One-step microwave synthesis method of metalloporphyrin-titanium dioxide composite catalyst

A composite catalyst, metal porphyrin technology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of time-consuming and cumbersome, and achieve easy process control. , the reaction conditions are mild, the effect of good photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Step 1, take 9 ml of absolute ethanol in a beaker, drop 7 ml of tetra-n-butyl titanate (TBOT) to obtain liquid A;

[0028] Weigh 1.63 mg of CoTCPP, dissolve it in 19 ml of absolute ethanol, then add 2 ml of distilled water, and wait until it is completely dissolved to obtain liquid B;

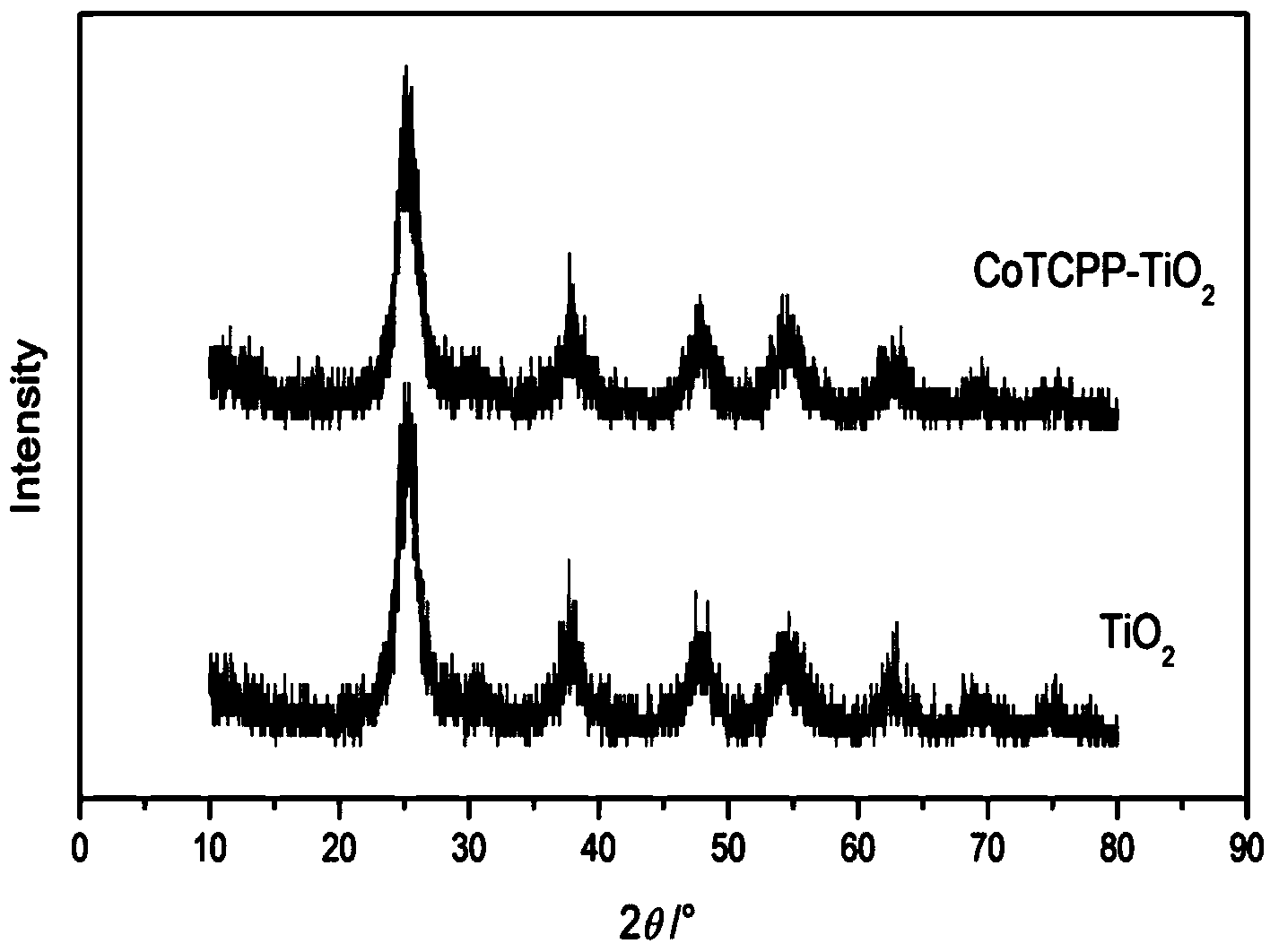

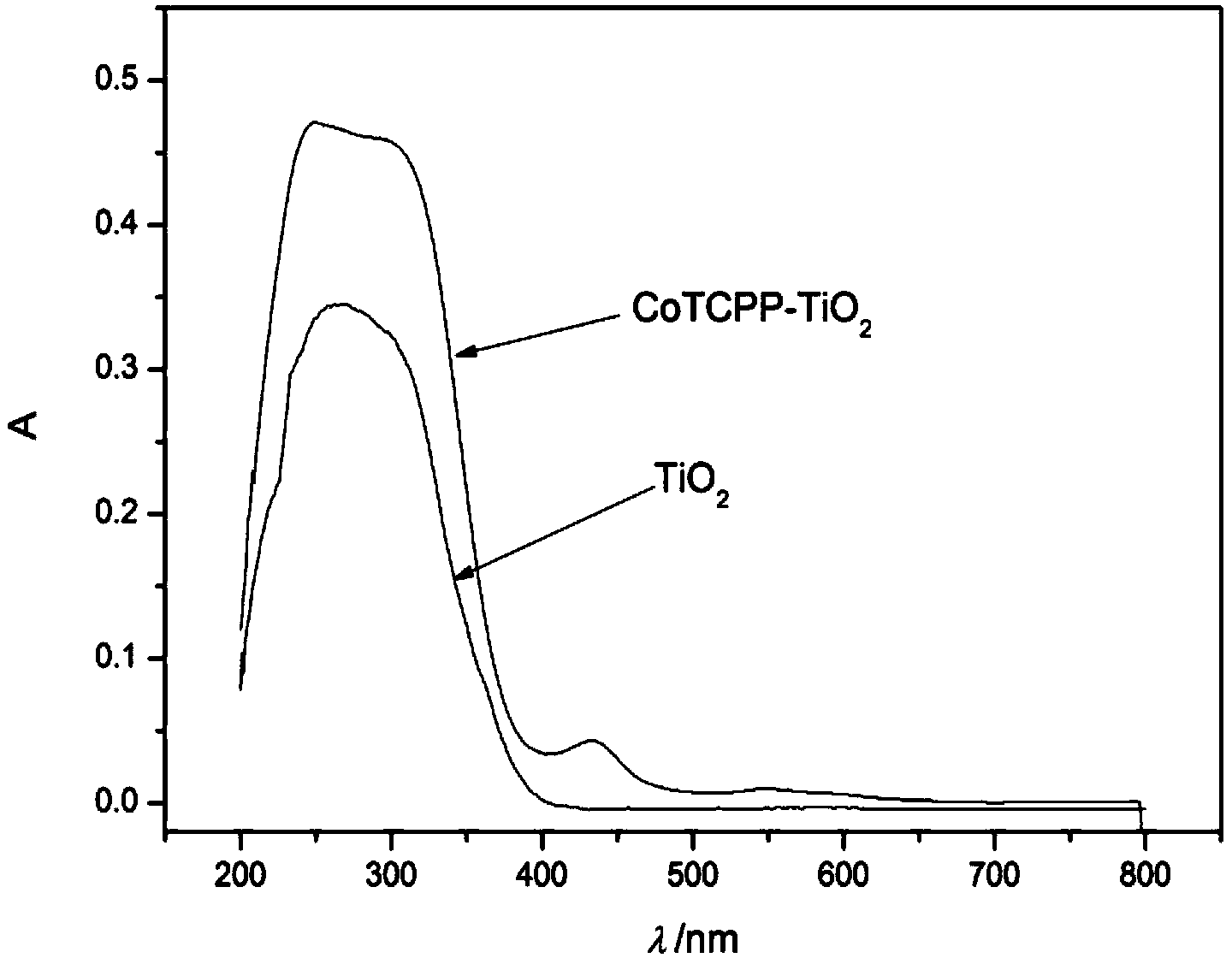

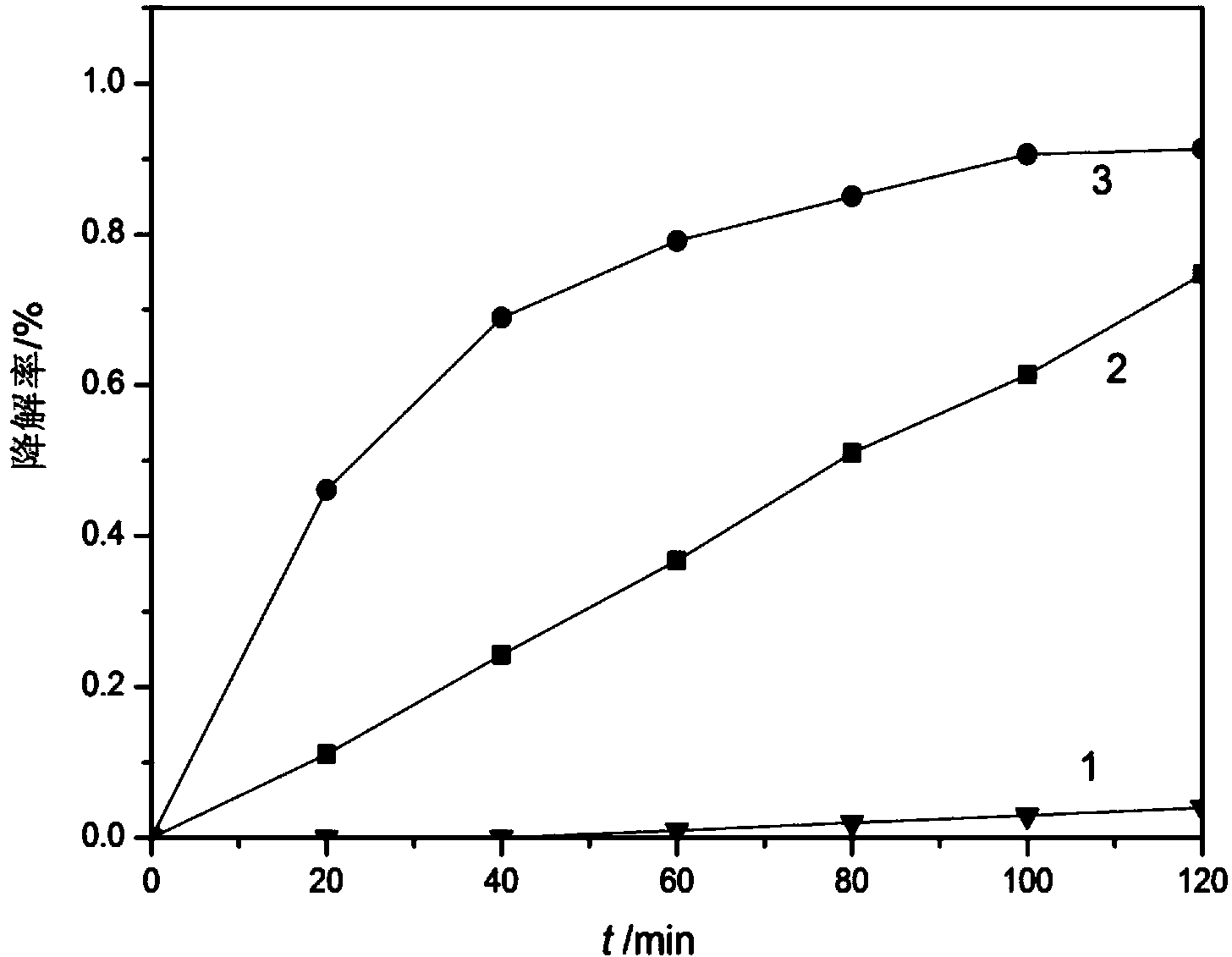

[0029] Step 2, slowly pour liquid B into liquid A under magnetic stirring state, and stir for 30 minutes; after the stirring is completed, put the above mixed liquid into a 50 ml microwave reaction tank, use a high-pressure microwave synthesis workstation, and the reaction conditions are temperature-controlled method, the reaction temperature is 100°C, and the reaction time is 10 minutes; after the reaction, cool to room temperature, take out the reaction kettle, add 10 ml of absolute ethanol to the solid product for washing once, pour out the upper liquid after centrifugation, and then add 10 ml of deionized water, washed three times repeatedly, and dried in an oven (60°C), the final ca...

Embodiment 2

[0031] Step 1, 2 ml of n-butyl titanate was dissolved dropwise into 9 ml of absolute ethanol under magnetic stirring conditions to obtain liquid A;

[0032] Then 8 mg of metalloporphyrin was dissolved in 19 ml of absolute ethanol, and 1 ml of deionized water was slowly added dropwise to obtain liquid B.

[0033] Step 2, slowly pour liquid B into liquid A under magnetic stirring, and stir for 20 minutes to obtain a mixed liquid;

[0034] After the stirring is completed, put the mixed solution into a microwave reaction tank, and use a high-pressure microwave synthesis workstation. The reaction conditions are temperature control mode, the microwave reaction temperature is 150°C, and the reaction time is 30 minutes;

[0035] After the microwave reaction, cool to normal temperature, take out the solid product in the reactor, wash with absolute ethanol and deionized water respectively, and finally put the solid product in an oven (60°C) to dry.

Embodiment 3

[0037] Step 1, dissolve 9 ml of n-butyl titanate dropwise into 9 ml of absolute ethanol under magnetic stirring conditions to obtain liquid A;

[0038] Then 0.2 mg of metalloporphyrin was dissolved in 19 ml of absolute ethanol, and then 3 ml of deionized water was slowly added dropwise to obtain liquid B.

[0039] Step 2, slowly pour liquid B into liquid A under magnetic stirring, and stir for 25 minutes to obtain a mixed liquid;

[0040] After the stirring is completed, put the mixed solution into a microwave reaction tank, and use a high-pressure microwave synthesis workstation. The reaction conditions are temperature control mode, the microwave reaction temperature is 130°C, and the reaction time is 20 minutes;

[0041] After the microwave reaction, cool to normal temperature, take out the solid product in the reactor, wash with absolute ethanol and deionized water respectively, and finally put the solid product in an oven (60°C) to dry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com