Preparation method of bamboo/wood mildew-resistant antiseptic

A preservative and wood technology, applied in the direction of wood impregnation, impregnated wood, wood processing equipment, etc., can solve the problems of long-lasting anti-mildew and anti-corrosion effects, insignificant fixation effects, and affecting the physical and mechanical properties of the treated materials, so as to improve the anti-corrosion effect. Loss performance, improvement of anti-loss performance, and improvement of anti-mold and anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

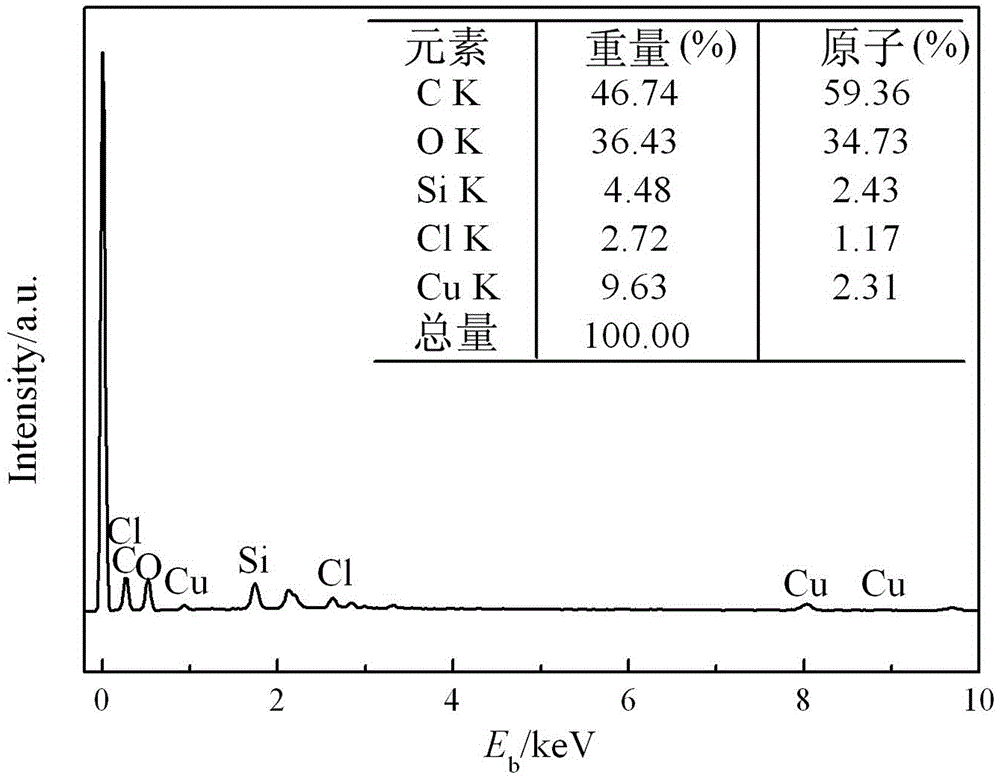

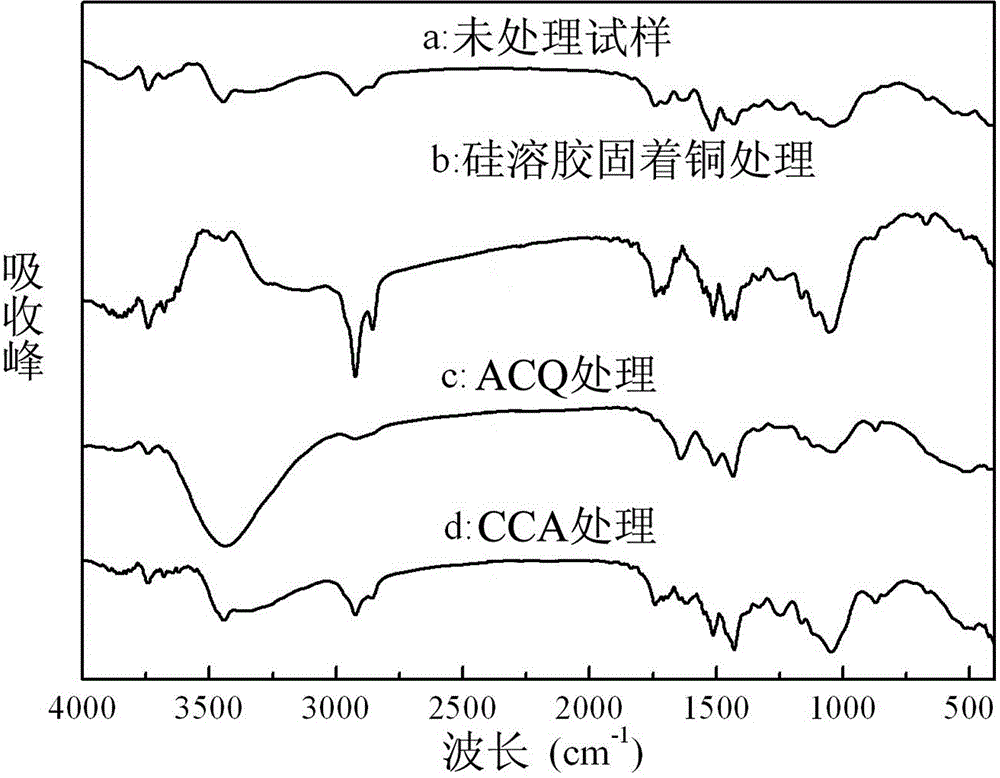

[0023] A preparation method of the bamboo wood anticorrosive and antifungal agent of the present invention includes the following steps:

[0024] 1) Preparation of the sol: weigh 60 parts by weight of ethyl orthosilicate at room temperature, and slowly drop it into a mixed solution of 40 parts by weight of absolute ethanol and 30 parts by weight of deionized water, and at the same time bathe the mixed solution at 40°C , Stir; then add an appropriate amount of dilute hydrochloric acid to adjust the PH value to 3-4, after the reaction proceeds for 30-45 minutes, a uniform sol is obtained;

[0025] 2) Preparation of anti-mildew and preservative: Under the condition of 40°C water bath and stirring on the sol prepared in step 1), slowly add 3 parts by weight of copper sulfate aqueous solution to the sol; then add 5 parts by weight of aminopropyltrimethoxy The base silane is used as a guiding agent, and it is fully stirred to make it react to prepare the required bamboo and wood anti-mil...

Embodiment 2

[0029] A preparation method of the wood antiseptic and antifungal agent of the present invention includes the following steps:

[0030] 1) Preparation of sol: weigh 60 parts by weight of n-butyl titanate at room temperature, slowly drip into the mixture of 40 parts by weight of absolute ethanol and 30 parts by weight of deionized water, and at the same time bathe the mixed solution at 40°C , Stir; then add an appropriate amount of dilute hydrochloric acid to adjust the PH value to 3-4, after the reaction proceeds for 30-45 minutes, a uniform sol is obtained;

[0031] 2) Preparation of anti-mildew and preservative: Under the conditions of 40°C water bath and stirring on the sol prepared in step 1), slowly add 3 parts by weight of copper sulfate aqueous solution to the sol, and then add 5 parts by weight of aminopropyl triacetate. Ethoxysilane is used as a guiding agent, and it is fully stirred to make it react, and the required bamboo and wood anti-mildew and preservative is prepare...

Embodiment 3

[0033] A preparation method of the wood antiseptic and antifungal agent of the present invention includes the following steps:

[0034] 1) Preparation of sol: weigh 100 parts by weight of sodium silicate solution with 2.8 modulus at room temperature, slowly drip into the mixture of 55 parts by weight of absolute ethanol and 45 parts by weight of deionized water, and perform the mixing 60℃ water bath, stir; then add appropriate amount of glacial acetic acid to adjust the PH value to 3-4, after the reaction proceeds for 30-45 minutes, a uniform sol is obtained;

[0035] 2) Preparation of anti-mildew and preservative: Under the condition of 60°C water bath and stirring on the sol prepared in step 1), slowly add 9 parts by weight of copper chloride aqueous solution to the sol, and then add 10 parts by weight of 3-aminopropyl Triethoxysilane is used as a directing agent, and it is fully stirred to make it react to prepare the required bamboo and wood anti-mildew and preservative.

[0036...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com