Patents

Literature

67 results about "Titanium tetrabutoxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polycarbonate resin composition

ActiveUS20120289655A1Excellent in flowabilityHigh mechanical strengthVehicle componentsChemical recyclingPhosphateHeat resistance

The present invention seeks to provide a resin composition which contains an aromatic polycarbonate resin and a polyester resin and which has excellent mechanical strength, flowability and thermal stability and also has excellent moist heat resistance together.The present invention is a resin composition containing 50 to 99 parts by weight of an aromatic polycarbonate resin (component A) and 1 to 50 parts by weight of a polyester resin (component B), the component B being a polyester resin polymerized in the presence of a titanium-phosphorus catalyst obtained by reacting titanium tetrabutoxide, etc., with monolauryl phosphate, etc.

Owner:TEIJIN KASEK KK

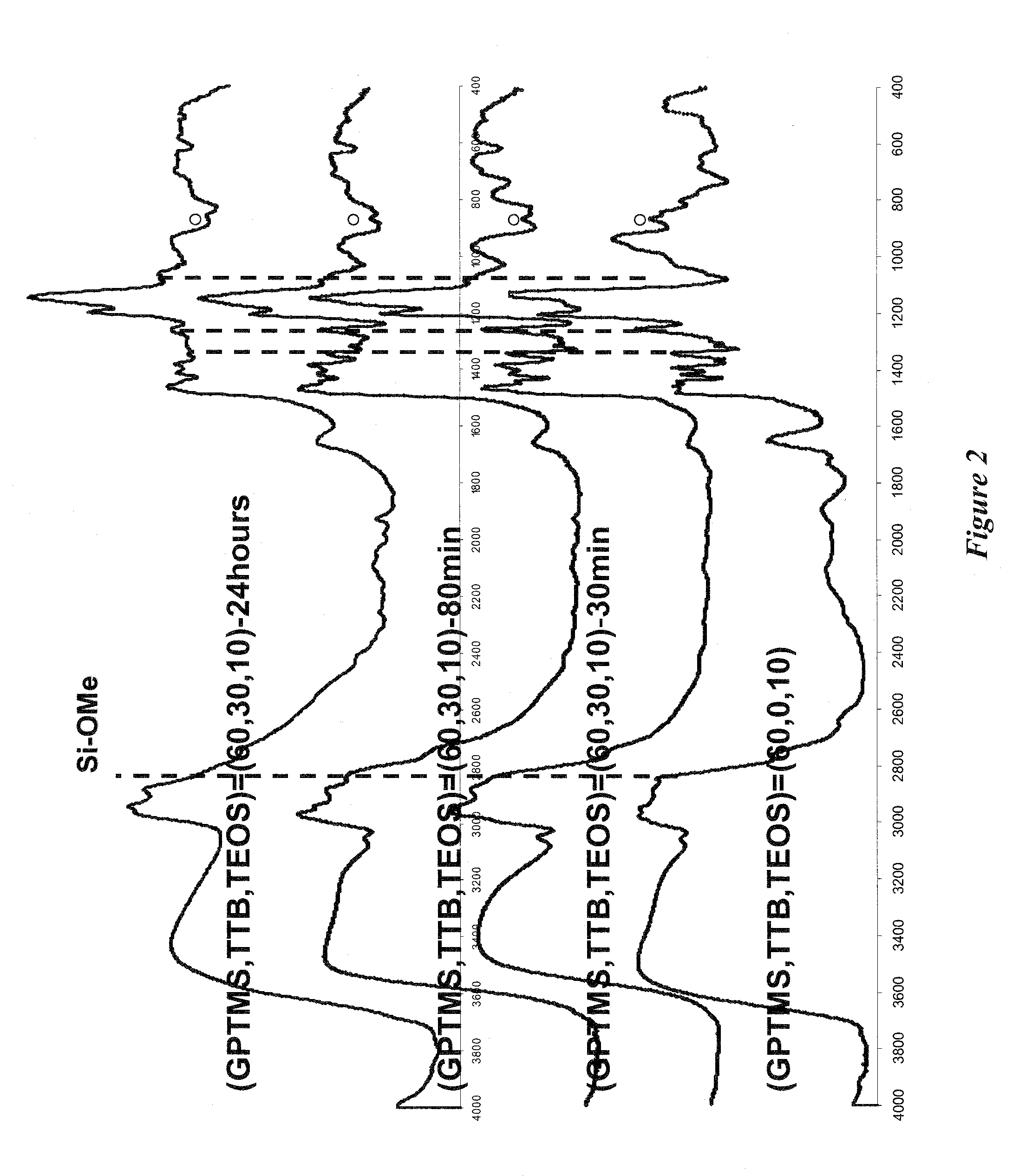

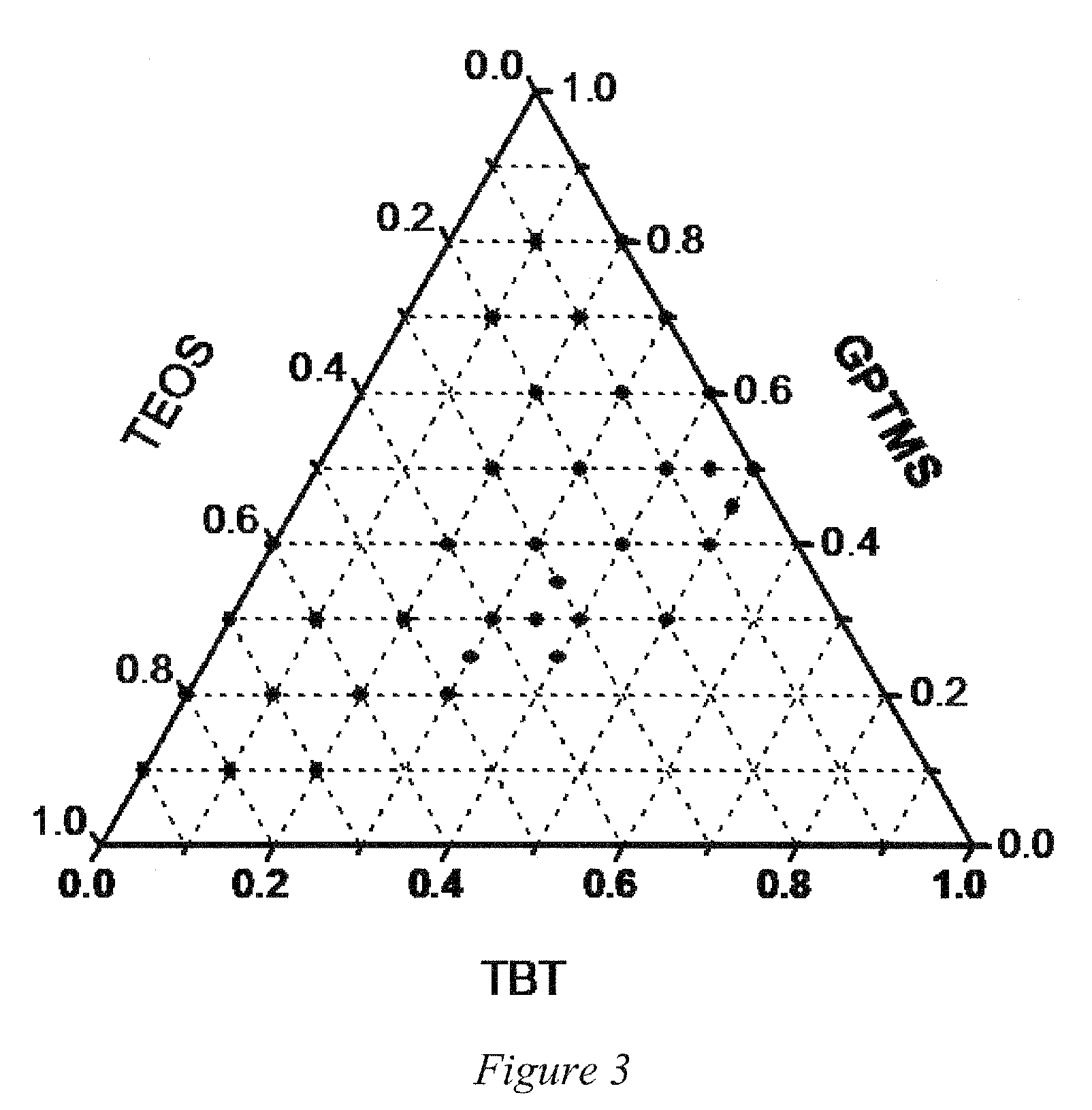

Nanoparticle sol-gel composite hybrid transparent coating materials

InactiveUS20110003142A1Effective diffusion barrierTransparent highSilicaLayered productsSilanesNanoparticle

A composite hybrid coating having a thick highly transparent hard coating with excellent barrier properties is described. The hybrid coating is the gelled dispersion of nanoparticles in a sol with least one hydrolyzable silane and at least one hydrolyzable metal oxide precursor. In one embodiment a composite hybrid coating is formed by the curing of a dispersion formed by the addition of a suspension of boehmite nanoplatelets in a sol prepared by the hydrolysis of tetraethoxysilane, γ-glycidoxypropyltrimethoxysilane and titanium tetrabutoxide in ethanol. A plastic substrate can be coated with the dispersion and the dispersion gelled to a thickness of at least 5 μm with heating to less than 150° C.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

Synthesis method of load type carbon modified titanium dioxide photocatalyst

InactiveCN102614859ALarge specific surface areaImprove adsorption capacityPhysical/chemical process catalystsWater/sewage treatment by irradiationActive agentCarbon particle

The invention discloses a synthesis method of a load type carbon modified titanium dioxide photocatalyst. The synthesis method comprises the following steps of mixing absolute ethanol and titanium tetrabutoxide to obtain a solution A; mixing HNO3 and absolute ethanol to obtain a solution B; adding the solution A into the solution B dropwise and adding NaOH solution dropwise to obtain titanium column brace liquid; adding cationic surfactant solution into natural bentonite solution dropwise to prepare organic modified bentonite turbid liquid; adding the titanium column brace liquid into the organic modified bentonite turbid liquid dropwise, ultrasonically oscillating and ageing to obtain powder; and calcining the powder under the vacuum condition to obtain load type carbon modified titanium dioxide. Carbon and TiO2 nanopaticles are implanted between the nano layers by utilizing the cation exchange characteristic of the bentonite to form a three-dimensional nanopore structure, so that the specific surface area of the bentonite is enlarged and the adsorption performance of the bentonite is enhanced. The TiO2 and the carbon particles are combined tightly on the surface, so that the surface photosensitivity of the TiO2 can be improved and the visible light degradability is improved. The TiO2 between the bentonite layers has nanosize, so that the nanoeffect can be exerted.

Owner:常州顺意新能源科技有限公司

Preparation method for synthesizing sheet-type cladding material by fluidized bed gas-phase method

ActiveCN103773084AImprove or change dispersionImprove or change surface activityChemical industryPigment treatment with non-polymer organic compoundsSilicic acidTitanium isopropoxide

The invention discloses a preparation method for synthesizing a sheet-type cladding material by a fluidized bed gas-phase method. According to the method, a sheet-type material is used as a matrix material, one or two of volatilizable metal or non-metal organic substances, such as titanium tetrabutoxide, isopropyl titanate, tetra(dimethylamino) titanium, tetra(dimethylamino) titanium, tetraethylortho silicate, 1,2-dimethyl silicon oxide, dichlorosilane, triisobutyl aluminium, carbonyl iron and chromium carbonyl, is or are used as a cladding raw material, and nitrogen, air, argon, helium or carbon dioxide is used as fluidizing gas, so that the sheet-type cladding material is prepared by pyrolysis through a fluidized bed. Metal oxide particles cladding the surface of sheet-type mica by the method can reach the nano level, are compact and uniform and have a wide application prospect in the aspects of decoration, catalysis, photocatalysis, batteries, gas storage and separation. The whole preparation process is executed in a closed container; the cladding raw material is recyclable, so that the preparation method is environmentally friendly, energy-saving and pollution-free; furthermore, the conversion rate o reactants is increased.

Owner:SHANXI LANHUA HUAMING NANO MATERIALS

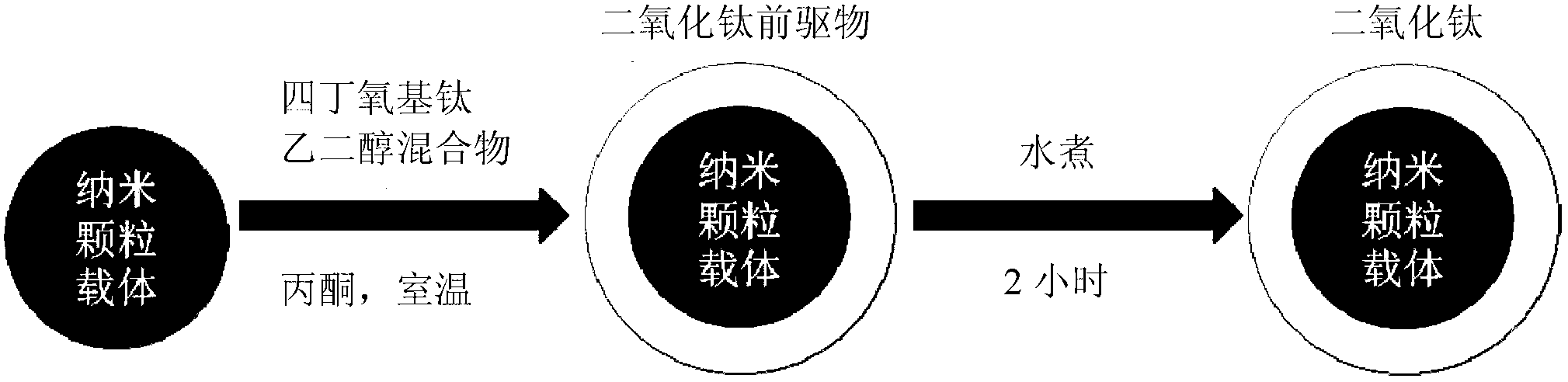

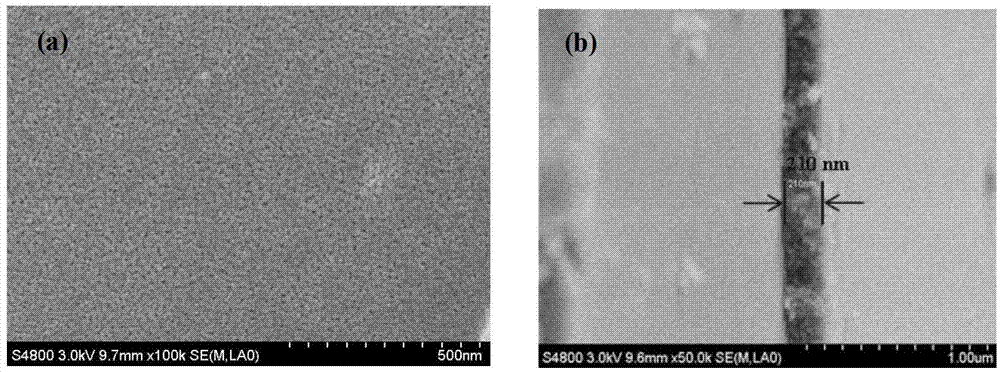

Preparation method of core-shell composite material wrapped in titanium dioxide nanoparticle coating

InactiveCN103192075ALarge specific surface areaImprove stabilityNanotechnologyWater bathsMetal oxide nanoparticles

A preparation method of core-shell composite material wrapped in a titanium dioxide nanoparticle coating includes: firstly, acquiring nanoparticle carrier; and secondly, wrapping the surface of the metal or metal oxide nanoparticle carrier with a titanium dioxide nanoparticle coating. The second step includes dissolving titanium isobutoxide in glycol, mixing at room temperature for 4-8 hours to obtain titanium dioxide precursor mixed solution A, dispersing the nanoparticle carrier in acetone, mixing well to obtain even mixed solution B, adding the titanium dioxide precursor mixed solution A into the mixed solution B, allowing for obtained solution to stand at room temperature to form precipitate mixed solution, and subjecting the precipitate mixed solution to centrifugal separation, and heating in water bath at 80-100 DEG C. The preparation method of the core-shell composite material wrapped in the titanium dioxide nanoparticle coating allows for increasing of photocatalysis efficiency and is low in cost.

Owner:杨晓红

Degradable corrugated paperboard glue and preparation process thereof

InactiveCN107974207AExtended service lifeImprove curing speedNon-macromolecular adhesive additivesOrganic non-macromolecular adhesivePolyethylene glycolPaperboard

The invention discloses degradable corrugated paperboard glue and a preparation process thereof and relates to the technical field of corrugated paperboard glue. The corrugated paperboard glue comprises the following raw materials in parts by weight: 40-60 parts of corn starch, 10-20 parts of polyvinyl alcohol resin, 5-15 parts of ethyl alcohol, 0.2-0.6 part of caustic soda flakes, 1-4 parts of polyethylene glycol, 0.2-0.6 part of defoaming agent, 0.1-0.5 part of stabilizer, 0.02-0.08 part of plasticizer, 0.05-0.3 part of borax, 0.002-0.008 part of titanium tetrabutoxide, 0.005-0.01 part of triphenyl phosphate and 80-150 parts of water; and the preparation process comprises the steps: degrading the polyvinyl alcohol resin; and mixing the materials. The corrugated paperboard glue disclosedby the invention is high in curing speed, bonding strength and degradation rate and incapable of generating environment pollution.

Owner:天长市天翔包装有限公司

Method for synthesizing anatase titanium dioxide nanorod

ActiveCN103864141AGood size controlEasy to makeMaterial nanotechnologyTitanium dioxideButanedioic acidSolar cell

The present invention relates to a method for synthesizing anatase titanium dioxide nanorod. The method comprises firstly adding a certain amount of acetic acid in a container, then adding butanedioic acid, ultrasonic agitating, and then adding N,N-dimethyl acetamide, carrying out ultrasonic agitating and finally adding titanium tetrabutoxide, mixing well, adding into a hydrothermal reaction vessel, reacting while heating to obtain anatase titanium dioxide nanorod after the reaction is completed. The titanium dioxide nanorod is a one-dimensional nanorod having anatase crystalline morphology. The anatase titanium dioxide nanorod prepared by the invention has characteristics of controllable size, simple preparation process and low cost. The anatase titanium dioxide nanorod can be used as a working electrode material of dye-sensitized solar cells and quantum dot solar cells.

Owner:NANJING UNIV OF TECH

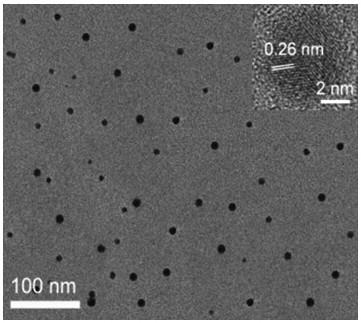

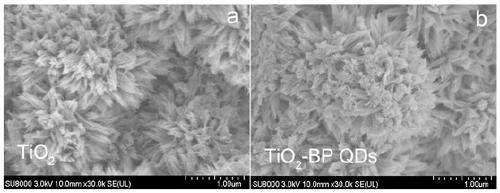

Black phosphorus quantum dots, titanium dioxide/black phosphorus quantum dot composite material, production methods of black phosphorus quantum dots and titanium dioxide/black phosphorus quantum dot composite material and application of titanium dioxide/black phosphorus quantum dot composite material

ActiveCN110229667AUniform sizeHigh yieldMaterial nanotechnologyWater/sewage treatment by irradiationIce waterNitrogen gas

The invention discloses a production method of a titanium dioxide / black phosphorus quantum dot composite material. The production method of the titanium dioxide / black phosphorus quantum dot compositematerial comprises the steps of (1) dispersing titanium tetrabutoxide and glycerin in ethyl alcohol respectively, then mixing obtained solutions, stirring an obtained mixture evenly, transferring themixture into a reaction kettle for reaction to obtain white powder, and then annealing the obtained white solid powder in a muffle furnace to obtain titanium dioxide micrometer flower; and (2) mixingthe titanium dioxide micrometer flower obtained in the step (1) and black phosphorus, conducting full grinding, then adding a ground mixture into a saturated aqueous solution of nitrogen, under the action of an ice-water bath, placing mixed liquid in a reaction kettle for hydrothermal treatment, and conducting centrifugal drying to obtain the titanium dioxide / black phosphorus quantum dot compositematerial. The titanium dioxide / black phosphorus quantum dot composite material can completely degrade dye methyl orange in 150 minutes, has photocatalytic activity higher than those of other photocatalysts relative to black phosphorus quantum dots under the same condition, and has the advantages of environmental protection, low consumption, high efficiency and good industrial prospects.

Owner:SHANGQIU NORMAL UNIVERSITY

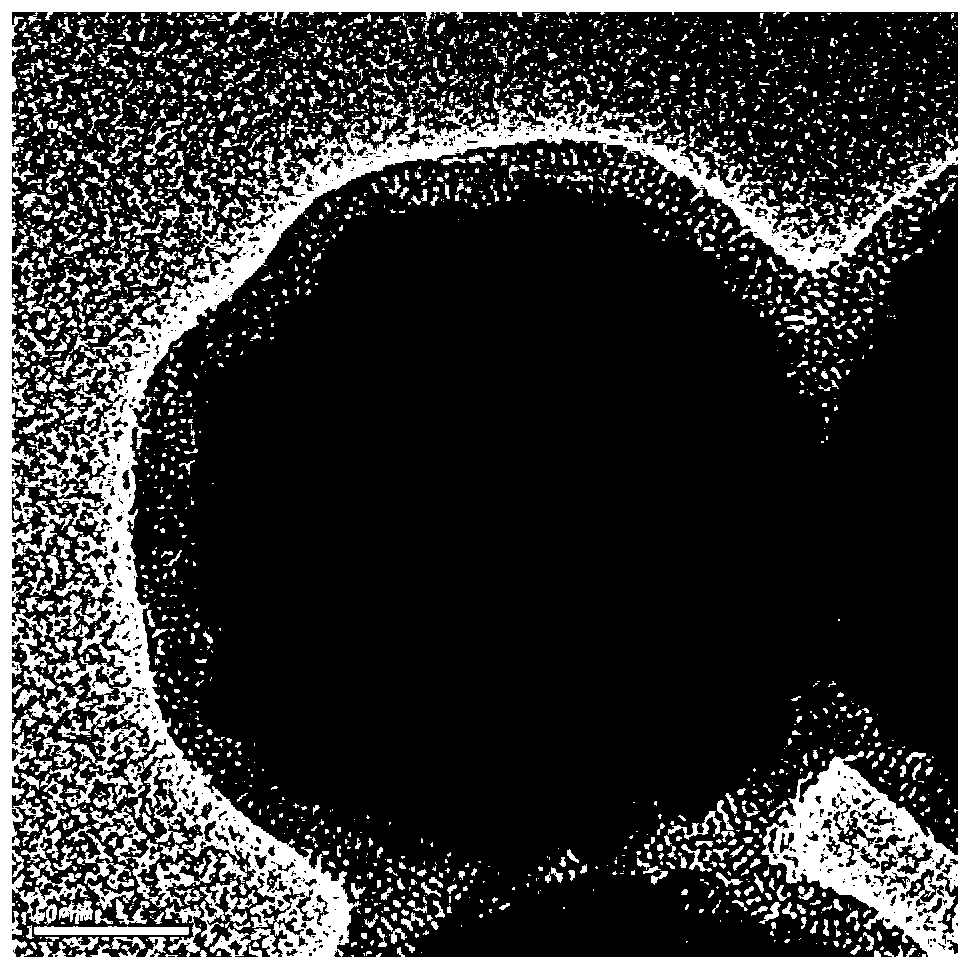

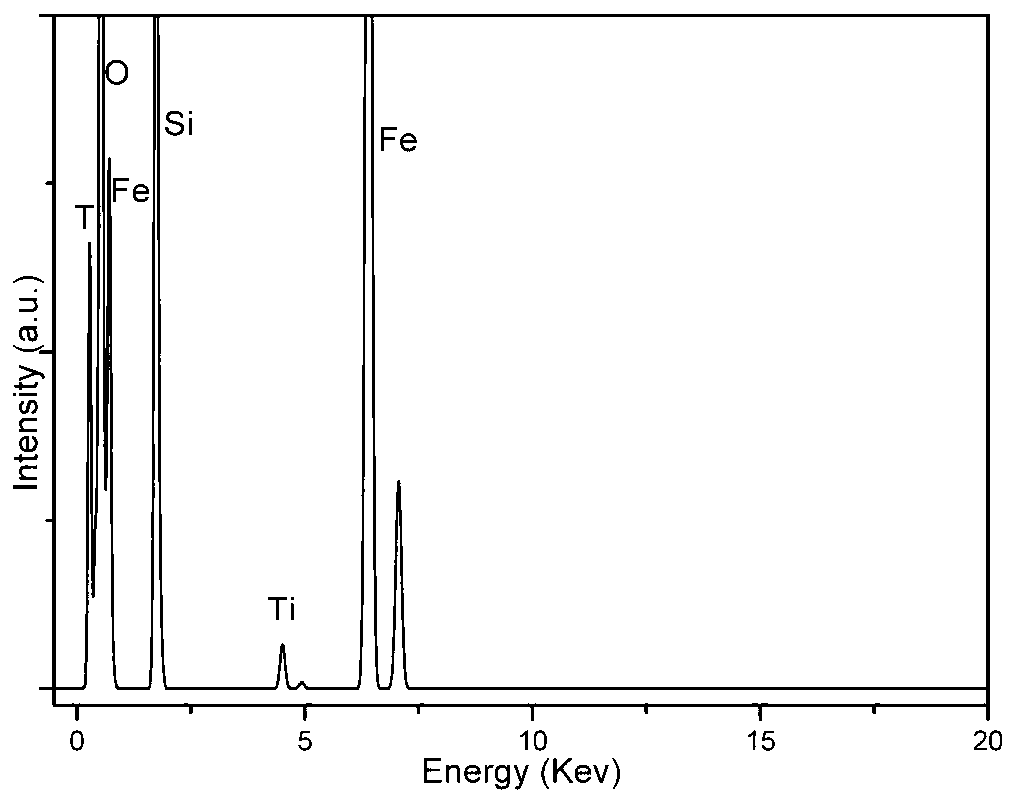

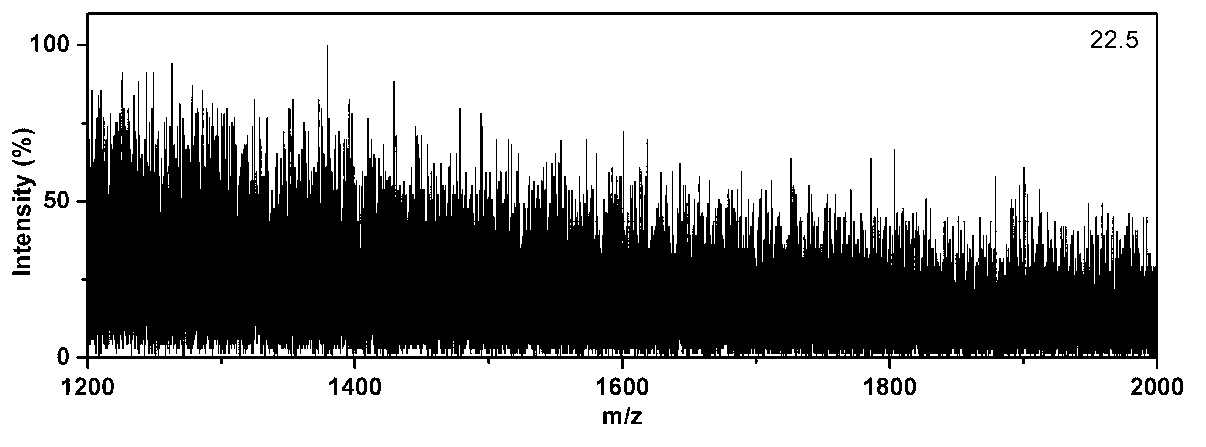

Magnetic mesoporous silica core-shell structure affinity microsphere based on metal ion modification as well as preparation method and application thereof

InactiveCN103285791ASimple purification processSave operating timePeptide preparation methodsMicroballoon preparationMicrosphereMesoporous silica

The invention relates to the technical field of a functional material, and discloses a preparation method of a magnetic mesoporous silica core-shell structure affinity microsphere based on metal ion modification. The method comprises the following steps of: 1) preparing magnetic particles from hexahydrate ferric trichloride; 2) preparing particle dispersion liquid by utilizing the magnetic particles; 3) adding ethanol solution containing ethyl silicate and titanium tetrabutoxide to the particle dispersion liquid, carrying out ultrasound, agitation and magnetic separation, and removing template molecules to obtain the magnetic mesoporous silica core-shell structure taking the magnetic particles as a core and the SiO2 as a shell. Polypeptide and protein with low molecular weight can be gathered and purified from a complicated biological sample by utilizing the magnetic mesoporous silica core-shell structure affinity microsphere based on the metal ion modification. The purification and separation processes of complicated low-abundance protein and low-molecular weight protein sample are greatly simplified by utilizing the magnetic property of an affinity material; and the operation time is also shortened.

Owner:SHENZHEN UNIV +1

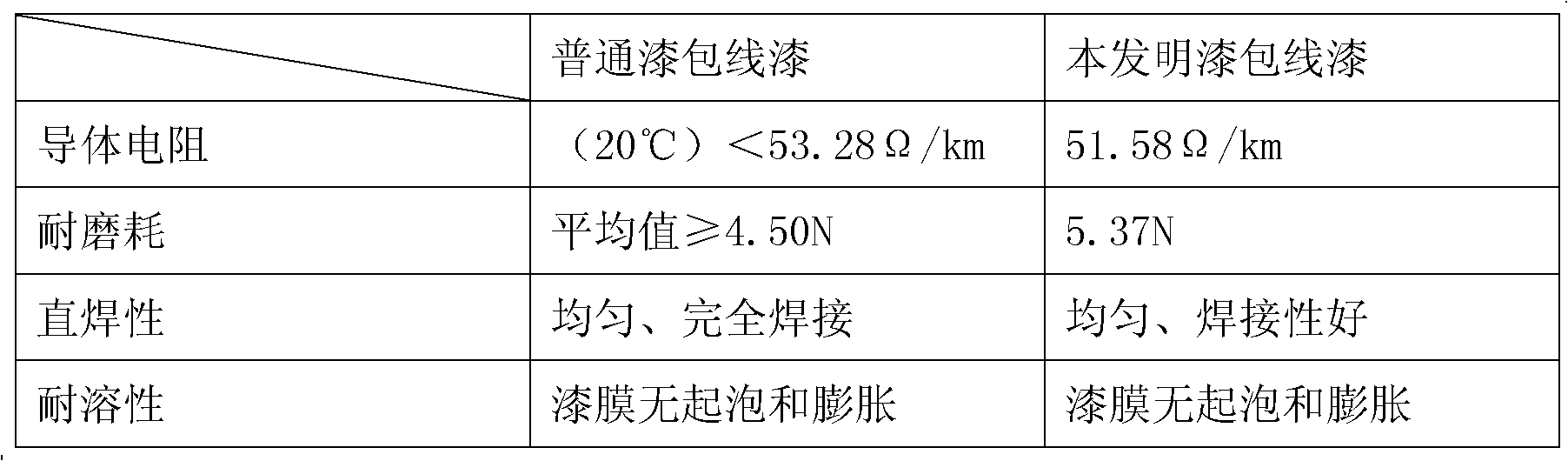

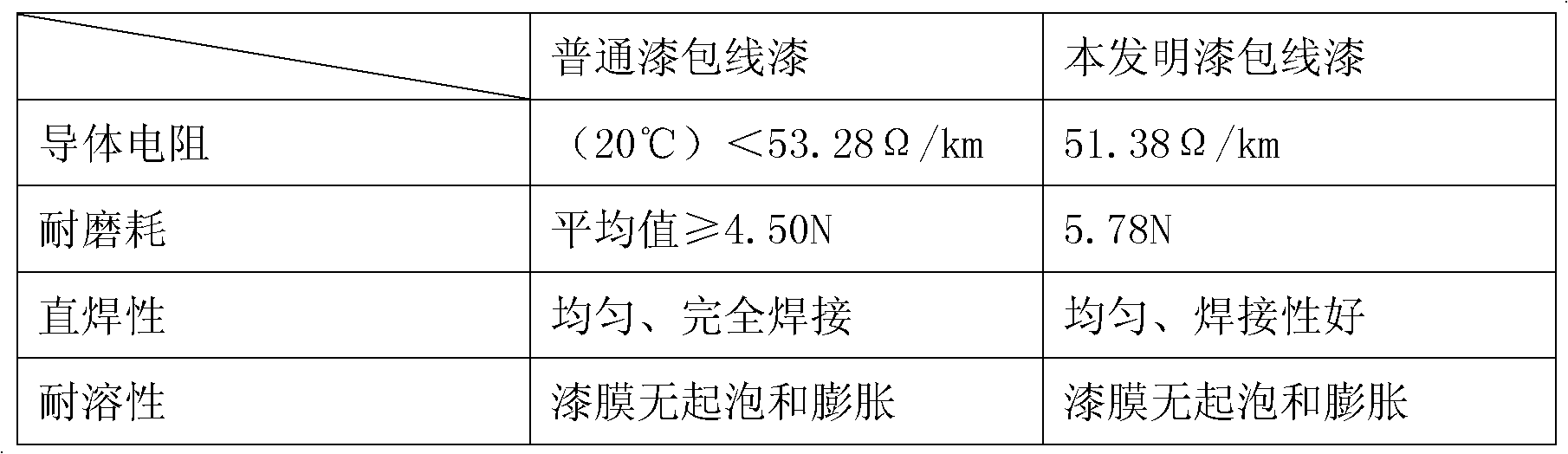

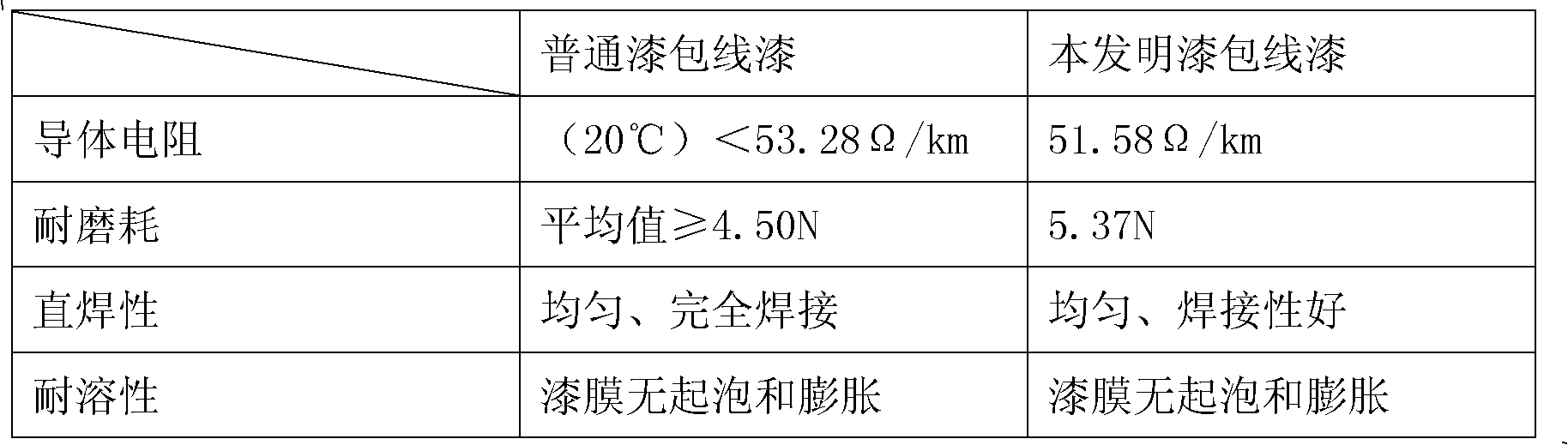

Phenol type polyester wire enamel and preparation method thereof

The invention relates to phenol type polyester wire enamel and a preparation method thereof. The phenol type polyester wire enamel is mainly prepared by mixing raw material components including methylphenol, trimellitic anhydride, diaminodiphenyl methane, cis-butenedioic anhydride, acrylic ester, glycerol, neopentyl glycol, dimethyl terephthalate, titanium tetrabutoxide, attapulgite and an additive according to a certain weight part ration, and reacting to obtain finished product. The preparation method disclosed by the invention is simple and low in cost; and the prepared wire enamel has high heat resistance, solvent resistance and freezing resistance.

Owner:BENGBU YINGLU PHOTOELECTRIC

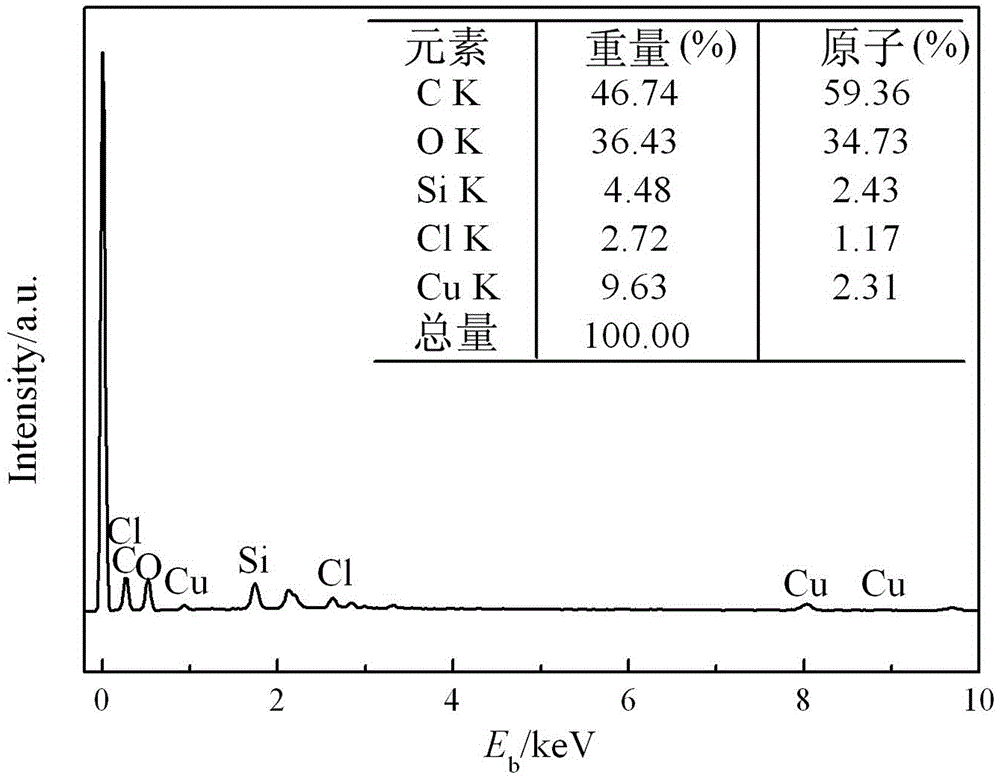

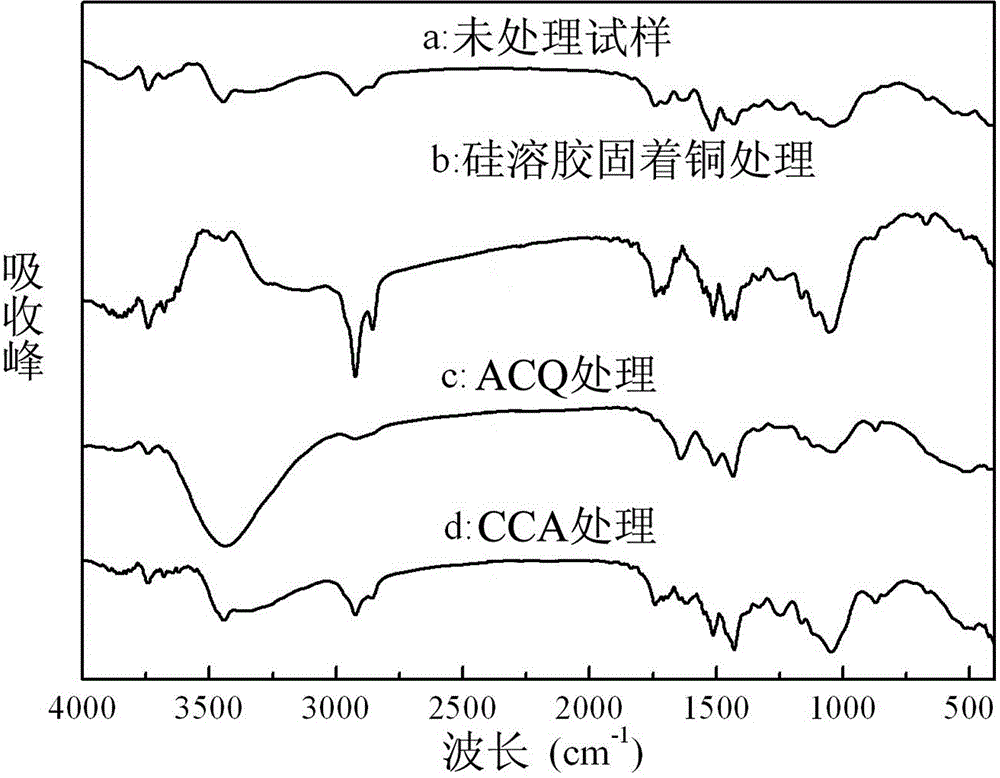

Preparation method of bamboo/wood mildew-resistant antiseptic

ActiveCN104526806AGood anti-loss performanceImproves loss resistanceWood impregnation detailsSilicic acidEthyl ester

The invention discloses a preparation method of a bamboo / wood mildew-resistant antiseptic. The preparation method comprises the following steps: weighing 60-150 parts by weight of tetraethoxysilane, sodium silicate solution or titanium tetrabutoxide at room temperature, slowly and dropwise adding tetraethoxysilane, sodium silicate solution or titanium tetrabutoxide into a mixed liquor of 40-75 parts by weight of anhydrous ethanol and 30-36 parts by weight of deionized water, and simultaneously treating the mixed liquor by water bath at 40-80 DEG C and stirring; adjusting pH to 3-4 by adding a proper amount of acid, and reacting for 30-45 min to prepare uniform sol; and slowly adding 3-12 parts by weight of an aqueous solution containing a copper compound into the sol under the condition of treating the sol by water bath at 40-80 DEG C and stirring, adding 5-15 parts by weight of an aminosilane coupling agent used as a guiding agent, fully stirring and reacting so as to prepare the bamboo / wood mildew-resistant antiseptic. The prepared bamboo / wood mildew-resistant antiseptic has excellent leach resistance and has simple components. The preparation method is simple, has relatively low production cost, is environmentally friendly and is less harmful to the health of human body.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

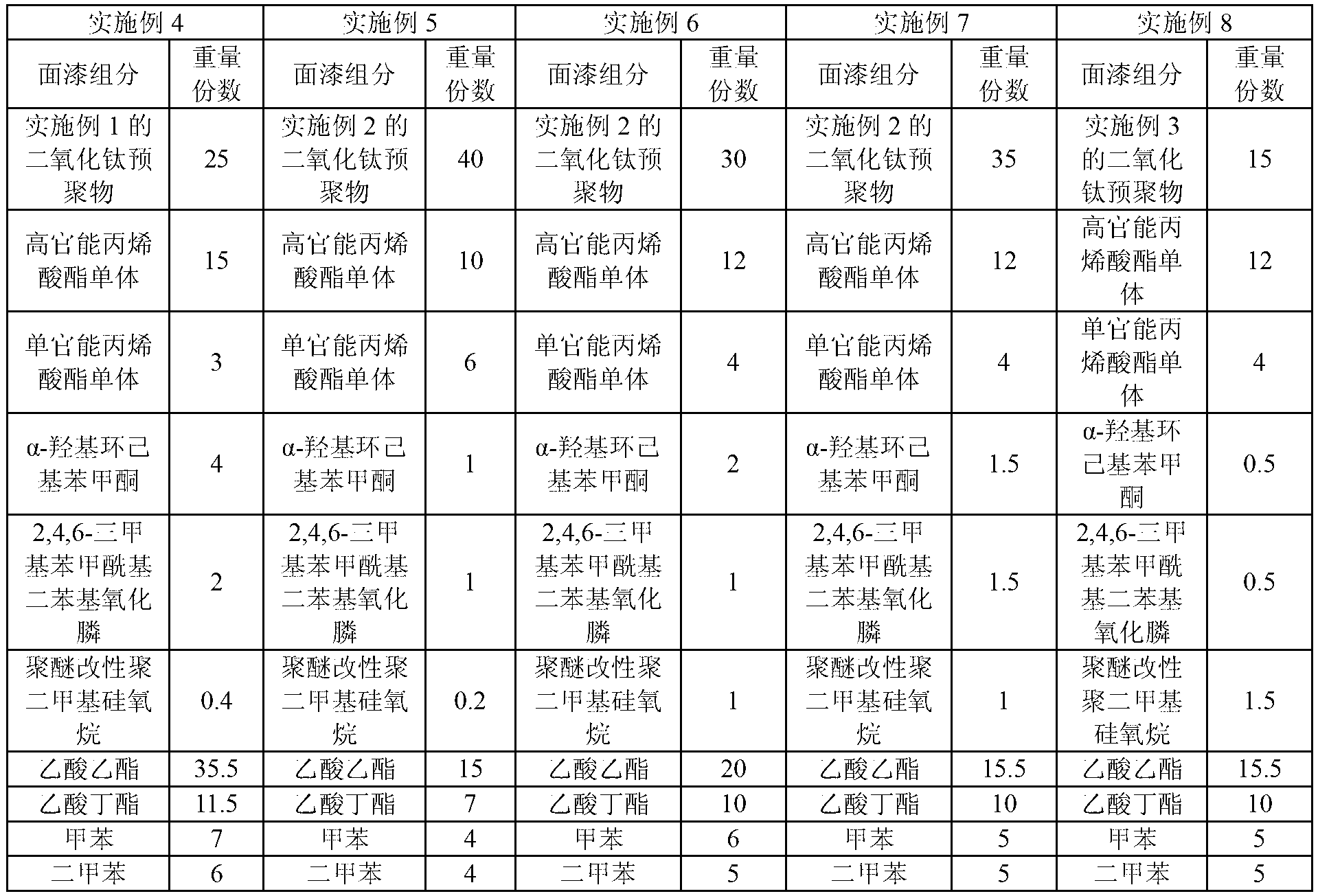

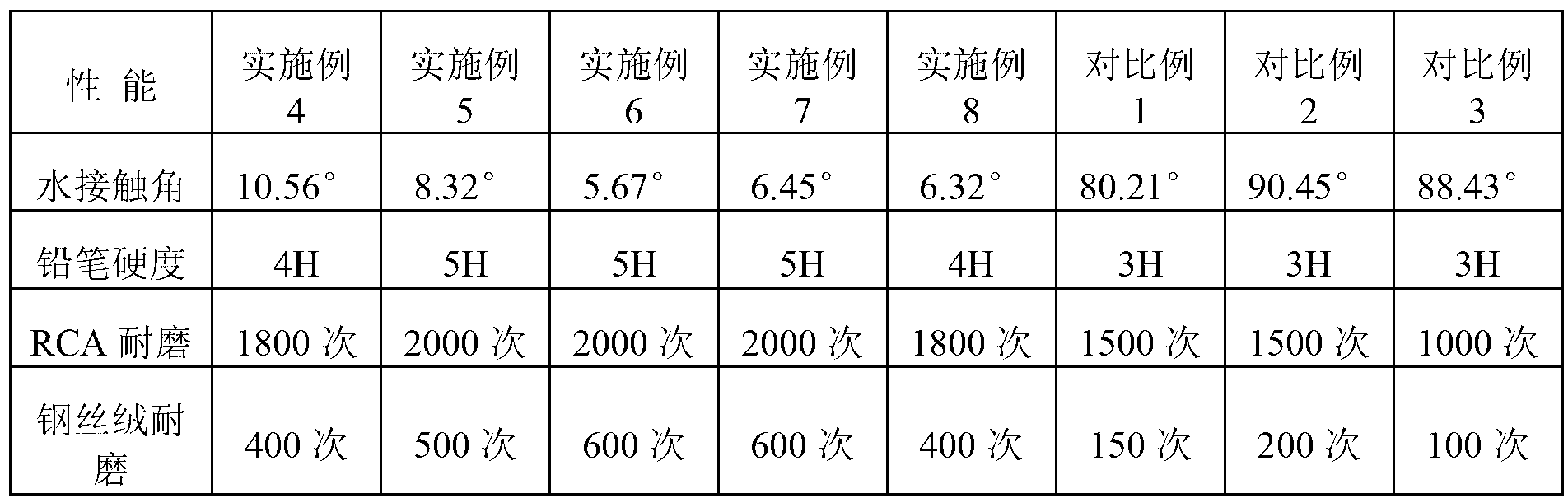

Titanium dioxide prepolymer and preparation method thereof as well as photocatalyst ultraviolet light curing paint with same

ActiveCN103059263AEvenly dispersedImprove bindingPolyurea/polyurethane coatingsOrganic solventAcrylic resin

The invention provides a titanium dioxide prepolymer and a preparation method of the titanium dioxide prepolymer and a photocatalyst ultraviolet light curing paint containing the titanium dioxide prepolymer. The method of preparing the titanium dioxide prepolymer comprises the following steps of: carrying out carboxylation reaction on titanium tetrabutoxide in ethanol to obtain carboxylated titanium dioxide; and dissolving a polyurethane acrylic resin in an organic solvent, and then heating and reacting the polyurethane acrylic resin with carboxylated titanium dioxide for 24 hours at 80 DEG C to obtain the titanium dioxide prepolymer. The photocatalyst ultraviolet light curing paint prepared by the invention comprises the titanium dioxide prepolymer, a high-function acrylic monomer, a single-function acrylic monomer, a diluent, an initiator and an assistant. The technical scheme provided by the invention solves the technical problems of poor storage stability of titanium dioxide, and bad dirty resistance and poor scratch resistance ability of the photocatalyst ultraviolet light curing paint in the prior art.

Owner:HUNAN SOKAN NEW MATERIAL

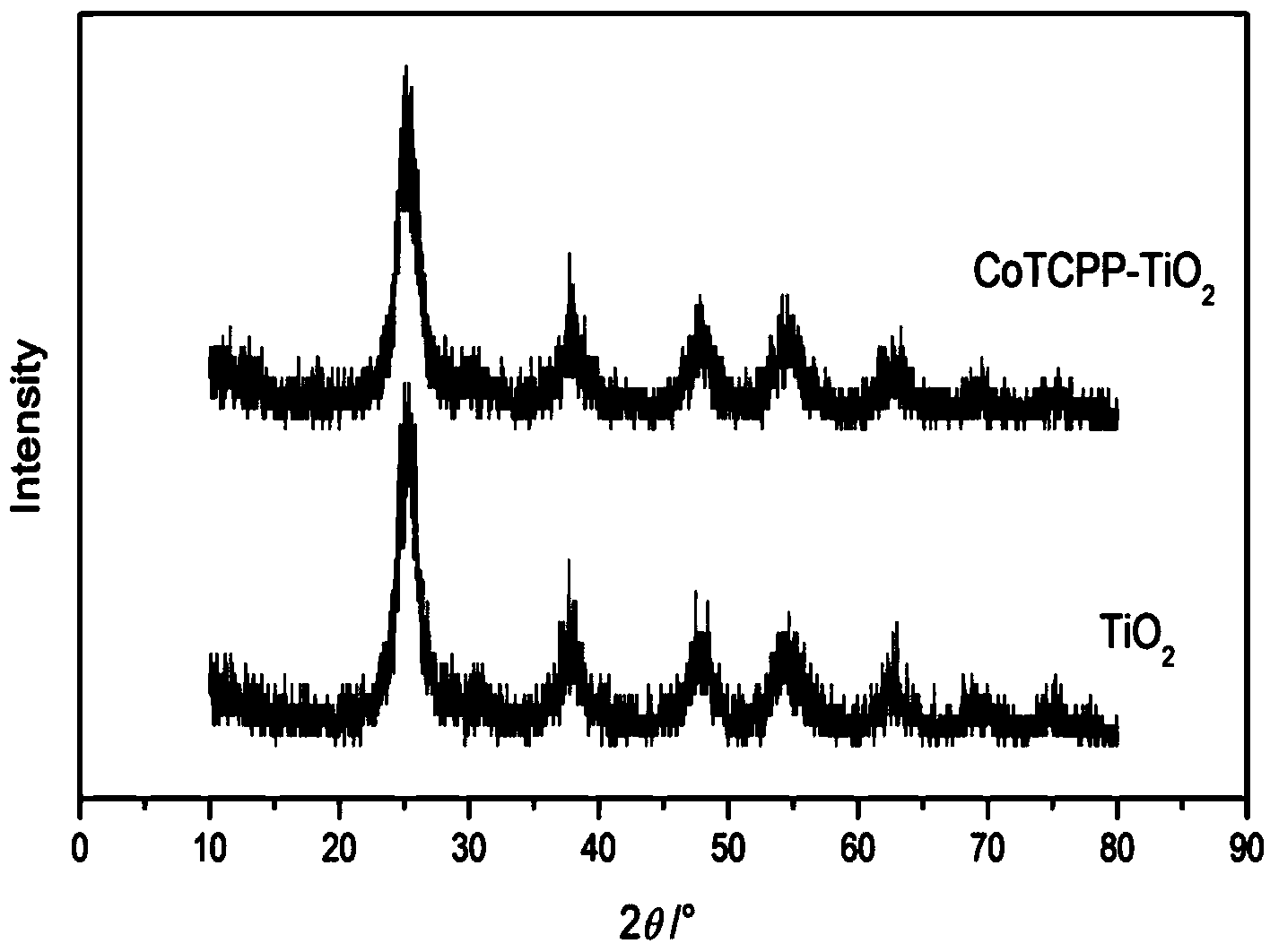

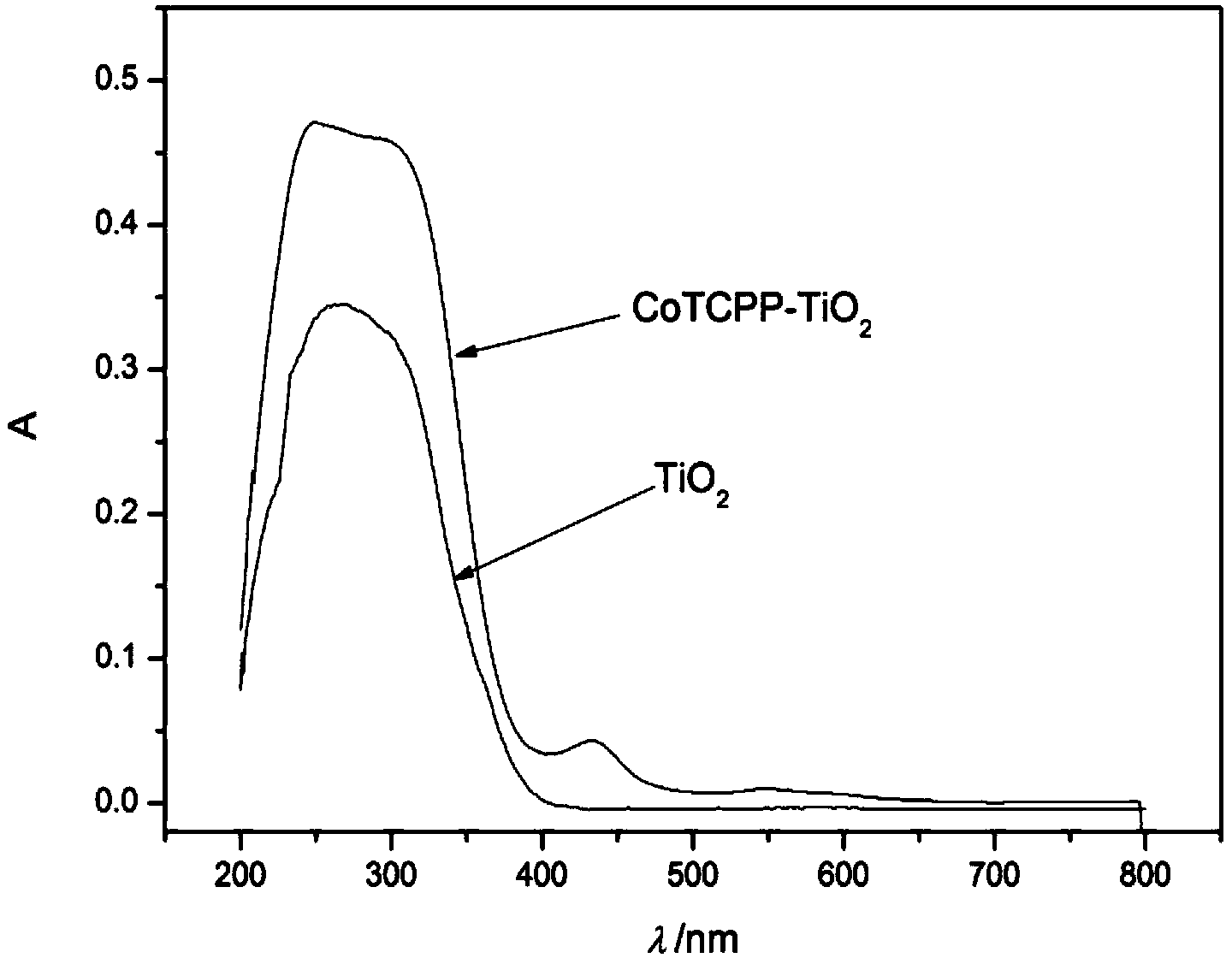

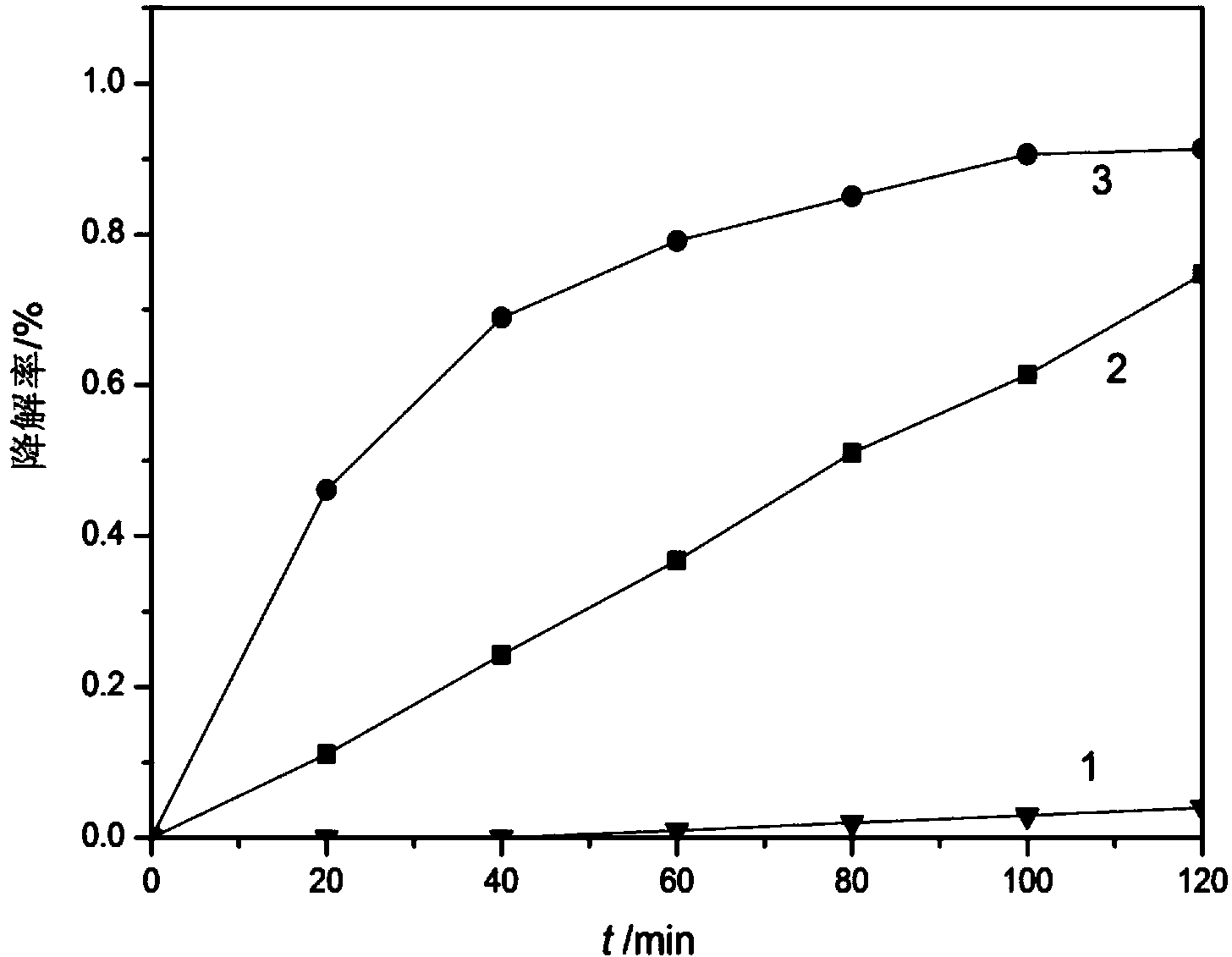

One-step microwave synthesis method of metalloporphyrin-titanium dioxide composite catalyst

InactiveCN103406155AImprove photocatalytic performancePromote absorptionOrganic-compounds/hydrides/coordination-complexes catalystsMicrowaveSynthesis methods

The invention discloses a one-step microwave synthesis method of a metalloporphyrin-titanium dioxide composite catalyst. The method comprises: step 1, blending titanium tetrabutoxide into ethanol absolute dropwisely under a magnetic stirring condition, keeping the volume ratio of titanium tetrabutoxide to ethanol absolute at 2-9ml:9ml, thus obtaining a solution A; dissolving metalloporphyrin in ethanol absolute, keeping the ingredient ratio of metalloporphyrin to titanium tetrabutoxide at 0.2-8mg:4.28ml, then adding deionized water slowly in a dropwise manner, keeping the volume ratio of deionized water to ethanol absolute at 1-3ml:19ml, thus obtaining a solution B; and step 2, pouring the solution B into the solution A under a magnetic stirring condition to obtain a mixed solution; subjecting the mixed solution to a microwave reaction; conducting cooling to room temperature, taking out the solid product, conducting washing respectively with ethanol absolute and deionized water, and finally placing the solid product in a drying oven to dry it. According to the preparation method disclosed in the invention, the product related performance is good, and the working efficiency is high.

Owner:CHONGQING TIANYI HENGHUA TECH CO LTD

Method for synthetising 2-thenoic acetate by thiophene

InactiveCN1955174AReduce manufacturing costQuick responseOrganic chemistryGlyoxylic acidSTANNOUS OXIDE

This invention belongs to technique field of fine chemical industry, it relates to a preparation of composing 2-thiophene acetic acid of thiophene, mainly including: after ethanal acid is dewatered, mixed with thiophene and amorphous phosphorus in acid medium, they are reacted by effect of catalytic agent, 2-thiophene acetic acid is obtained. The used ethanal acid is technica grade ethanal acid, in the reactive process the thrown mol share ratio of thiophene and ethanal acid is 1-8:1,when the purity of ethanal acid is lower than 80%, acidity or neutral can be added to raise reaction velocity. Dehydrater addition is adjusted according to purity of ethanal acid to make water content of ethanal acid decrease to lower than 20%, dehydration time is 0.5-2h,dehydration temperature is 20-50DEG C. Thrown mol share ratio of amorphous phosphorus and ethanal acid is 0.2-1.0:1. The used catalytic agent is catalytic agent of un-protonic acid such as stannous oxide, titanium tetrabutoxide, stannic chloride, iron chloride, zinc chloride and so on, Thrown mol share ratio of catalytic agent and ethanal acid is 0.025-0.1:1.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

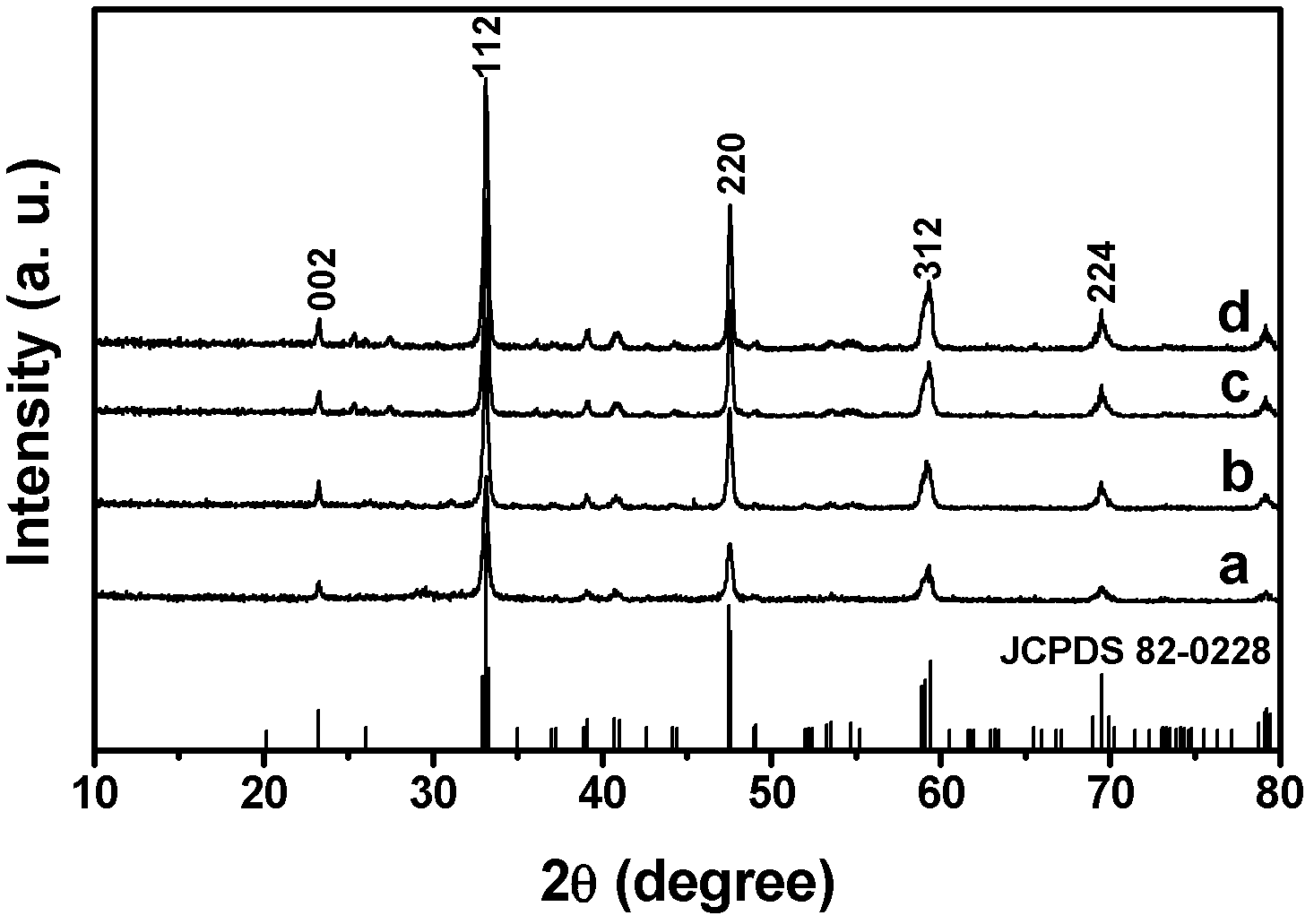

Preparation method of praseodymium-doped calcium titanate luminescent powder

The invention provides a preparation method of praseodymium-doped calcium titanate luminescent powder. The method comprises: under room temperature, and according to Pr<3+> / Ca<2+> in a mole ratio of 0.005 / 1, weighing certain amounts of CaCO3 and Pr6O11 solids which are dissolved in dilute nitric acid, conducting heating to expel excess acid, and when the pH value of the solution reaches 2-3, reheating the solution to a melt state; leaving the solution to cool to room temperature, then respectively adding stoichiometric titanium tetrabutoxide and 20mL of a water-ethanol solution, then adding a certain amount of citric acid as a complexing agent, adding polyethylene glycol, and carrying out stirring for 2h, thus obtaining a transparent sol precursor; subjecting the obtained precursor solution to spray drying so as to obtain precursor powder; putting the precursor into a programmed heating furnace, and heating the precursor to a temperature of 600DEG C-1000DEG C, then maintaining the temperature constant for 3h, thus obtaining CaTiO3:Pr<3+> fluorescent powder. The praseodymium-doped calcium titanate fluorescent powder prepared by the method of the invention has good crystallization degree and high purity, and is a CaTiO3 pure phase in a perovskite structure.

Owner:HARBIN ENG UNIV

Preparation method of strontium-doped titanium dioxide magnetic nanometer photocatalyst

InactiveCN103623830AEasy to recycleWide band gapMetal/metal-oxides/metal-hydroxide catalystsCalcinationTitanium tetrabutoxide

The invention discloses a preparation method of a strontium-doped titanium dioxide magnetic nanometer photocatalyst. The preparation method comprises the following steps: using Ni-Zn-Fe nitrate as a raw material, synthesizing an Ni0.6Zn0.4Fe2O4 magnetic substrate by adopting a self-propagating combustion method, using strontium as a dopant, using titanium tetrabutoxide as a titanium source, covering the Ni0.6Zn0.4Fe2O4 magnetic substrate, and finally, carrying out calcinations processing at a high temperature of 550 DEG C to obtain the strontium-doped titanium dioxide magnetic nanometer photocatalyst. The prepared strontium-doped titanium dioxide magnetic nanometer photocatalyst has the characteristics of high pollutant treatment efficiency and easiness to recover, has a potential application value in the aspect of treating pollutant effluents through large-scale application of titanium dioxide and has certain scientific research significance in further exploring the influence generated after the alkali metal is doped in titanium dioxide.

Owner:江西农人园林开发有限公司 +1

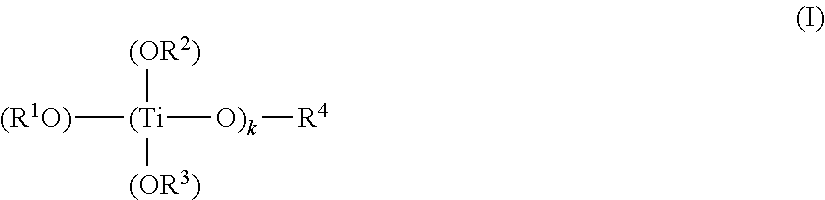

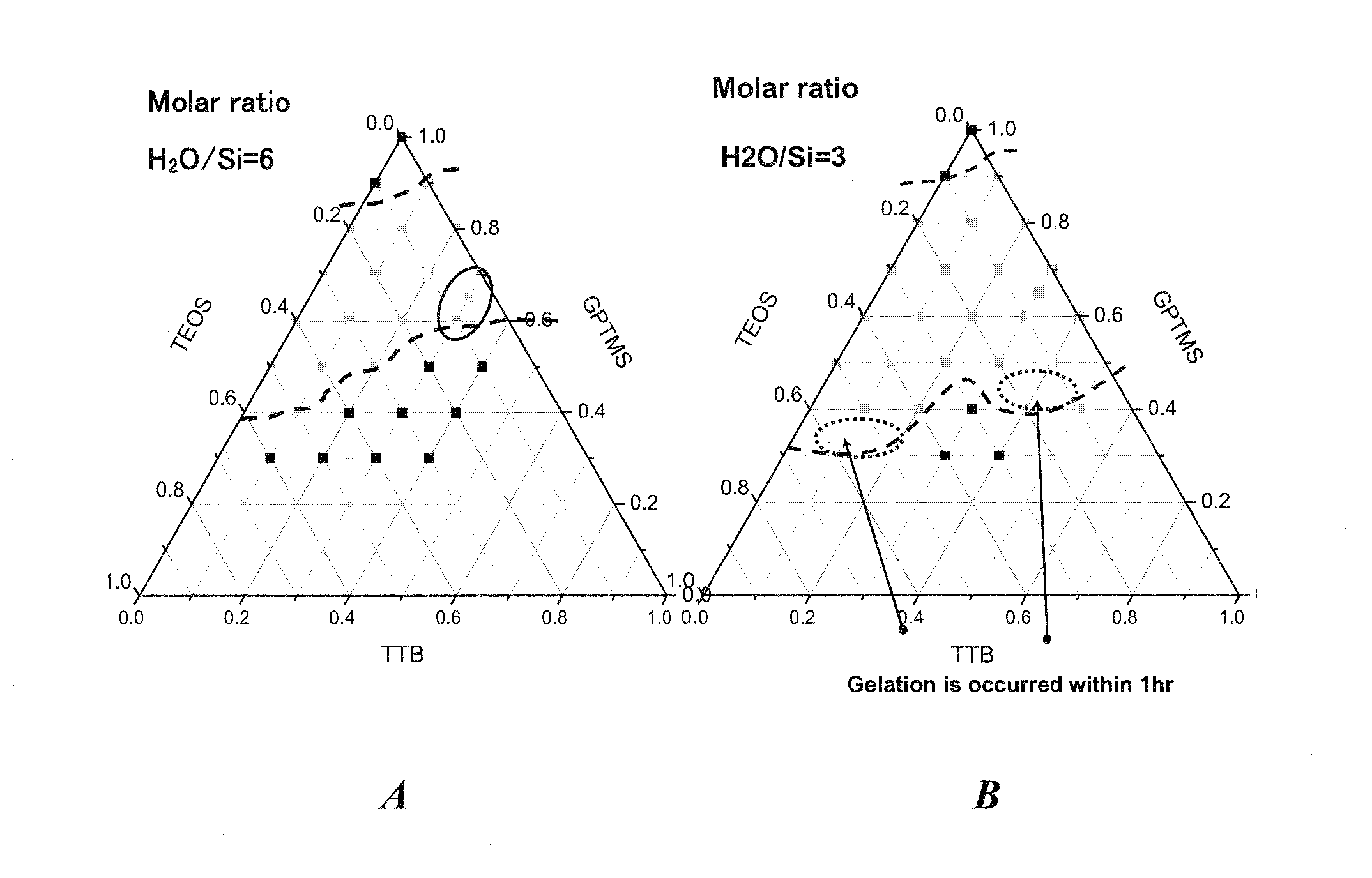

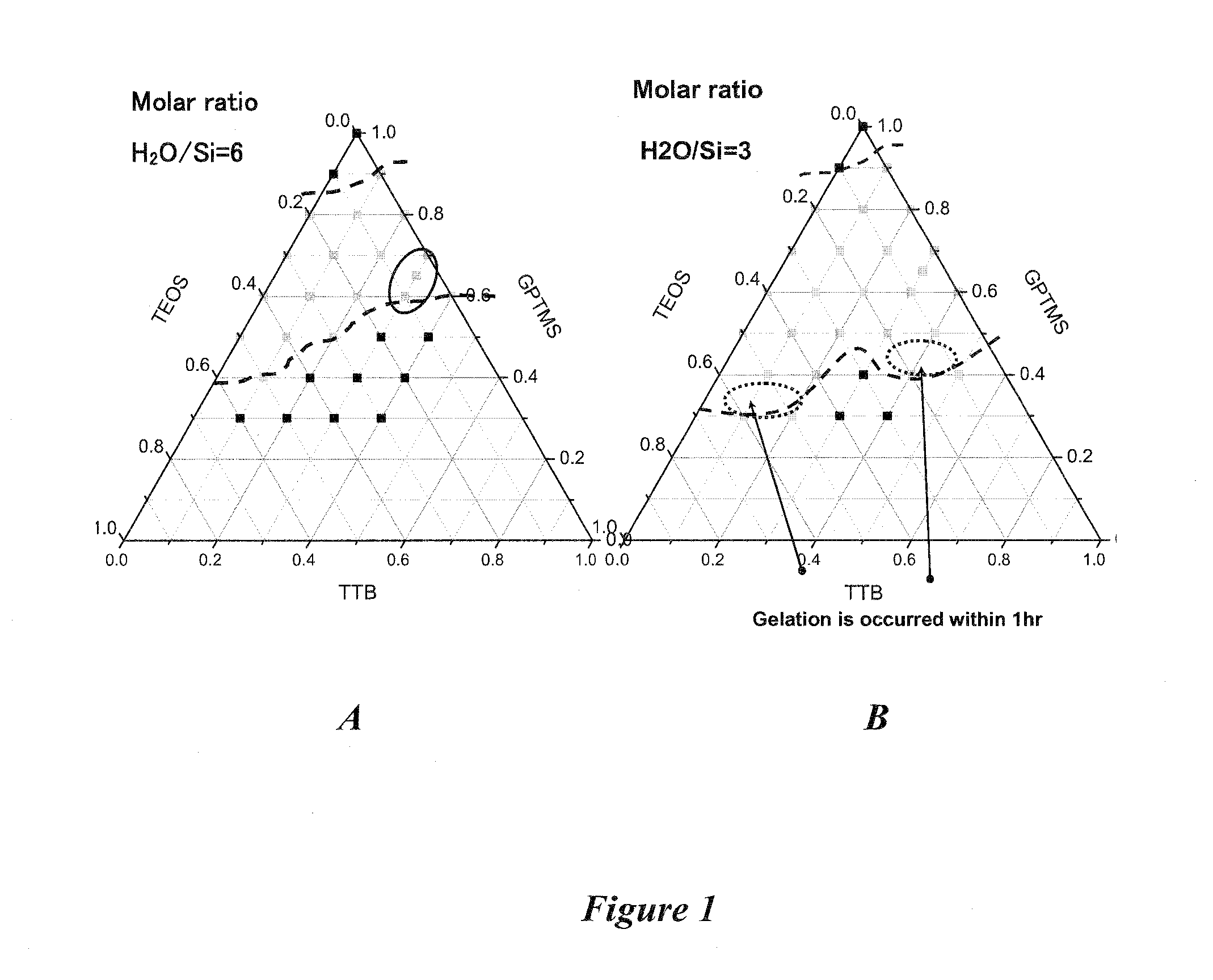

Transparent inorganic-organic hybrid materials via aqueous sol-gel processing

A sol to form an inorganic-organic hybrid coating having a thick highly transparent hard coating is described. The hybrid coating is formed from a combined aqueous sol with least one hydrolyzable silane and at least one hydrolyzable metal oxide precursor where the only organic solvents present are those liberated upon hydrolysis of the silanes and metal oxide precursors. In one embodiment an inorganic-organic hybrid coating is formed by combination of a sol, prepared by the hydrolysis of tetraethoxysilane and γ-glycidoxypropyltrimethoxysilane with an excess of water, and a sol, prepared by the hydrolysis of titanium tetrabutoxide and γ-glycidoxypropyltrimethoxysilane with a deficiency of water. A plastic substrate can be coated with the combined sol and the combined sol gelled to a thickness of at least 5 μm with heating to less than 150° C.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

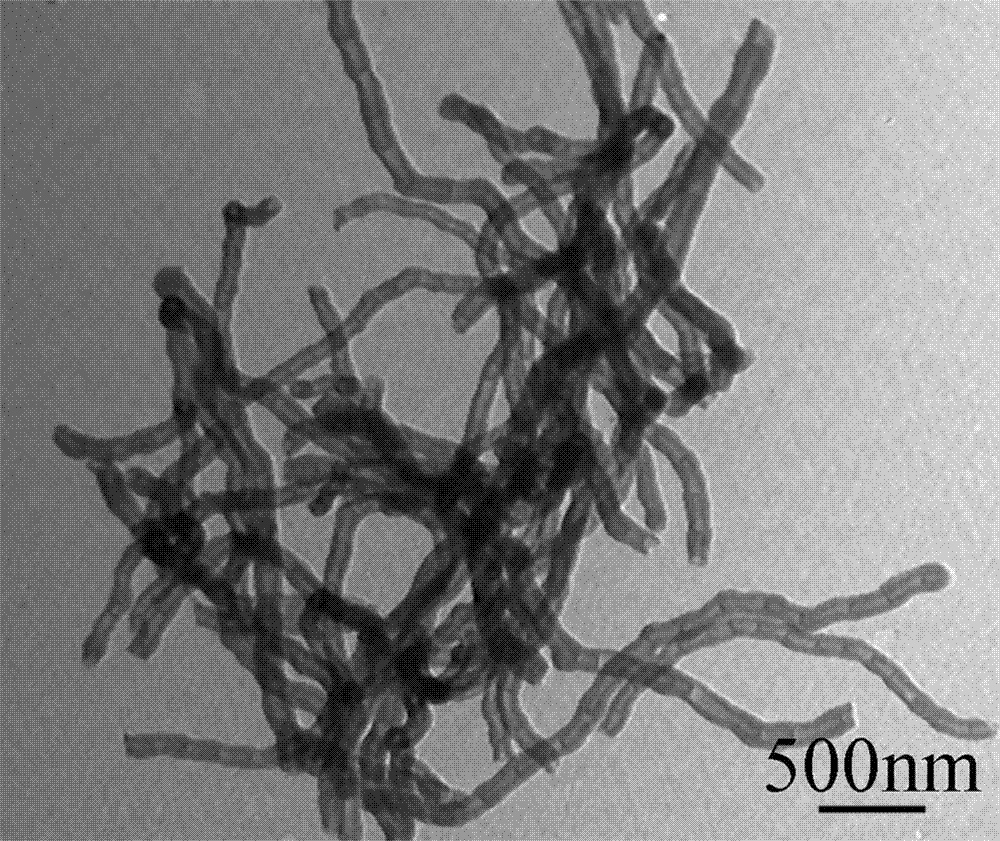

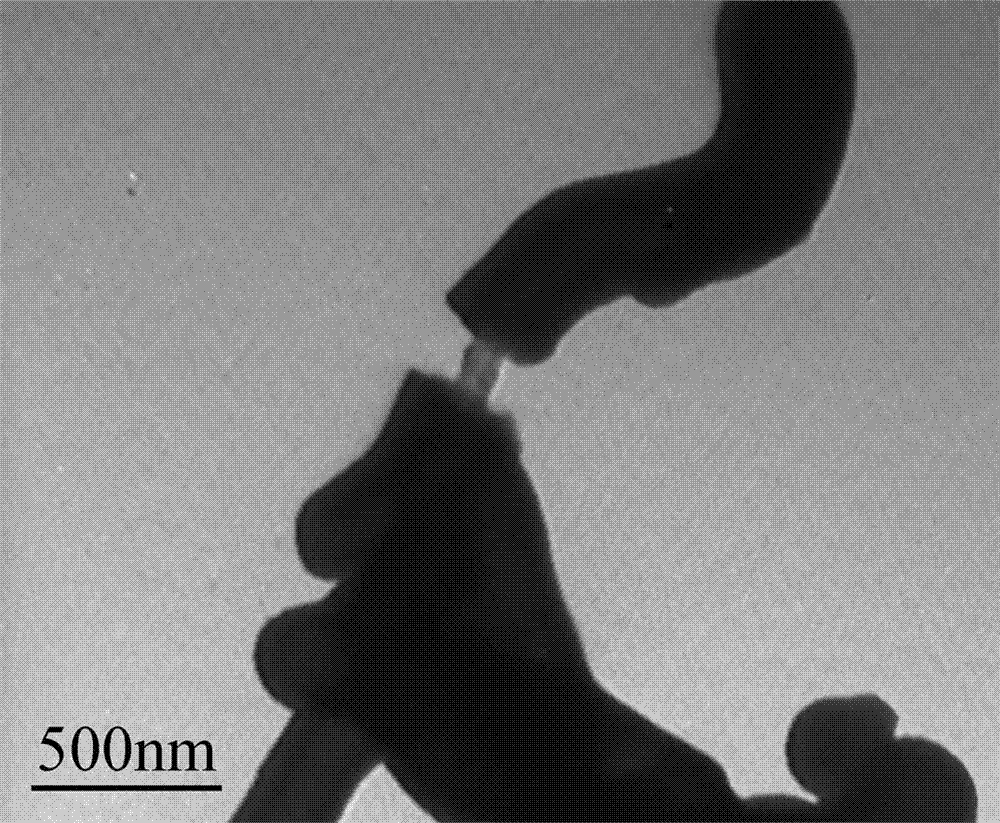

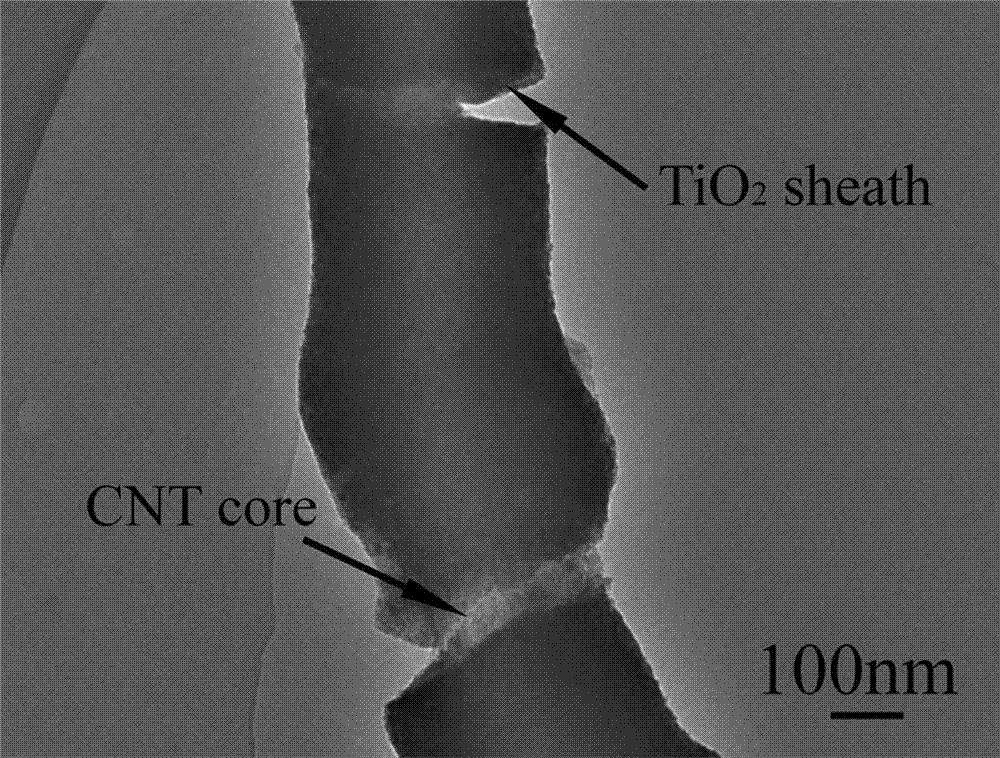

Preparation method and application of carbon nanotube/titanium dioxide coaxial nanometer cable composite material

The invention provides a preparation method of a carbon nanotube / titanium dioxide coaxial nanometer cable composite material. The preparation method comprises the following steps of: carrying out sulfonation and modification on the surface of a bamboo-like polymer nanotube which is used as a template and a carbon source; and inducting titanium tetrabutoxide to hydrolyze by gel and roast in an inert atmosphere to prepare the carbon nanotube / titanium dioxide coaxial nanometer cable composite material. The carbon nanotube / titanium dioxide coaxial nanometer cable composite material is composed of a carbon nanotube core layer, which is of a hierarchical pore, and a titanium dioxide shell layer which is of a mesoporous structure. As a lithium ion battery negative electrode material, the carbon nanotube / titanium dioxide coaxial nanometer cable composite material has better specific capacity and cycling stability, and can be used for showing reversible lithium storage capacity of 231mAh / g after being circulated by 100 cycles under the current of 1000mA / g. The preparation method of the carbon nanotube / titanium dioxide coaxial nanometer cable composite material provided by the invention is simple in process and capable of easily obtaining materials; moreover, the carbon nanotube / titanium dioxide coaxial nanometer cable composite material can be produced in a large-scale manner, excellent in performances, and therefore, the composite material is a lithium ion battery negative electrode material with a favorable application prospect.

Owner:XINJIANG UNIVERSITY

A polypropylene conductive plastic and a preparation method thereof

The invention discloses a polypropylene conductive plastic and a preparation method thereof. The polypropylene conductive plastic comprises the following components in parts by weight: 40-50 parts of PP, 30-40 parts of carbon black, 20-25 parts of PP-g-MAH, 8-10 parts of ethylene-propylene rubber, 10-15 parts of powdered aluminum, 1-15 parts of titanium tetrabutoxide, 5-9 parts of dioctyl terephthalate, 5-6 parts of sodium sulfite, 10-19 parts of ammonium persulfate, 12-18 parts of diisobutyl phthalate, and 11-17 parts of isoeugenol. The polypropylene conductive plastic of the present invention has very good mechanical properties, high impact strength and relatively low shrinkage, good stability and no proneness of deformation; and also has good conductivity, so the plastic can be widely used in anti-electromagnetic interference products, etc., and can be used to replace metal materials, wherein superior performance and lower cost can be achieved.

Owner:SUZHOU NEW DISTRICT JIAHE PLASTIC

Primer composition for metal oxide ceramics

ActiveUS20110143015A1Excellent adhesion durabilityHigh strengthImpression capsPretreated surfacesOxide ceramicsTriethyleneglycol dimethacrylate

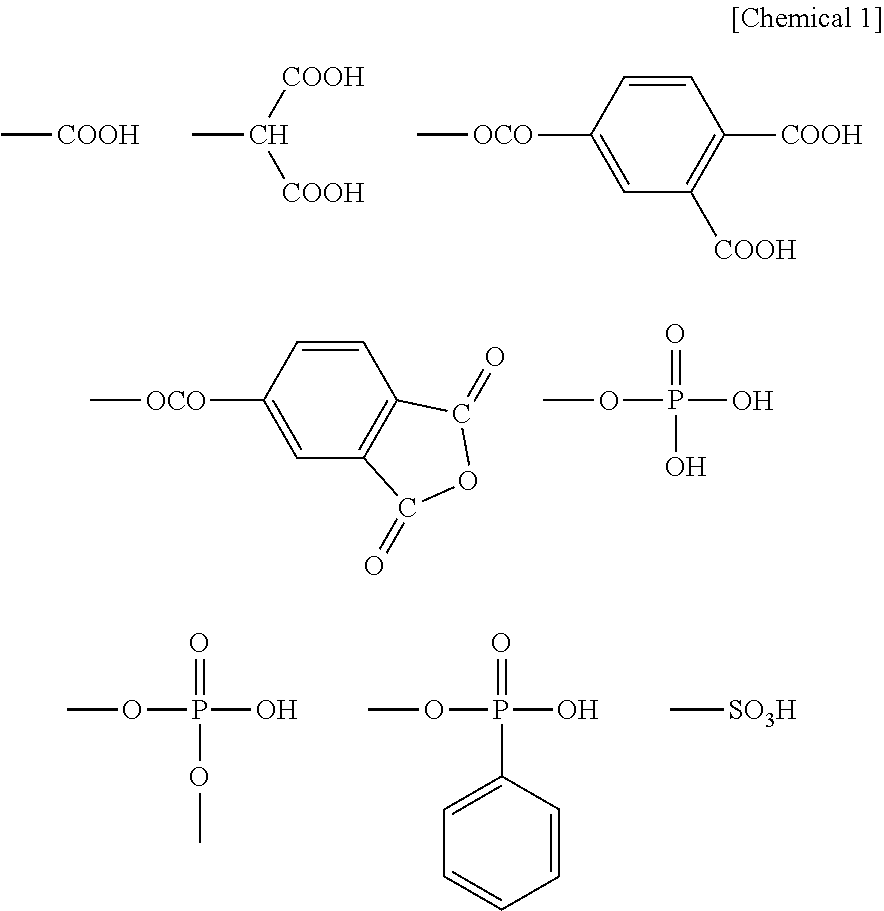

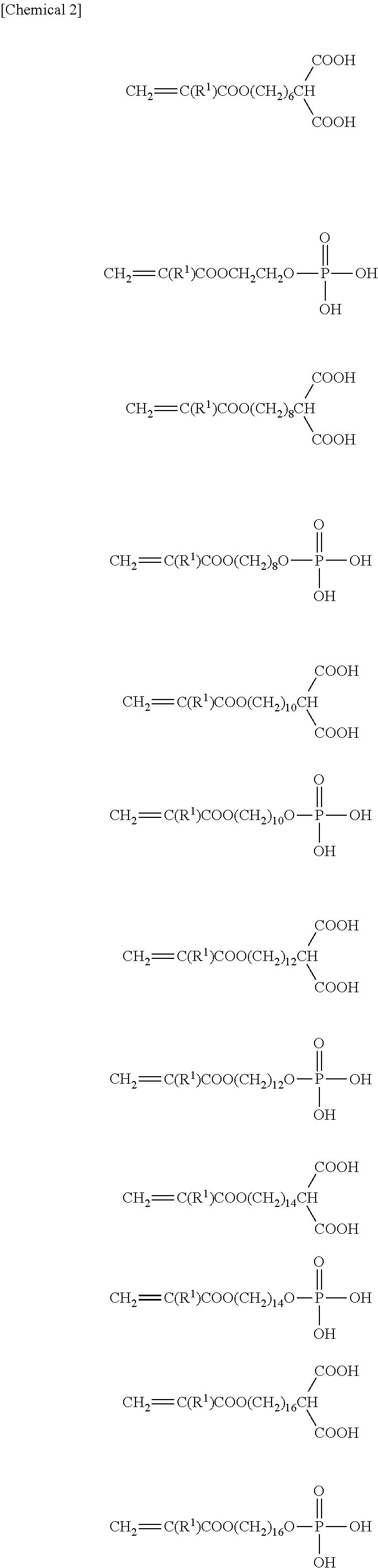

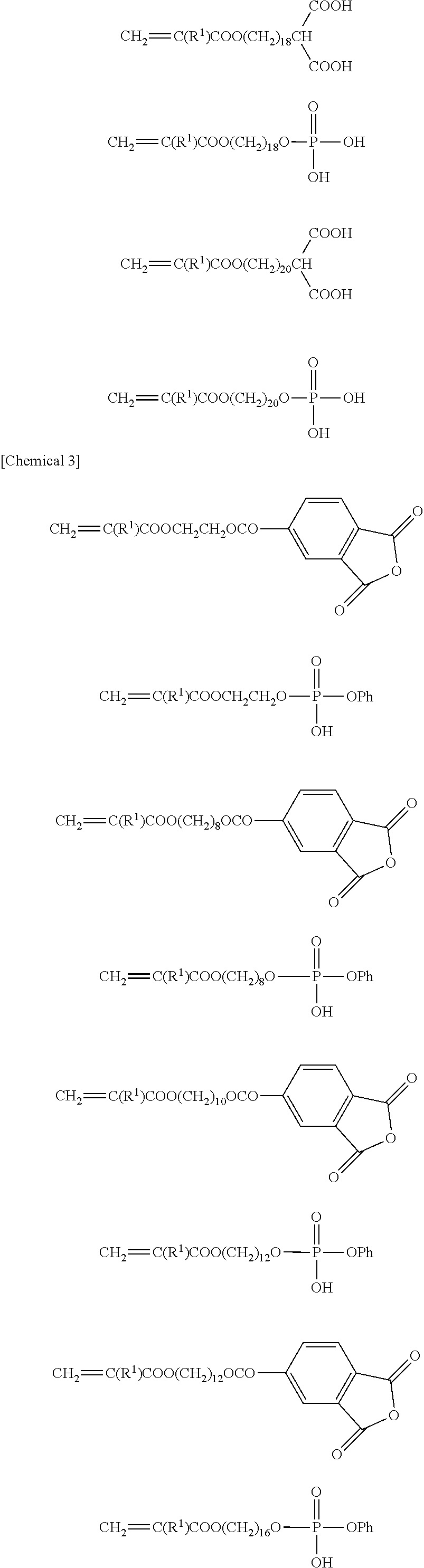

[Problems] A primer used for pre-treating the surfaces of a prosthetic, which exhibits a large adhering force at the time of adhering a prosthetic of metal oxide ceramics to an object to be joined by using an adhesive such as a dental cement, the large adhering force being maintained for extended periods of time even in a severe environment such as in an oral cavity.[Means for Solution] A primer composition for metal oxide ceramics, comprising (A) a polymerizable monomer component containing 5% by mass or more, preferably, 5% by mass to 80% by mass of an acidic group-containing polymerizable monomer as represented by a 11-methacryloyloxy-1,1-undecanedicarboxylic acid and a rest of a polymerizable monomer without acidic group, such as triethylene glycol dimethacrylate; (B) polyvalent metal ions resulting from a titanium tetrabutoxide or the like; and (C) an organic solvent such as acetone or ethyl alcohol, wherein water is not substantially contained.

Owner:TOKUYAMA DENTAL CORP

Preparation method of efficient mesoporous zinc oxide photocatalyst

ActiveCN108014779ABroaden the preparation routeLarge specific surface areaWater/sewage treatment by irradiationWater contaminantsN dimethylformamideZinc

Owner:FUJIAN AGRI & FORESTRY UNIV

Low-temperature environment-friendly polyesterimide wire enamel and preparation method thereof

InactiveCN102304320AImprove heat resistanceGood solvent resistanceCoatingsPolyesterEnvironmental resistance

The invention relates to low-temperature environment-friendly polyesterimide wire enamel and a preparation method thereof. The low-temperature environment-friendly polyesterimide wire enamel is prepared by mixing raw material components including dimethyl phenol, cis-butenedioic anhydride, acrylic ester, diaminodiphenyl ether, glycerol, glycol, n-butyl titanate, straw ash, titanium tetrabutoxide, attapulgite and chlorinated olefin according to a certain weight part ratio, and reacting to obtain a finished product. The preparation method is simple and low in cost; and the prepared wire enamel has high heat resistance, solvent resistance and freezing resistance.

Owner:BENGBU YINGLU PHOTOELECTRIC

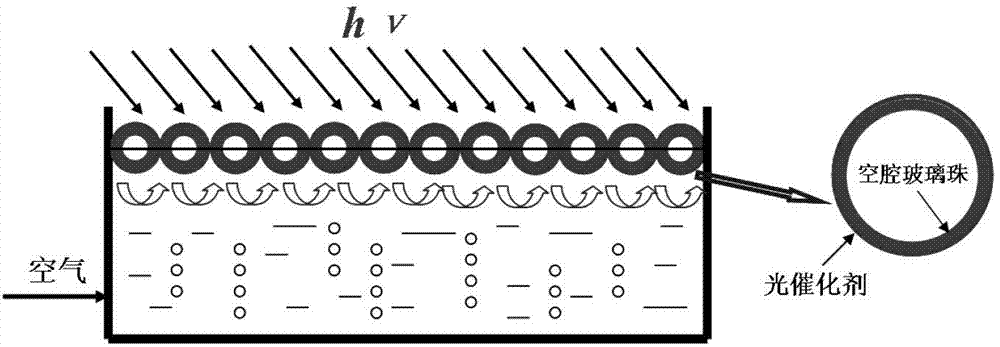

Process for coating Bi2O3/TiO2 photocatalysis film on surface of hollow lightweight glass sphere

InactiveCN103084163ASolve separation and recyclingHigh light utilization efficiencyMetal/metal-oxides/metal-hydroxide catalystsPhotocatalytic reactionPolyethylene glycol

The invention discloses a process for coating a Bi2O3 / TiO2 photocatalysis film on the surface of a hollow lightweight glass sphere and discloses application of the hollow lightweight glass sphere with a surface coated with the Bi2O3 / TiO2 photocatalysis film. According to the process, bismuth nitrate, titanium tetrabutoxide, nitric acid, water, pentanediol, polyethylene glycol, acetylacetone and the like are adopted for forming a precursor solution; the sphere is rotatably coated with a film and then is quickly dried to obtain the uniform Bi2O3 / TiO2 catalyst film; the glass sphere with the Bi2O3 / TiO2 photocatalysis film coated on the surface is placed into a suspending type photocatalysis reactor and can be used for degrading organic pollutants such as methyl orange under illumination, and the glass sphere is excellent in photocatalysis performance; the process has the advantages that the raw materials are easily available, the preparation cost is low, the film coating process is simple, and the condition is easy to control; and the liquid film on the surface of the glass sphere is thin, has high light transmittance and high transfer efficiency, does not need to be separated and recycled and is capable of continuously working; and simultaneously, the process provides reference value respect to other film coating technologies and brings basic theoretical basis for designing and amplifying the photocatalysis reactor in future.

Owner:SHANGHAI NORMAL UNIVERSITY

Heat-resistance polyesterimide wire enamel and preparation method thereof

The invention relates to heat-resistance polyesterimide wire enamel and a preparation method thereof. The heat-resistance polyesterimide wire enamel is mainly prepared by mixing raw material components including dimethyl phenol, trimellitic anhydride, diaminodiphenyl methane, cis-butenedioic anhydride, acrylic ester, glycerol, glycol, dimethyl terephthalate, straw ash, titanium tetrabutoxide, attapulgite, N-methyl pyrrolidone and chlorinated olefin according to a certain weight part ratio, and reacting to obtain a finished product. The preparation method disclosed by the invention is simple and low in cost; and the prepared wire enamel has high heat resistance, solvent resistance and freezing resistance.

Owner:BENGBU YINGLU PHOTOELECTRIC

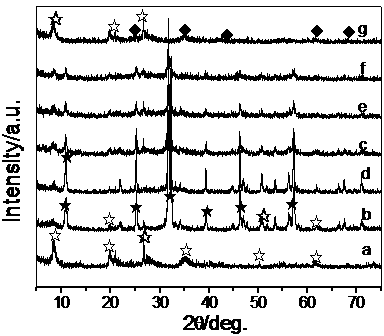

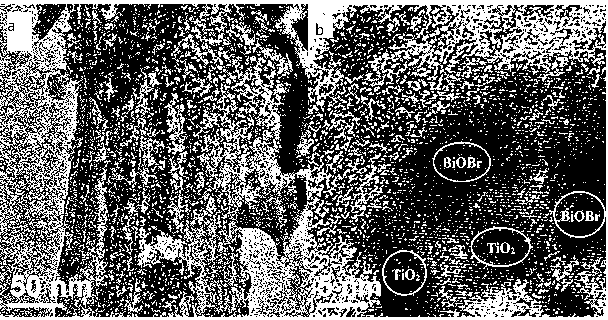

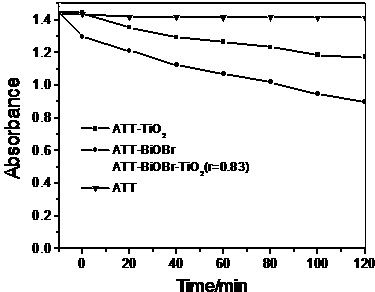

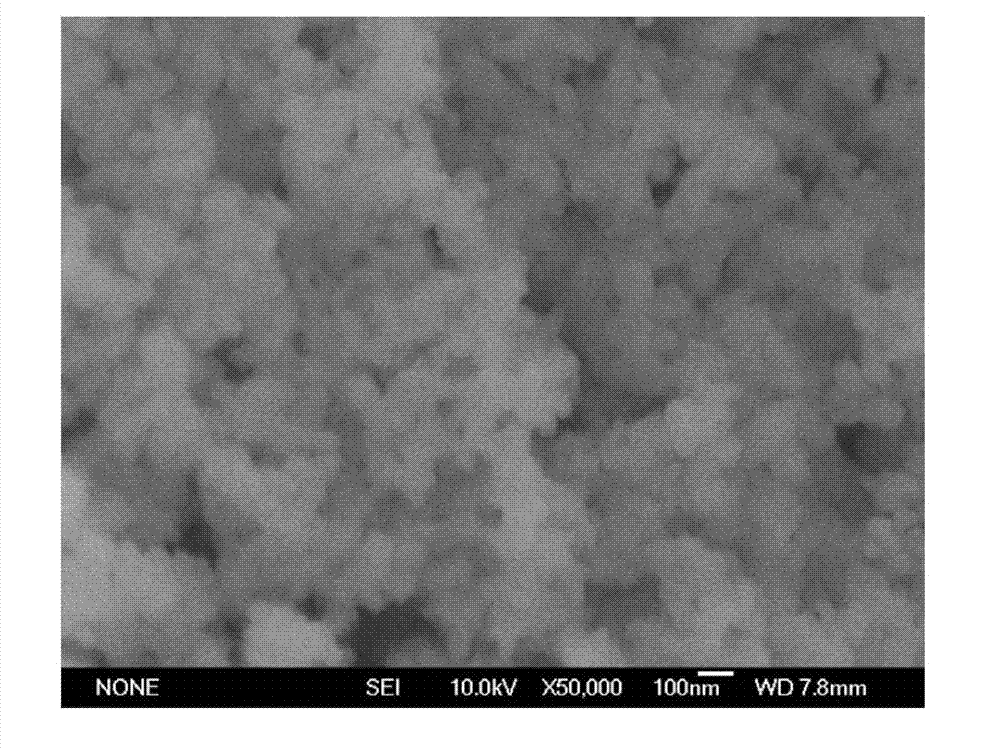

Preparation method of visible-light response type attapulgite-BiOX-TiO2 compound photo-catalyst

ActiveCN103212428AGood coating effectHigh visible light photocatalytic performancePhysical/chemical process catalystsUltrasonic dispersionMuffle furnace

The invention discloses a preparation method of a visible-light response type attapulgite-BiOX-TiO2 compound photo-catalyst. The preparation method of the visible-light response type attapulgite-BiOX-TiO2 compound photo-catalyst comprises the following steps of: dispersing attapulgite into deionized water with the amount being 40-50 times that of the attapulgite; stirring and removing deposited mud, carrying out ultrasonic dispersion on the treated attapulgite, and removing mud against, so as to obtain a attapulgite suspension; dropping a Bi(NO3)3.5H2O acid solution to the attapulgite suspension, stirring the mixture, dropping a halogen inorganic salt water solution into the stirred mixture, stirring for 30 minutes, then adjusting the pH value to be 6-7 by strong ammonia water, stirring for 4-5 hours, standing and aging for one night, extracting and filtering, drying at 60-100 DEG C, grinding, and baking the ground mixture in a muffle furnace at 150-350 DEG C for 2-6 hours, so as to obtain an ATT-BiOX semi-finished product; and adding certain amount of titanium tetrabutoxide in the ATT-BiOX semi-finished product, stirring uniformly, adding 100mL of deionized water, stirring for 4-8 hours, standing and aging or one night, extracting and filtering, washing by the deionized water, drying at 60 DEG C-100 DEG C, grinding, and baking the ground mixture in the muffler furnace at 150-350 DEG C for 4-8 hours, so as to obtain an ATT-BiOX-TiO2 compound photo-catalyst. The ATT-BiOX-TiO2 compound photo-catalyst provided by the invention has a favorable visible light degrading effect, also can lower the cost, reduces the pollution, and has a favorable application prospect and an economical benefit on the aspect of sewage treatment.

Owner:江苏诚丰新材料股份有限公司

Technology for preparing magnetic reflective glass beads through sol-gel method

InactiveCN107365084ACompact structureGood refractive indexGlass shaping apparatusParaffin waxAlcohol

The invention discloses a technology for preparing magnetic reflective glass beads through a sol-gel method. The technology comprises the following steps: using tetraethyl orthosilicate as a silicon source and titanium tetrabutoxide as a titanium source, adding an alcohol solution of iron chloride to obtain an iron-doped mixed sol system, dropwise adding the iron-doped mixed sol system to paraffin having a certain temperature, and dispersing the sol under the action of surface tension to form SiO2-TiO2 glass bead bodies having a good roundness; and controlling the addition amount of the alcohol solution of iron chloride to make the glass beads have a good refractive index and endow the glass beads with a certain magnetic property, and carrying out bead implantation treatment through a magnetic field to make the produced product have a magnetic property in order to enhance the use performances of the product.

Owner:HEFEI DINGLIANG OPTICAL TECH

Preparation method of Mn-Ti oxide system low-temperature selective catalytic reduction (SCR) catalyst

ActiveCN102824908AControllableEasy to implementMetal/metal-oxides/metal-hydroxide catalystsSolventTitanium tetrabutoxide

The invention discloses a preparation method of a Mn-Ti oxide system low-temperature selective catalytic reduction (SCR) catalyst. The preparation method comprises the following steps of: in a stirring condition, adding titanium tetrabutoxide in acrylic acid to uniformly mix, adding manganous nitrate and a solvent, and stirring a mixture to form a homogeneous phase solution, wherein a mol ratio of the titanium tetrabutoxide to the manganous nitrate ranges from 10: 1 to 10: 6, and a mol ratio of sum of the titanium tetrabutoxide and the manganous nitrate to the acrylic acid ranges from 1: 5 to 1: 1; deoxidizing by introducing nitrogen, and adding an initiator to polymerize, so as to obtain solid polyacrylate; and drying and carrying out pyrolysis on the solid polyacrylate, and then grinding to obtain Mn-Ti oxide powder. The preparation method provided by the invention has the advantages of easiness of control and convenience in implementation; metal ions in a prepared polymer precursor can be horizontally and uniformly mixed in an ion level; the grain size of the Mn-Ti oxide powder prepared by sintering the polymer precursor can reach a nanometer level and a narrow distribution range so that the Mn-Ti oxide system low-temperature SCR catalyst has a better application prospect in a low-temperature smoke SCR denitration reaction catalyst field.

Owner:WUHAN IRON & STEEL ENG TECH GROUP

Cabin-oriented aromatic paint with excellent heat resistance and thermal conductivity and preparation method thereof

InactiveCN104293174AImprove heat resistanceImprove waterproof performanceBituminous coatingsHexamethylphosphoramideCarbon fibers

The invention discloses a cabin-oriented aromatic paint with excellent heat resistance and thermal conductivity, which is characterized by being prepared from the following raw materials in parts by weight: 15-19 parts of organic silicon resin, 12-16 parts of organic fluorine resin, 3-6 parts of aminoethylpiperazine, 0.5-1.0 part of polymethacrylate, 1-3 parts of hexamethylphosphoramide, 4-6 parts of vinyl chloride-vinylidene chloride copolymer emulsion, 1-2 parts of alkenyl succinate, 0.4-1.0 part of ethoxylated dodecylalcohol, 1-3 parts of carbon fiber, 13-17 parts of modified asphalt, 1-3 parts of rosewood oil, 0.5-1.0 part of citronellal, 0.5-1.0 part of vanillin, 2-3 parts of silica gel powder, 6-8 parts of modified waste sodium silicate-bonded sand, 1-2 parts of simethicone, 2-3 parts of quartz powder, 2-3 parts of Turkey red oil, 1-2 parts of titanium tetrabutoxide, 10-13 parts of dimethylbenzene and 8-10 parts of n-butyl acetate. In the paint disclosed by the invention, the added organic fluorine resin has the characteristics of excellent high and low temperature resistance, chemical stability, weather resistance, noninflammability, non-viscidity, and the like; the added vinyl chloride-vinylidene chloride copolymer emulsion is non-toxic, non-combustible, good in film-forming property, and ensures a compact film; the added carbon fiber has good high temperature resistance, acid / alkali corrosion resistance and thermal conductivity; the added silica gel powder improves the heat resistance of the paint; and in the invention, the waste sodium silicate-bonded sand is modified, so that the reutilization of wastes is realized, and the heat resistance, water resistance and fire resistance of the paint are improved.

Owner:TIANCHANG YINHU PAINT

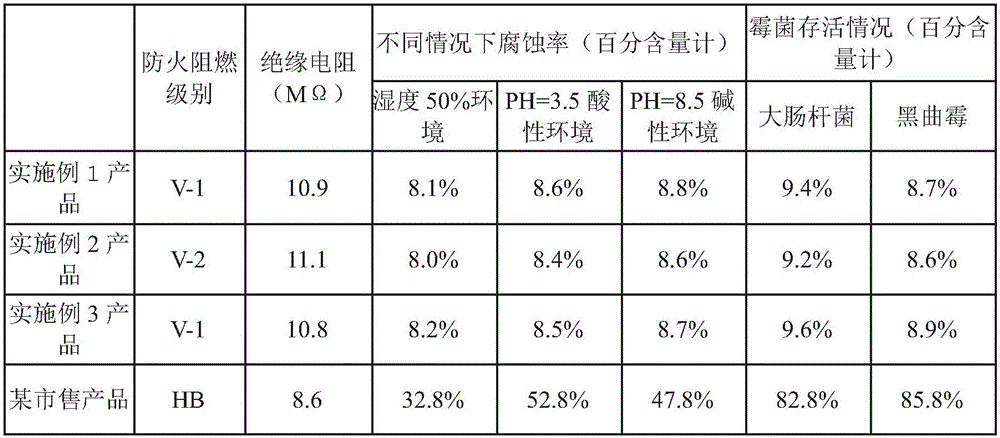

Packaging thin film material for electronic commerce logistics transportation

InactiveCN105907075AExcellent flame retardantGood acid and alkali resistanceBenzoic acidDecabromobiphenyl ether

The invention relates to a packaging thin film material for electronic commerce logistics transportation. The packaging thin film material is prepared from the following components: epichlorohydrin rubber, chloroprene rubber adhesive, neoprene, deca-brominated diphenyl ether, titanium tetrabutoxide, sodium stannate, barium stearate, parachlormetaxylenol, garlic extract, beta-bromo-beta-nitrotrimethyleneglycol, 2-mercaptobenzothiazole, garlic oil, sodium dihydrogen phosphate, lead oxide powder, lead iodate powder, vermiculite powder, camellia pollen, modified attapulgite powder, pearl powder, amyl acetate, sesame oil, methyl isobutyl carbinol, trimethyl borate, N-nitro sodimethylamine, arabinogalactan, amino propyl trimethoxy silane, a barium-zinc stabilizer, benzotriazole, benzoic acid and ricinoleic acid polyoxyethylene allyl ester. The packaging thin film material has relatively excellent flame resistance, acid and alkali resistance and mildew and mold resistance; and the product performance is improved.

Owner:王根夫

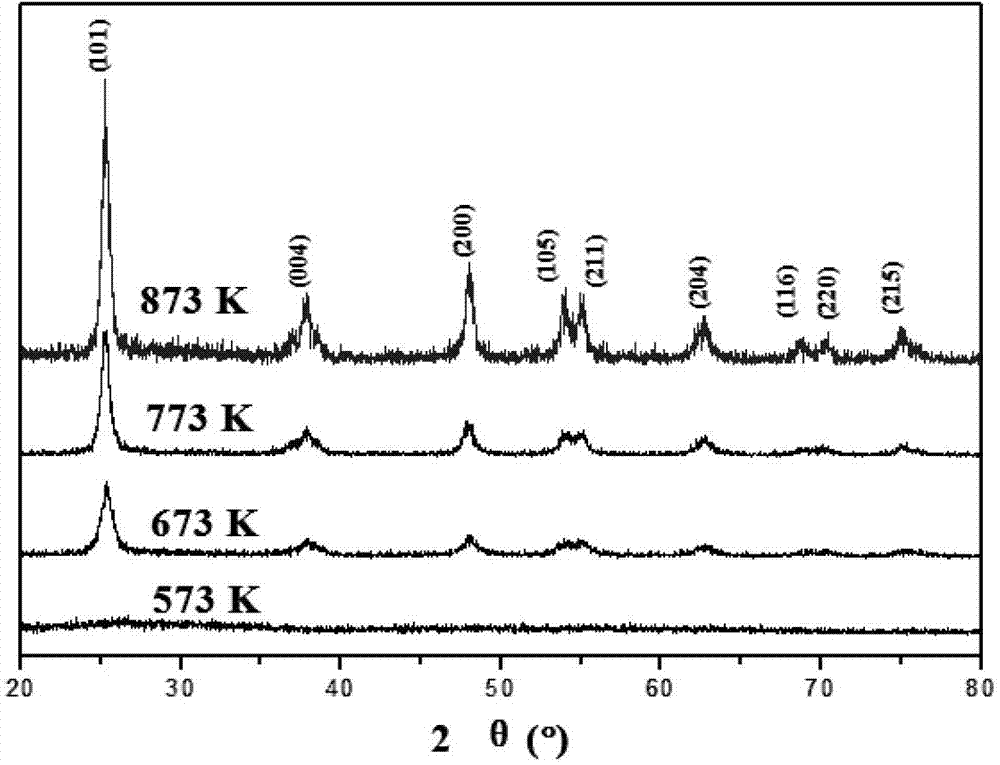

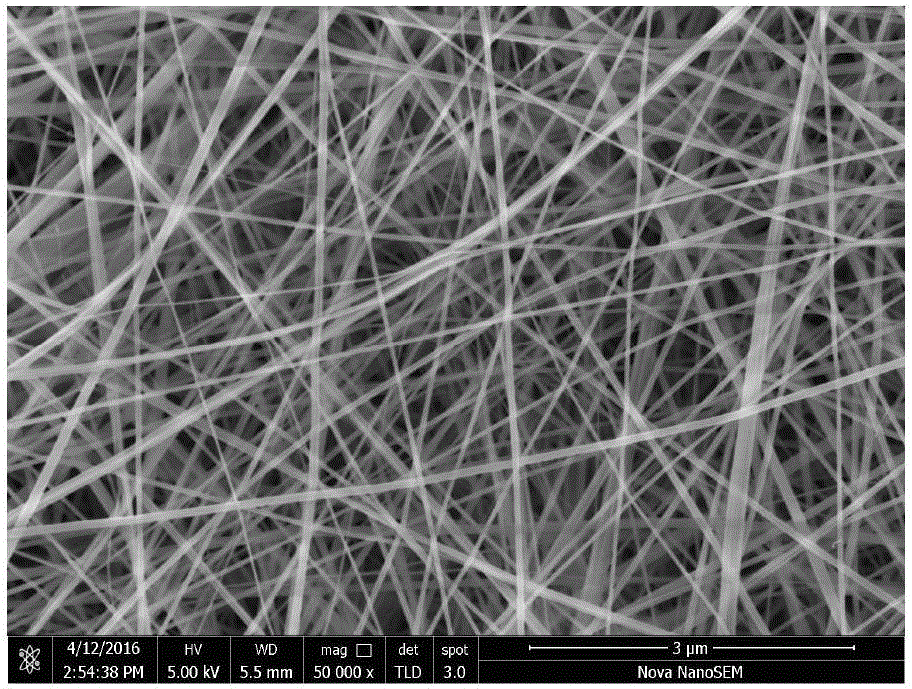

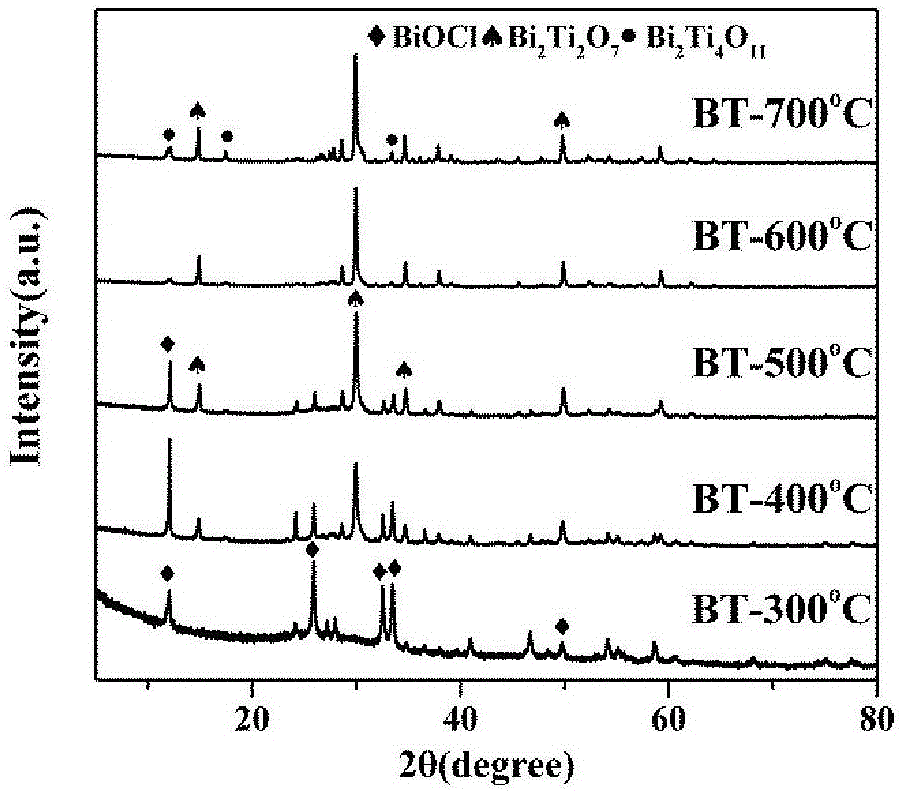

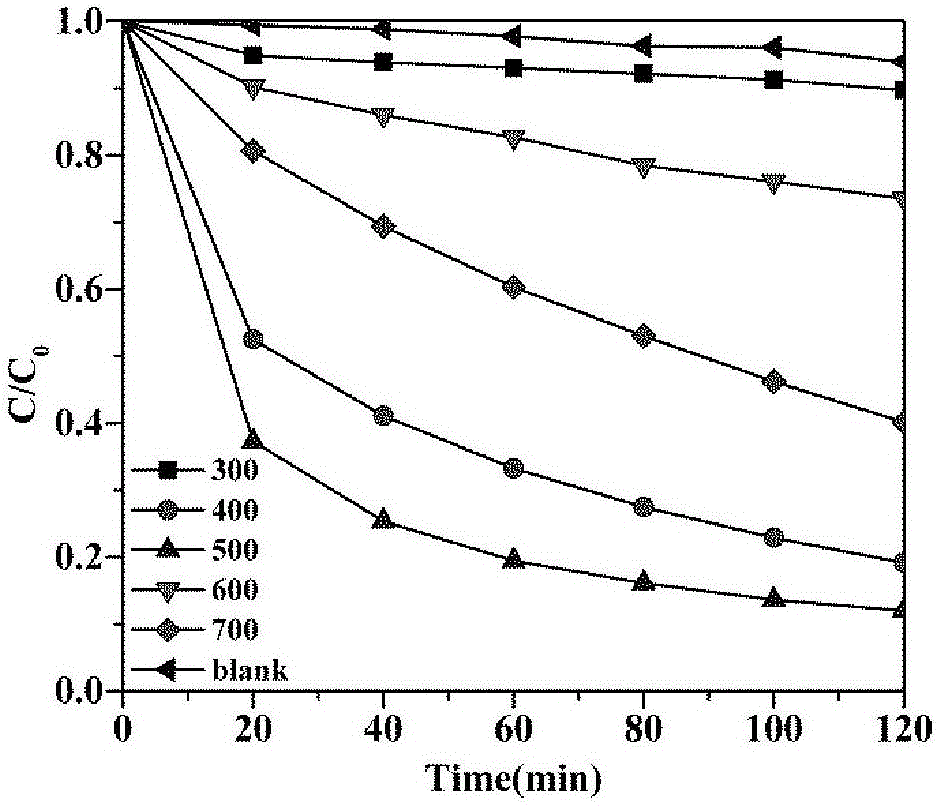

Method for preparing simply regulated and controlled different-crystal-form bismuth-titanium composite oxide photocatalysts and application of method

InactiveCN106540676AThe synthesis process is simpleEasy to operateWater/sewage treatment by irradiationWater treatment compoundsFiberTetracycline Hydrochloride

The invention discloses a method for preparing simply regulated and controlled different-crystal-form bismuth-titanium composite oxide photocatalysts and application of the method. The method comprises the following steps: electrospinning prepared a polyvinylpyrrolidone / bismuth chloride / titanium tetrabutoxide precursor solution into polyvinylpyrrolidone / bismuth chloride / titanium tetrabutoxide composite nanofibers by using a prepared electrostatic spinning solution through an electrostatic spinning device under the effect of high-voltage static electricity; and then calcining the composite nanofibers at different temperatures to generate different-crystal-form bismuth-titanium composite oxides. Crystal forms of the oxides can be regulated and controlled by controlling the calcination temperature of the prepared polyvinylpyrrolidone / bismuth chloride / titanium tetrabutoxide composite nanofibers, and the composite oxides obtained by calcination can effectively degrade a tetracycline hydrochloride solution under simulated sunlight.

Owner:FUJIAN NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com