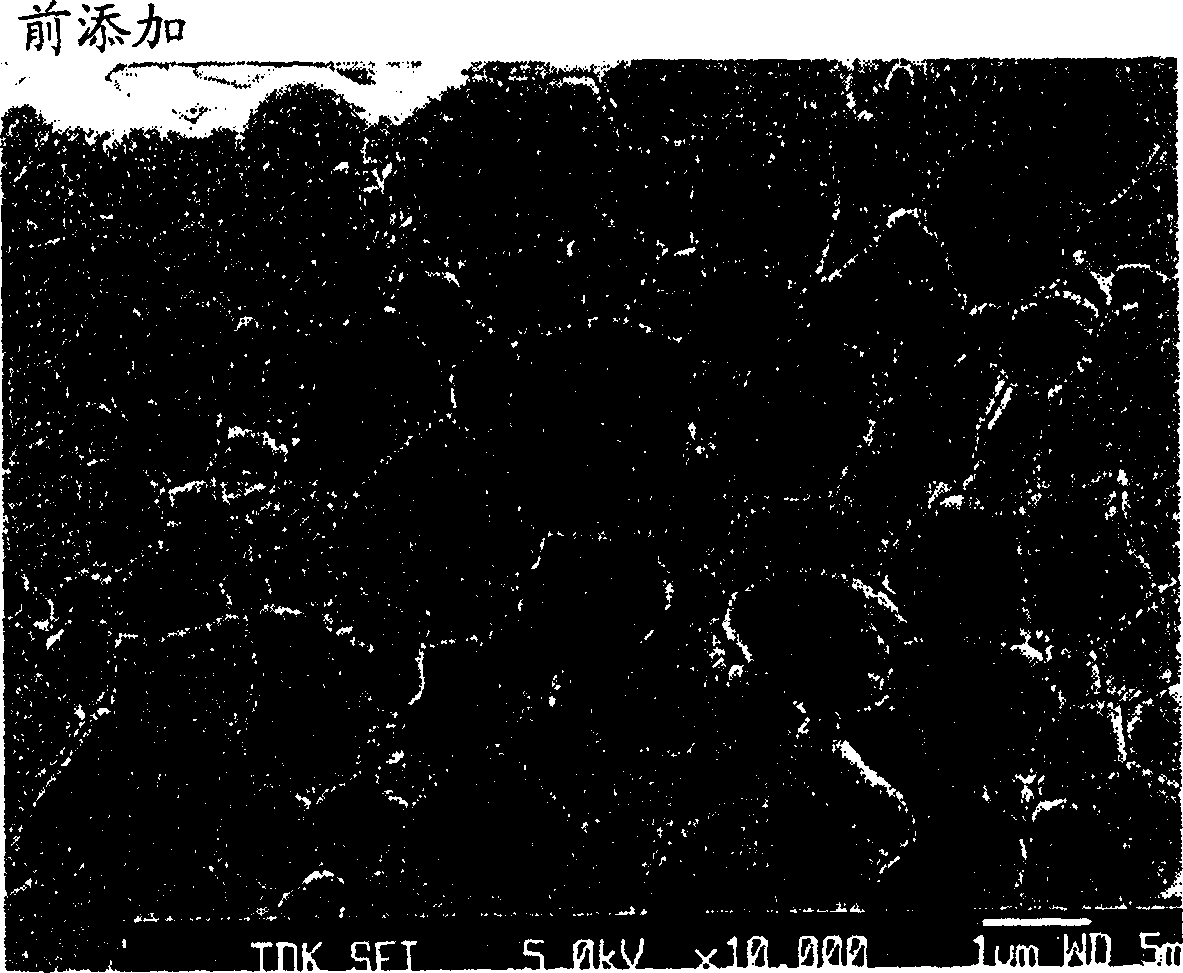

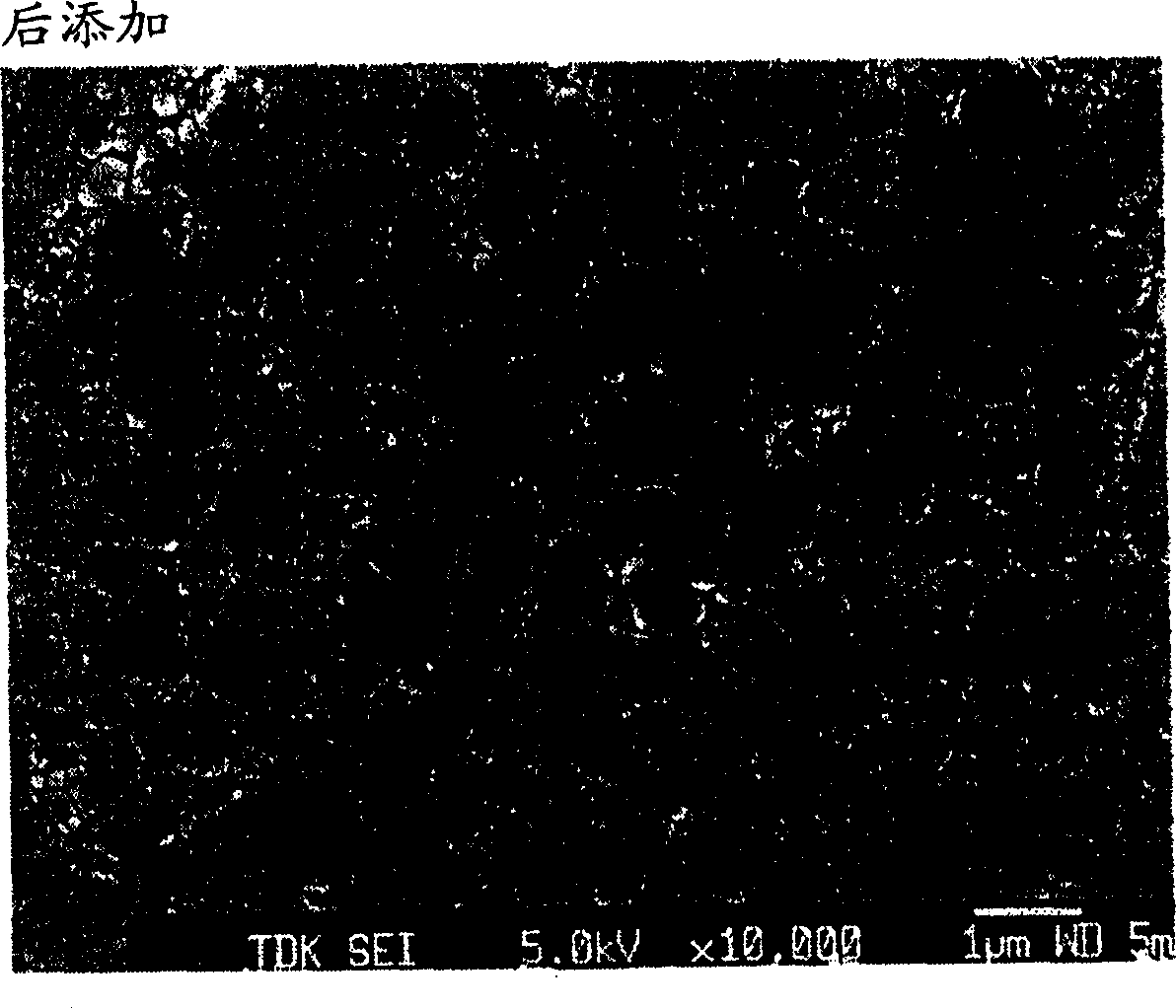

[0118] Next, by pre-adding and post-adding the first to fourth subcomponent raw materials, dielectric ceramic composition raw materials (powders) having the final composition are respectively obtained.

[0119] In t...

Embodiment 2

[0148] Capacitor samples were produced in the same manner as in Example 1 except that the pre-added components and post-added components were changed as shown in Table 2, and the same characteristics were evaluated. As a result, all samples had tanδ of 0.01% or less, dielectric constant ε of 45 or more, and resistivity ρ of 1×10 12 A good capacitor of Ωcm. Regarding the temperature characteristic of the electrostatic capacity, the rate of change of the electrostatic capacity with respect to the above temperature also satisfies -3000 to 0 ppm / °C. The average crystal grain size and high temperature load life are shown in Table 2.

[0149] In addition, the pre-added component mentioned in the present invention is a subcomponent raw material added to the starting raw material for producing the main component raw material when producing the calcined raw material containing the main component raw material. The post-added raw material is an auxiliary component raw material added to...

Embodiment 3

[0161] Capacitor samples were produced in the same manner as in Example 1 except that the addition amounts of the first to fourth subcomponents as post-addition components were changed as shown in Table 3, and the same characteristics were evaluated. As a result, all samples had tanδ of 0.01% or less, dielectric constant ε of 45 or more, and resistivity ρ of 1×10 12 A good capacitor of Ωcm. Regarding the temperature characteristic of the electrostatic capacity, the rate of change of the electrostatic capacity with respect to the above temperature also satisfies -3000 to 0 ppm / °C. The average crystal grain size and high temperature load life are shown in Table 3.

[0162] In addition, the post-addition component mentioned in this Example is a subcomponent raw material added to the calcined raw material containing a main component raw material.

[0163] sample

Amount of post-added ingredients added

characteristics

1st sub-ingredient

V 2 o 5 conv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com