Method for modifying sodium ion battery negative electrode material titanium dioxide

A sodium-ion battery and negative electrode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of low rate performance, poor electronic conductivity, etc., and achieve the goal of improving electronic conductivity, improving conductivity, and inhibiting volume expansion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

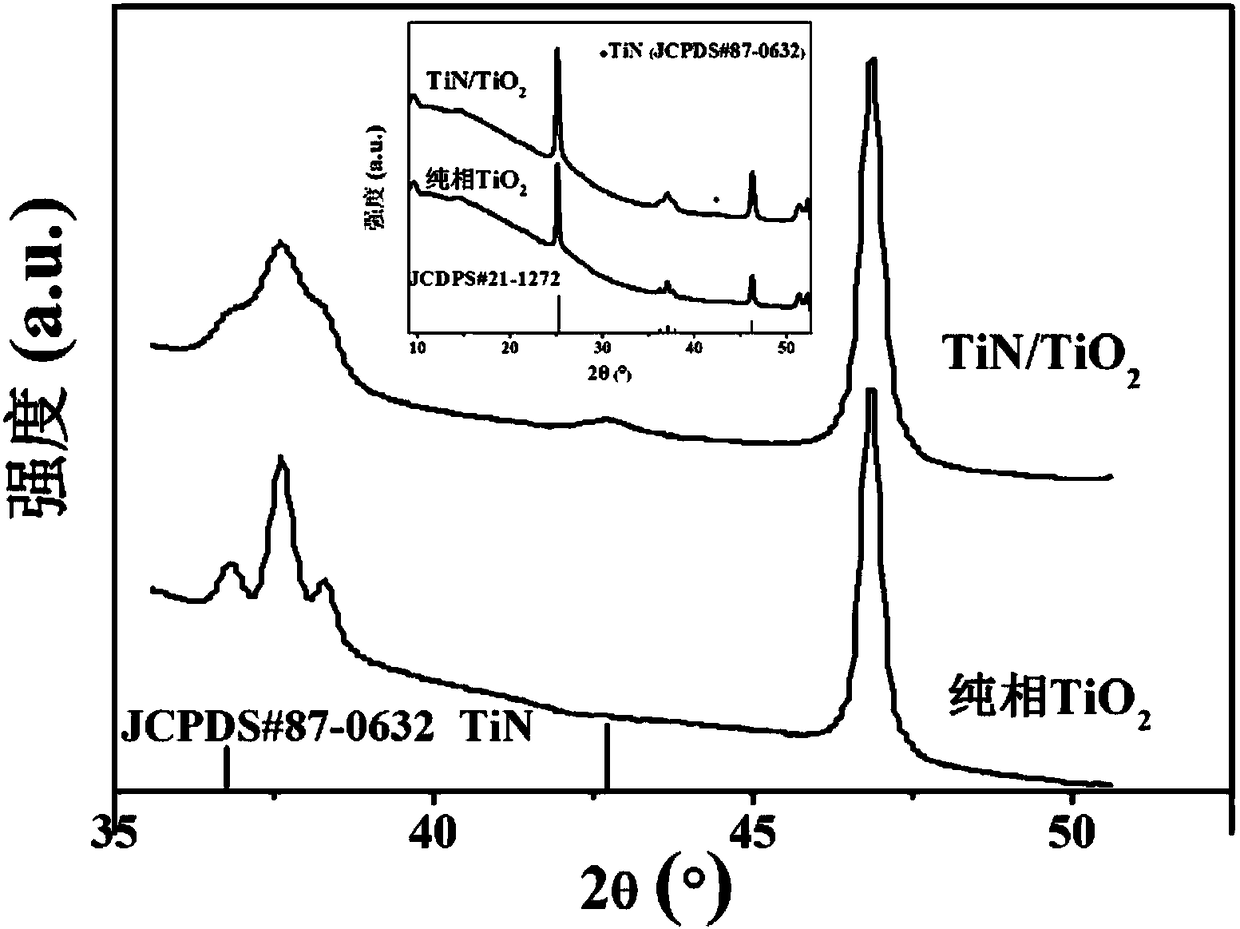

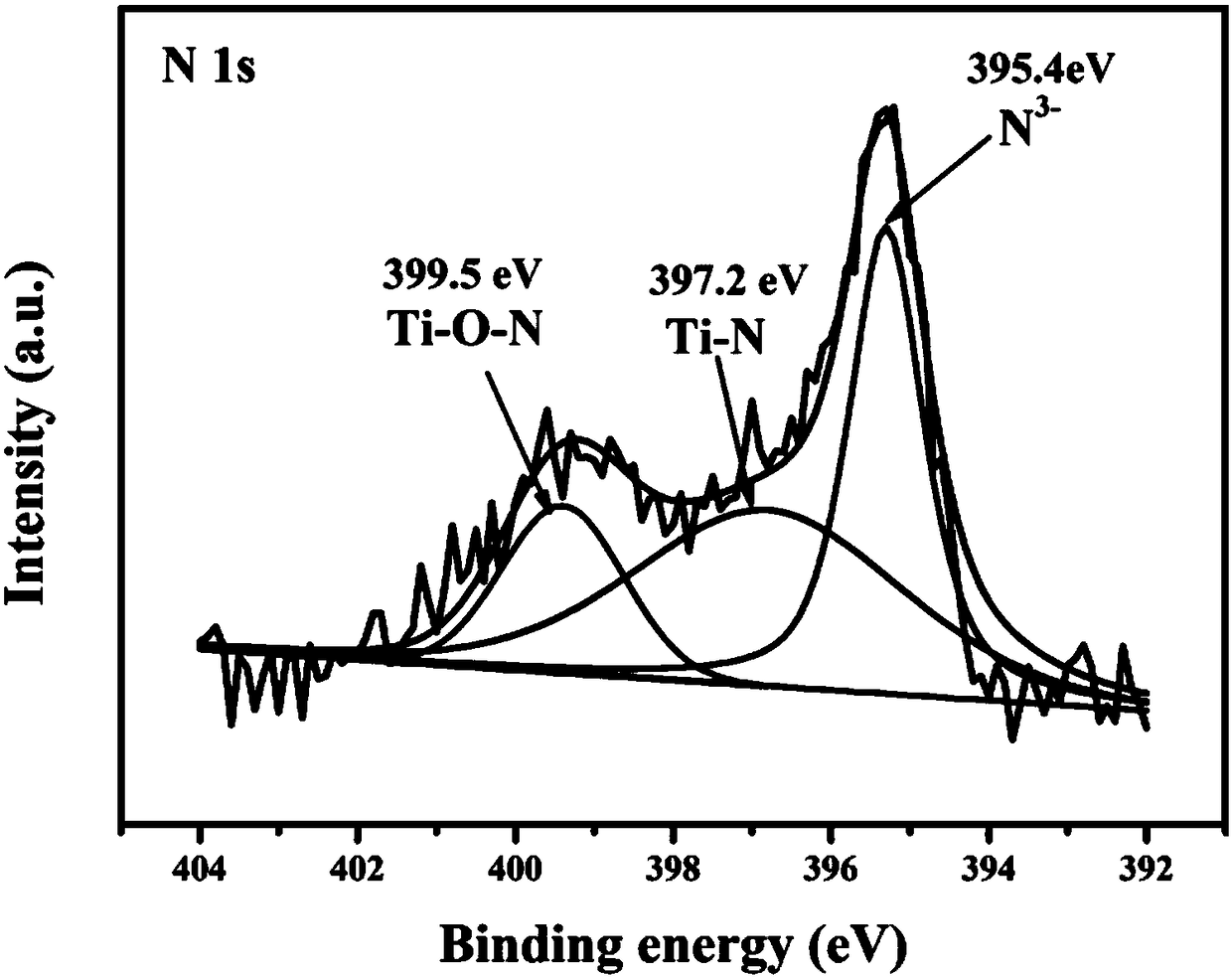

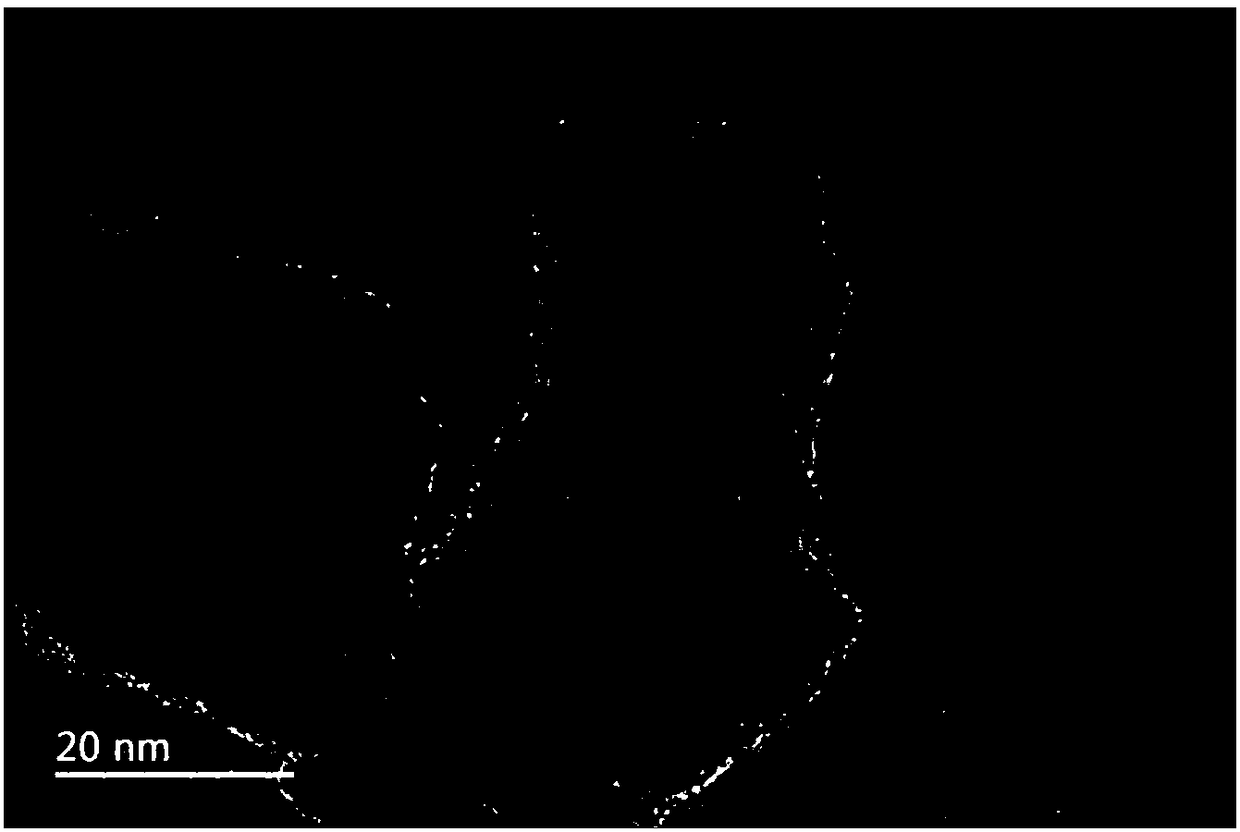

[0035] Add 3.4g of tetrabutyl titanate to 20ml of absolute ethanol, then add 5ml of 40% hydrofluoric acid solution, stir well, conduct a hydrothermal reaction at 180°C for 24 hours, collect the precursor by centrifugation, and mix it with 1g of biuret Then, under a nitrogen atmosphere, the tube furnace was used to raise the temperature to 500° C. at a rate of 3° C. / min and keep at a constant temperature for 4 hours. After natural cooling, a titanium nitride-coated nitrogen-doped titanium dioxide material was obtained. figure 1 It is an XRD pattern, as can be seen from the figure, the material prepared by the above method is anatase titanium dioxide (JCPDS: No.21-1272); 2 In contrast, the modified sample has a weaker new diffraction peak at 42.7 degrees, corresponding to the diffraction peak of TiN (JCPDS: No.87-0632), which proves the existence of titanium nitride in the composite material. Calculated by the Scherrer formula, it can be known that the grain size of the titanium...

Embodiment 2

[0041] Add 3.4g of tetrabutyl titanate to 20ml of absolute ethanol, then add 5ml of 40% hydrofluoric acid solution, stir well, react with hydrothermal reaction at 180°C for 24 hours, collect the precursor by centrifugation, mix it with 1g of melamine Under a nitrogen atmosphere, the temperature was raised to 700°C at a rate of 3°C / min in a tube furnace and kept at a constant temperature for 4 hours. After natural cooling, a nitrogen-doped titanium dioxide material coated with titanium nitride was prepared.

[0042] Negative electrode preparation: mix the titanium nitride-coated nitrogen-doped titanium dioxide negative electrode material prepared above, conductive carbon black, and binder carboxymethyl cellulose (CMC) in a mass ratio of 8:1:1, and coat it on a copper foil After drying, it was punched into electrode sheets and dried in vacuum at 100°C for 12 hours.

Embodiment 3

[0044] Add 3.4g of tetrabutyl titanate to 50ml of absolute ethanol, then add 5ml of 40% hydrofluoric acid solution, stir well, conduct a hydrothermal reaction at 180°C for 24 hours, collect the precursor by centrifugation, mix it with 1g of urea Under a nitrogen atmosphere, the temperature was raised to 700°C at a rate of 3°C / min in a tube furnace and kept at a constant temperature for 4 hours. After natural cooling, a nitrogen-doped titanium dioxide material coated with titanium nitride was prepared.

[0045] Negative electrode preparation: mix the titanium nitride-coated nitrogen-doped titanium dioxide negative electrode material prepared above, conductive carbon black, and binder carboxymethyl cellulose (CMC) in a mass ratio of 8:1:1, and coat it on a copper foil After drying, it was punched into electrode sheets and dried in vacuum at 100°C for 12 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com