Preparation method of praseodymium-doped calcium titanate luminescent powder

A technology of calcium titanate and luminescent powder, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems that it is difficult to obtain regular morphology, the particle size of the product is difficult to control, and the particles are easy to agglomerate and have irregular morphology. The effect of long synthesis time, simple operation and high sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

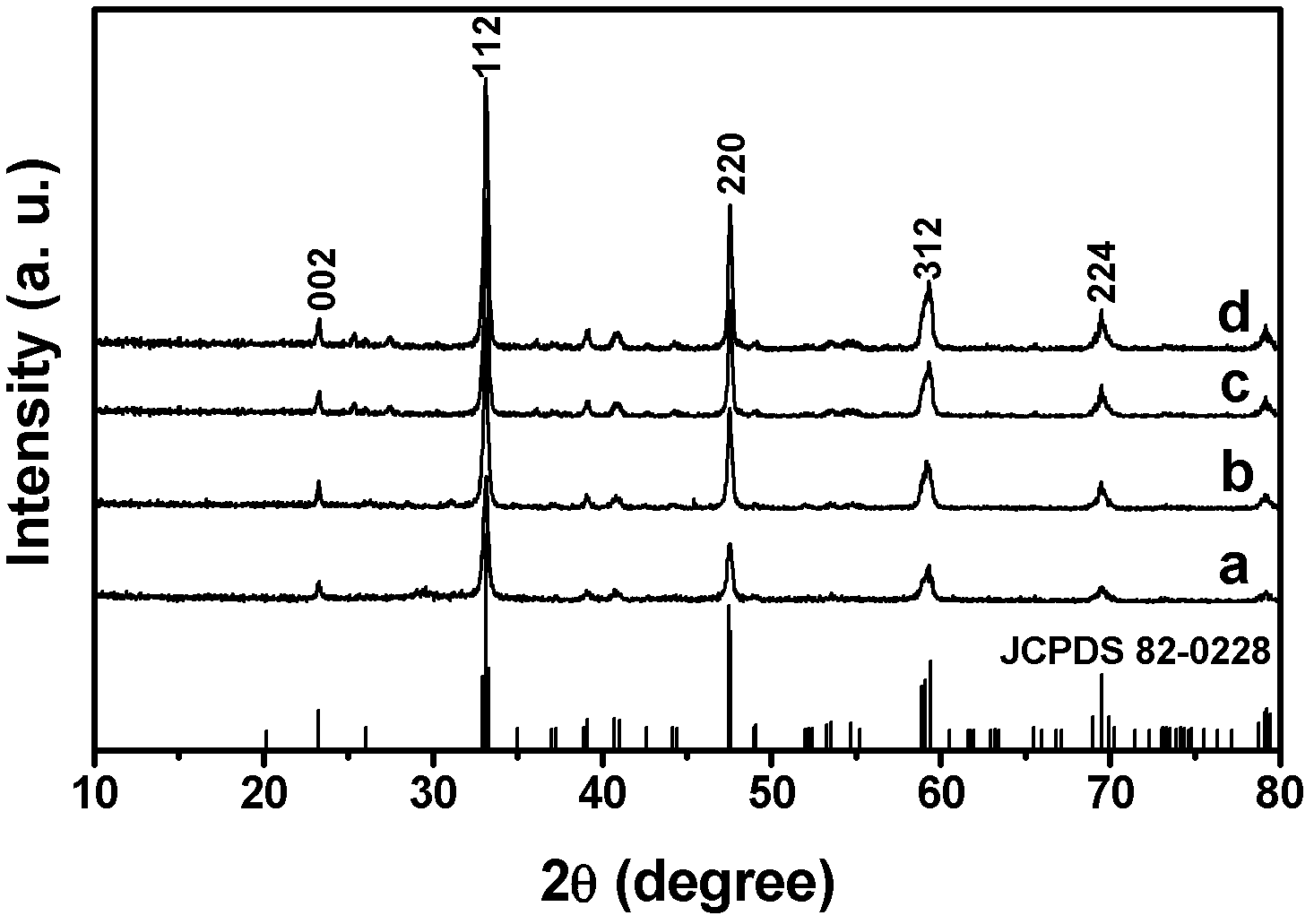

Embodiment 1

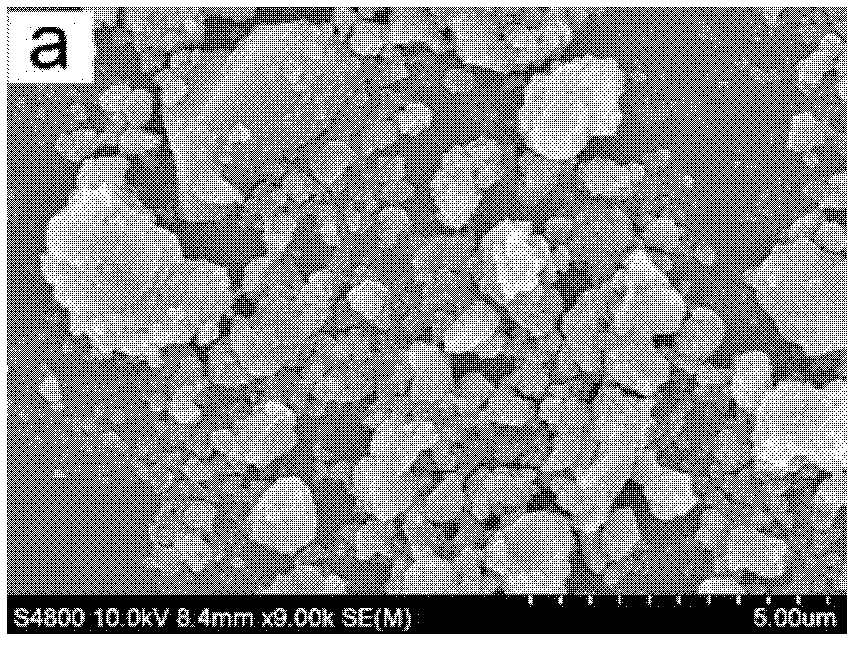

[0022] The starting material used was calcium carbonate CaCO 3 (analytical pure), tetrabutyl titanate Ti(OC 4 h 9 ) 4 (analytical pure), praseodymium oxide Pr 6 o 11 (99.99%), concentrated nitric acid HNO 3 (analytical pure), citric acid (analytical pure), polyethylene glycol (analytical pure). CaTiO 3 :Pr 3+ In phosphor, Pr 3+ The doping concentration is controlled at about 0.5% Ca 2+ atomic fraction.

[0023] Weigh 0.1g (1mmol) CaCO 3 , 0.009g (0.005mmol) Pr 6 o 11 Dissolve in dilute nitric acid, heat and stir to drive out the acid until the pH value of the solution is 2-3, then heat until it melts; after cooling to room temperature, add 0.34g (1mmol) n-butyl titanate, water-ethanol solution 20mL (the volume ratio of water and ethanol is 1:9), then add 0.42g (2mmol) citric acid (ratio to metal ions: 2:1) as a complexing agent, and stir for 2 hours to obtain a homogeneous transparent sol precursor. The resulting precursor solution was introduced into a spray dry...

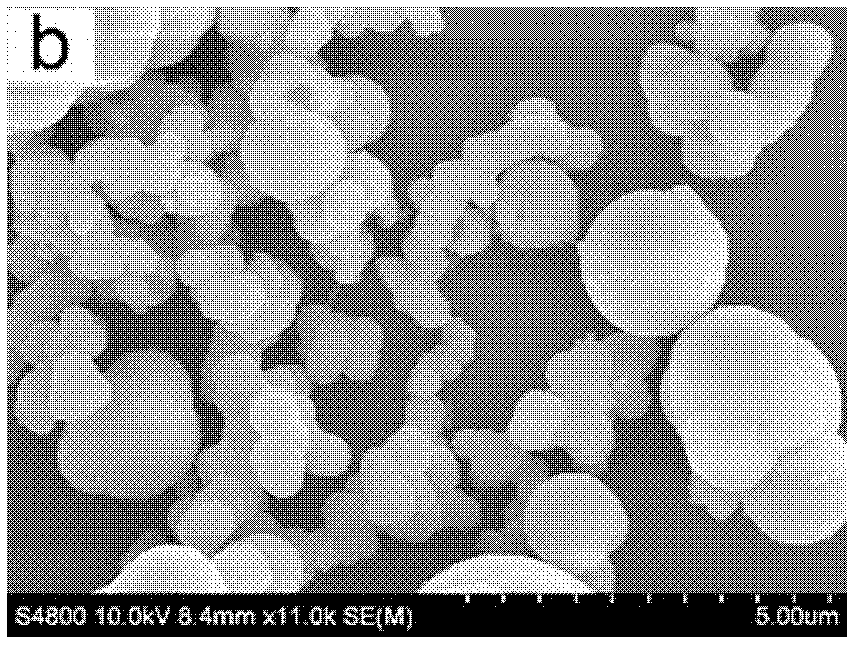

Embodiment 2

[0025] Weigh 0.1gCaCO 3 , 0.009gPr 6 o 11Dissolve in dilute nitric acid, heat and stir to drive out the acid until the pH value of the solution is 2-3, then heat until it melts; after cooling to room temperature, add 0.34g of n-butyl titanate, 20mL of water-ethanol solution (water The volume ratio with ethanol is 1:9), then add 0.42g citric acid (ratio with metal ion is 2:1) as complexing agent, add 0.4g (0.002mol / L) polyethylene glycol, stir for 2 hours That is, a homogeneous transparent sol precursor is obtained. The resulting precursor solution was introduced into a spray dryer (BüCHI Mini Spray Dryer B-191) and spray-dried to obtain a precursor powder sample. Put the precursor into a temperature-programmed furnace, raise the temperature to 800 °C at a rate of 1 °C / min, and then keep the temperature at this temperature for 3 hours to obtain CaTiO 3 :Pr 3+ Phosphor. In this implementation, a sample with a PEG concentration of 0.002 mol / L and a calcination temperature o...

Embodiment 3

[0027] Weigh 0.1gCaCO 3 , 0.009g Pr 6 o 11 Dissolve in dilute nitric acid, heat and stir to drive out the acid until the pH value of the solution is 2-3, then heat until it melts; after cooling to room temperature, add 0.34g of n-butyl titanate, 20mL of water-ethanol solution (water The volume ratio with ethanol is 1:9), then add 0.42g citric acid (ratio with metal ion is 2:1) as complexing agent, add 0.8g (0.004mol / L) polyethylene glycol, stir for 2 hours That is, a homogeneous transparent sol precursor is obtained. The resulting precursor solution was introduced into a spray dryer (BüCHI Mini Spray Dryer B-191) and spray-dried to obtain a precursor powder sample. Put the precursor into a temperature-programmed furnace, raise the temperature to 800 °C at a rate of 1 °C / min, and then keep the temperature at this temperature for 3 hours to obtain CaTiO 3 :Pr 3+ Phosphor. In this implementation, a sample with a PEG concentration of 0.004 mol / L and a calcination temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com