Black phosphorus quantum dots, titanium dioxide/black phosphorus quantum dot composite material, production methods of black phosphorus quantum dots and titanium dioxide/black phosphorus quantum dot composite material and application of titanium dioxide/black phosphorus quantum dot composite material

A technology of titanium dioxide and composite materials, which is applied in the preparation of titanium dioxide and phosphorus, chemical instruments and methods, etc., can solve the problems of poor size controllability and stability, agglomeration of black phosphorus quantum dots, and limited photocatalytic activity. Fluid transport performance, uniform size, and good industrial prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

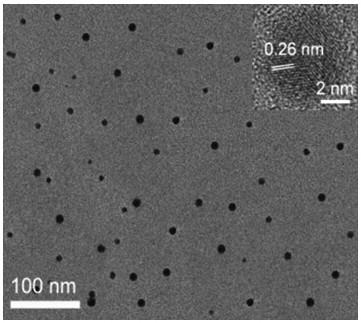

[0024] A preparation method of black phosphorus quantum dots, the specific steps are as follows: in the aqueous solution saturated with nitrogen, add block black phosphorus, the mass ratio of water and black phosphorus is 4000: (1-4), under the action of ice water bath, ultrasonic 2-6 hours to obtain a dispersion of black phosphorus nanosheets; then place the dispersion of black phosphorus nanosheets in a reaction kettle at 180-200° C. for 6-12 hours to obtain an aqueous solution containing black phosphorus quantum dots. The preparation process of black phosphorus quantum dots is as follows: figure 1 As shown, the transmission electron microscope pictures of black phosphorus quantum dots are as follows figure 2 It can be seen from the figure that the size of the black phosphorus quantum dots is within 5nm, and the dispersion is good.

[0025] Black phosphorus quantum dots prepared by the above-mentioned preparation method.

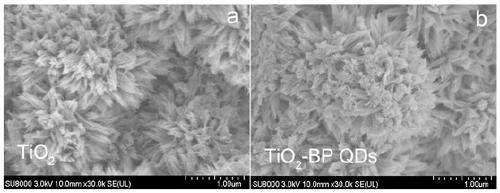

[0026] A preparation method of titanium dioxide / b...

Embodiment 1

[0032] A preparation method of black phosphorus quantum dots, the specific steps are as follows: in the aqueous solution saturated with nitrogen, add block black phosphorus, the mass ratio of water and black phosphorus is 4000:1, under the action of ice water bath, ultrasonic 2h, obtain black phosphorus Phosphorus nanosheet dispersion; then place the black phosphorus nanosheet dispersion in a reaction kettle for 6 hours at 180° C. to obtain an aqueous solution containing black phosphorus quantum dots.

Embodiment 2

[0034] A method for preparing black phosphorus quantum dots, the specific steps are as follows: in a nitrogen-saturated aqueous solution, block black phosphorus is added, the mass ratio of water to black phosphorus is 4000:2, and under the action of an ice-water bath, ultrasonic waves are used for 3 hours to obtain black phosphorus. Phosphorus nanosheet dispersion; then place the black phosphorus nanosheet dispersion in a reaction kettle and heat it under water at 185° C. for 7 hours to obtain an aqueous solution containing black phosphorus quantum dots.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com