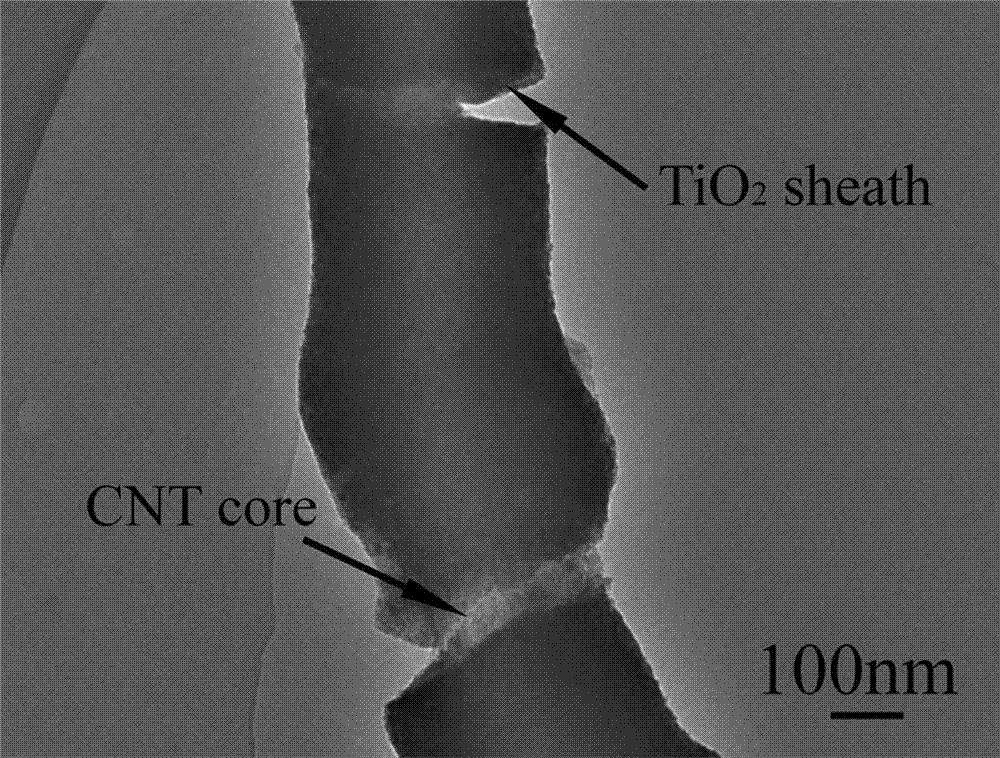

Preparation method and application of carbon nanotube/titanium dioxide coaxial nanometer cable composite material

A technology of titanium dioxide and carbon nanotubes, applied in circuits, electrical components, battery electrodes, etc., can solve problems such as low ion diffusion coefficient, hindering application, and low conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The present invention will be described in further detail below in conjunction with specific embodiments.

[0020] 1. Preparation of polydivinylbenzene: Put 100 g of n-heptane in a 250 mL single-necked flask, add 4 g of monomer divinylbenzene to form a solution, and then add 150 mg (10 drops) of trifluoro Boronium diethyl ether complex was used as an initiator. After sealing, a large amount of reddish-brown precipitate was obtained by ultrasonication in an ultrasonic wave. After 15 minutes, ethanol was added to terminate the reaction, and a white cotton mass was obtained by filtration.

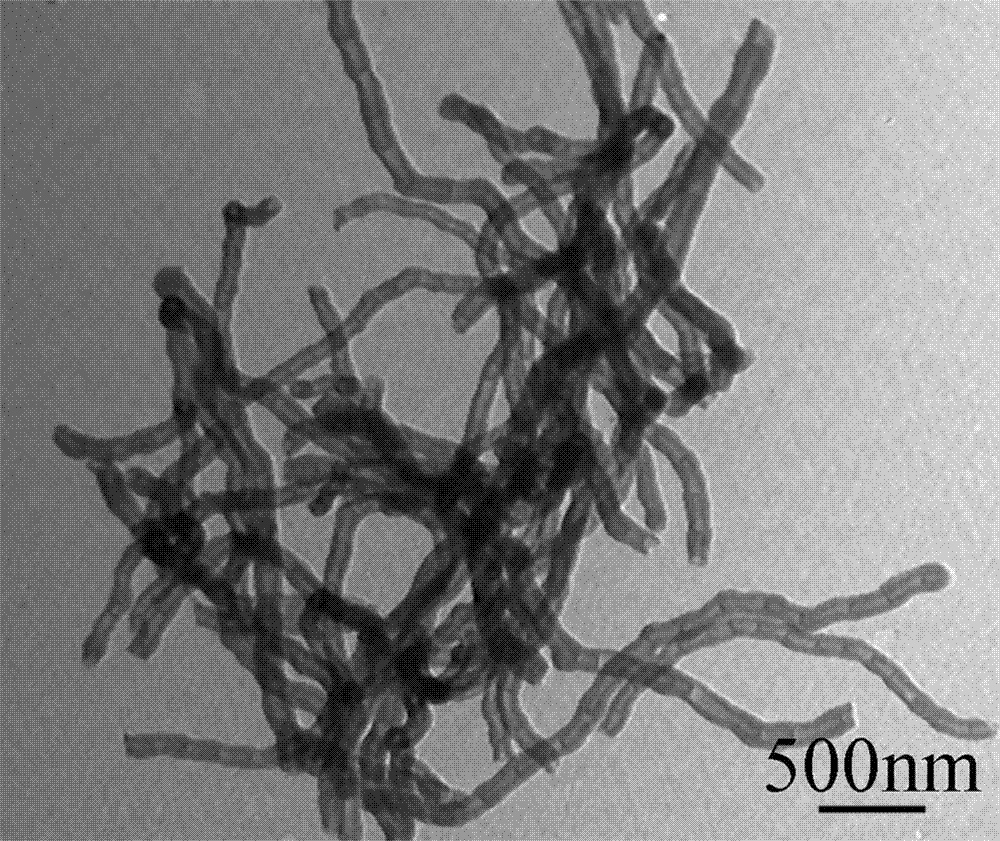

[0021] 2. Preparation of sulfonated polydivinylbenzene: Weigh 0.2 g of dry polymer nanotubes into a flask, add 30 mL of concentrated sulfuric acid, place in a constant temperature environment of 50°C for sulfonation for 12 h, dilute with a large amount of water, filter, Dry to obtain the product. figure 1 It is a TEM photo of sulfonated polydivinylbenzene, which is a bamboo-shaped nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com