Preparation method of core-shell composite material wrapped in titanium dioxide nanoparticle coating

A nanoparticle, titanium dioxide technology, applied in nanotechnology and other directions, can solve the problems of complex preparation method of silver-titanium dioxide nanocomposite materials, high requirements for synthesis conditions, high cost, etc., to achieve excellent photocatalytic properties and improve photocatalysis. The effect of improving the efficiency of solid-liquid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

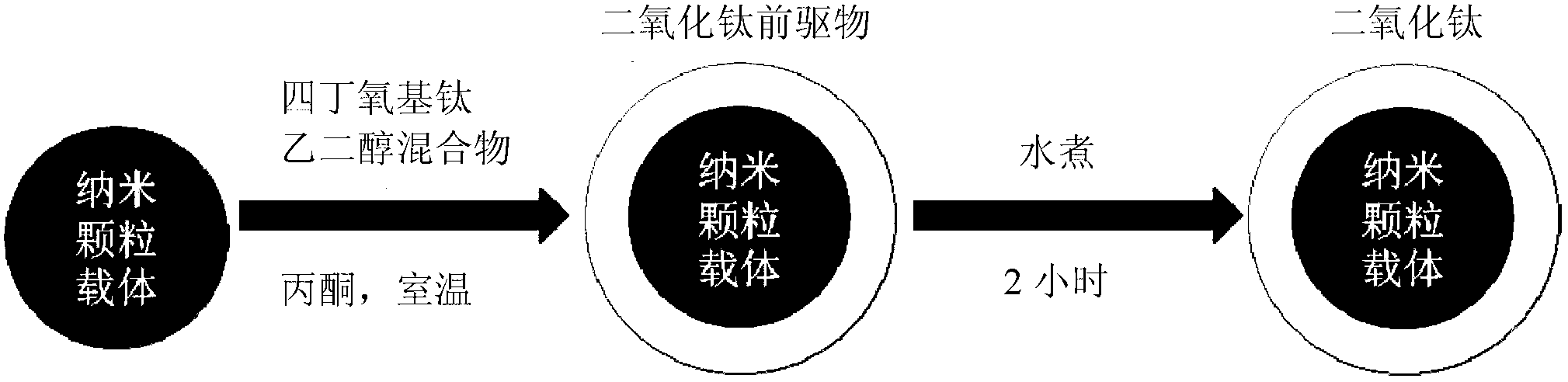

[0043] see figure 1 , the present invention provides a preparation method of a core-shell composite material wrapped with a titanium dioxide nanoparticle coating, which is suitable for wrapping a titanium dioxide nanocoating on the surface of different nanoparticle carriers (such as: noble metal nanoparticles, metal oxide nanoparticles , the method includes the following steps:

[0044] 1) Obtain an aqueous solution of nanoparticle carrier; the nanoparticle carrier can be metal (gold, platinum or palladium) or metal oxide (such as zinc oxide, iron oxide, cobalt oxide); the nanoparticle carrier can be prepared according to the existing chemical preparation process come, or directly carry out market purchases, because the present invention is directly selected, therefore, this preparation process is not described in detail, in order to illustrate the problem, the present invention is simply explained with metallic silver as example:

[0045] 1.1) Dissolve polyvinylpyrrolidone (...

Embodiment 1

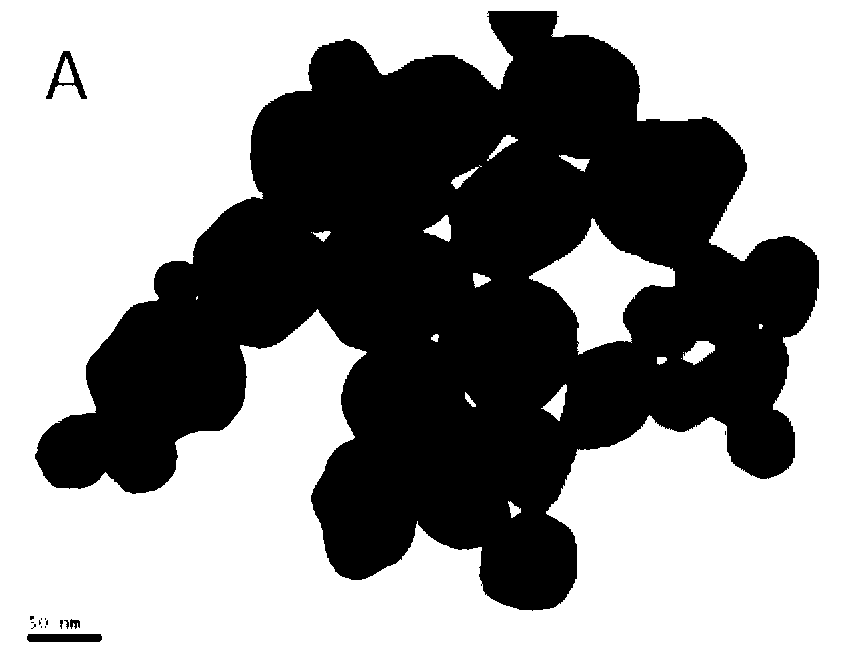

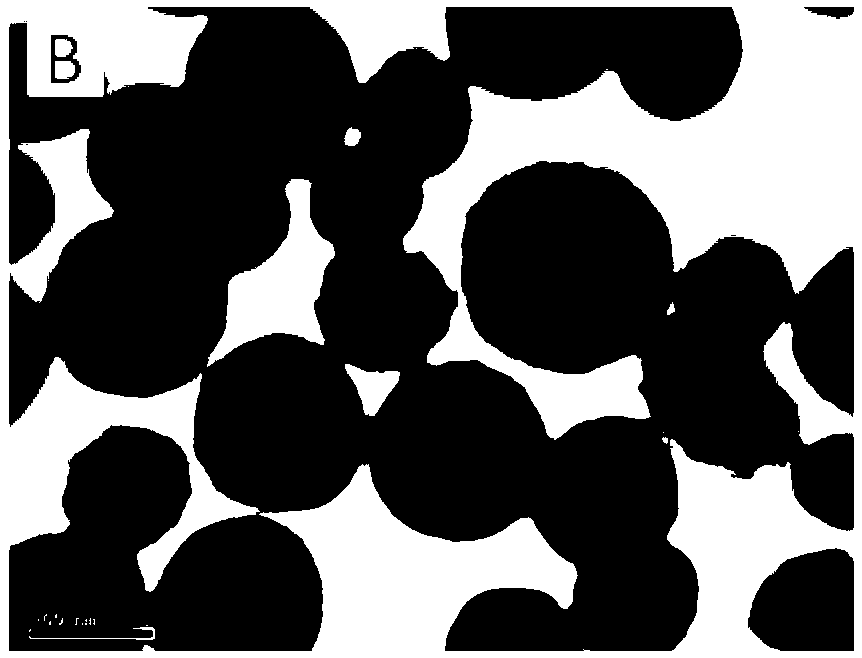

[0063] Dissolve 0.05g of commercially available PVP in 10ml of ethylene glycol solution and stir vigorously until the solution is transparent. Add 0.025g of silver nitrate to 5ml of ethylene glycol solution and stir vigorously until the solution is completely mixed. Pour the above two solutions into a 25 ml reagent bottle and stir vigorously until the solution is completely mixed, and then put it into an autoclave and heat it at 180° C. for two hours, and the reaction solution turns from light yellow to brown. Silver nanoparticles were collected by centrifugation at 3000rpm, washed with deionized water and ethanol, and dispersed in an aqueous solution for subsequent use; 0.05ml of commercially available tetrabutoxytitanium was dissolved in 10ml of ethylene glycol, and stirred at room temperature for about 8 hours to form a mixed solution A. Disperse 3ml of 0.01M silver nanoparticle aqueous solution into 10ml of acetone and stir until uniform to form mixed solution B. Add 0.5...

Embodiment 2

[0065] Dissolve 0.03g of commercially available PVP in 10ml of ethylene glycol solution and stir vigorously until the solution is transparent. Add 0.03g of silver nitrate to 5ml of ethylene glycol solution and stir vigorously until the solution is completely mixed. Pour the above two solutions into a 25 ml reagent bottle and stir vigorously until the solution is completely mixed, and then put it into an autoclave and heat it at 180° C. for two hours, and the reaction solution turns from light yellow to brown. Silver nanoparticles were collected by centrifugation at 3000rpm, washed with deionized water and ethanol, and dispersed in an aqueous solution for subsequent use; 0.03ml of commercially available tetrabutoxytitanium was dissolved in 10ml of ethylene glycol, and stirred at room temperature for about 7 hours to form a mixed solution A. Disperse 5ml of 0.01M silver nanoparticle aqueous solution into 10ml of acetone, stir well until uniform, and form mixed solution B. Add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com