Patents

Literature

92results about How to "Improves loss resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

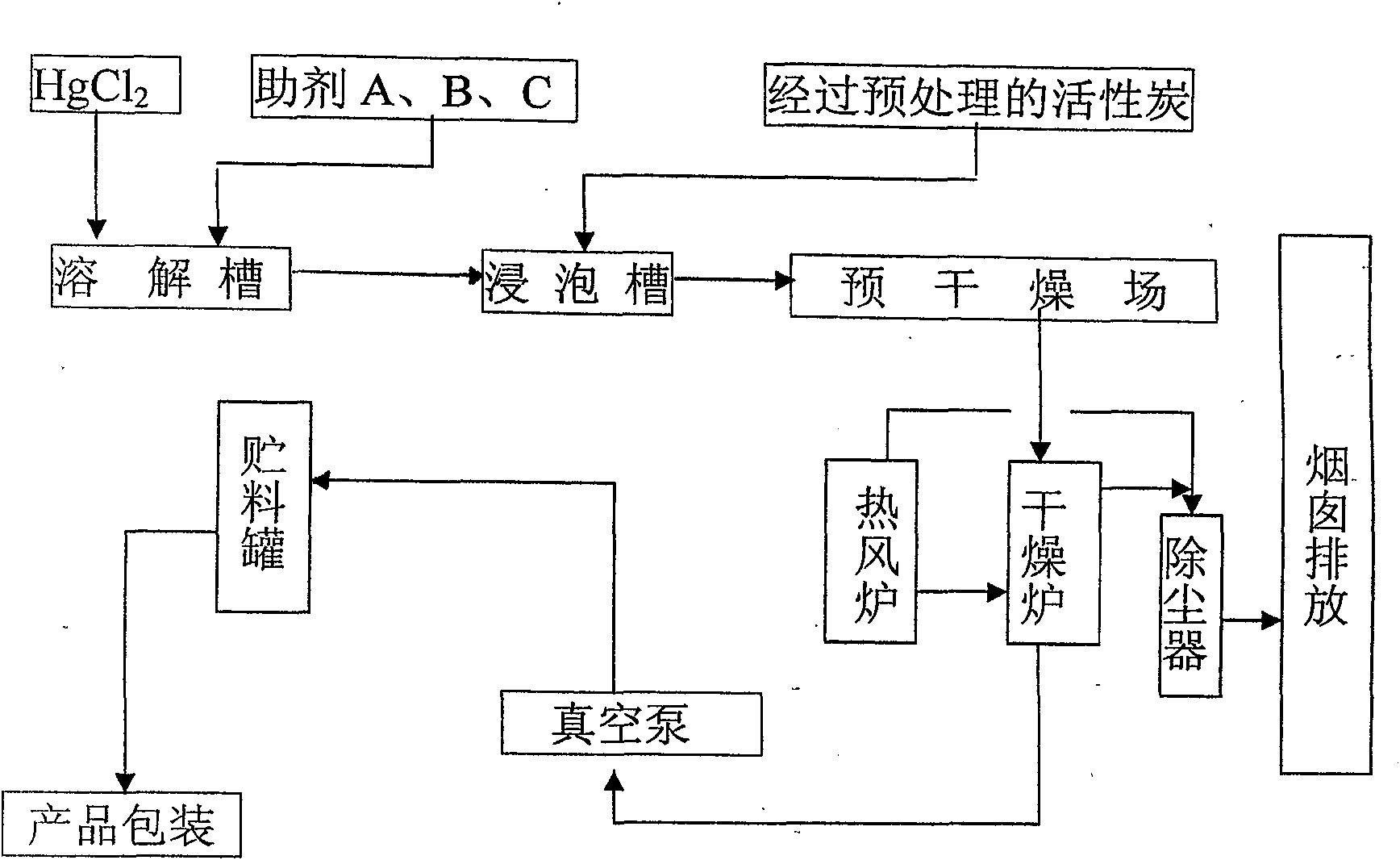

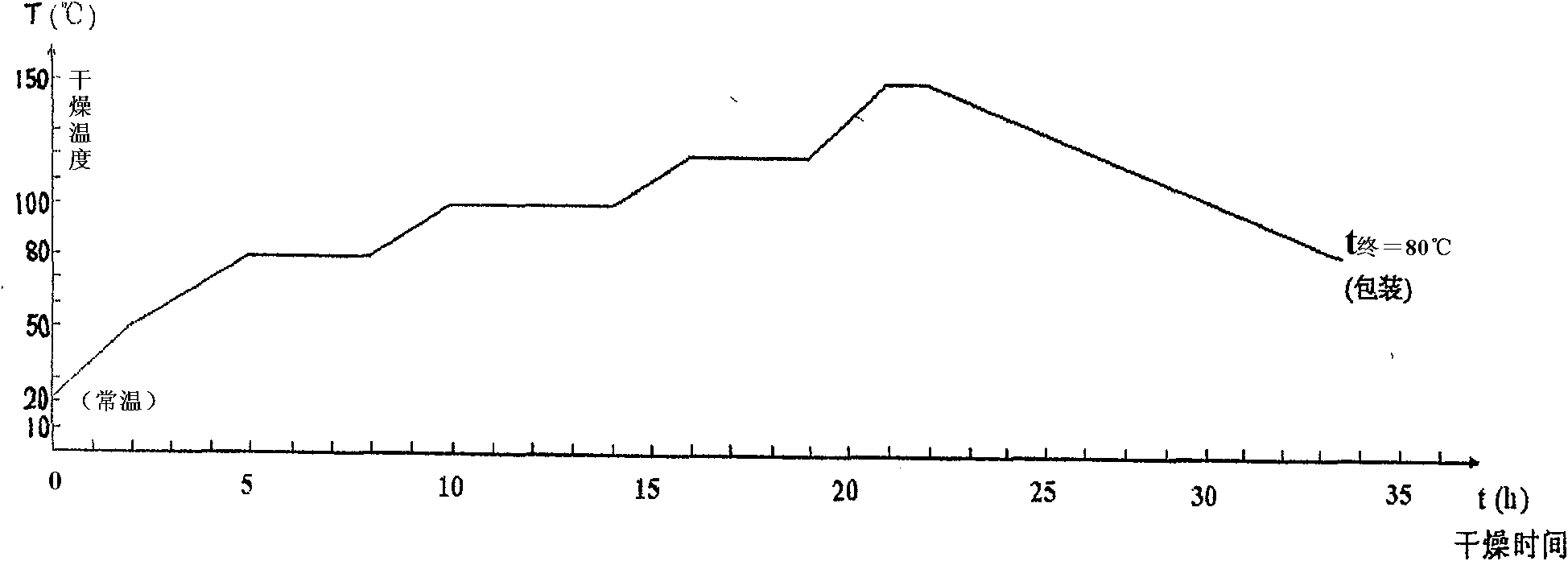

Mercuric chloride low-mercury catalyst and preparation method thereof

InactiveCN101596459AReduce resource consumptionRelieve pressurePhysical/chemical process catalystsHalogenated hydrocarbon preparationActivated carbonChemistry

The invention provides a mercuric chloride low-mercury catalyst and a preparation method thereof. The catalyst adopts active carbon as a carrier to adsorb mercuric chloride, and the formula of the catalyst comprises 8.0 to 10.0 percent of mercuric chloride, 8 to 13 percent of rare earth chloride assistant A, 5 to 25 percent of alkaline earth metal chloride assistant B, 10 to 20 percent of assistant C, and the balance of active carbon. The preparation method comprises the following steps: firstly, soaking the active carbon in hydrochloric acid solution at low temperature for standby; simultaneously dissolving the mercuric chloride, the assistant A, the assistant B and the assistant C together, and soaking the active carton in the solution; performing low-temperature pre-drying on an intermediate product; continuously drying the catalyst; and finally pumping a product at vacuum into a storage silo, packaging and leaving factory. The catalyst can reduce resource consumption and the pressure of treating mercury pollution; simultaneously the production cost is reduced, the poisoning resistance, reduction resistance and loss resistance are greatly improved, the catalytic performance of the catalyst is fully guaranteed, the using time can be prolonged and the using consumption can be reduced; and the catalyst is suitable for polyvinyl chloride manufacturers.

Owner:贵阳白云银星化工有限公司

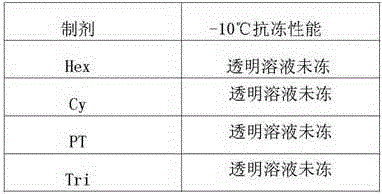

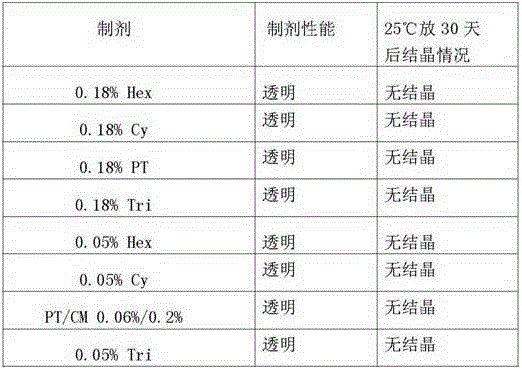

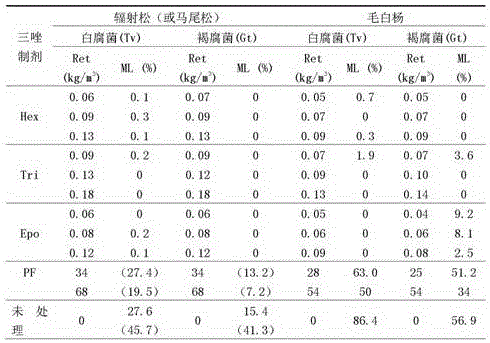

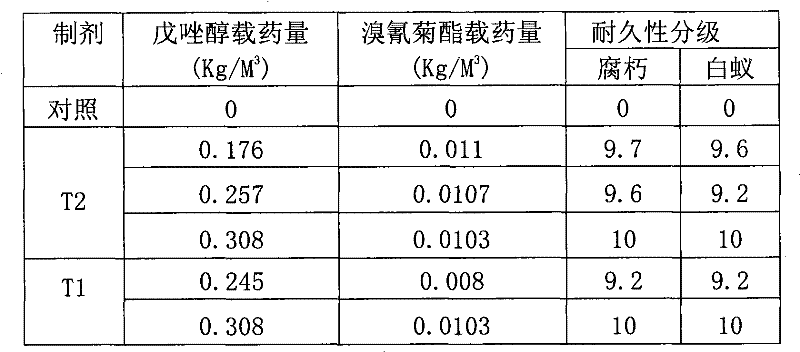

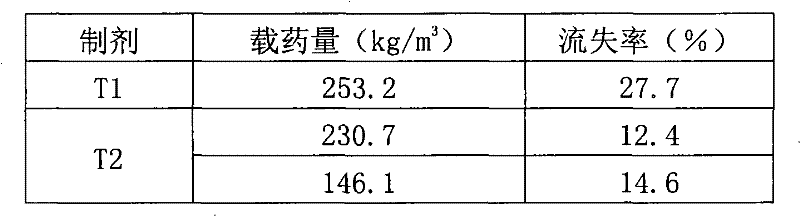

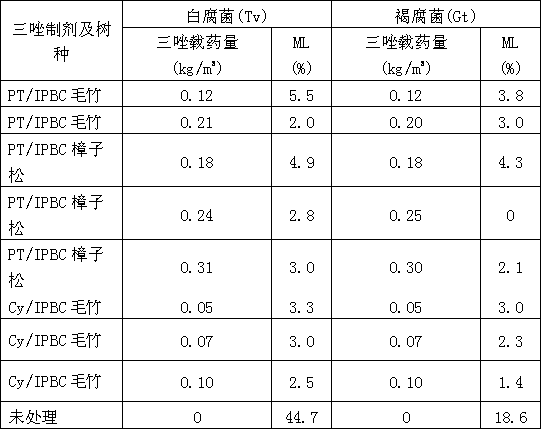

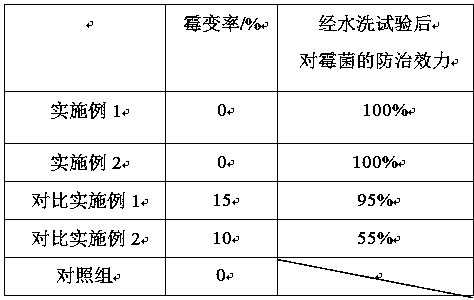

Wood bamboo material corrosion and discoloration prevention triazole composition and preparation method thereof

ActiveCN106003312AImprove anti-corrosion performanceImprove mildew resistanceWood treatment detailsReed/straw treatmentFatty alcoholHexaconazole

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

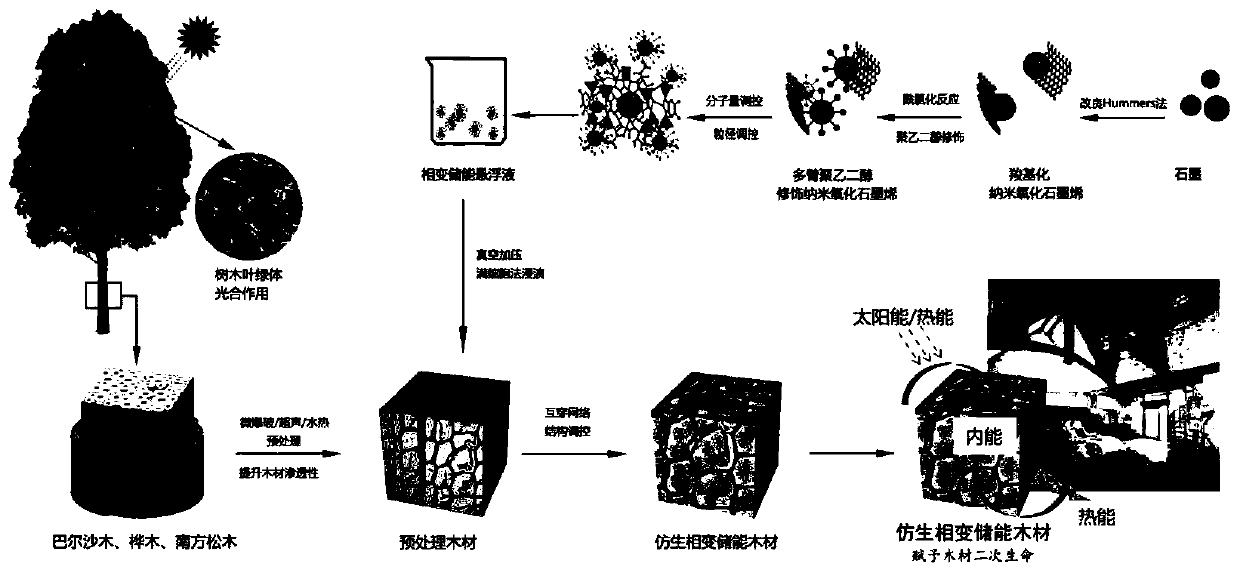

Method for preparing thermal conduction enhanced phase change energy storage wood based on photothermal response

InactiveCN110126043AImproves loss resistanceWide molecular weight rangeWood treatment detailsHeat-exchange elementsSulfite saltPolyethylene glycol

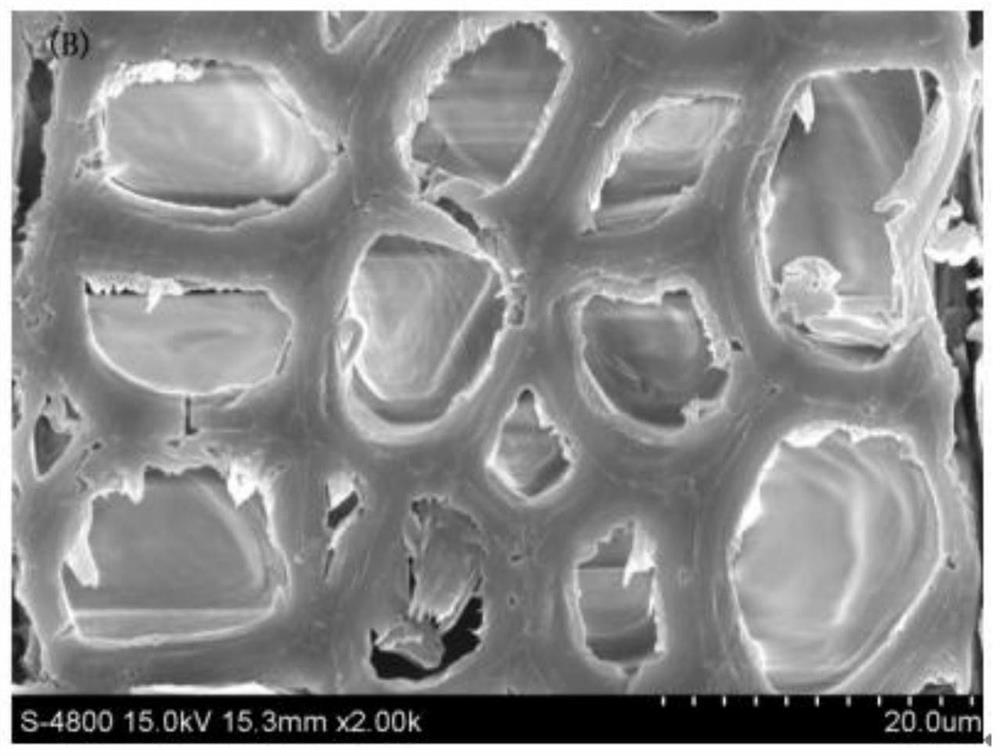

The invention discloses a method for preparing a thermal conduction enhanced phase change energy storage wood based on photothermal response. The method mainly comprises the following steps: (1) carboxylating graphene oxide to obtain carboxylated graphene oxide, performing conjugate grafting on the carboxylated graphene oxide by using ammoniated multi-arm polyethylene glycol, controlling the amount of polyethylene glycol grafted on the surface of graphene, and blending the polyethylene glycol-grafted graphene with polyethylene glycol to prepare a phase change energy storage material; and (2) preprocessing wood with a low-concentration sodium hydroxide and sodium sulfite solution, preparing a solution by using maleic anhydride as esterification agent and acetone as a solvent, impregnating the preprocessed wood in the solution, allowing the above obtained graphene / polyethylene glycol phase change energy storage suspension to infiltrate the wood by a vacuum pressurizing full-cell process,and regulating a multidimensional interpenetrating network structure to obtain the thermal conduction enhanced phase change energy storage wood. A firm amide bond can be formed between graphene and polyethylene glycol to ensure the stability of the phase change system.

Owner:BEIJING FORESTRY UNIVERSITY

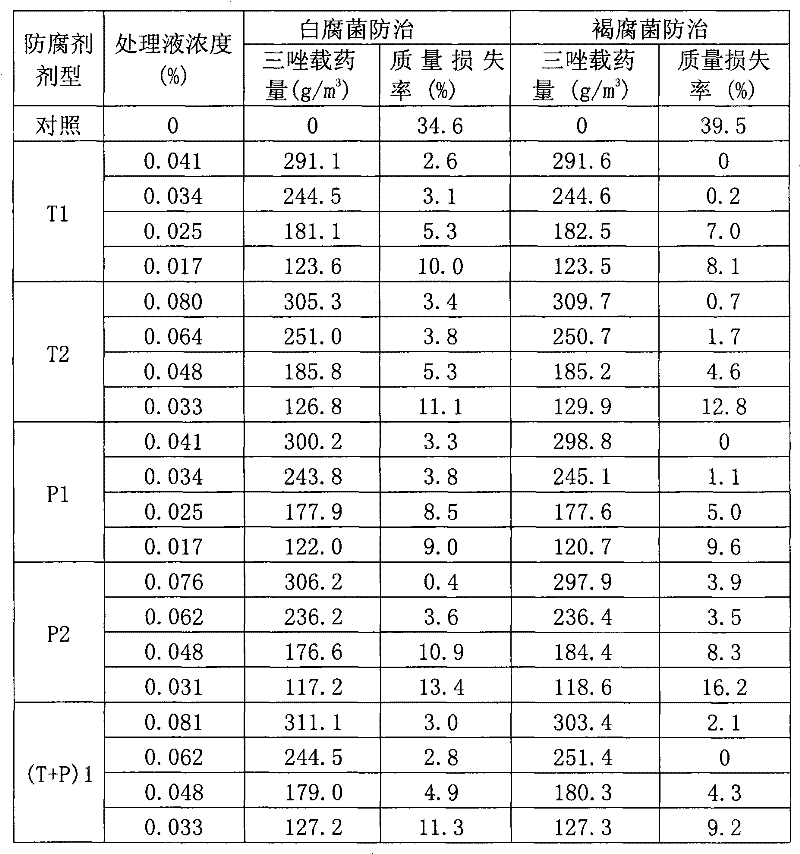

Water-soluble antiseptic anti-discoloration insect repellent composite for timber and bamboo wood as well as preparation method and application thereof

InactiveCN102232387AGood control effectAchieve anticorrosionBiocideFungicidesMethyl carbamateSolvent

The invention relates to a water-soluble triazole antiseptic anti-discoloration insect repellent composite for timber and bamboo wood as well as a preparation method and application thereof. Based on the total weight of the composite, the composite comprises the following components in percentage by weight: 3-8% of triazole compound, 24-48% of organic solvent, 24-40% of cosolvent, 3-10% of N-(2-benzimidazolyl)-methyl carbamate hydrochloride, 0-10% of prochloraz, 0.1-0.8% of esbiothrin insecticide and the balance of water, wherein the triazole compound is propiconazole, tebuconazole, cyproconazole or any combination of propiconazole, tebuconazole and cyproconazole. The composite can be used for processing timber and bamboo wood or timber and bamboo wood products indoor and outdoor. In the processing method, a vacuum pressurization or normal-pressure dipping method are used so that the processed timber and bamboo wood or timber and bamboo wood products have the antiseptic, anti-fungus discoloration and mothproof properties.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Method for manufacturing bamboo redwood

InactiveCN102528892ALarge specific surface areaImprove accessibilityWood working apparatusFlat articlesFiberResin adhesive

A method for manufacturing bamboo redwood includes steps of selecting and cutting off materials, and radially splitting a bamboo barrel into 10 to 15 equal parts by a bamboo cutting machine; removing bamboo green parts, bamboo yellow parts and bamboo joints by a bamboo slicer, and preparing bamboo chips in certain sizes; grinding the bamboo chips, dividing the bamboo chips into threads, subjecting bamboo bundles to activating treatment: applying dyeing adhesive; dipping the bamboo bundles in dyeing phenolic resin adhesive solution for 3 minutes to 5 minutes in a pressurization manner, manually paving dyed adhesive-dipped bamboo bundles longitudinally to form a plate blank with a certain thickness; feeding the blank into a hot press to realize solidifying and forming, and preparing a reconstructed bamboo plate; and finally splitting and sawing the bamboo plate according to needs, and processing and using the bamboo plate. The dyeing phenolic resin adhesive solution contains from 20 to 40% of solid. The crystallinity of bamboo fibers and the specific surface areas of the bamboo bundles are reduced by means of pressurized activating treatment, accessibility and leaching resistance of dye are improved, imitated redwood bamboo furniture and decorative materials are manufactured, and additional values of reconstructed bamboo are increased by 40% at least under the condition that cost is seldom increased.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

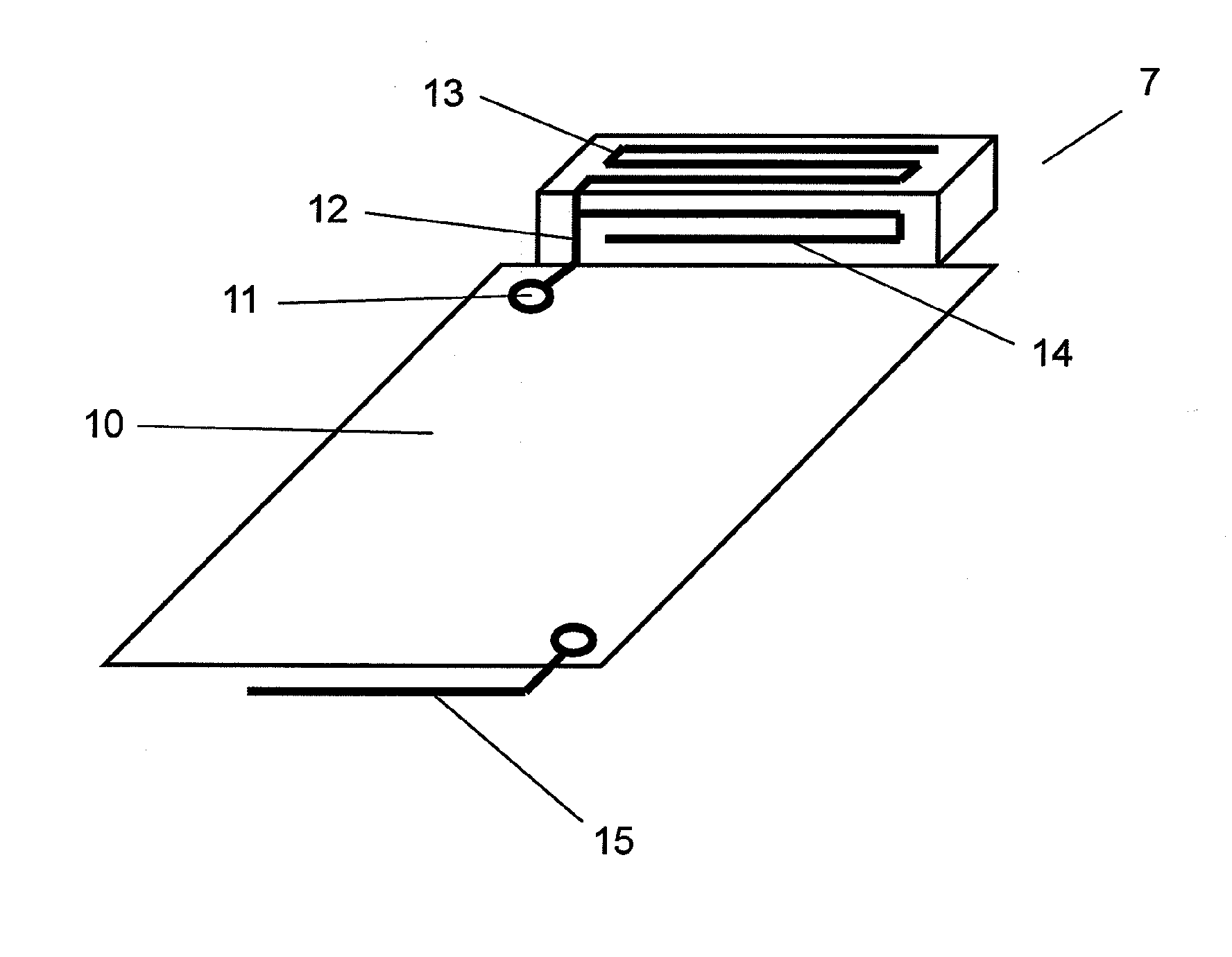

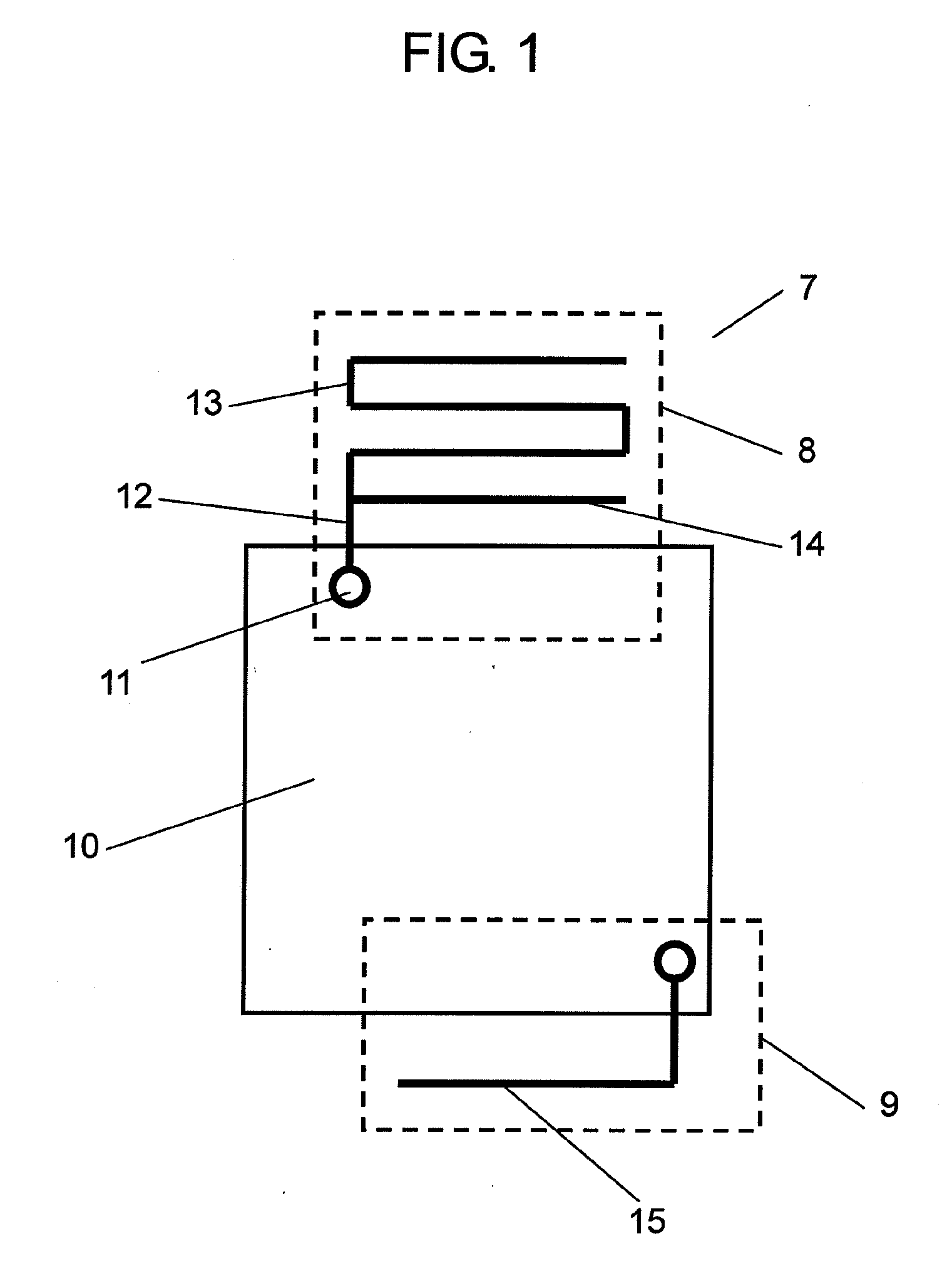

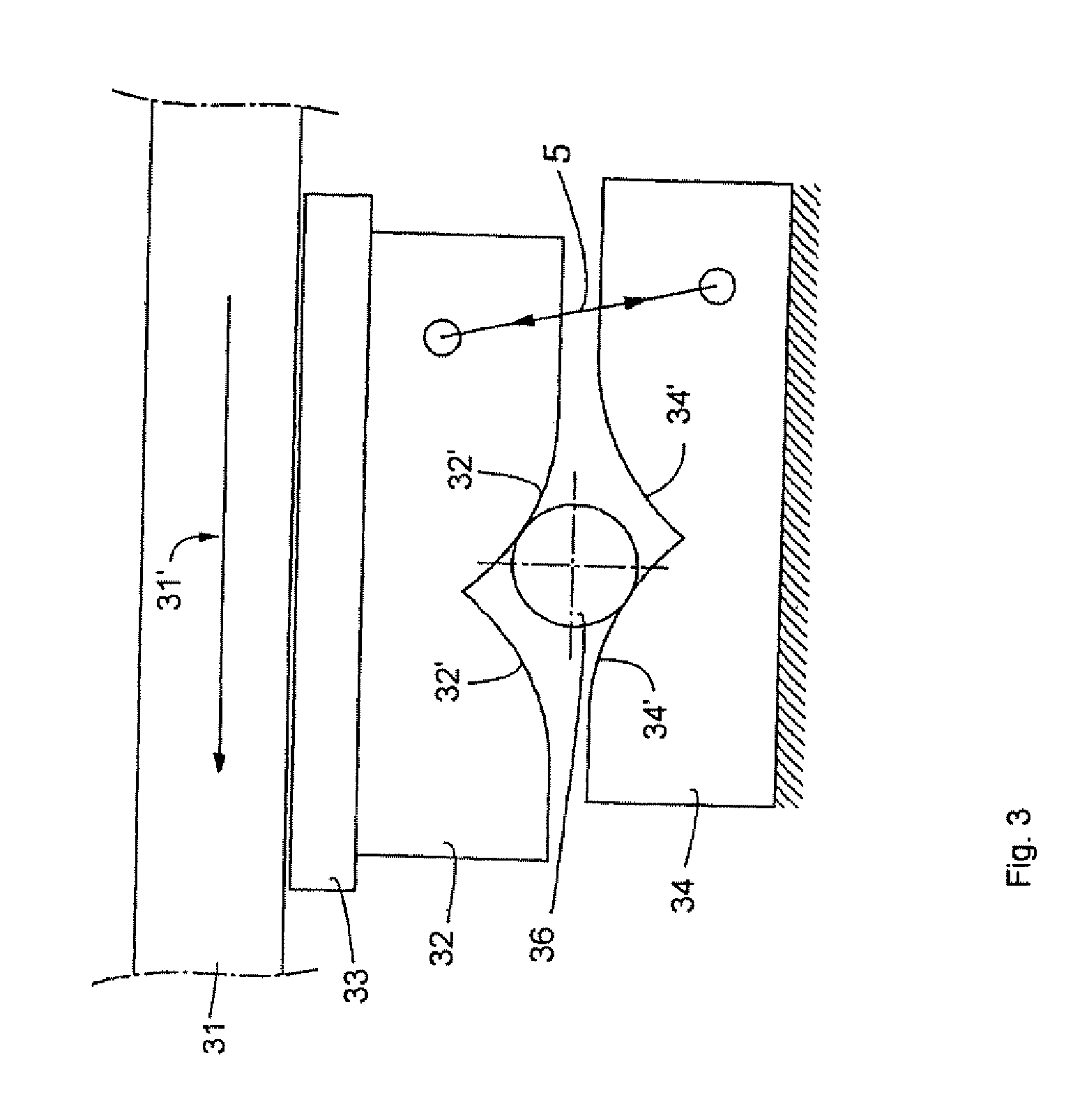

Antenna device and electronic apparatus using the same

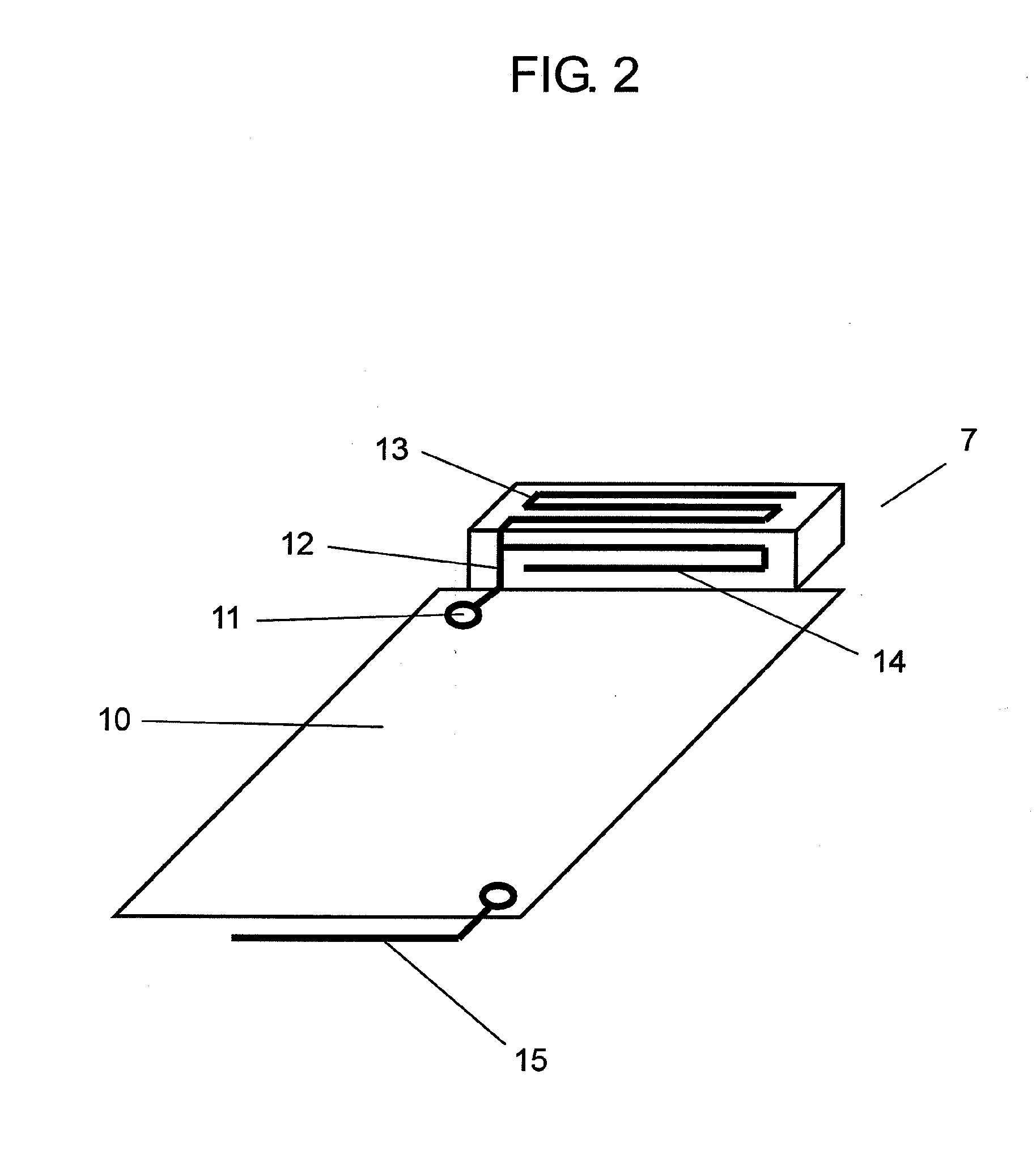

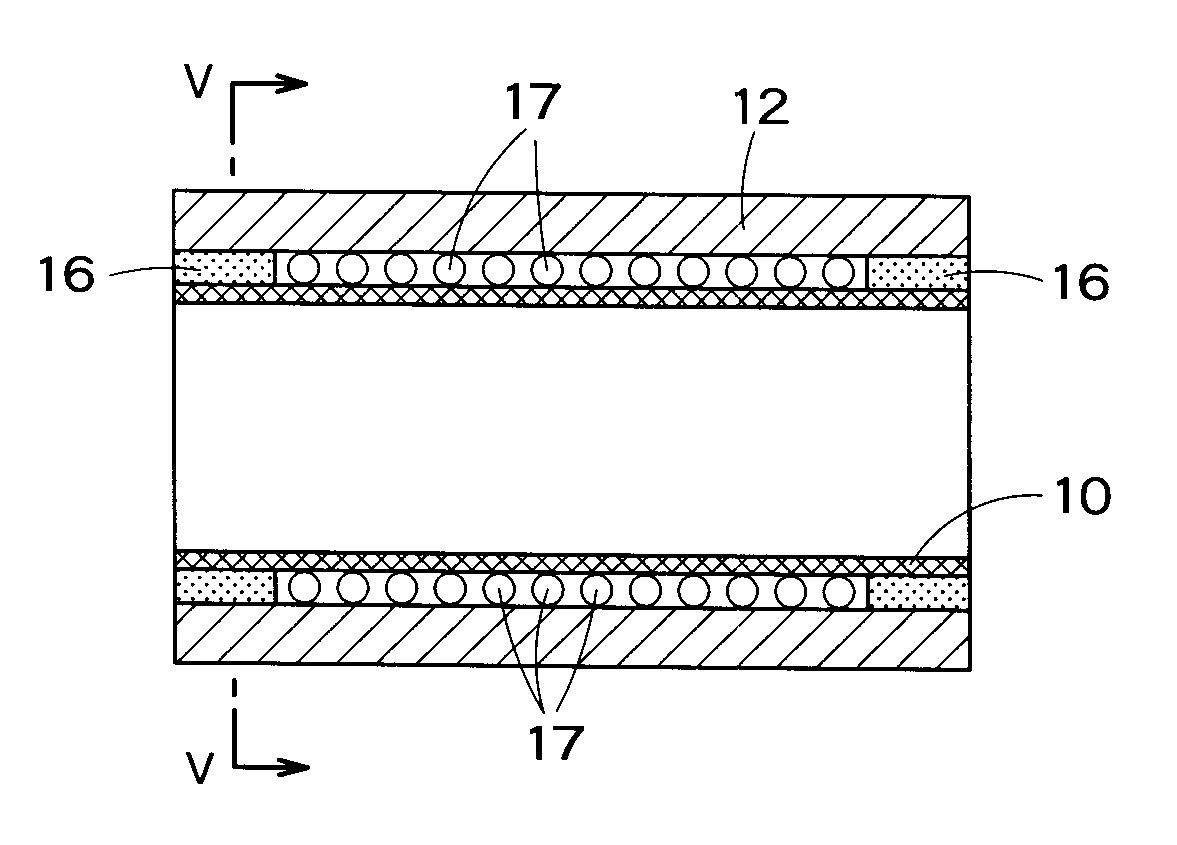

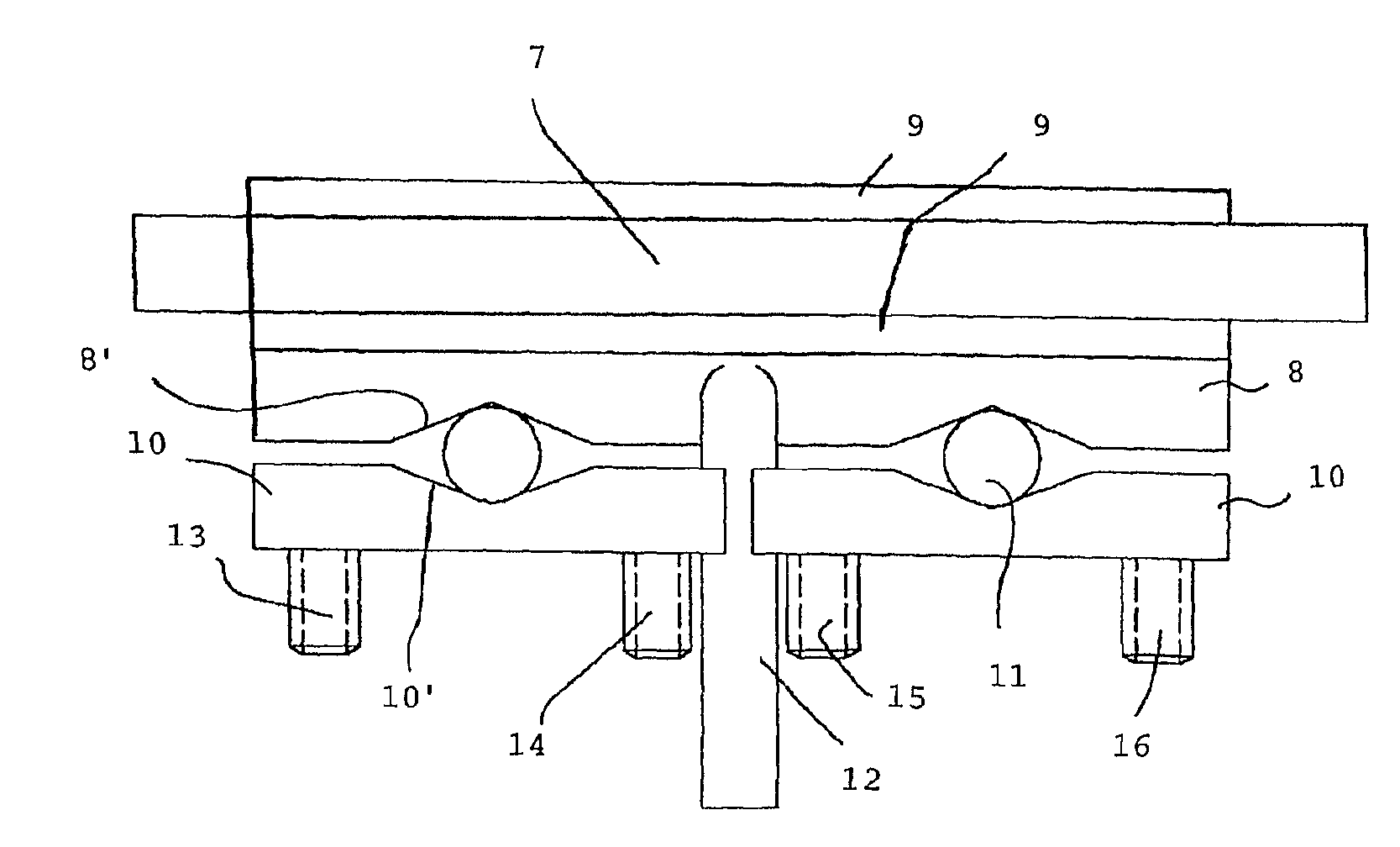

InactiveUS20100066615A1Improve reception qualityDecreases radiation resistanceSimultaneous aerial operationsAntenna supports/mountingsElectrical conductorEngineering

The present invention improves reception quality in an electronic apparatus including plural antenna devices. For this purpose, first antenna device (8) of electronic apparatus (7) according to the present invention includes ground organizer (10); feeding unit (11) placed on ground organizer (10); first antenna conductor (12) with its one end connected to feeding unit (11); and second antenna conductor (13) and third antenna conductor (14) both branch connected to the other end of first antenna conductor (12). The sum of the length of first antenna conductor (12) and that of second antenna conductor (13) is substantially (¼+n / 2) times the wavelength of a signal in the first frequency band, and additionally the sum of the length of second antenna conductor (13) and that of third antenna conductor (14) is substantially (½+m / 2) times the wavelength of a signal in the second frequency band.

Owner:PANASONIC CORP

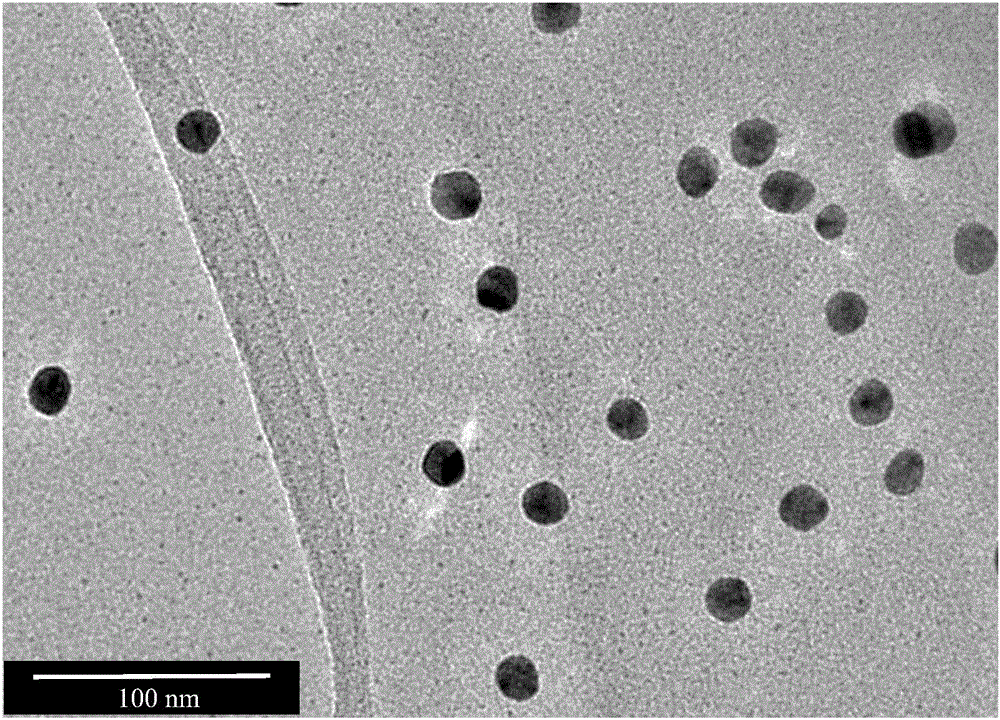

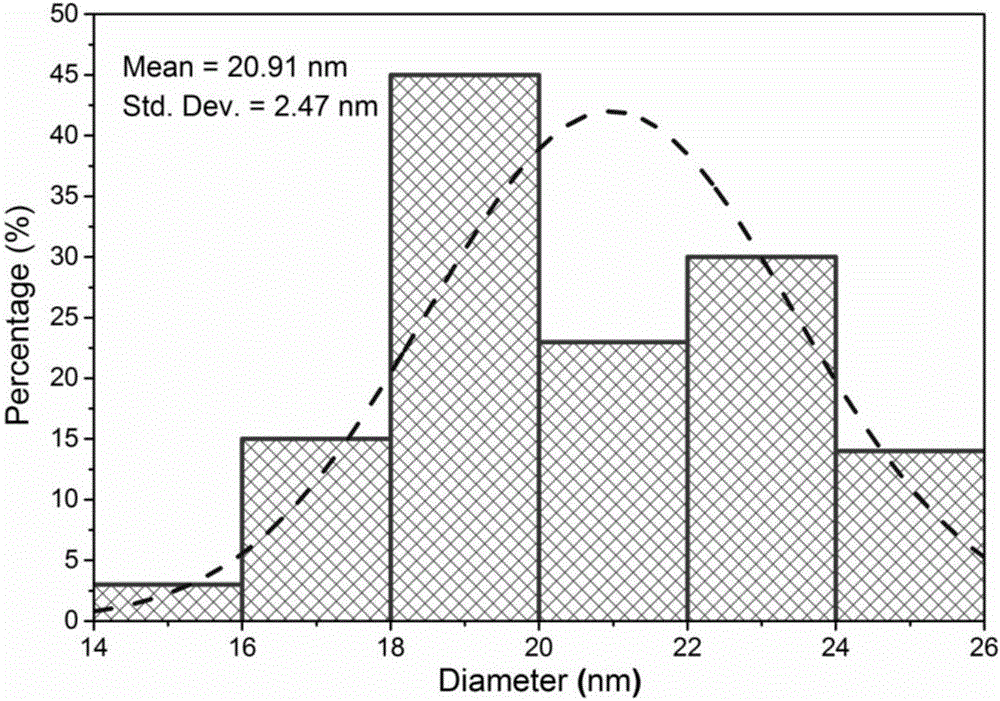

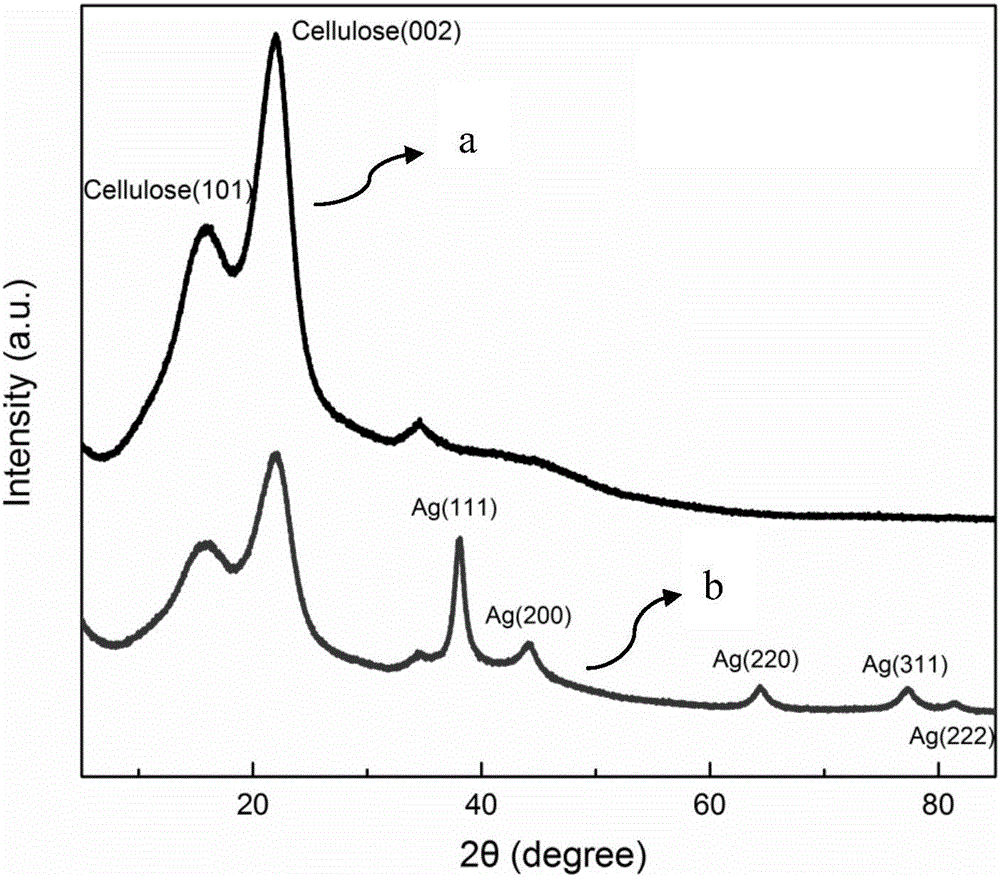

Environment-friendly long-acting type nano-silver base wood and bamboo material antibacterial mould inhibitor and preparing method and application thereof

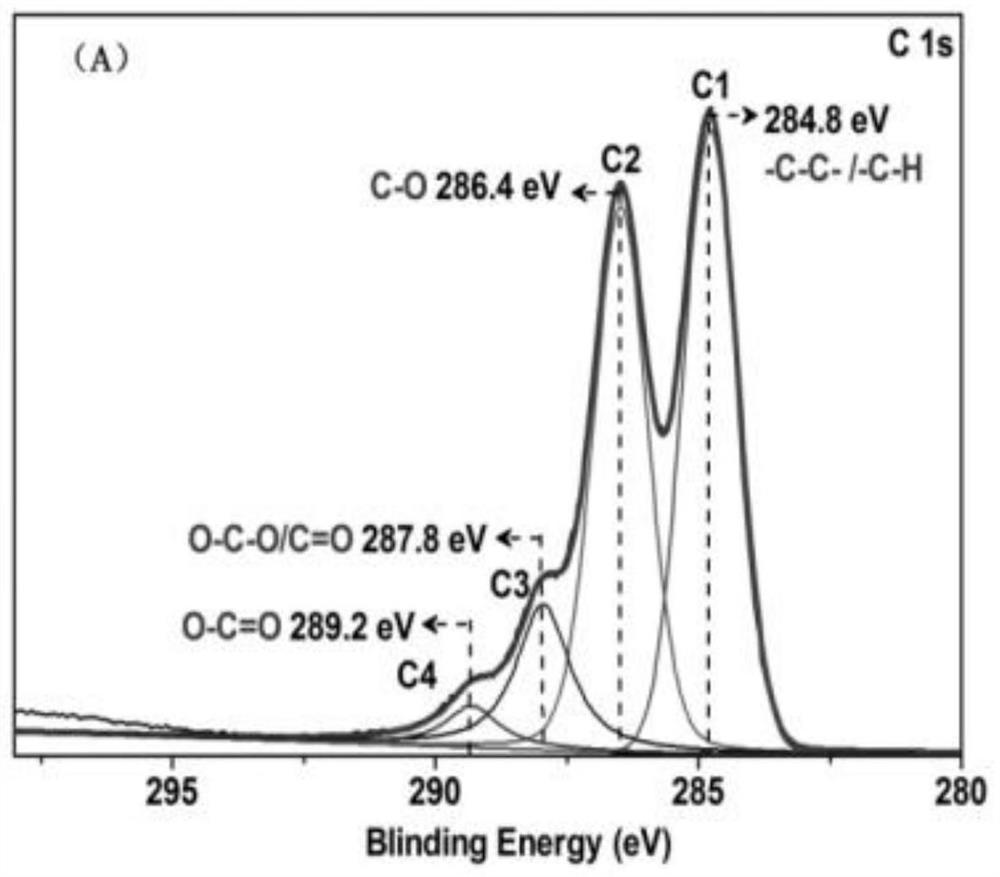

InactiveCN106217542AImprove the sustained release effectImproves loss resistanceWood treatment detailsNanotechnologySolventPollution

The invention relates to an environment-friendly long-acting type nano-silver base wood and bamboo material antibacterial mould inhibitor and a preparing method and application thereof. The antibacterial mould inhibitor is rapidly prepared with carboxymethyl chitosan, silver salt and a reducing agent serving as raw materials and water serving as a solvent through an efficient microwave radiation method. According to the prepared nano-silver base wood and bamboo material antibacterial mould inhibitor, silver nanoparticles are uniform in particle size and are evenly distributed in a carboxymethyl chitosan base, and agglomeration is not likely to happen; the nano-silver base wood and bamboo material antibacterial mould inhibitor can be well combined with a wood and bamboo material, has high wide spectrum efficiency and is high in loss resistance and durable in antibacterial effect; and in addition, the particle size is small and viscosity is low so that the antibacterial mould inhibitor can better enter a processed material. According to the method, the raw materials are cheap, the technology is simple, operation is convenient, the production efficiency is high, the product reproducibility is high, no complex and expensive equipment is needed, no pollution is caused to the environment, energy consumption is reduced, and industrial popularization is facilitated.

Owner:BEIJING FORESTRY UNIVERSITY

High-performance wood-plastic material for 3D printing forming and preparation method of wood-plastic material

InactiveCN106752012AWide operating temperature rangeHigh mechanical strengthAdditive manufacturing apparatusEngineering plasticAlloy

The invention belongs to the technical field of wood-plastic composites and preparation methods of the wood-plastic composites, and particularly relates to a high-performance wood-plastic material for 3D printing forming and a preparation method of the wood-plastic material. A high-performance wood-plastic wire rod for 3D printing and a preparation method of the wood-plastic wire rod aim to solve the problems of poor size stability and low mechanical strength of the existing wood-plastic material for the 3D printing. The wood-plastic wire rod for the 3D printing forming comprises a modified plant material, engineering plastic or a plastic alloy, a coupling agent or an interfacial compatibilizer, a lubricant, a heat stabilizer and a mineral packing, wherein the modified plant material is a plant material after modification. The preparation method of the wood-plastic wire rod comprises the steps that the plant material is subjected to modification treatment and mixed with other raw materials (or a modifier, the plant material and extruded raw materials are directly mixed); melt blending is performed; a blend compound is added to an extruder; extrusion and wire drawing are performed to obtain the wood-plastic wire rod for the 3D printing.

Owner:NORTHEAST FORESTRY UNIVERSITY

Flame-retardant thermal modification wood and preparation method thereof

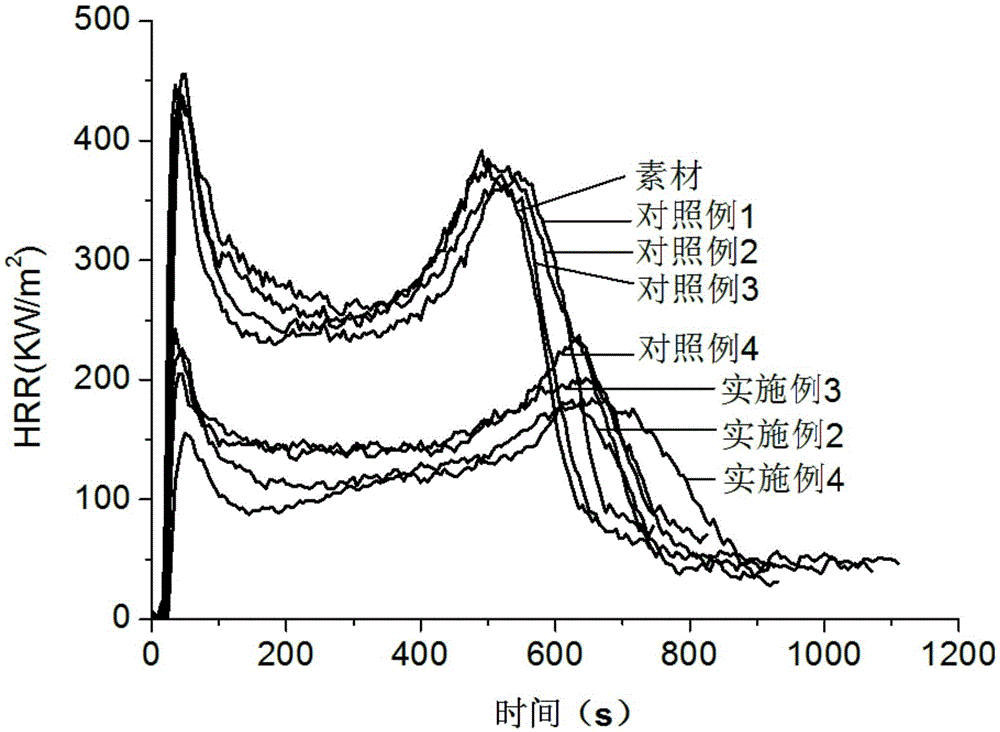

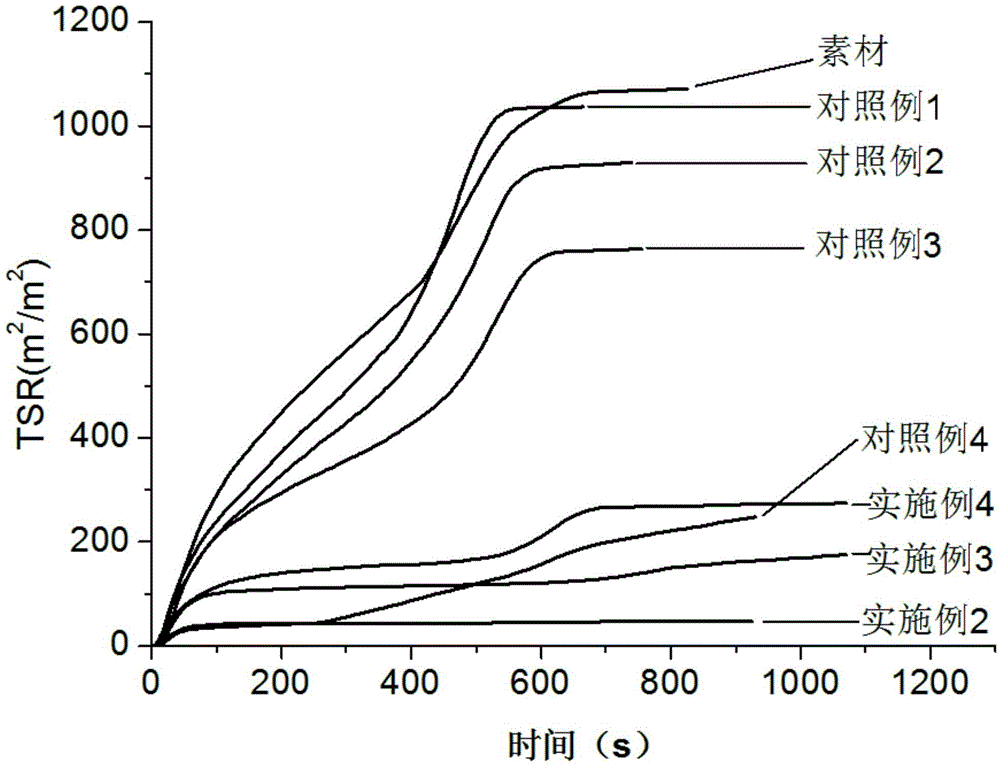

ActiveCN105666612AImprove fire safetyGood surface decorationWood treatment detailsThermal wood treatmentCombustionMaterials science

The invention relates to flame-retardant thermal modification wood and a preparation method thereof. The preparation method comprises the step that after being subjected to immersion treatment, the wood is subjected to heat treatment. According to the flame-retardant thermal modification wood and the preparation method thereof, the flame-retardant thermal modification wood is prepared by combining the wood high-temperature heat treatment with the wood flame-retardant technology; the dual characteristics that the wood is subjected to high-temperature heat treatment and flame retarding are achieved at the same time; the flame-retardant thermal modification wood has the good surface decorative performance, dimensional stability and the like, and the excellent flame-retardant property is also achieved; the combustion heat release rate and smoke production are substantially decreased, and the fireproof safety of processed wood products is greatly increased.

Owner:BEIJING FORESTRY UNIVERSITY

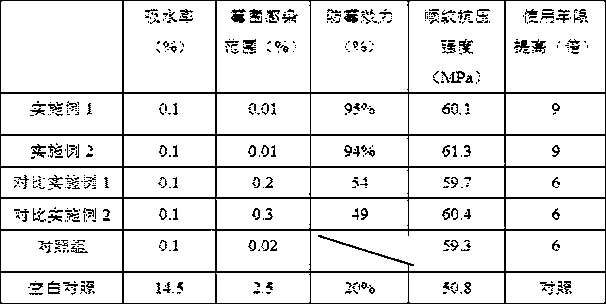

Melt supply pipe for aluminum die casting and method for producing the same

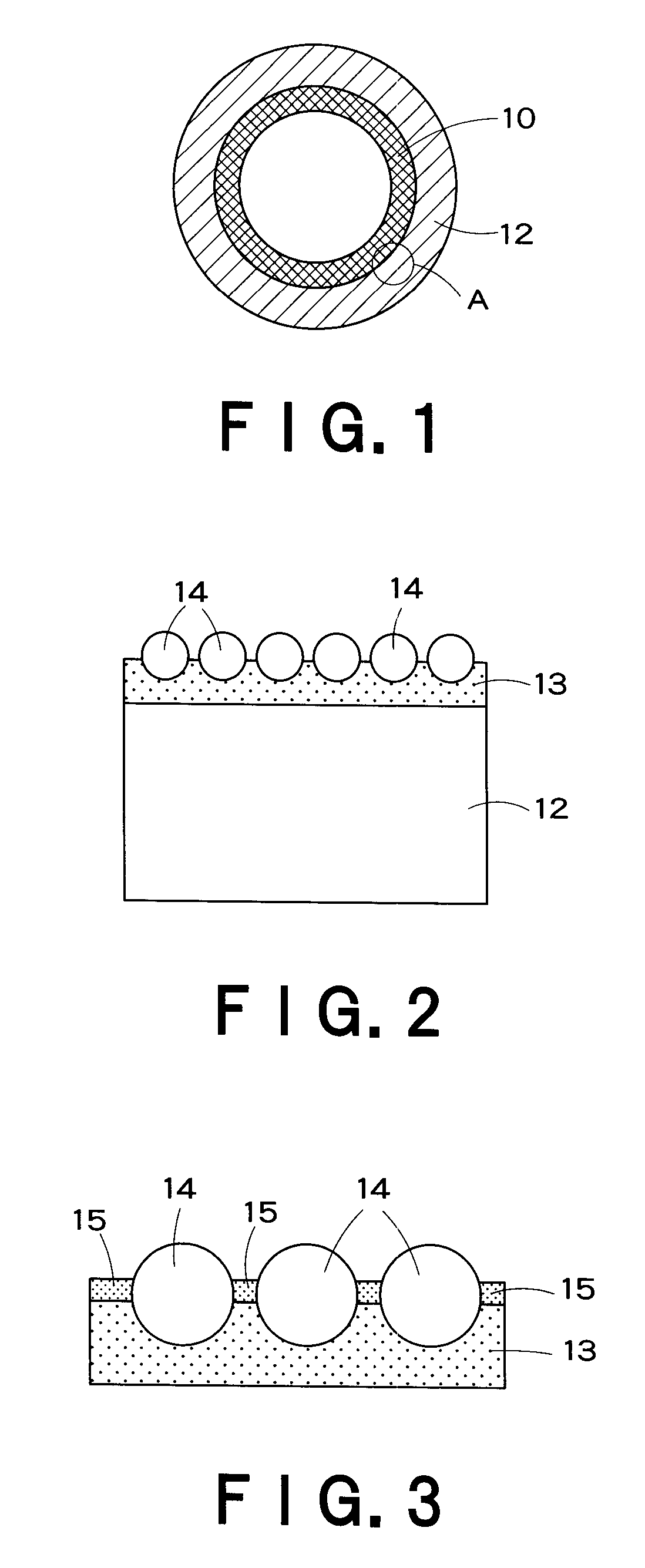

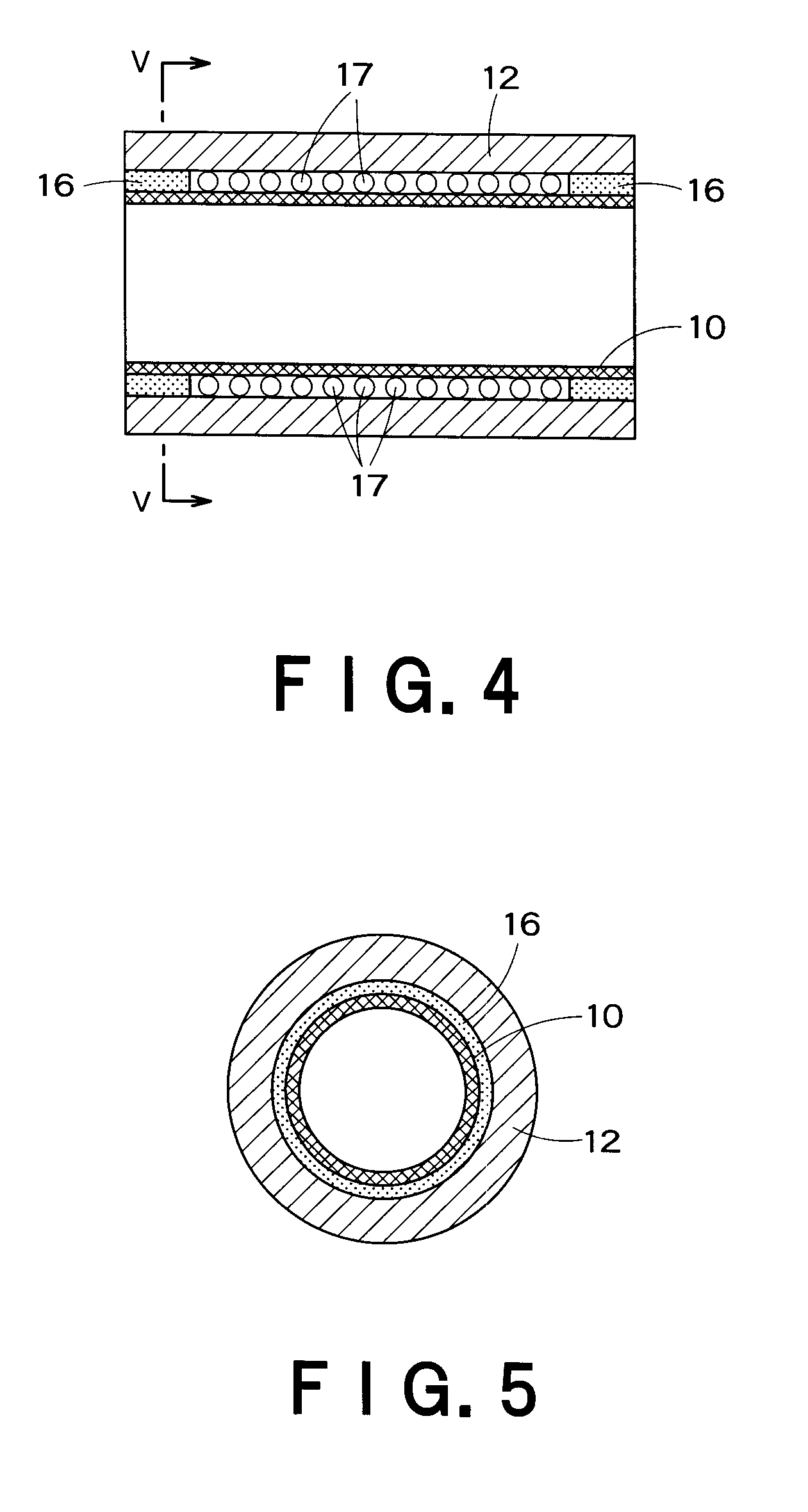

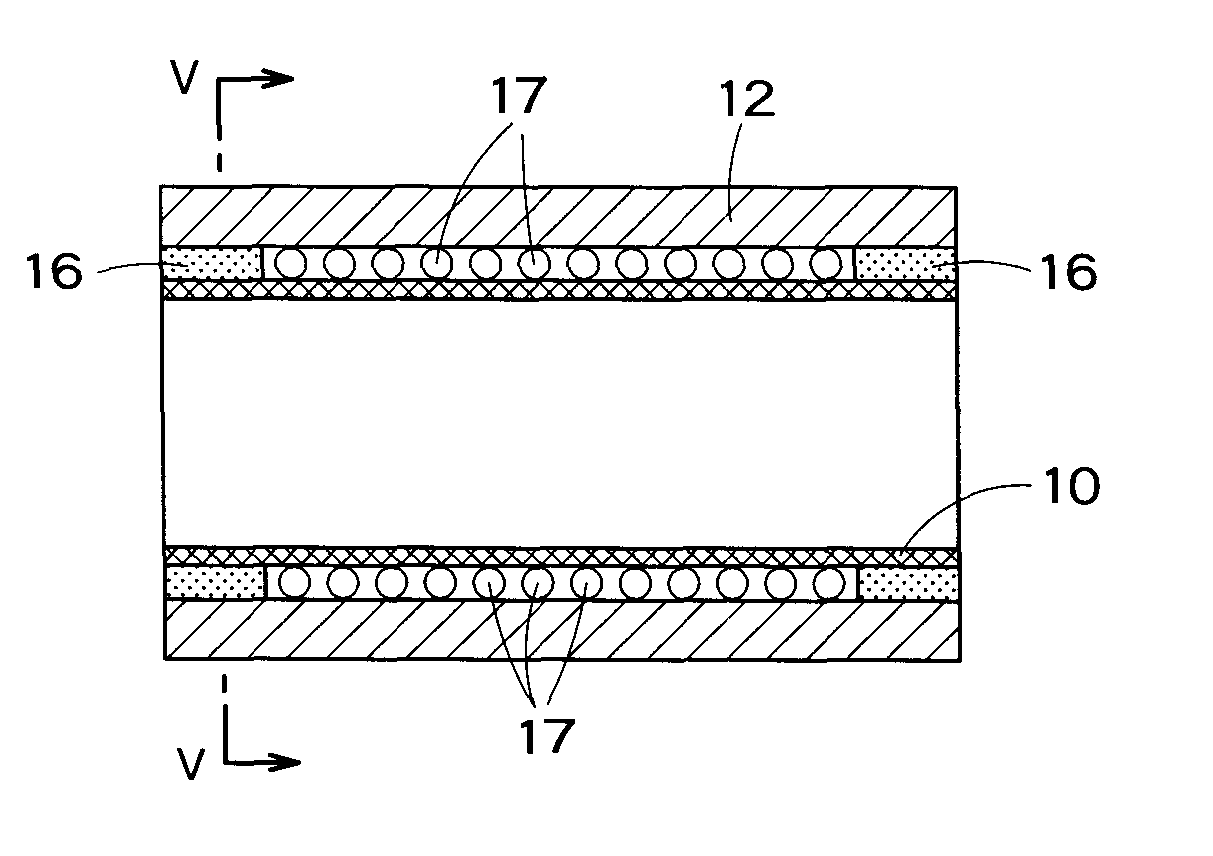

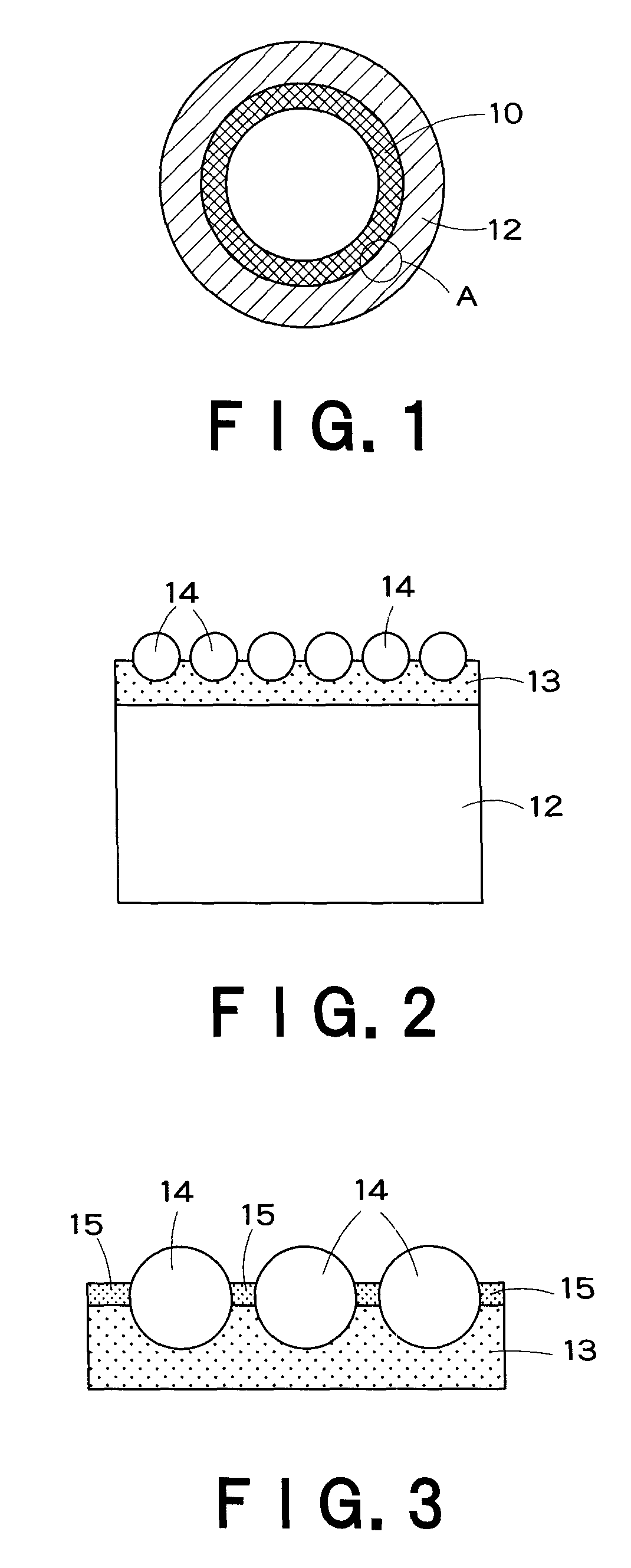

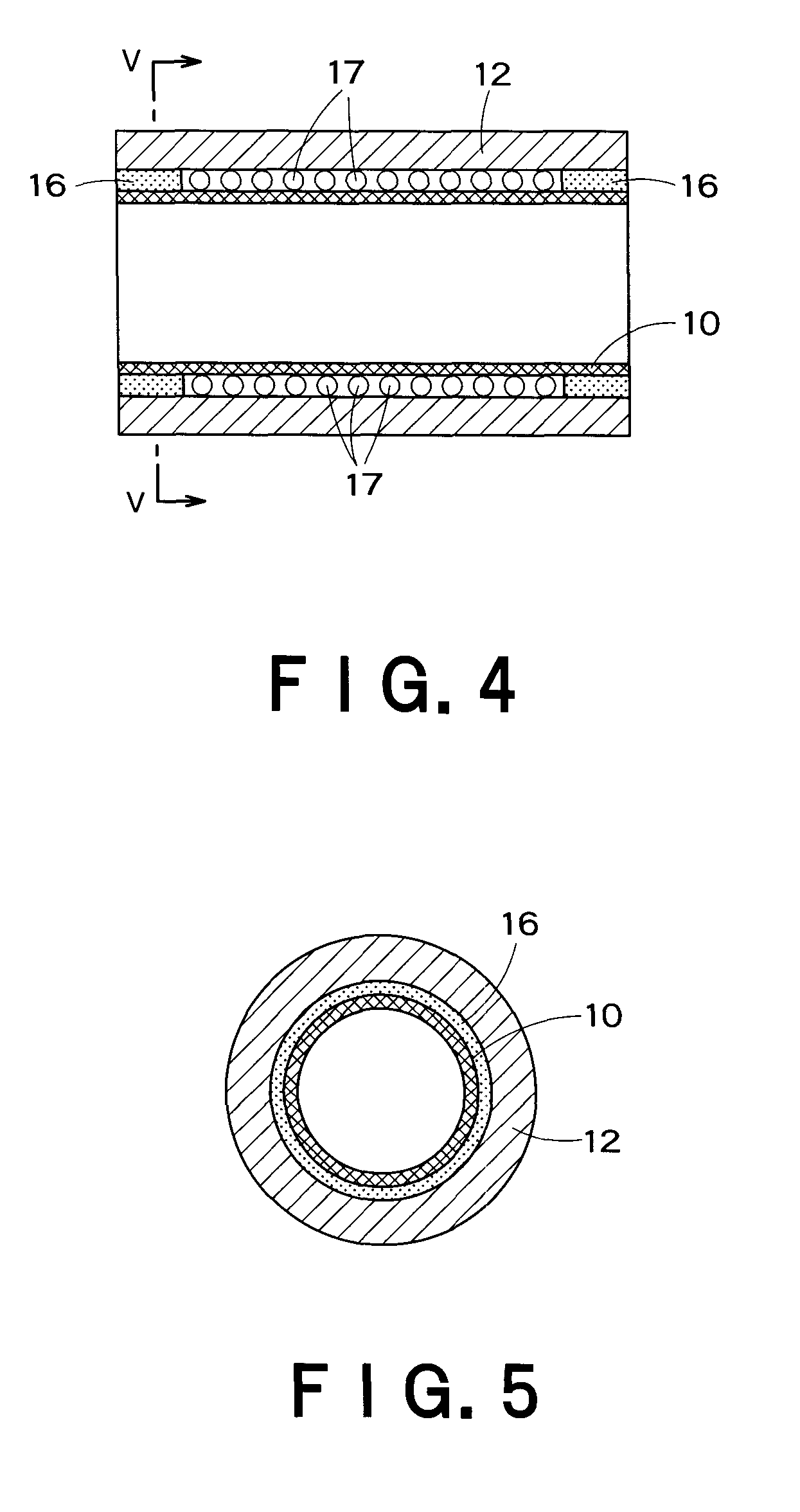

InactiveUS20070144627A1Strong impactImproves loss resistanceTuyeresBlast furnace detailsDie castingMechanical impact

There is provided a melt supply pipe for aluminum die casting which is strong to mechanical impact and is excellent in the melting loss resistance to a molten aluminum alloy and which has a significantly extended life. The melt supply pipe for connecting a melting furnace and a plunger sleeve of a die casting machine, includes an inner ceramic pipe and an outer steel pipe fitted to the inner pipe, wherein a Ni alloy layer is formed over the inner circumferential surface of the outer steel pipe, and TiC particles are bonded to the surface of the Ni alloy layer.

Owner:TOSHIBA MASCH CO LTD

Production method of mould-proof, anti-bacterial and flame-retardant wall decoration bamboo curtain

InactiveCN104015241AGood dimensional stabilityIncrease holeCovering/liningsWood treatment detailsChemical synthesisPreservative

The invention discloses a production method of a mould-proof, anti-bacterial and flame-retardant wall decoration bamboo curtain. The production method is characterized by comprising the following steps: processing bamboo into bamboo chips, and removing organic matters by using a charring process to improve the permeability and the dimensional stability of the bamboo; splitting the bamboo chips into bamboo skins and bamboo filaments, soaking the bamboo skins and the bamboo filaments into saturated dicyandiamide solution containing an antibacterial agent namely silver-loaded titanium dioxide, and then soaking into saturated phosphoric acid solution containing a preservative; generating a guanylurea phosphate flame retardant by virtue of chemical synthesis reaction inside the bamboo skins and the bamboo filaments; finally, sewing or lining the bamboo skins and the bamboo filaments which are mould-proof, anti-bacterial and flame-retardant to prepare the wall decoration bamboo curtain with excellent mould-proof, anti-bacterial and flame-retardant properties. The production method has the advantages of good mould-proof, anti-bacterial and flame-retardant effects, durability, simple production process and the like. The mould-proof, anti-bacterial and flame-retardant wall decoration bamboo curtain prepared by virtue of the preparation method is mainly applicable to building decoration materials and plays an important role in efficiently utilizing bamboo materials, alleviating wood supply and demand contradiction and the like.

Owner:湖北楚风竹韵科技有限公司 +1

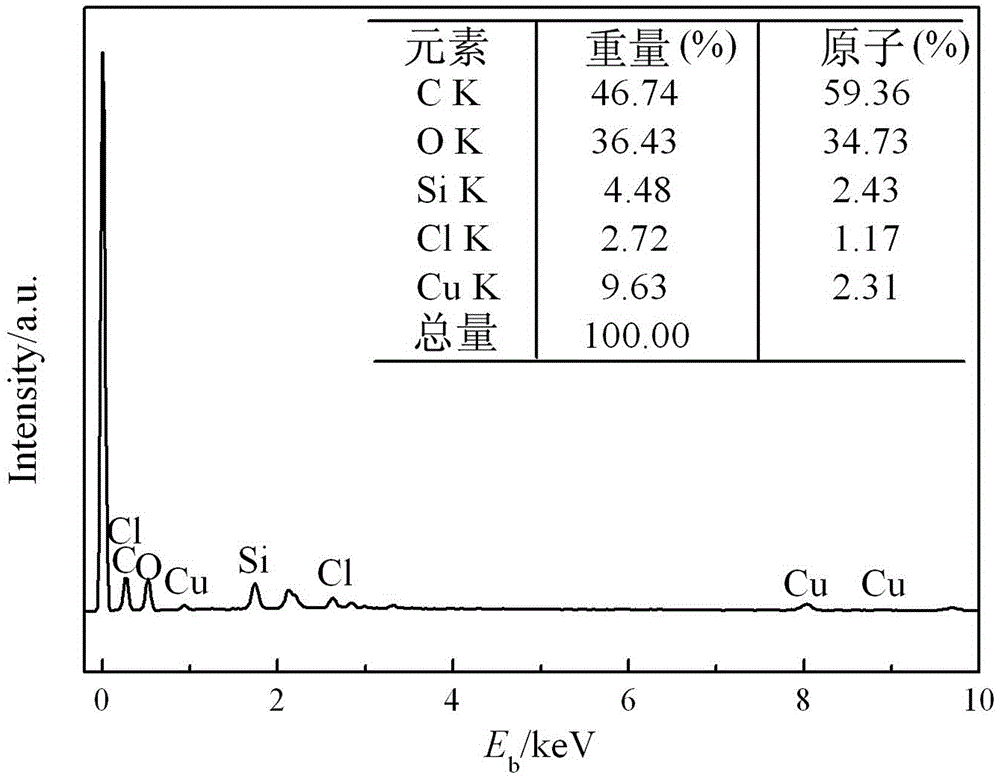

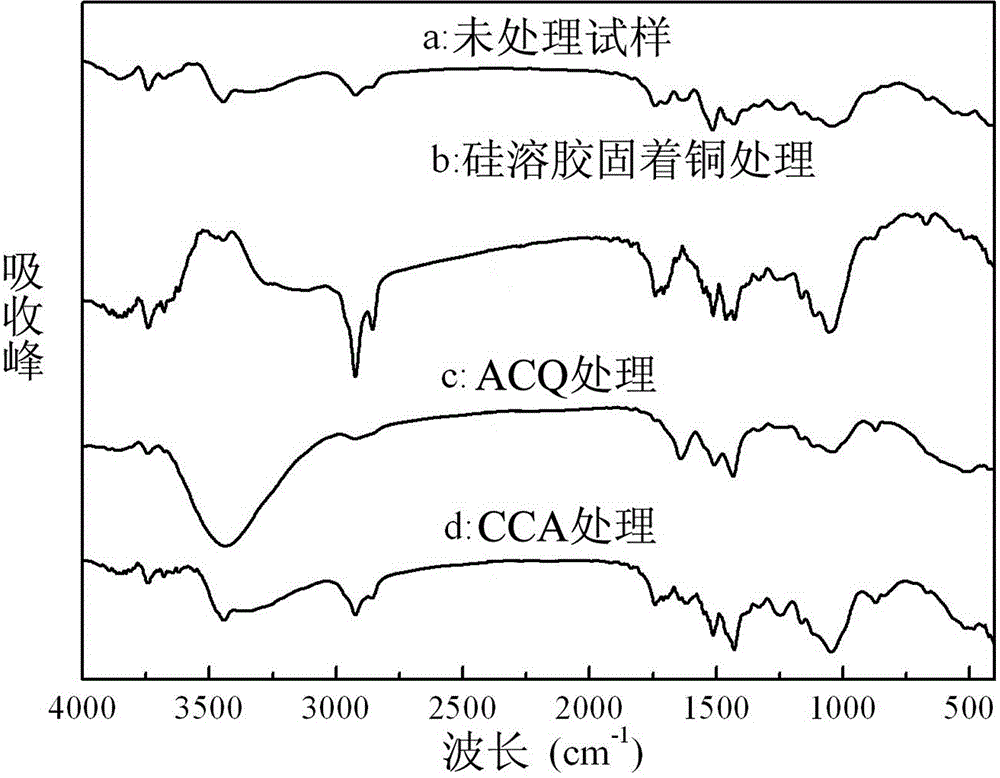

Preparation method of bamboo/wood mildew-resistant antiseptic

ActiveCN104526806AGood anti-loss performanceImproves loss resistanceWood impregnation detailsSilicic acidEthyl ester

The invention discloses a preparation method of a bamboo / wood mildew-resistant antiseptic. The preparation method comprises the following steps: weighing 60-150 parts by weight of tetraethoxysilane, sodium silicate solution or titanium tetrabutoxide at room temperature, slowly and dropwise adding tetraethoxysilane, sodium silicate solution or titanium tetrabutoxide into a mixed liquor of 40-75 parts by weight of anhydrous ethanol and 30-36 parts by weight of deionized water, and simultaneously treating the mixed liquor by water bath at 40-80 DEG C and stirring; adjusting pH to 3-4 by adding a proper amount of acid, and reacting for 30-45 min to prepare uniform sol; and slowly adding 3-12 parts by weight of an aqueous solution containing a copper compound into the sol under the condition of treating the sol by water bath at 40-80 DEG C and stirring, adding 5-15 parts by weight of an aminosilane coupling agent used as a guiding agent, fully stirring and reacting so as to prepare the bamboo / wood mildew-resistant antiseptic. The prepared bamboo / wood mildew-resistant antiseptic has excellent leach resistance and has simple components. The preparation method is simple, has relatively low production cost, is environmentally friendly and is less harmful to the health of human body.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

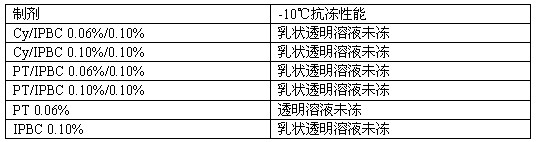

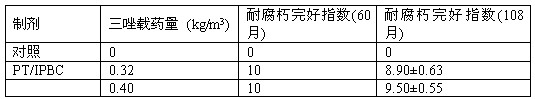

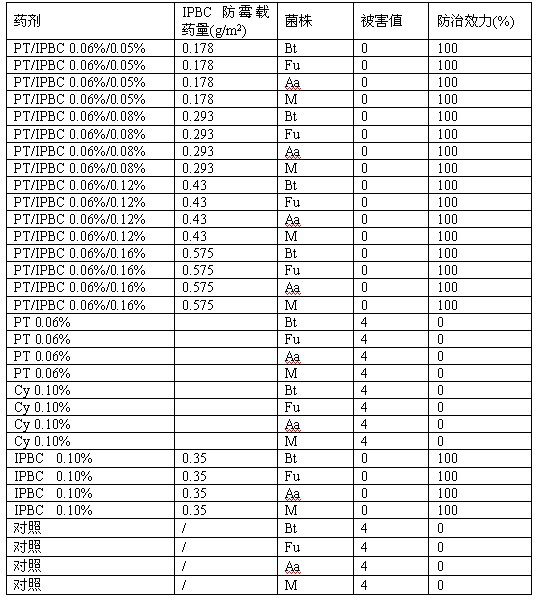

Wood and bamboo material corrosion and mold prevention modified combination agent and wood and bamboo material treating method

ActiveCN109015981AAnti-corrosionMildew proofWood treatment detailsReed/straw treatmentWater solubleFire retardant

The invention belongs to a wood and bamboo material corrosion and mold prevention modified combination agent and a wood and bamboo material treating method. The wood and bamboo material corrosion andmold prevention modified combination agent comprises, by weight, 0.04-0.10 part of triazole, 0.05-0.12 part of 3-iodo-2-propynyl butylcarbamate, 1-6 parts of water soluble dyes, 1-6 parts of dyeing assistants, 1-6 parts of fire retardants and 1-10 parts of polymerization inhibitors. A wood and bamboo material treated through the modified combination agent can simultaneously have the functions of corrosion prevention, mold prevention, dyeing, inflaming retarding and pharmaceutical composition loss resistance, and has the advantages of easy operation, easy implementation, low preparation and using cost, good durability and long service life.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

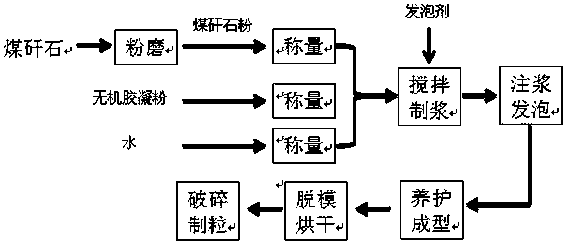

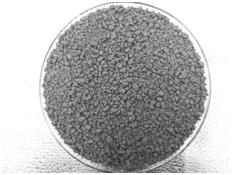

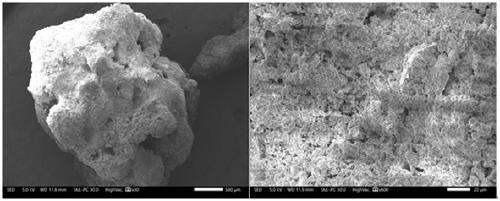

Coal gangue porous soil conditioner and preparation method thereof

InactiveCN111117629AEfficient use ofEasy to manufactureAgriculture tools and machinesOrganic fertilisersSoil scienceFoaming agent

The invention discloses a coal gangue porous soil conditioner and a preparation method thereof, belongs to the technical field of coal gangue utilization and soil conditioner preparation, and aims toprovide a preparation method for preparing a soil conditioner from coal gangue so as to solve the problems of resource utilization of the coal gangue and improvement of air permeability and water retention of hardened soil. The preparation method comprises the following steps: grinding the coal gangue into powder, adding a cementing material and water to prepare slurry, adding a foaming agent intothe slurry, carrying out injection molding foaming, carrying out maintenance molding on the foaming body, and crushing the molded block into particles to obtain the coal gangue porous soil conditioner. The porous soil conditioner prepared by taking the coal gangue as the main raw material not only can efficiently utilize the coal gangue on a large scale, but also can improve the soil performance,improve the water retention property, the loss resistance, the air permeability and the heat preservation property of soil, and is beneficial to plant growth and water and soil loss prevention.

Owner:SHANXI UNIV

Method for manufacturing anti-flaming wood blind blades

ActiveCN102825641AImproves loss resistanceImprove flame retardant performanceWood impregnation detailsSodium silicateFire retardant

The invention relates to a method for manufacturing wood blind blades with anti-firing and anti-flaming functions, which belongs to a wood processing industry. The method for manufacturing anti-flaming wood blind blades sequentially comprises the following steps of wood blind blades manufacture, dipping anti-flaming treatment, drying treatment, sanding treatment and paint treatment, wherein the dipping anti-flaming treatment comprises primary dipping and secondary dipping, the primary dipping is carried out by dipping the wood blind blades into water solution of a primary flame retardant of a N-P-B system, the second dipping is carried out by taking out single plates after the primary dipping and putting the single plates in the water solution of a secondary flame retardant, the dipping time is 0.5-2 hours, the dipping temperature is 50-90 DEG C, and the secondary flame retardant comprises sodium silicate and transition metal salt. The method disclosed by the invention has the advantages of solving the flammable problem of the wood blind blades, having high stability, having strong leaching resistance and being safe and environment-friendly.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Multiple-effect timber fire retardant and its preparation method and treatment process

InactiveCN104647537AGood anti-loss performanceGood flame retardant performancePressure impregnationWood impregnation detailsPhosphoric acidAmmonium polyphosphate

The invention discloses a multiple-effect timber fire retardant and its preparation method and treatment process. The multiple-effect timber fire retardant comprises, by mass, 20-40% of phosphoric acid, 10-20% of dicyandiamide, 10-20% of melamine, 5-10% of boric acid, 5-20% of ammonium polyphosphate, 5-20% of silica sol, 3-8% of a smoke inhibitor, 0.5-3% of a surfactant and 0.1-2% of a mildew inhibitor. Compared with the existing timber fire retardant, the multiple-effect timber fire retardant has good fire retardant performances, good smoke inhibition performances, good loss resistance performances, large timber impregnation depth and good corrosion-resistant, mildew-resistant and mothproof effects. The preparation method has simple processes. The multiple-effect timber fire retardant has good timber protection and processing effects and is economical and practical.

Owner:高天红

Melt supply pipe for aluminum die casting

InactiveUS8333920B2Strong impactImproves loss resistanceTuyeresBlast furnace detailsMechanical impactDie casting

There is provided a melt supply pipe for aluminum die casting which is strong to mechanical impact and is excellent in the melting loss resistance to a molten aluminum alloy and which has a significantly extended life. The melt supply pipe for connecting a melting furnace and a plunger sleeve of a die casting machine, includes an inner ceramic pipe and an outer steel pipe fitted to the inner pipe, wherein a Ni alloy layer is formed over the inner circumferential surface of the outer steel pipe, and TiC particles are bonded to the surface of the Ni alloy layer.

Owner:TOSHIBA MASCH CO LTD

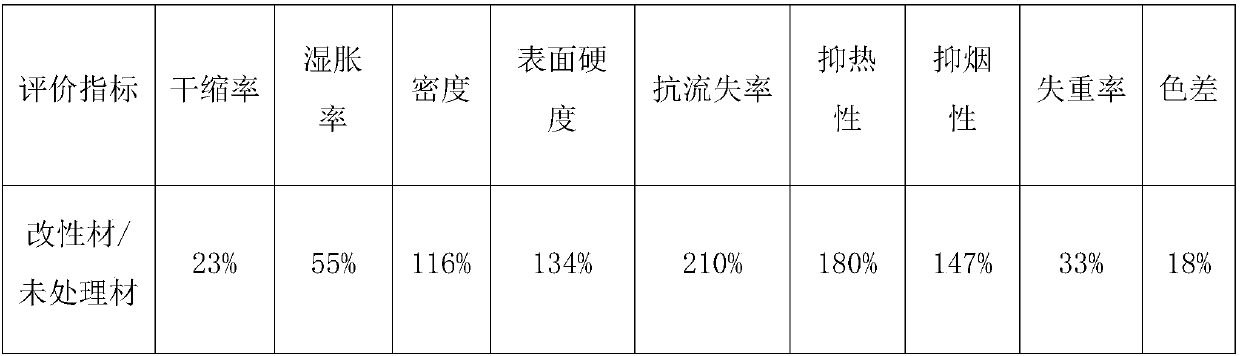

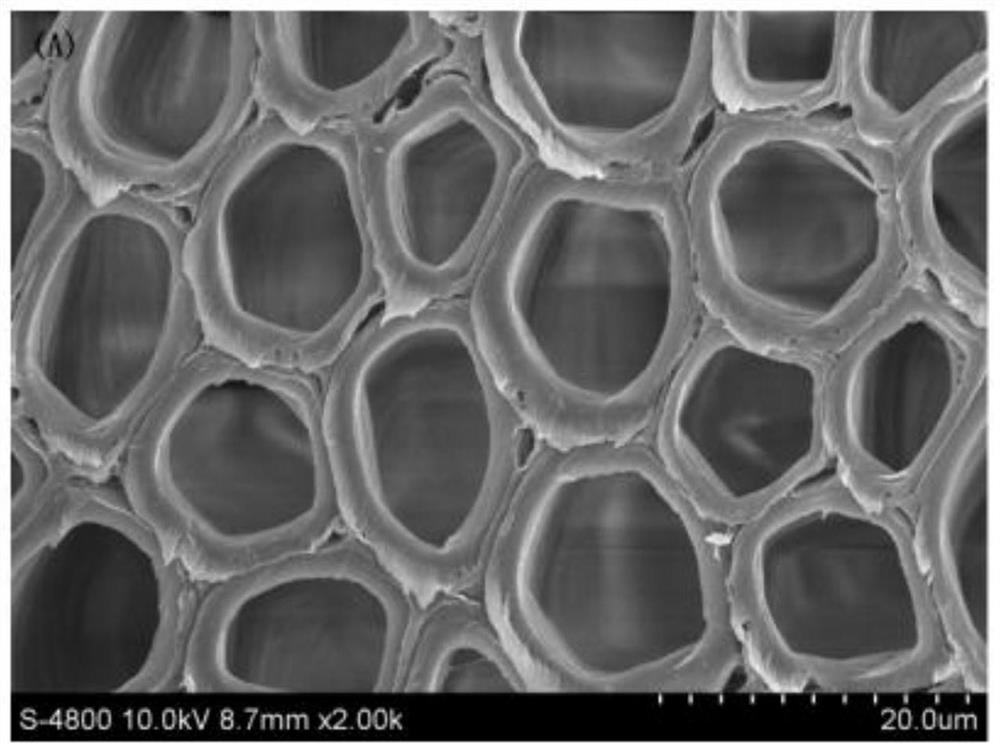

A kind of resin type silicate wood modifier and preparation method of modified material thereof

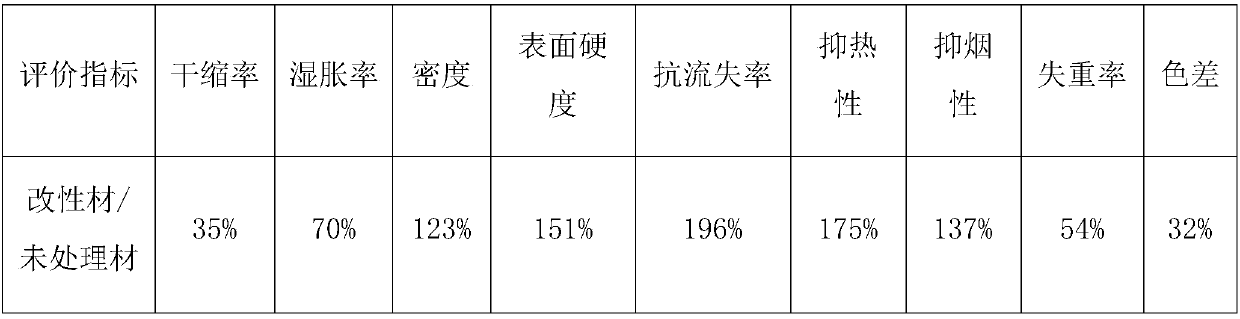

ActiveCN104044193BImproves loss resistanceGood dimensional stabilityWood impregnation detailsTougheningPollution

The invention belongs to a resin type silicate wood modifier and a preparation method of a modified material of the modifier. According to the preparation method, the resin type silicate wood modifier is prepared by taking melamine, formaldehyde, urea and soluble sodium silicate as main raw materials as well as respectively taking polyvinyl alcohol and diethylene glycol as a toughening agent and a stabilizer; the resin type silicate wood modifier can be stably stored for a long time and can be repeatedly recycled. The modifier has the advantages that the dimensional stability, the density, the surface hardness, the anti-bending strength, the anti-bending elastic modulus, the impact toughness and the wear resistance of artificial forest wood processed by virtue of the modifier are substantially improved, the modifier has the advantages that the flame retardance and environment-friendly effect are achieved, no pollution is caused to a human body and the environment, the leachability resistance of the modifier in the processed wood is improved, and the application value of the artificial forest wood is improved.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

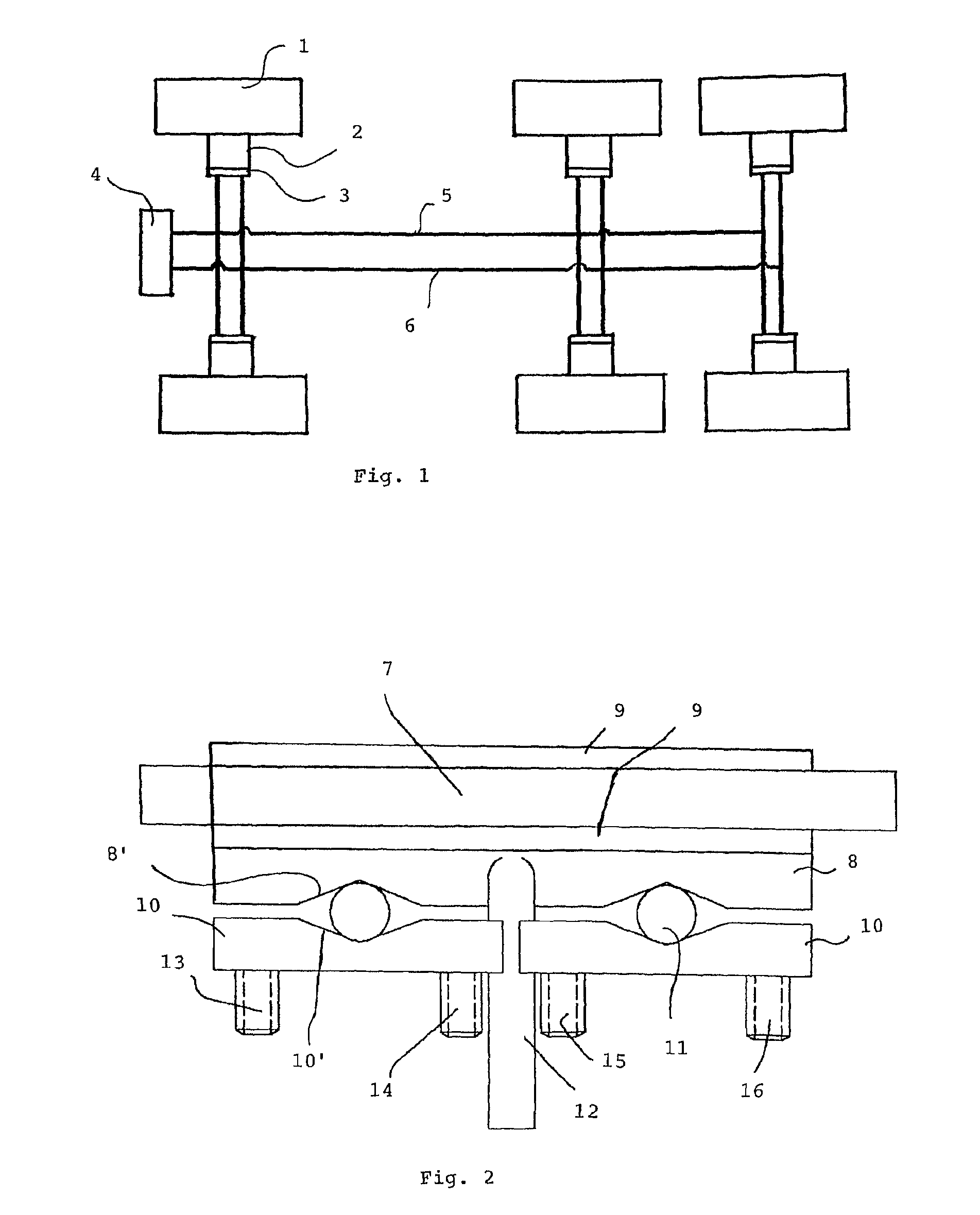

Brake System With Redundancy

InactiveUS20080156598A1Slack may be eliminatedGreat dimensionBraking element arrangementsMechanically actuated brakesBiological activationBraking system

The present invention concerns a brake system creating redundancy in electromechanical brakes. At least two drive units are provided at each single brake for activation of the brake. The at least two units may be controlled and / or energized separately. To safeguard the function the control and / or energy source systems are formed in two nets. The at least two units of each brake are connected to separate nets. The at least two units may be separate electrical motors.

Owner:HALDEX BRAKE PROD AB

Method of treating wood by means of impregnation in compounded mildewproof preservative liquid and high-temperature thermal treatment

InactiveCN108714947AGood anti-mildew effectInhibits mold growthRadiation/waves wood treatmentWood treatment detailsChemistryTitanium dioxide

The invention discloses a method of treating wood by means of impregnation in a compounded mildewproof preservative liquid and high-temperature thermal treatment. The method comprises the following steps: uniformly mixing a copper-containing compound impregnation liquid with a mildew preventive chitosan copper complex solution, a camphor tree leaf extract solution, a burdock leaf extract medicinalliquid and a nano titanium dioxide-Chinese herbal medicine compound preservative liquid to obtain the compounded mildewproof preservative liquid; impregnating wood in water for ultrasonic cleaning, drying the wood to a constant weight, impregnating the wood in the compounded mildewproof preservative liquid to be treated in a vacuum state, then pressurizing and impregnating the wood, taking the wood out, and drying the wood to a constant weight; putting the impregnated wood in a thermal treatment tank, setting the pressure of a steam generator and the vapor carbonizing pressure, and discharging oxygen in the thermal treatment tank after treatment; stopping steam thermal treatment, starting electric heating treatment, and setting the thermal treatment temperature for thermal treatment; andstarting the steam generator and introducing steam into the tank to reduce the temperature to obtain the mildewproof preservative wood. The wood is impregnated and pressurized by the compounded mildewproof preservative liquid, the thermally treated wood is obtained by applying a wood thermal treatment technology, and the mildewproof efficacy of the wood is good.

Owner:阜南县创发工艺品有限公司

Process method for modifying preservative treatment material based on nanometer silicon dioxide and emulsified wax

InactiveCN108032393AGood dimensional stabilityHigh densityWood treatment detailsPretreatment apparatusWaxWeather resistance

The invention relates to the technical field of preservative treatment material production, and discloses a process method for modifying preservative treatment material based on nanometer silicon dioxide and emulsified wax. The process method mainly comprises the following steps of firstly, performing pretreatment, secondly, preparing a nanometer silicon dioxide modifier, next, preparing emulsified wax or preservative modification liquid, then carrying out three-time dipping treatment, and finally drying. According to the process method for modifying the preservative treatment material based on the nanometer silicon dioxide and the emulsified wax, the preservative treatment material has no obvious appearance change after being subjected to the treatment, however, size stability, density, surface hardness, anti-loss performance, fire resistance and weather resistance of the preservative treatment material are greatly improved.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

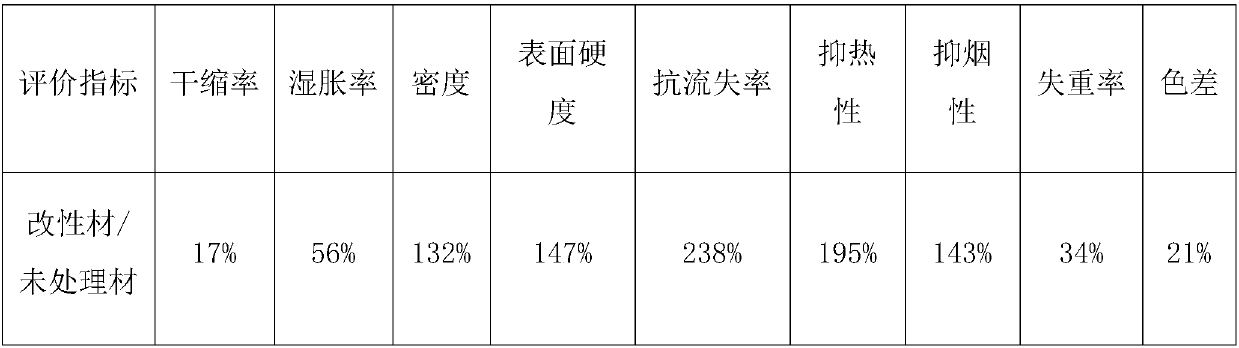

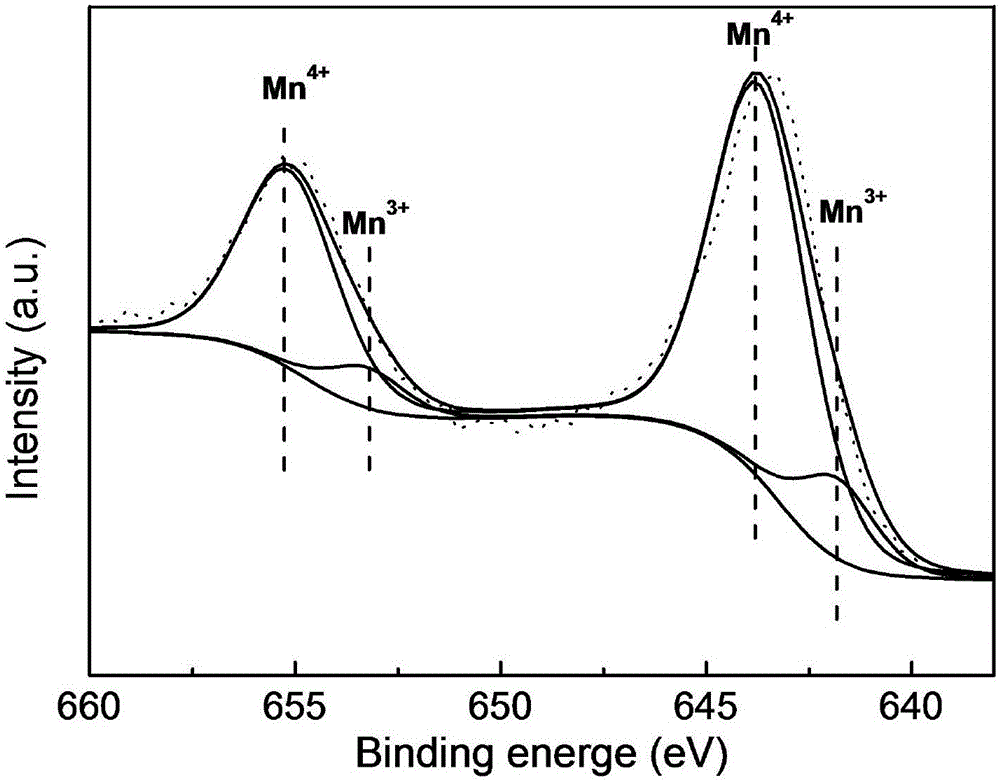

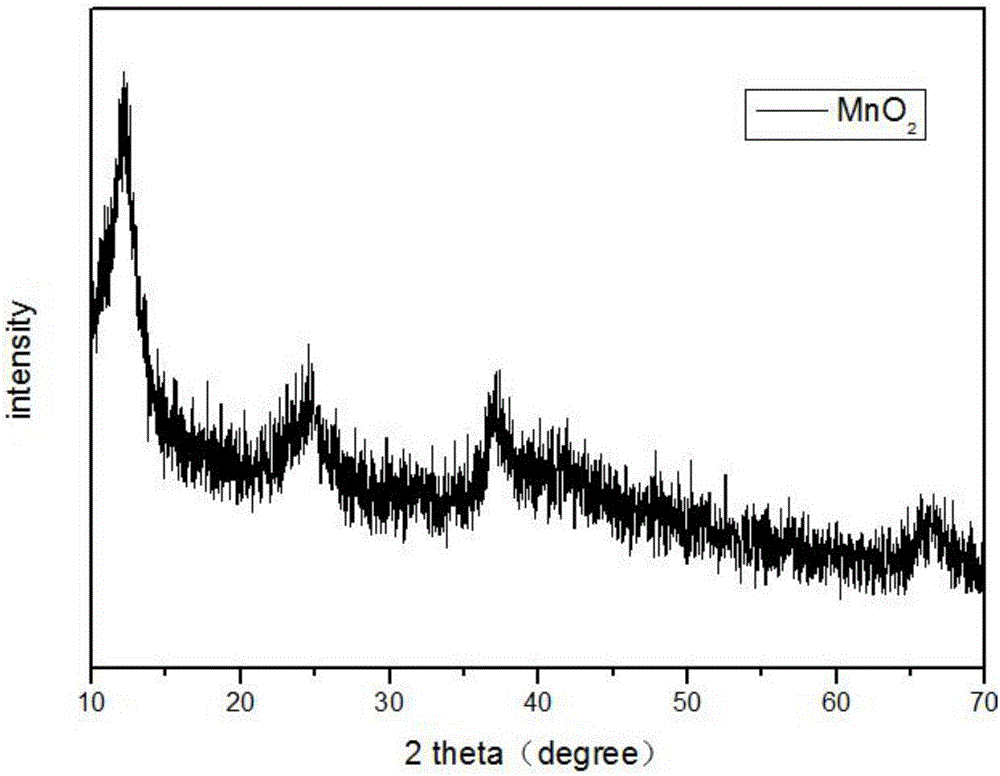

Wet oxidation catalyst and preparation method thereof

ActiveCN106807364AImproves loss resistanceGood activity at low temperatureWater contaminantsManganese oxides/hydroxidesManganeseOxidizing agent

The invention provides a wet oxidation catalyst and a preparation method thereof. The preparation method for the wet oxidation catalyst comprises the steps of mixing precursor manganese salt and water; dripping an alkaline solution to an obtained mixture to adjust the pH value to an alkaline value; dripping oxidizing agents such as hydrogen peroxide and so on to the mixture to carry out oxidation reaction on the mixture; after mixing the oxidized manganese salt solution and hydrogen peroxide, carrying out hydrothermal reaction on the mixed manganese salt solution and hydrogen peroxide; filtering an obtained reactant to obtain a solid; drying and roasting the obtained solid in the oxygen atmosphere to obtain the catalyst. The wet oxidation catalyst provided by the invention has the advantages of low price, good low temperature activity and stability and good loss resistance.

Owner:XIAMEN UNIV

Wood preservative treatment method

The invention provides a wood preservative treatment method. The method comprises the following steps: (1) sawing the sapwood of a standing tree until heartwood is exposed so that the sapwood of the standing tree is vertically disconnected; (2) after sawing the sapwood, carrying out water sealing on the heartwood; infusing a chloroprene rubber adhesive to the sections of the sapwood, and at the same time sealing the exposed heartwood after sawing the sapwood by using liquid paraffin; (3) drilling an infusion hole used for infusing a preservative in the standing tree; (4) putting the prepared preservative into a container, hanging the container on a trunk above the infusion hole of the standing tree, infusing the preservative in the container into the infusion hole of the standing tree by using an infusion tube. Compared with a traditional preservative treatment method, the treatment method is good in preservative treatment effect, does not have treatment for preservative waste liquid, and is higher in environmental safety.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

Sterilization and smoke suppression halogen-free wood fire retardant

InactiveCN106363742AImprove photocatalytic activityGood killing effectWood treatment detailsWood impregnation detailsDecabromodiphenyl etherMoisture absorption

The invention discloses a sterilization and smoke suppression halogen-free wood fire retardant. The sterilization and smoke suppression halogen-free wood fire retardant is composed of, by mass, 40-80 parts of guanyl urea phosphate, 30-50 parts of urea, 10-20 parts of zinc borate, 5-10 parts of ammonium molybdate, 3-10 parts of pentaerythritol, 1-20 parts of ammonium dihydrogen phosphate, 12-25 parts of silica sol, 3-15 parts of decabromodiphenyl ether, 5-10 parts of fatty alcohol-polyoxyethylene ether, 1-20 parts of hexadecyltrimethoxysilane, and 1-20 parts of nanometer titania modified by one of Pt, Ag and Fe<3+>. The sterilization and smoke suppression halogen-free wood fire retardant is good in flame retardant property, high in anti-moisture absorption property and leaching resistance, good in stability, completely non-poisonous and low in cost and has the smoke suppression and sterilization effects.

Owner:GUANGXI UNIV

A kind of antiseptic and anti-mildew modified combination agent for wood and bamboo and method for treating wood and bamboo

ActiveCN109015981BImprove stabilityImprove anti-corrosion performanceWood treatment detailsReed/straw treatmentCarbamateMildew

The invention belongs to a wood and bamboo wood antiseptic and mildew-proof modified composition and a method for treating wood and bamboo wood. ~ 0.12 parts of iodopropynyl n-butyl carbamate, 1 to 6 parts of water-soluble dyes, 1 to 6 parts of dyeing auxiliaries, 1 to 6 parts of flame retardants, and 1 to 10 parts of polymerization inhibitors. The wood and bamboo treated by the invention can simultaneously have the functions of antisepsis, mildew proof, dyeing, flame retardant, and anti-loss of pharmaceutical ingredients, and has the advantages of simple operation, easy realization, low cost for preparation and use, good durability and long service life.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Wood preservative modification treatment method and application thereof

ActiveCN111975906AIncreased durabilityImproves loss resistanceWood treatment detailsPressure impregnationOXALIC ACID DIHYDRATEAlcohol

The invention discloses a wood preservative modification treatment method. The wood preservative modification treatment method is characterized in that wood is treated by using a chemical agent containing quercetin and oxalic acid, wherein the quercetin is grafted to the cell wall of the wood through the oxalic acid. The specific method comprises the steps that 5-20 parts of quercetin and 2-50 parts of oxalic acid are weighed and dissolved in 150-300 parts of absolute ethyl alcohol, 0.4-2 parts of p-toluenesulfonic acid is added, and the chemical agent for treating wood is formed; the wood tobe treated is soaked for 48-96 h at normal temperature and normal pressure; and the impregnated wood blocks are placed in the environment of 120 DEG C to be treated for 2-8 h. According to the method,effective chemical bond combination can be formed between quercetin and wood cell walls, the durability of wood is improved, the loss resistance of the wood is improved, the technical problem that quercetin serving as a botanical natural antibacterial component is difficult to fix and easy to lose in the wood is solved, and the application of quercetin in the technical field of wood preservationis expanded.

Owner:NORTHWEST A & F UNIV

Heat treatment and chemical treatment method for improving mildew-proof and antibacterial effects of bamboo strips

InactiveCN108818795AImprove wetting performanceImprove wetting propertiesWood treatment detailsCane mechanical workingEmulsionCinnamic alcohol

The invention discloses a heat treatment and chemical treatment method for improving mildew-proof and antibacterial effects of bamboo strips. The method comprises the steps that mildew-free three-year-old moso bamboo strips which are complete in appearance are selected, bamboo inner skin and bamboo outer skin are removed, the bamboo strips are soaked in a water bath then are taken out and are soaked in a hydrogen peroxide solution, then are taken out, are subjected to fully washing and are soaked in cleat water, and then are put into a boric acid solution for treatment, so that chemically treated moso bamboo strips are obtained; then dry heat treatment is carried out to obtain the bamboo strips subjected to the heat treatment; nano-zinc oxide modified by a silane coupling agent, cinnamyl alcohol and ethanol are mixed and are uniformed after ultrasonic dispersion, and then are sprayed on the pretreated bamboo strips; and a halloysite nanotube-loaded mildew-proof agent is added into an organic silicon-acrylic emulsion, after stirring, coating treatment is carried out on the moso bamboo strips subjected to spraying treatment in a brushing mode, and coated bamboo strip samples are placed in a dark place, and are ventilated and dried by air. According to the heat treatment and chemical treatment method, the silane modified zinc oxide has an inhibition effect on growth of mould, andcan change the permeability of a mould cell membrane so that the metabolism of the mould can be influenced.

Owner:阜南县猛发工艺品有限公司

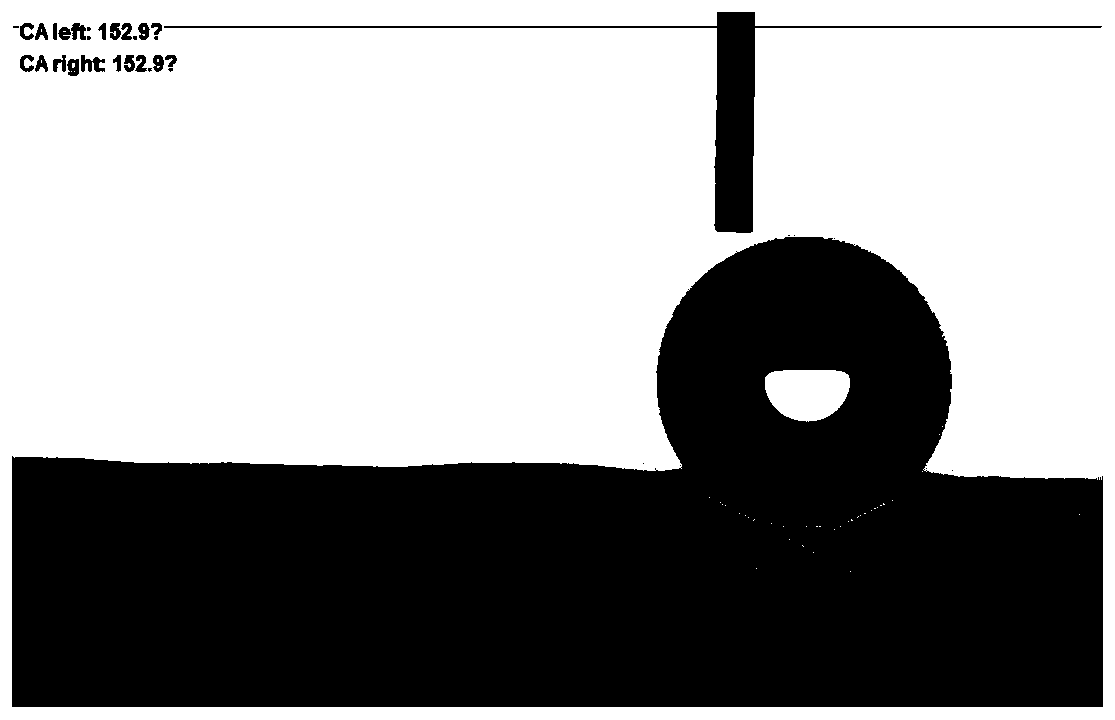

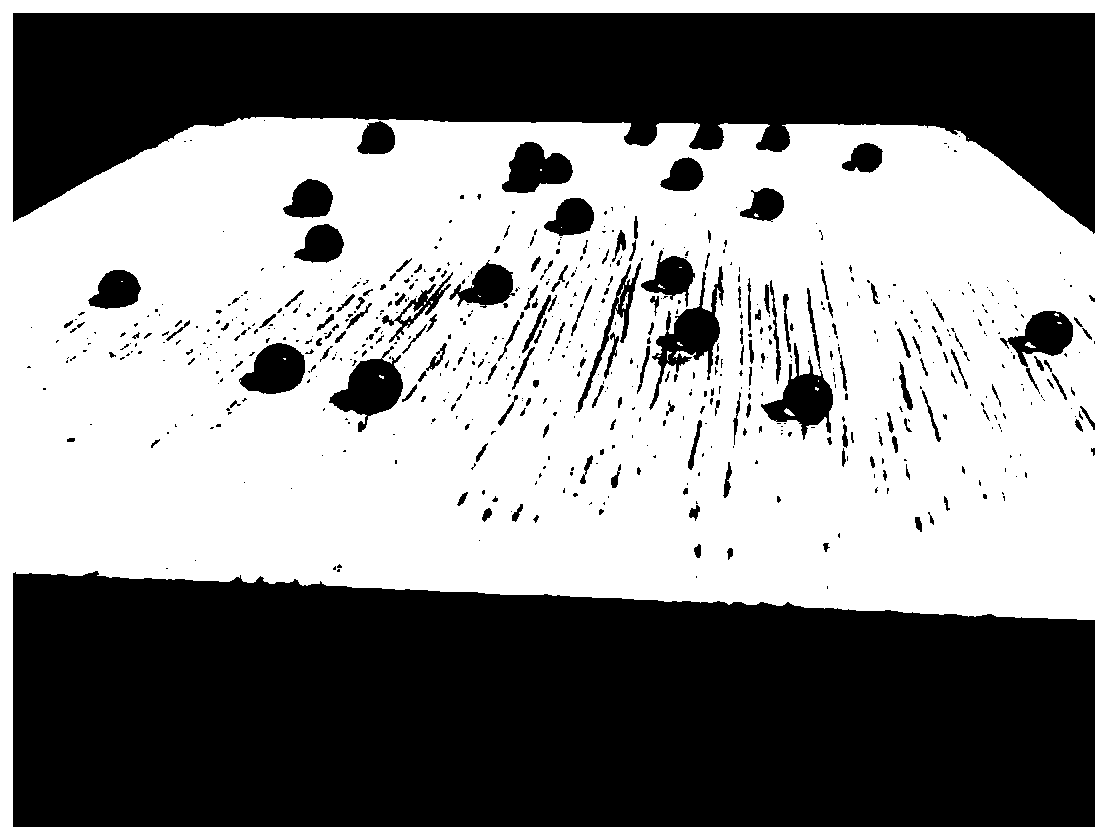

Preparation method of wood super-hydrophobic sterilization mildew-proof functional modifier and wood modification method

ActiveCN109702837AEasy to operateImproves loss resistanceWood treatment detailsPressure impregnationSolventChemistry

The invention discloses a preparation method of a wood super-hydrophobic sterilization mildew-proof functional modifier and a wood modification method. The invention relates to the preparation methodof the wood modifier and the wood modification method, and mainly aims at solving the problems that an existing wood modifier is high in toxicity, short in storage time at room temperature and poor inloss resistance. The preparation method comprises the following steps: (1) weighing hydrophobic polymer resin, a functional additive, a surfactant and a solvent, and carrying out mixing by stirring to obtain a functional reagent A; (2) weighing nano-particles, polydimethylsiloxane and toluene, carrying out stirring after mixing, and carrying out cleaning, centrifuging and drying to obtain a functional reagent B; and (3) adding the functional reagent B into the functional reagent A, and carrying out ultrasonic treatment to obtain the wood modifier. When the modifier prepared by the method is used for modifying wood, loss resistance of the wood is improved by 90% or above, and the storage period at room temperature exceeds 2 years. The wood modifier has a super-hydrophobic property. Anticorrosion and bactericidal performance of the wood is improved by 92% or above. The invention belongs to the field of wood modifiers.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

High-temperature coextrusion wood-plastic profile

InactiveCN106827729AImprove mechanical propertiesImprove creep resistanceSynthetic resin layered productsWood layered productsEngineering plasticEngineering

The invention discloses a high-temperature coextrusion wood-plastic profile, belongs to the technical field of wood-plastic profile coextrusion, particularly relates to the field of coextrusion of wood-plastic profiles under a high-temperature condition, and aims at solving the problems that the existing wood-plastic composite material is relatively low in strength and poor in creep resistance and an engineering plastic or engineering plastic alloy-based wood-plastic profile is difficult to process and high in cost. The high-temperature coextrusion wood-plastic profile is formed by multiple layers of wood-plastic profiles, wherein at least one layer of wood-plastic profile is an engineering plastic or engineering plastic alloy-based wood-plastic composite material, and the other layers of wood-plastic profiles are universal plastic-based wood-plastic composite materials. A plant material is modified by using a modifier, so that coextrusion of the wood-plastic profiles under the high-temperature condition is achieved. The wood-plastic profile is applied to the field of the high-temperature coextrusion wood-plastic profiles.

Owner:NORTHEAST FORESTRY UNIVERSITY

Insect prevention adhesive for wood processing, and preparation method thereof

InactiveCN105176414AHas insect repellent effectStrong anti-mothNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveFiberNon toxicity

The invention provides an insect prevention adhesive for wood processing, and a preparation method thereof, and belongs to the technical field of wood processing. The adhesive is prepared by using sodium silicate, polyvinyl alcohol, lyxose, diethyl 1,4-cyclohexanedicarboxylate, modified alginic acid fibers, polyacrylamide, urea, aluminum sulfate, an antifoaming agent, a curing agent, glycerin, ethyl acetate, a lithium catalyst, wax, a filler, butyl acrylate, methyl acrylate and an insecticide. The adhesive integrates environmental protection with insect prevention, and has the advantages of non-toxicity, no formaldehyde, no pollution to environment, good adhesion and mechanical performances, insect prevention effect, wide insecticidal range, instant superpower penetration, and good loss resistance; after the adhesive is injected to wood and is cured, the adhesive instantly generates insoluble compounds and is nonvolatile; and additionally the preparation method has the advantages of simple production process and easy popularization.

Owner:MINGGUANG CITY SUNSHINE WOOD IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com