Electrodeposition of chromium from trivalent chromium using modulated electric fields

a trivalent chromium and electric field technology, applied in the field of electroplating of chromium metal from a trivalent chromium electroplating bath, can solve the problems of worker exposure to hexavalent chromium, and achieve the effect of improving the visual uniformity and density of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0041]The present invention will be illustrated by the following examples, which are intended to be illustrative and not limiting.

[0042]A visually uniform and scalable coating can be formed the inner diameter of 4130 steel pipes, used din the landing gear of aircrafts. A dimensionally stable anode (DSA) was used as the counter electrode. The electrodeposition process parameters used to deposit a visually uniform coating consisted forward only pulse waveform with a forward duty cycle of at least 80% and a frequency of at least 500 Hz at the applied forward current density between 25 and 45 A / dm2. The nominal electrolyte bath temperature was between 90 and 150° F. and electrolyte flow rate held constant throughout the deposition process.

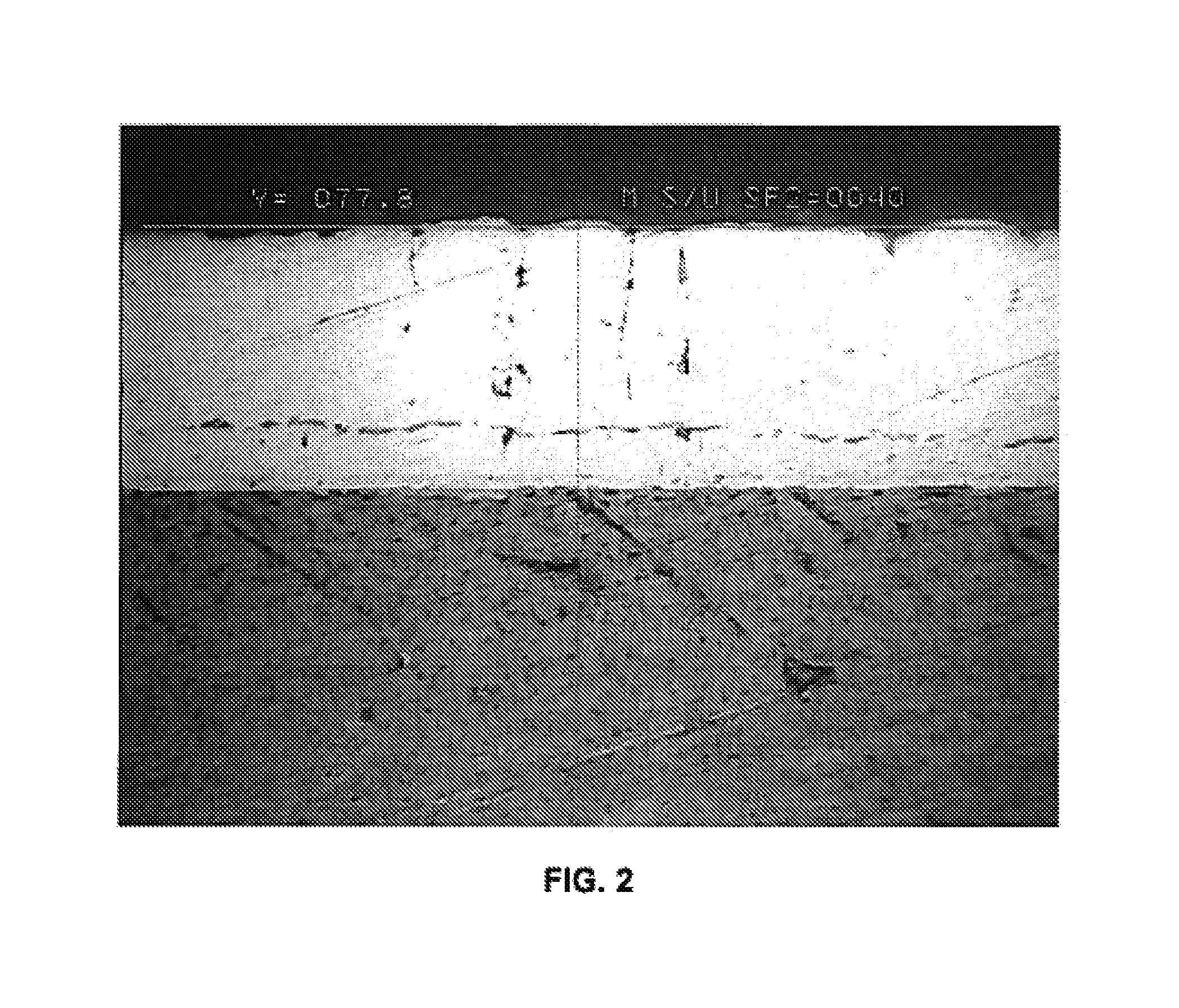

[0043]FIG. 2 and FIG. 3 demonstrate the microstructure of the coatings obtained during deposition the process. These cross-sections show a dense coating with few microcracks, which are advantageous for the production of a wear resistant chrome coating....

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com