Patents

Literature

46results about How to "Excellent in flowability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

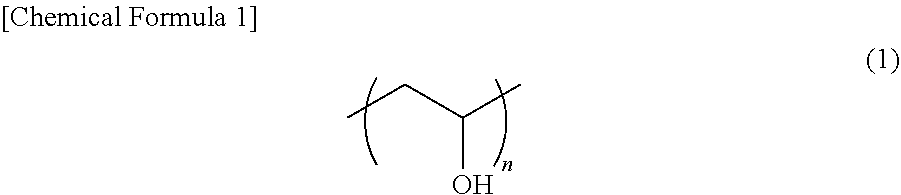

Thermoplastic resin composition and molded article thereof

ActiveUS20090275678A1Excellent in flowability and mechanical propertyExcellent in flowabilityOrganic chemistryInksPolycarbonateTransmittance

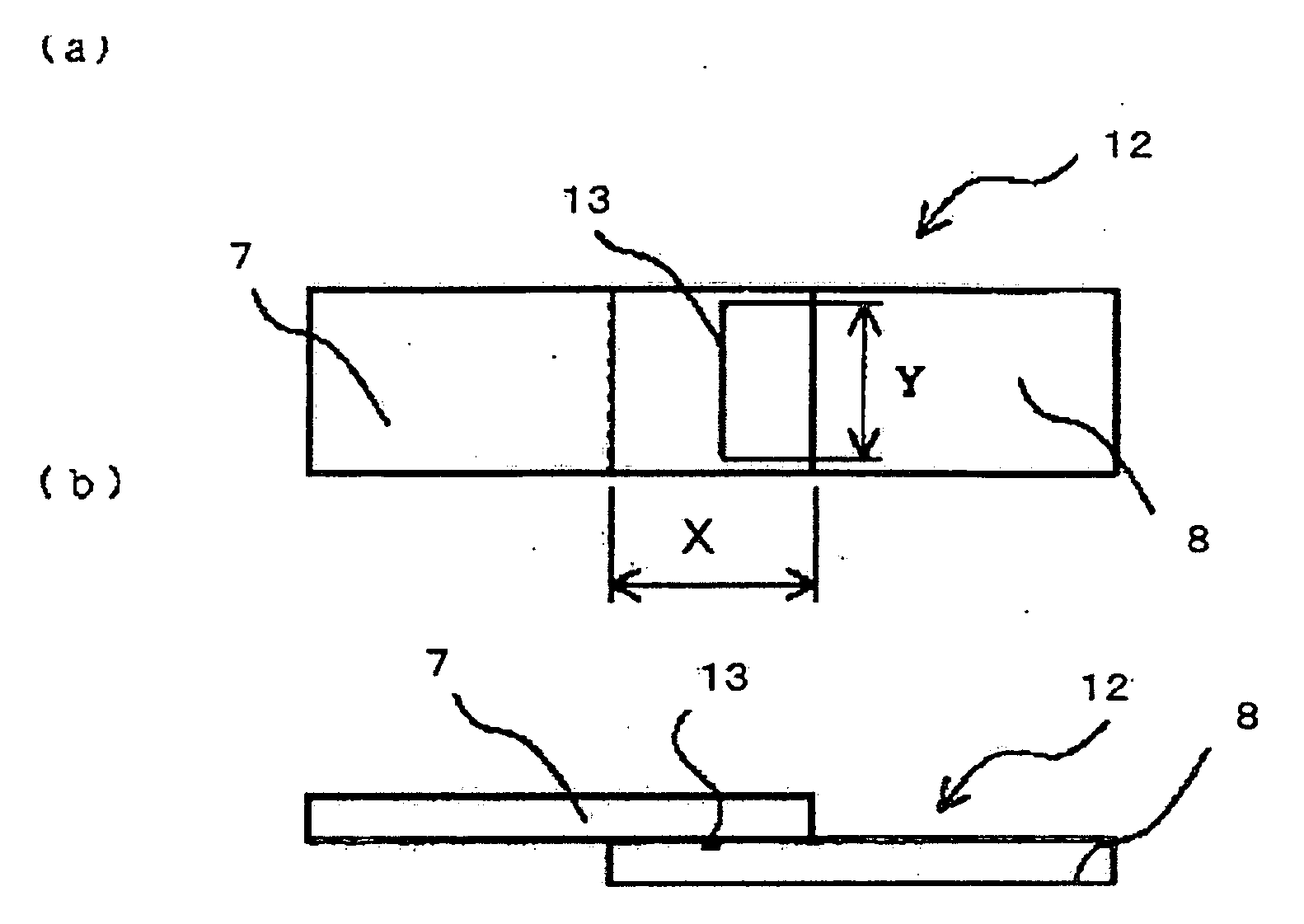

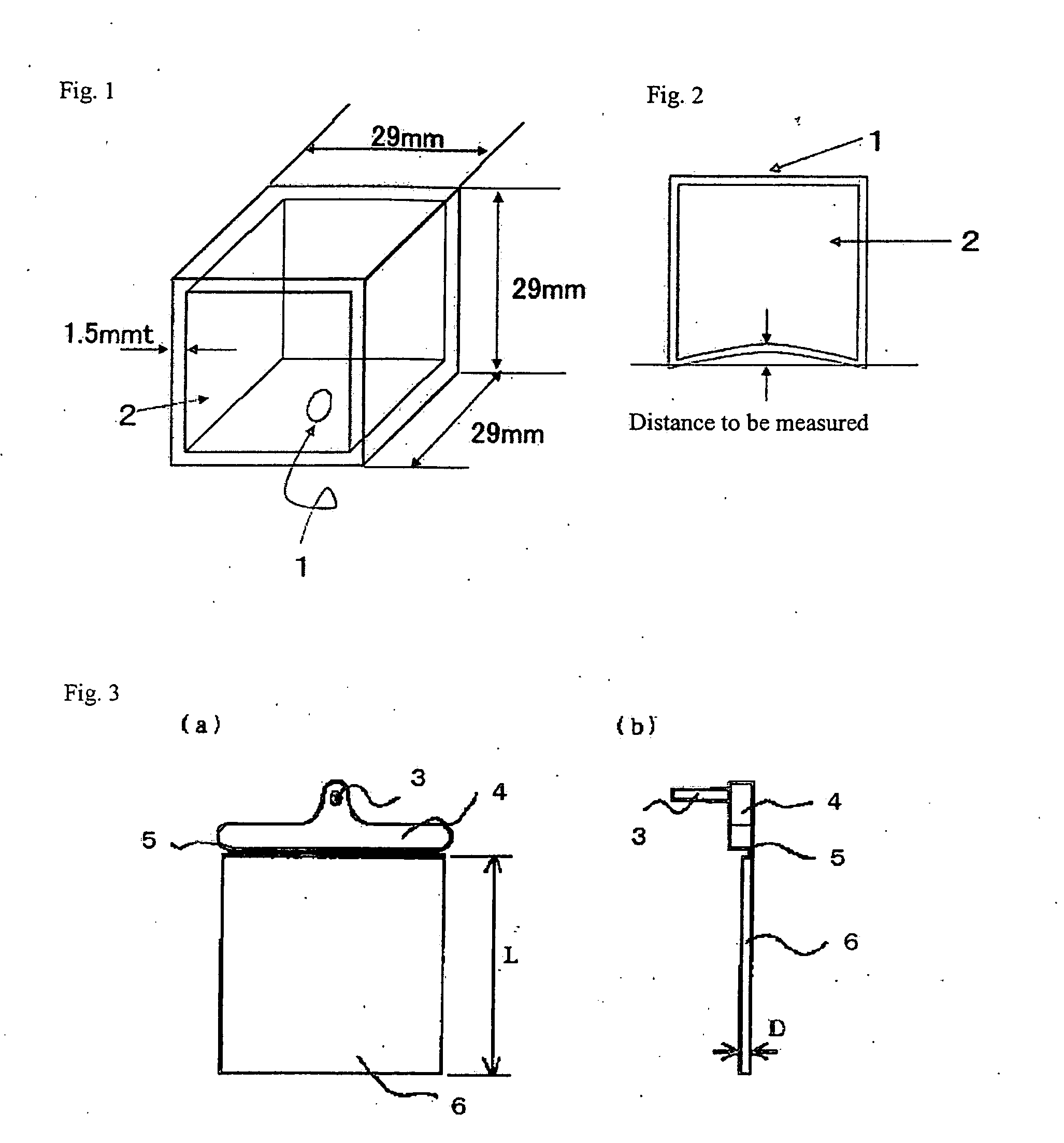

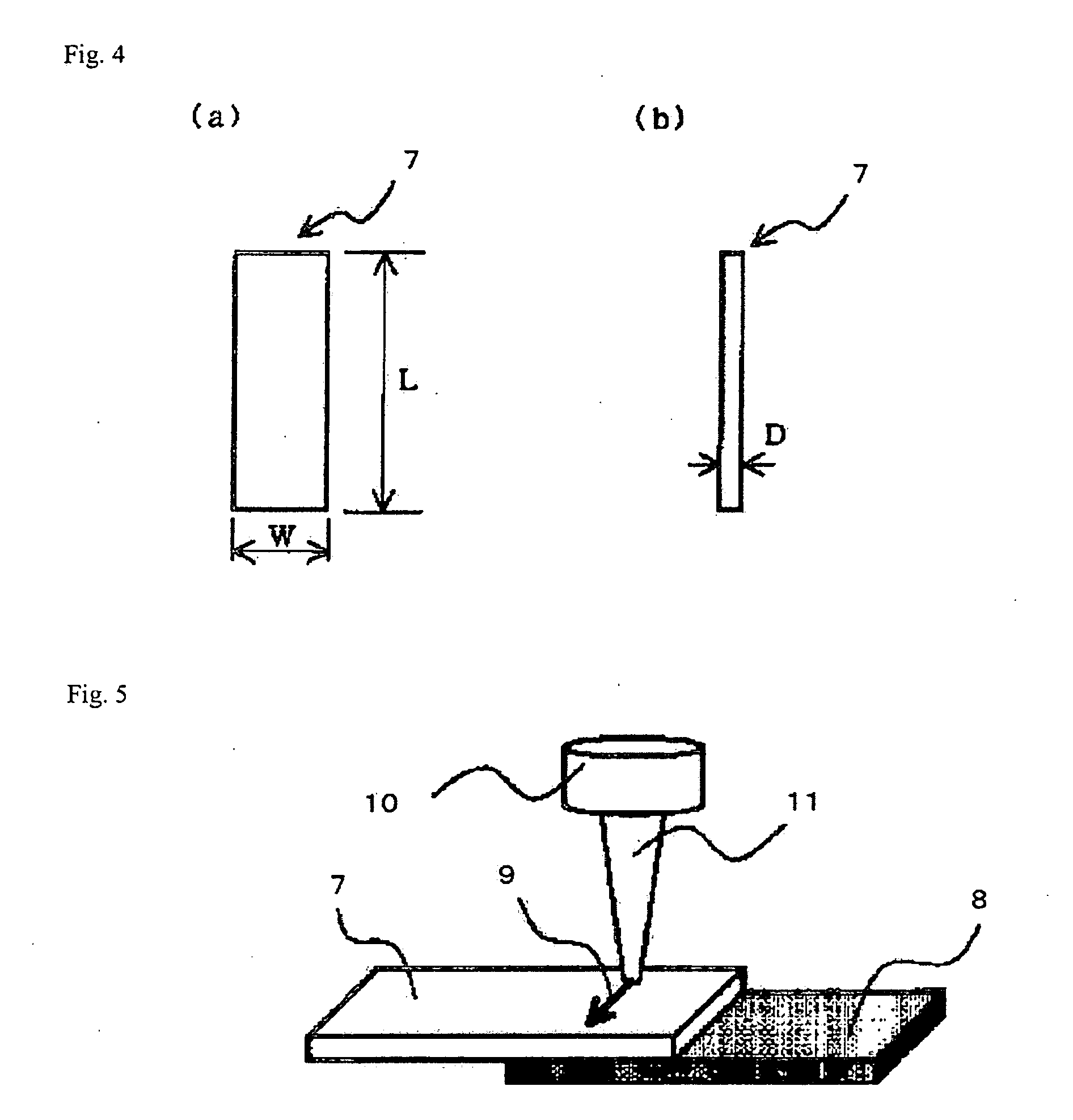

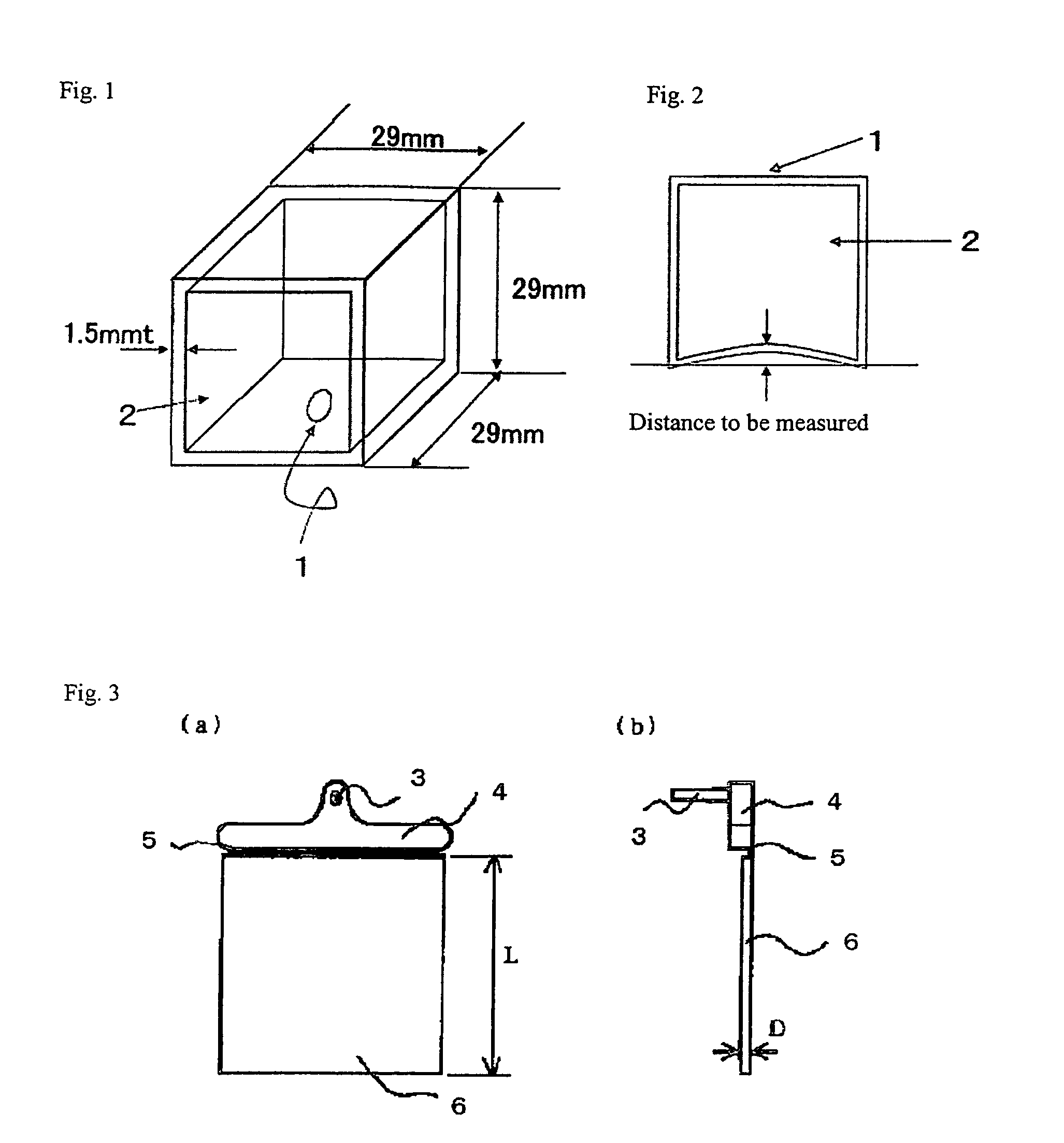

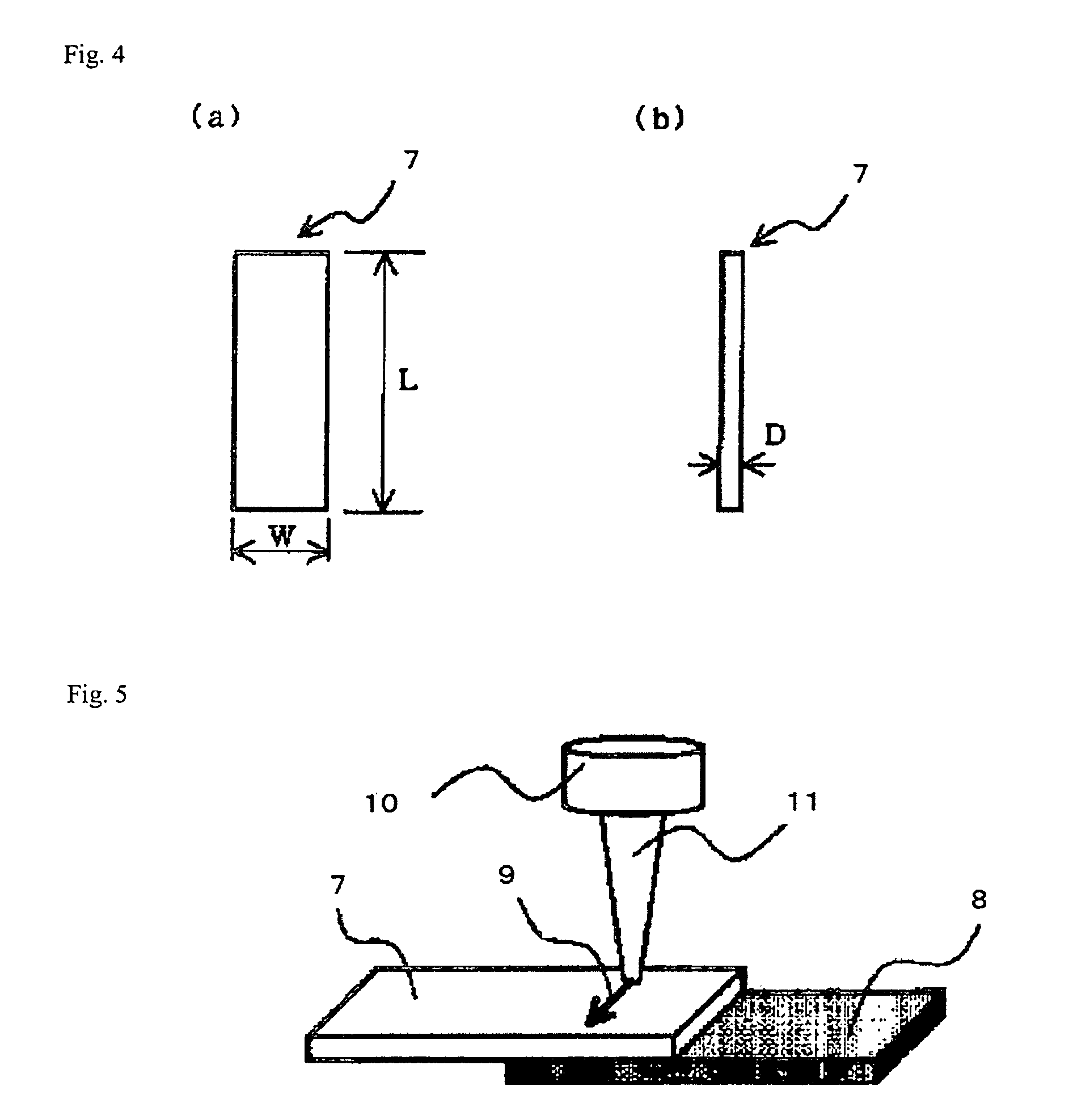

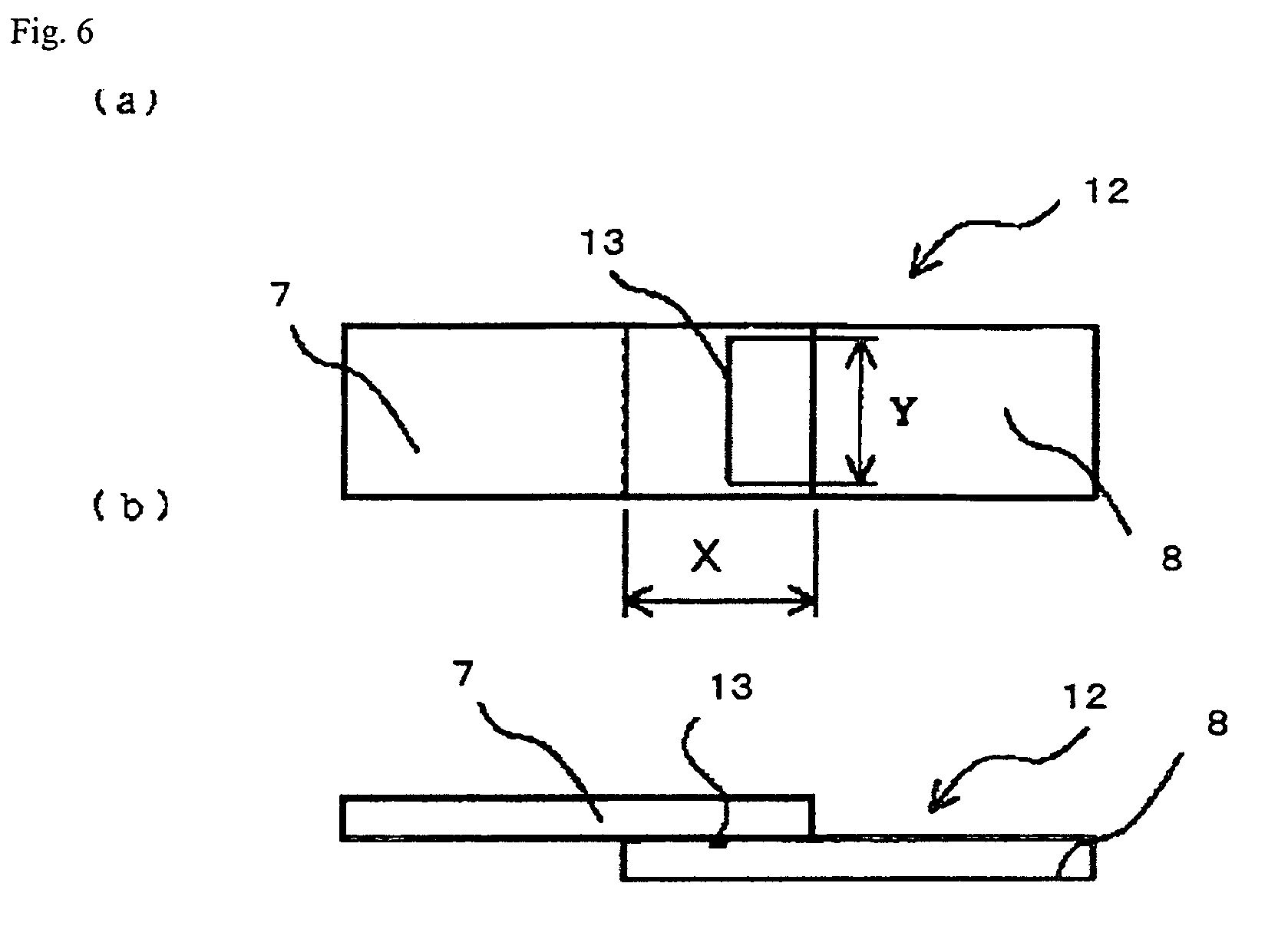

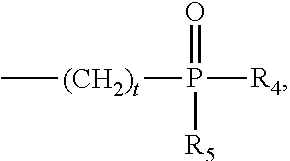

A thermoplastic resin composition and a molded article thereof, respectively excellent in flowability and mechanical properties, and, in a preferred mode, also excellent in low warping property, laser transmittance and laser weldability, is obtained by mixing (B) 0.1 to 4 parts by weight of a polyfunctional compound having three or more functional groups, in which at least one of the terminal structures having the functional groups is a structure containing alkylene oxide units, with (A) 100 parts by weight of a thermoplastic resin, and further provides a molded particle thereof. It is preferred that the (A) thermoplastic resin is one or more selected from a polyester resin and polycarbonate resin.

Owner:TORAY IND INC

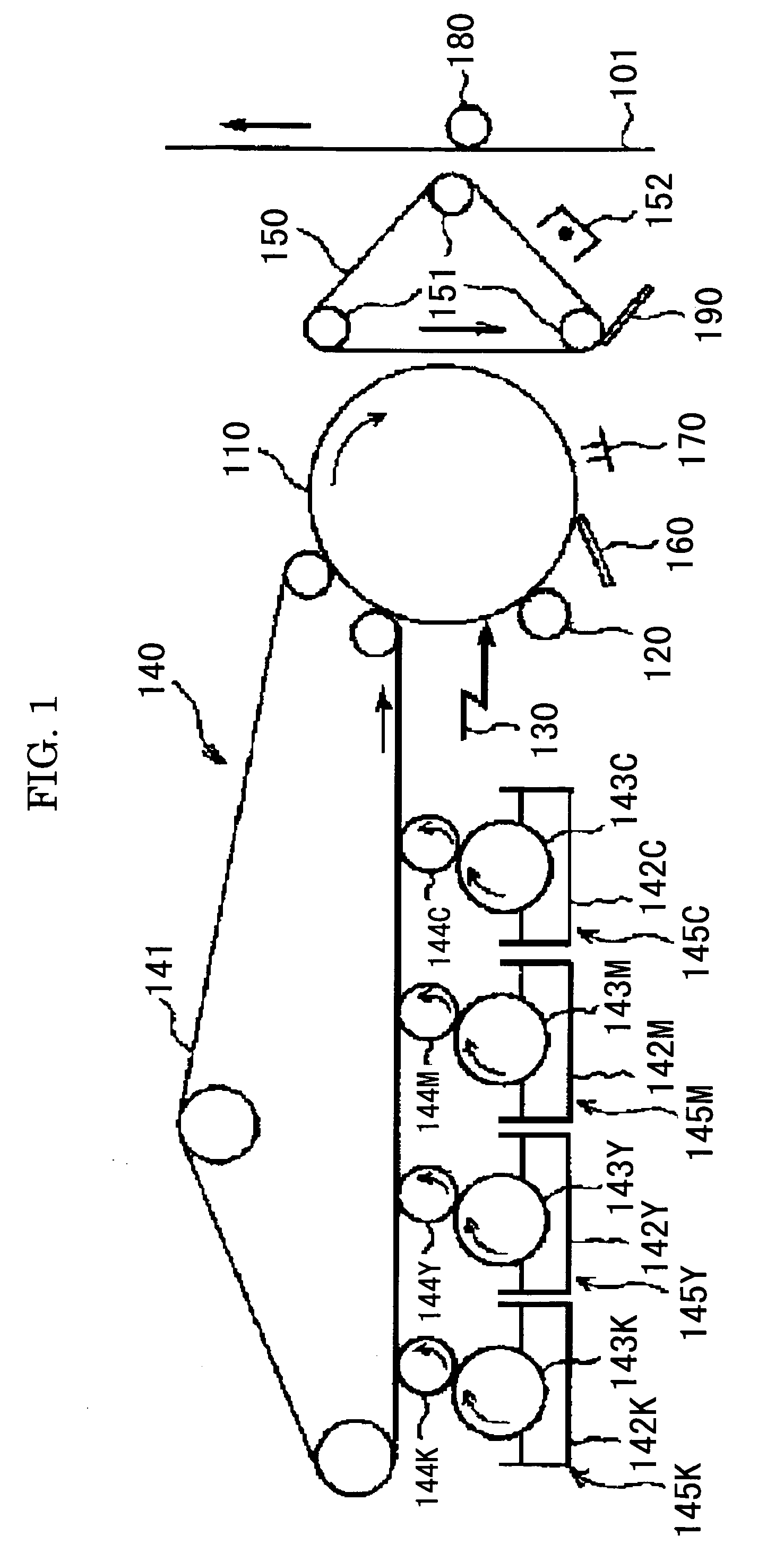

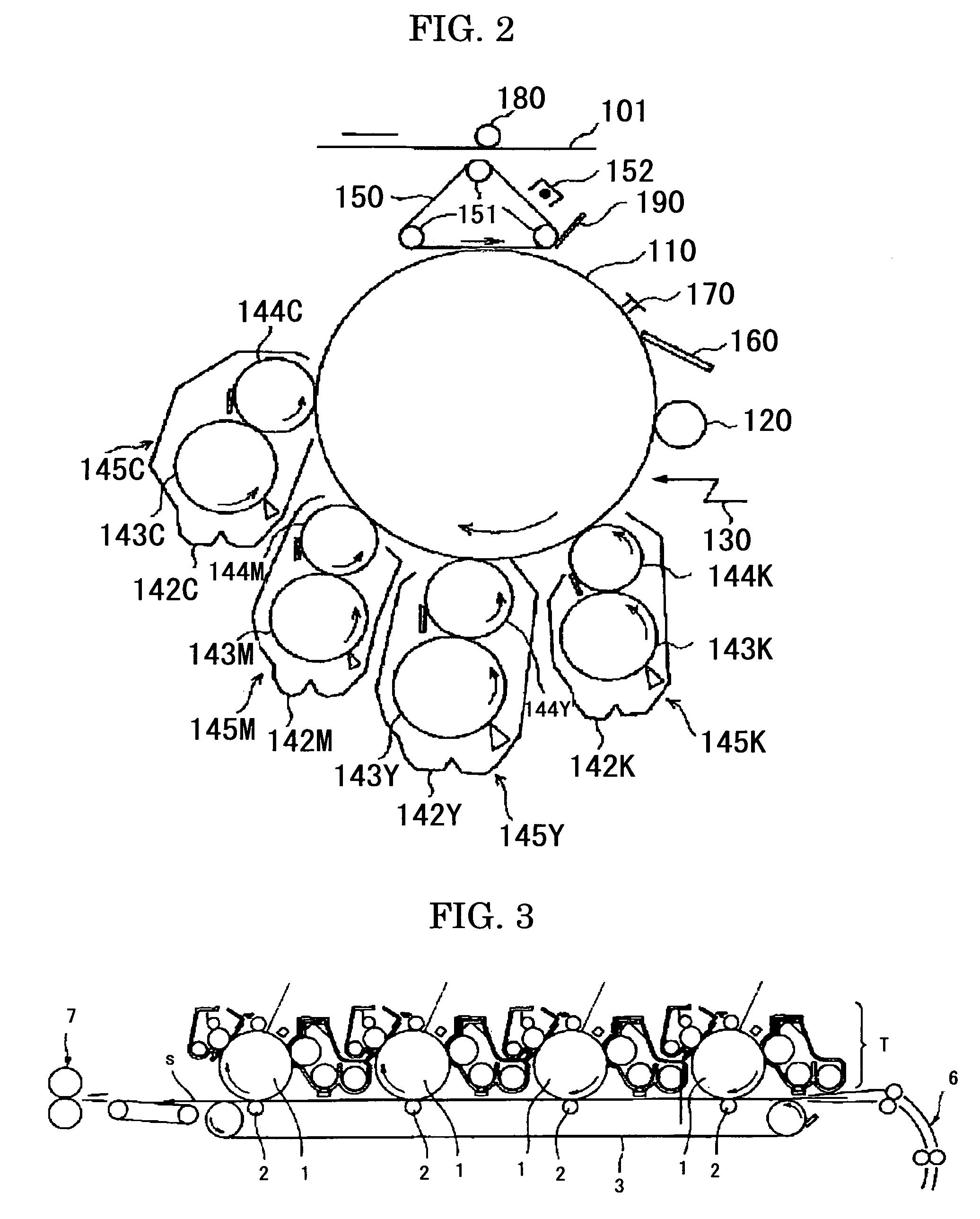

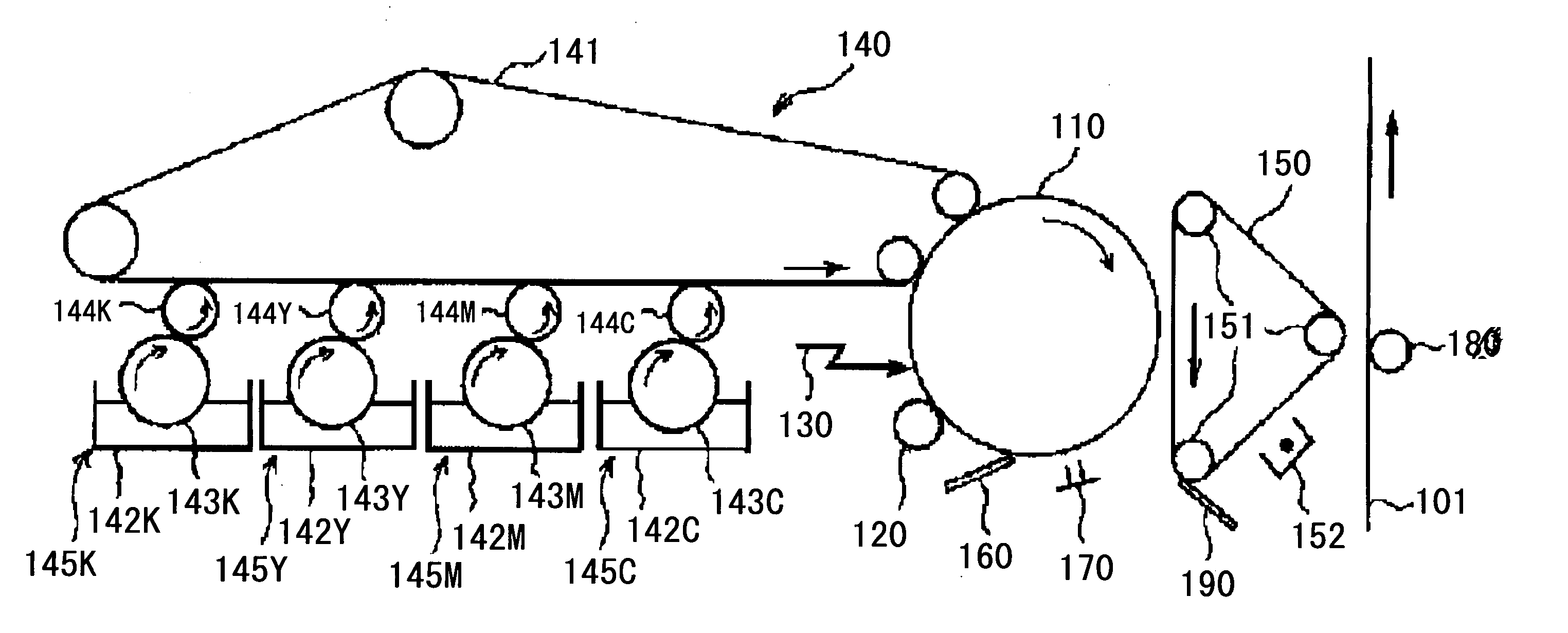

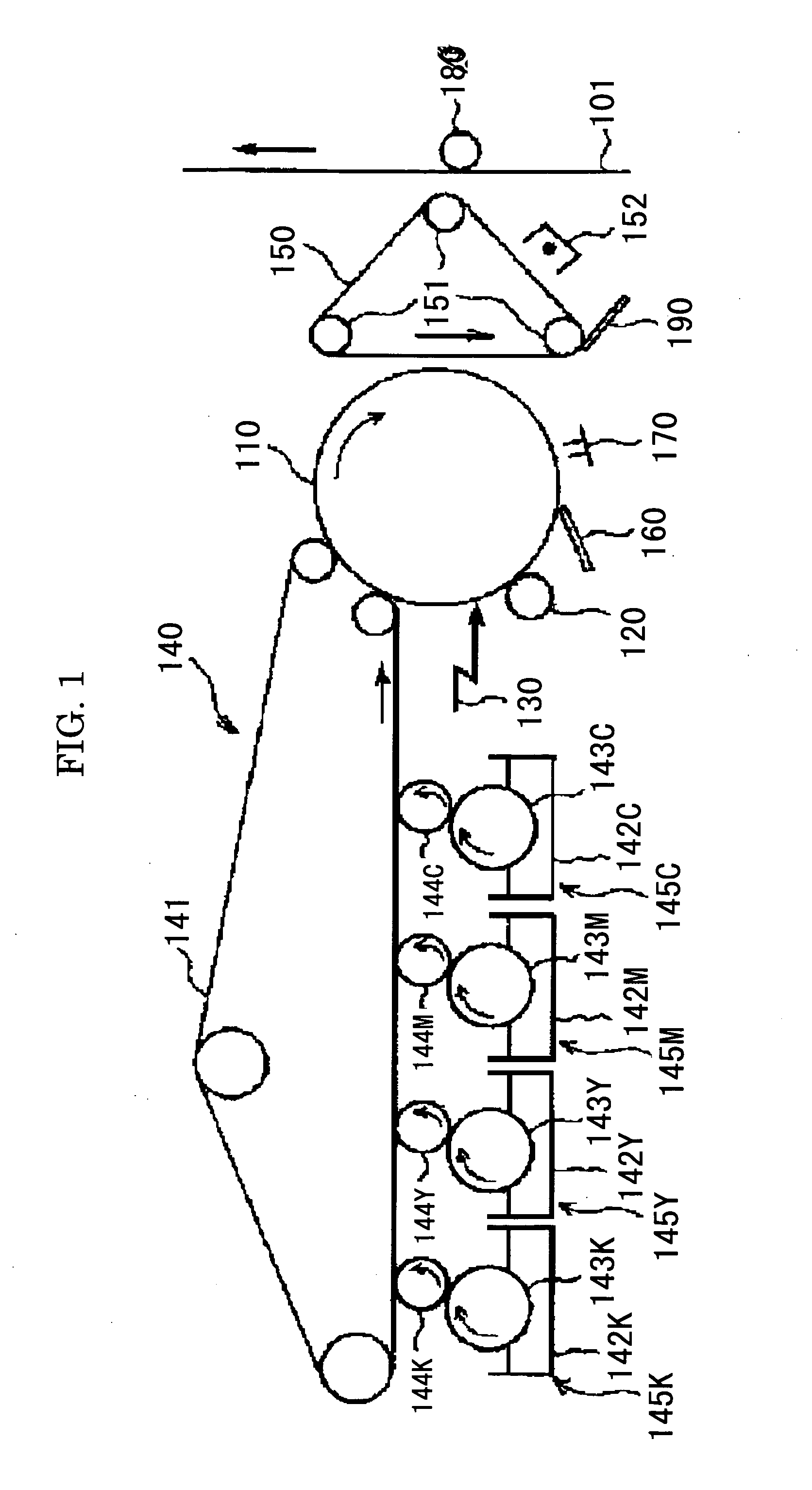

Toner for electrophotography and image forming apparatus

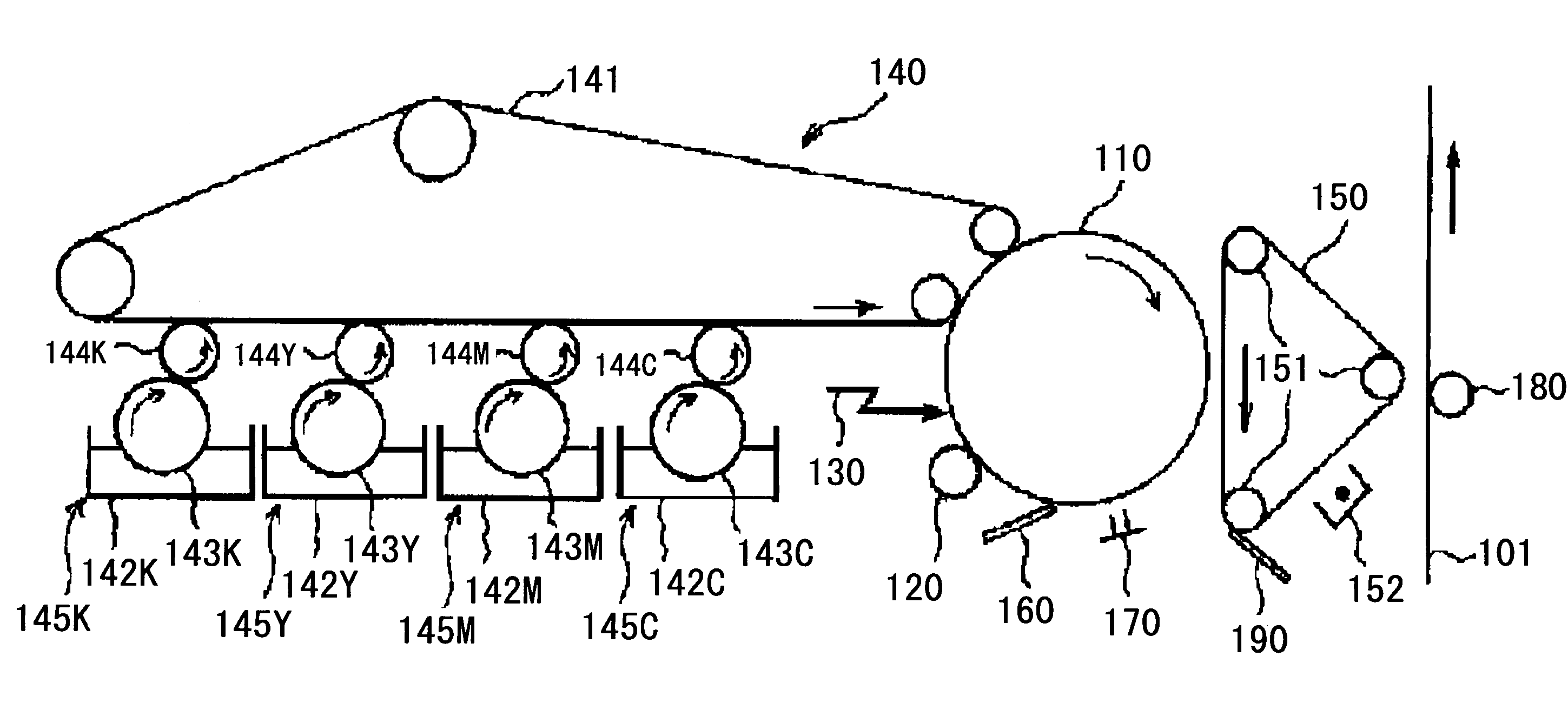

The object of the present invention is to provide a developer having a sharp charge amount distribution and bringing out high-quality image without substantially smearing a charging unit, developing units, a photoconductor, and an intermediate transferring member by the developer, namely, a developer capable of providing an appropriate image density and exhibiting extremely little background smear even when used over a long period of time and repeatedly used for a number of sheets of paper as well as to provide an image forming apparatus for electrophotography using the developer.

Owner:RICOH KK

Resin Composition and Molded Article Composed of the Same

ActiveUS20090030132A1Excellent in flowabilityImprove heat resistanceSpecial tyresOrganic dyesShell moldingGlass transition

A resin composition comprising a polylactic acid-based resin (A) and methacrylic resins (B), wherein the methacrylic resins having at least (a) a difference of 10° C. or more in glass transition temperature or (b) a difference of 3% or more in syndiotacticity; it is preferred that at least one of the methacrylic resins (B) is a methacrylic resin having a weight average molecular weight of 50,000 to 450,000, a glass transition temperature of 110° C. or higher and a syndiotacticity of 40% or more, and that the resin composition further contains a multilayer structure polymer formed as particles each consisting of a core layer and one or more shell layers covering it (C) A molded article made of said resin composition.

Owner:TORAY IND INC

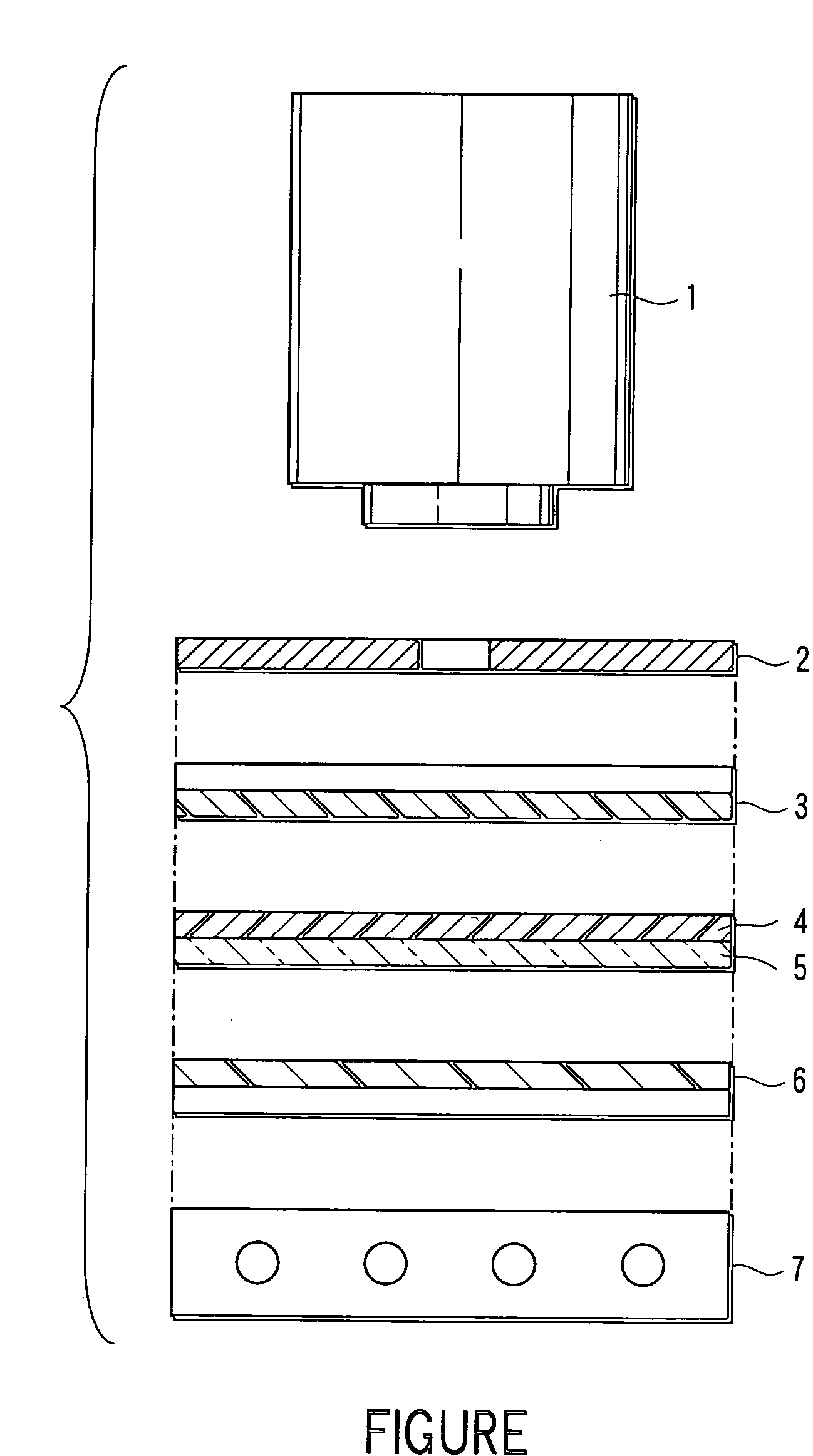

Blue colored composition for color filter and color filter

ActiveUS20050131114A1Increase brightnessExcellent in flowabilityDiffusing elementsOptical filtersColor gelBlue colored

A blue colored composition for a color filter contains a pigment carrier comprising a transparent resin, a precursor thereof or a mixture thereof, a blue pigment having a specific surface area of 90 to 140 m2 / g, and a violet pigment having a specific surface area in a range of 100 to 150 m2 / g, but having a greater specific surface area than that of the blue pigment used. A color filter includes a filter segment formed from the blue colored composition.

Owner:TOPPAN PRINTING CO LTD +1

Polycarbonate Resin Composition with Excellent Scratch Resistance and Impact Strength

A polycarbonate resin composition according to the present invention comprises a polycarbonate resin and an ultra-high molecular weight branched acrylic copolymer resin and can have excellent transparency, appearance, and flowability, as well as scratch resistance and impact strength.

Owner:LOTTE ADVANCED MATERIALS CO LTD

Electrophotography and image forming apparatus

The object of the present invention is to provide a developer having a sharp charge amount distribution and bringing out high-quality image without substantially smearing a charging unit, developing units, a photoconductor, and an intermediate transferring member by the developer, namely, a developer capable of providing an appropriate image density and exhibiting extremely little background smear even when used over a long period of time and repeatedly used for a number of sheets of paper as well as to provide an image forming apparatus for electrophotography using the developer.

Owner:RICOH KK

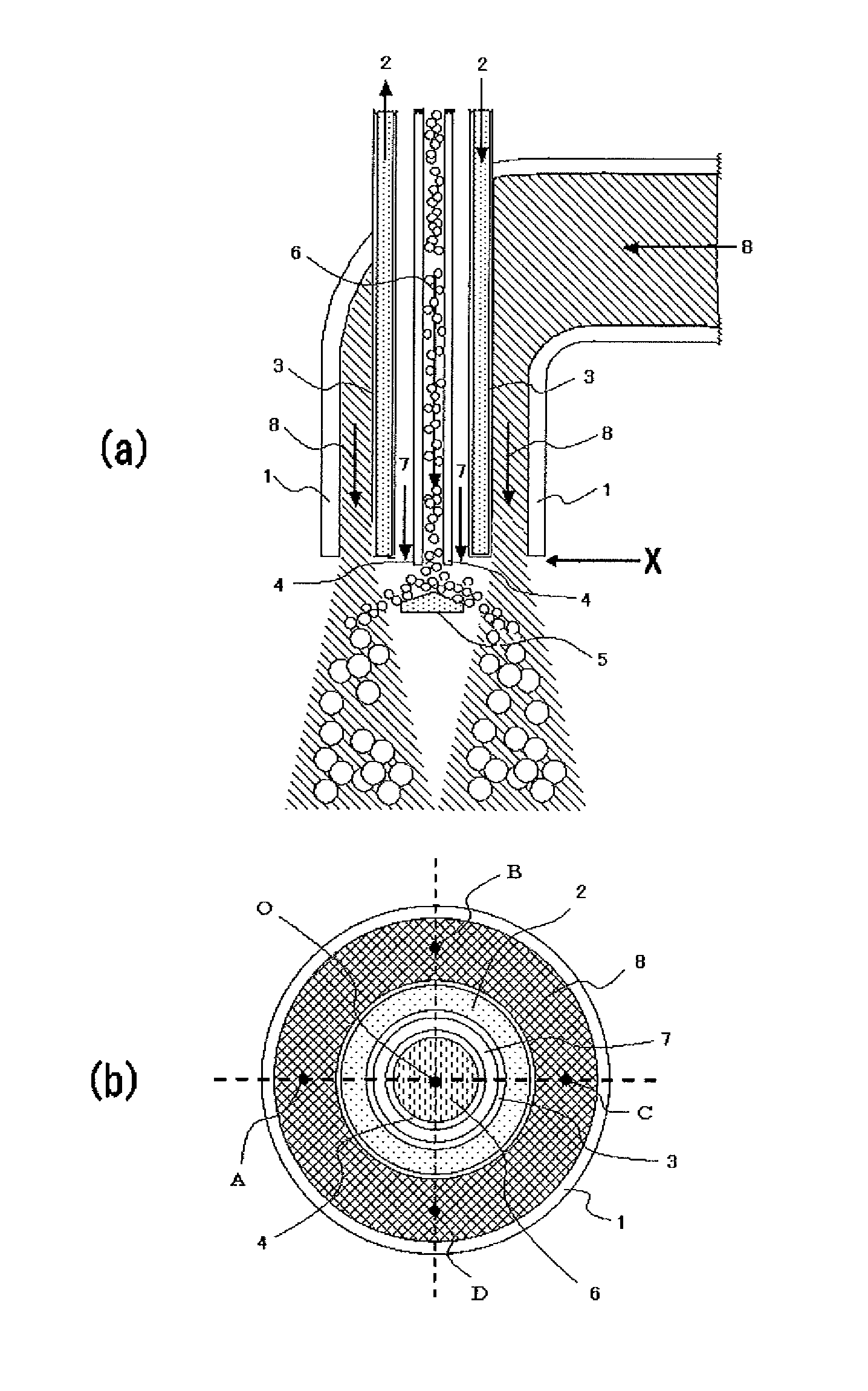

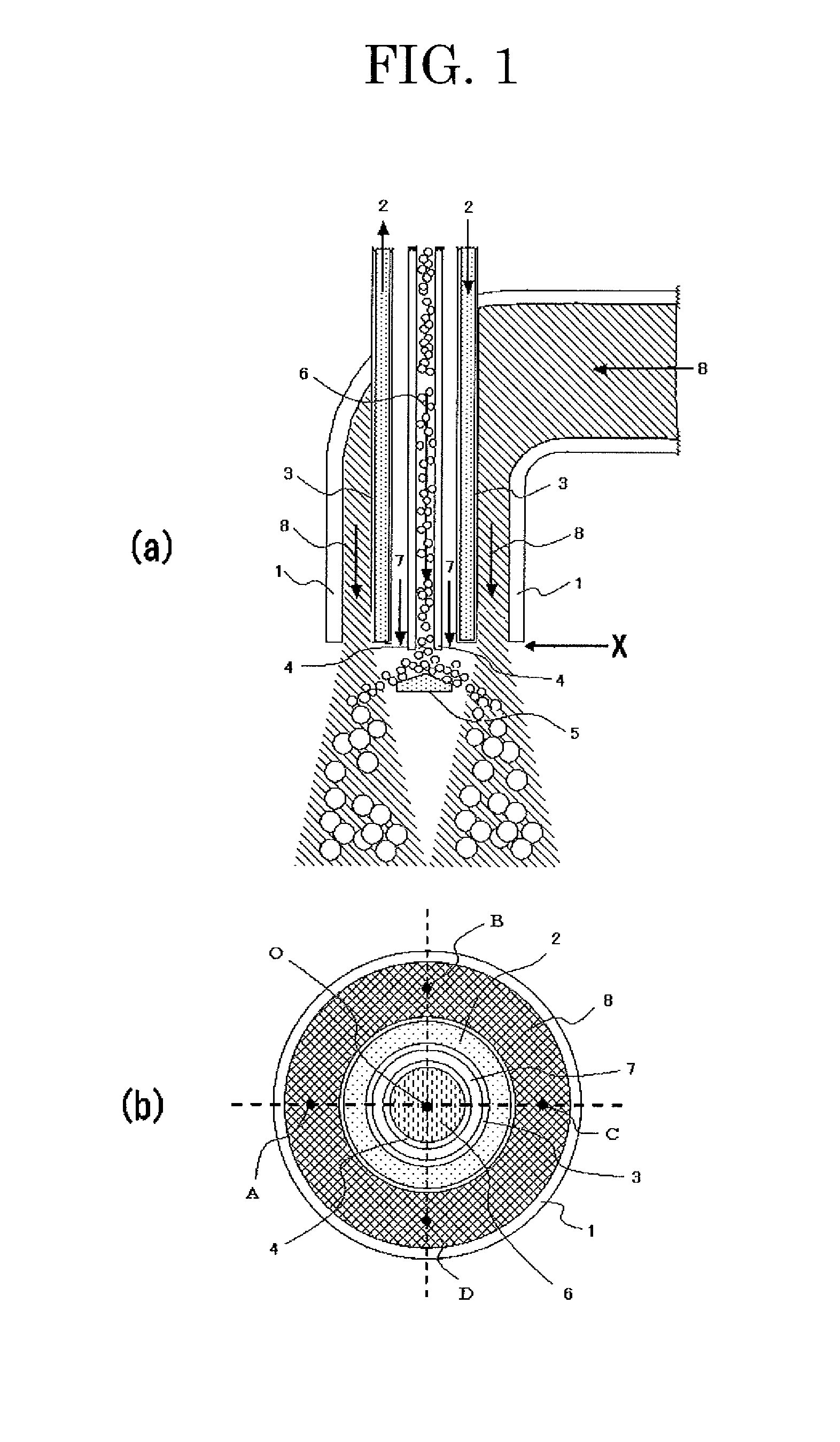

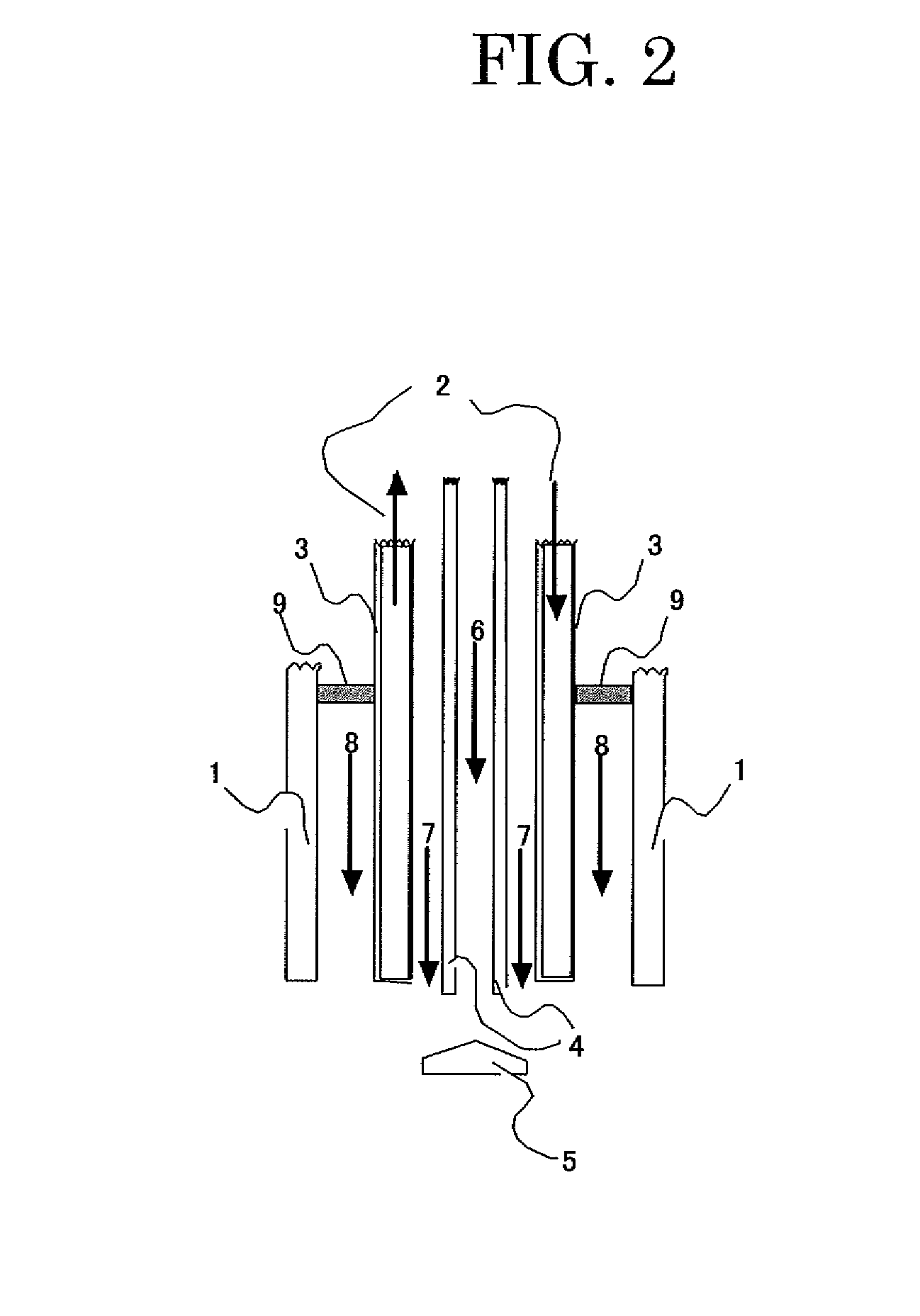

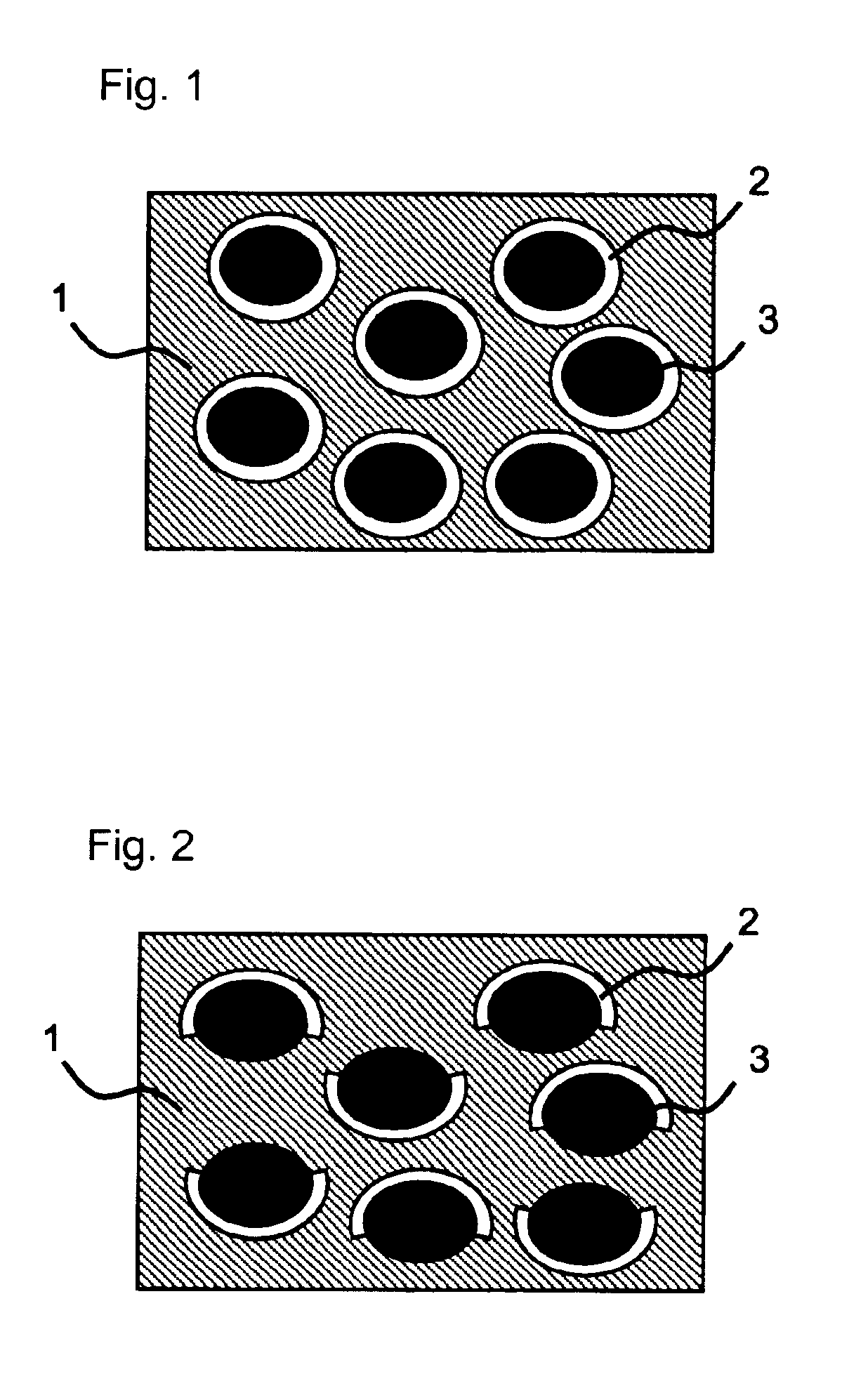

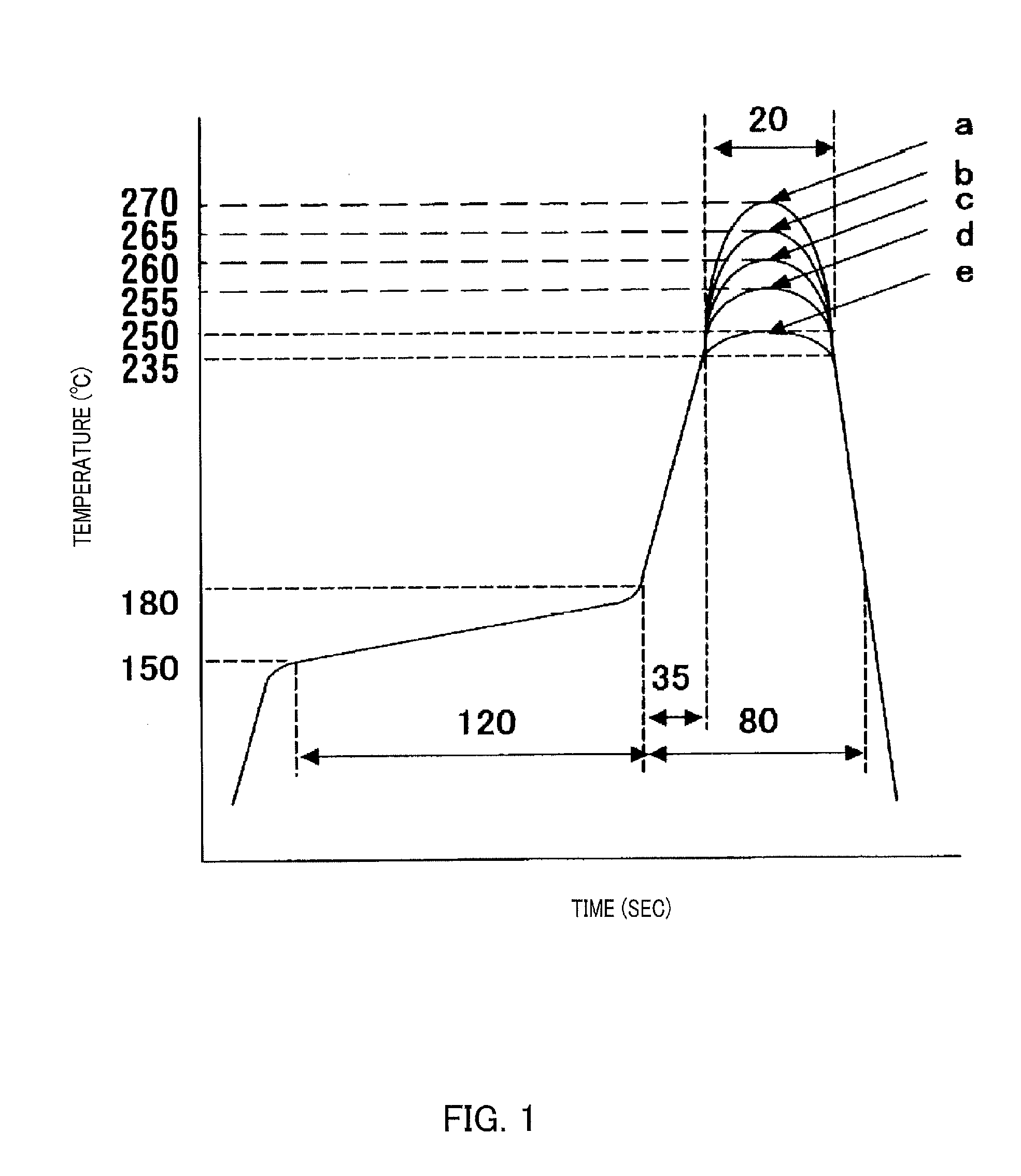

Thermally expanded microspheres and a process for producing the same

ActiveUS20090280328A1Improve efficiencyImprove liquiditySynthetic resin layered productsCellulosic plastic layered productsVoid ratioMicrosphere

The present invention provides heat-expanded microspheres having high packing efficiency, and a production method thereof. The heat-expanded microspheres are produced by expanding heat-expandable microspheres, which comprise shell of thermoplastic resin and a blowing agent encapsulated therein having a boiling point not higher than the softening point of the thermoplastic resin and have an average particle size from 1 to 100 micrometer, at a temperature not lower than their expansion initiating temperature, and the heat-expanded microspheres result in a void fraction not higher than 0.70.

Owner:MATSUMOTO YUSHI SEIYAKU

High-Rigidity Electromagnetic Shielding Composition and Molded Articles Thereof

InactiveUS20130177765A1High mechanical strengthImprove conductivityShielding materialsNon-conductive material with dispersed conductive materialFiberPolymer science

A high-rigidity electromagnetic shielding composition includes: (A) about 10 to about 34 wt % of polyamide resin including an aromatic moiety in the backbone structure; (B) about 65 to about 85 wt % of carbon fiber; and (C) about 1 to about 20 wt % of metallic filler. The composition can have high modulus, electromagnetic shielding effects, and high surface conductance, and can thus be used to replace frames, brackets and the like for electronic devices.

Owner:CHEIL IND INC

Thermoplastic resin composition for reflective material, reflective plate, and light-emitting diode element

ActiveUS20140167091A1High mechanical strengthImprove heat resistanceSemiconductor devicesOptical elementsPolymer sciencePolyolefin

The purpose of the present invention is to provide a thermoplastic resin composition for a reflective material which has excellent mechanical strength, excellent heat resistance, excellent high reflectance, and excellent moldability, and which makes it possible to obtain a reflective plate with little decline in reflectance caused by heating. A first embodiment of this thermoplastic resin composition for a reflective material includes: a polyester resin (A) that has a melting point or glass transition temperature of 250° C. or higher and includes an alicyclic hydrocarbon structure; a thermoplastic resin (B) that has a polyolefin backbone and a functional group; a white pigment (C); and an inorganic filler (D); the thermoplastic resin (B) either including 0.1 to 1.8 wt % of a functional group unit (B1) that further includes a heteroatom, or further including an aromatic hydrocarbon structure (B2), and the limiting viscosity [η] being 0.04 to 1.0 dl / g.

Owner:MITSUI CHEM INC

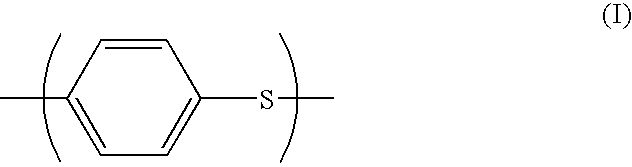

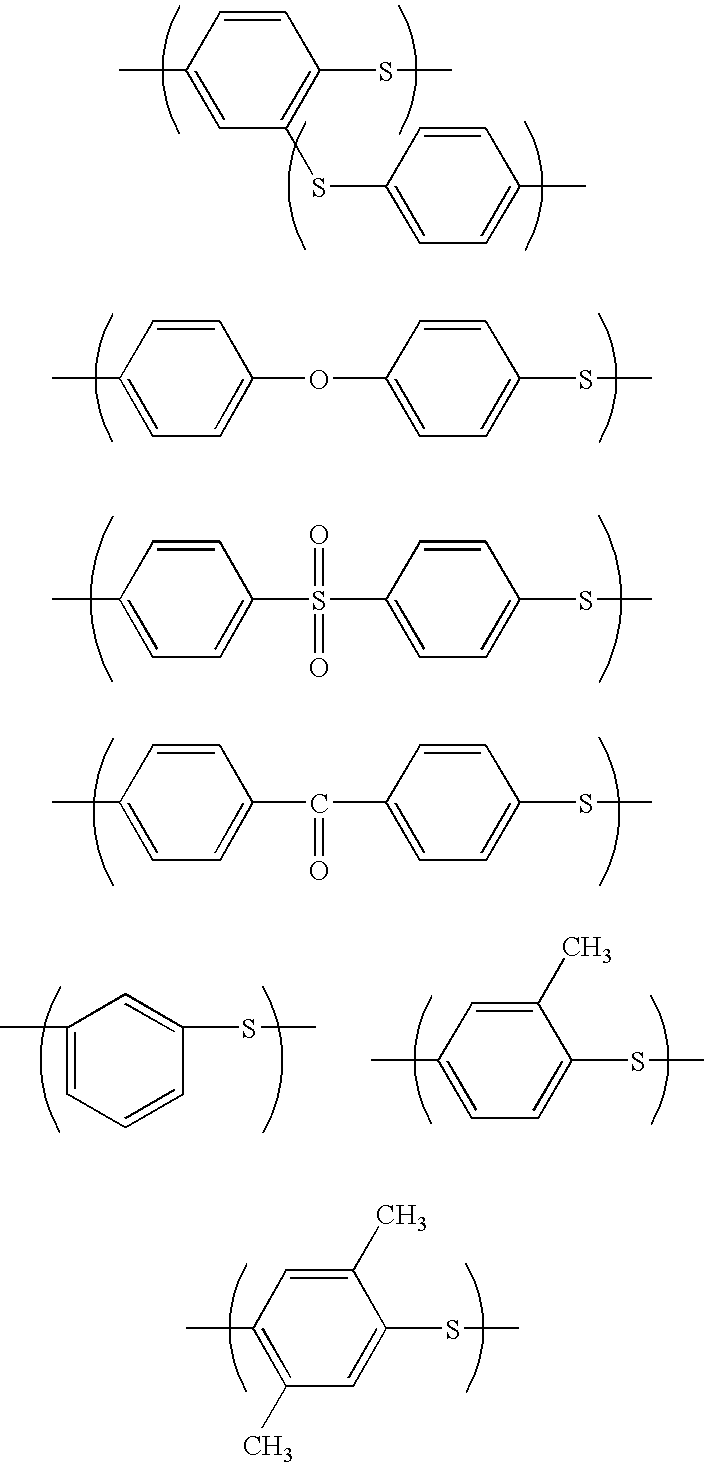

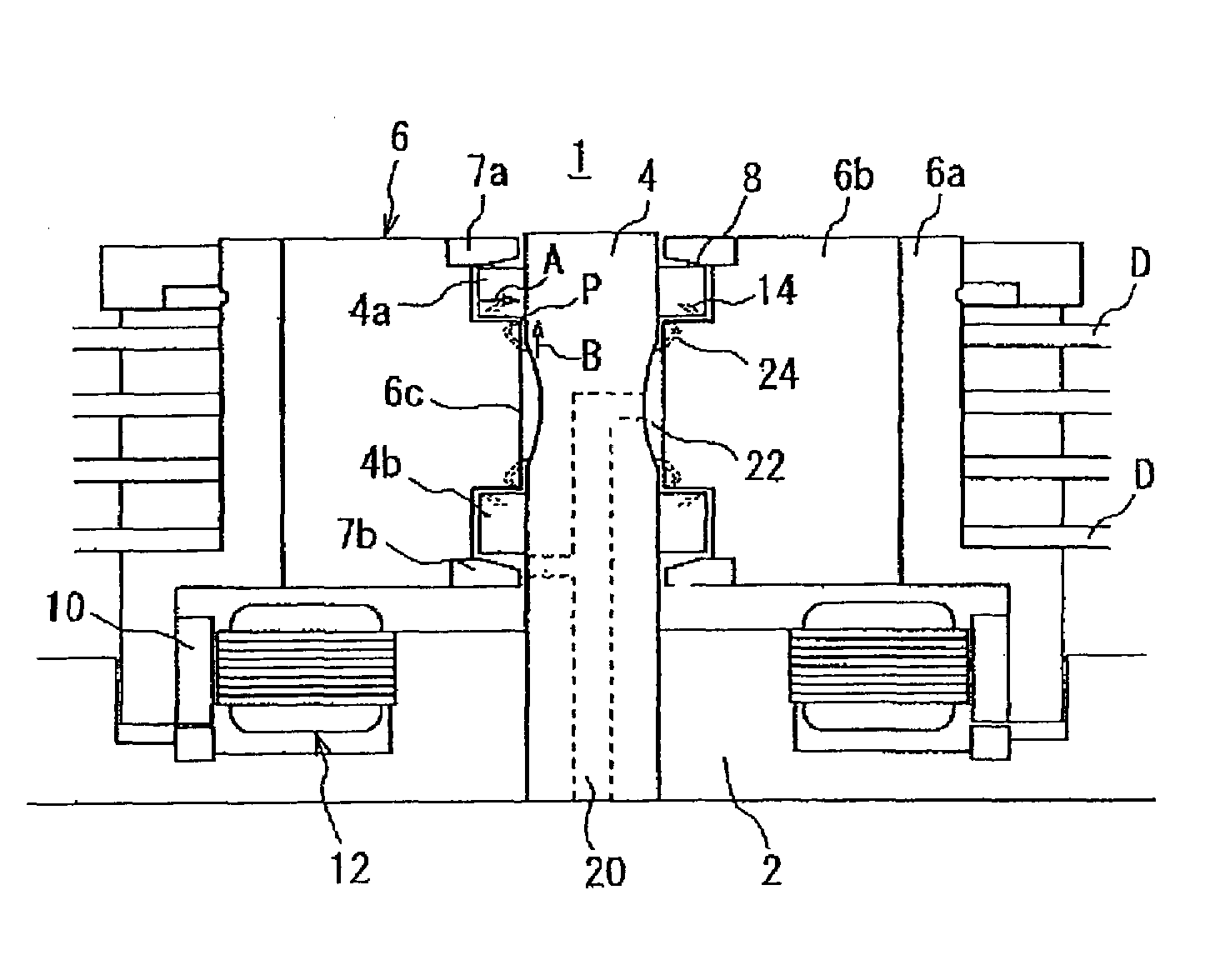

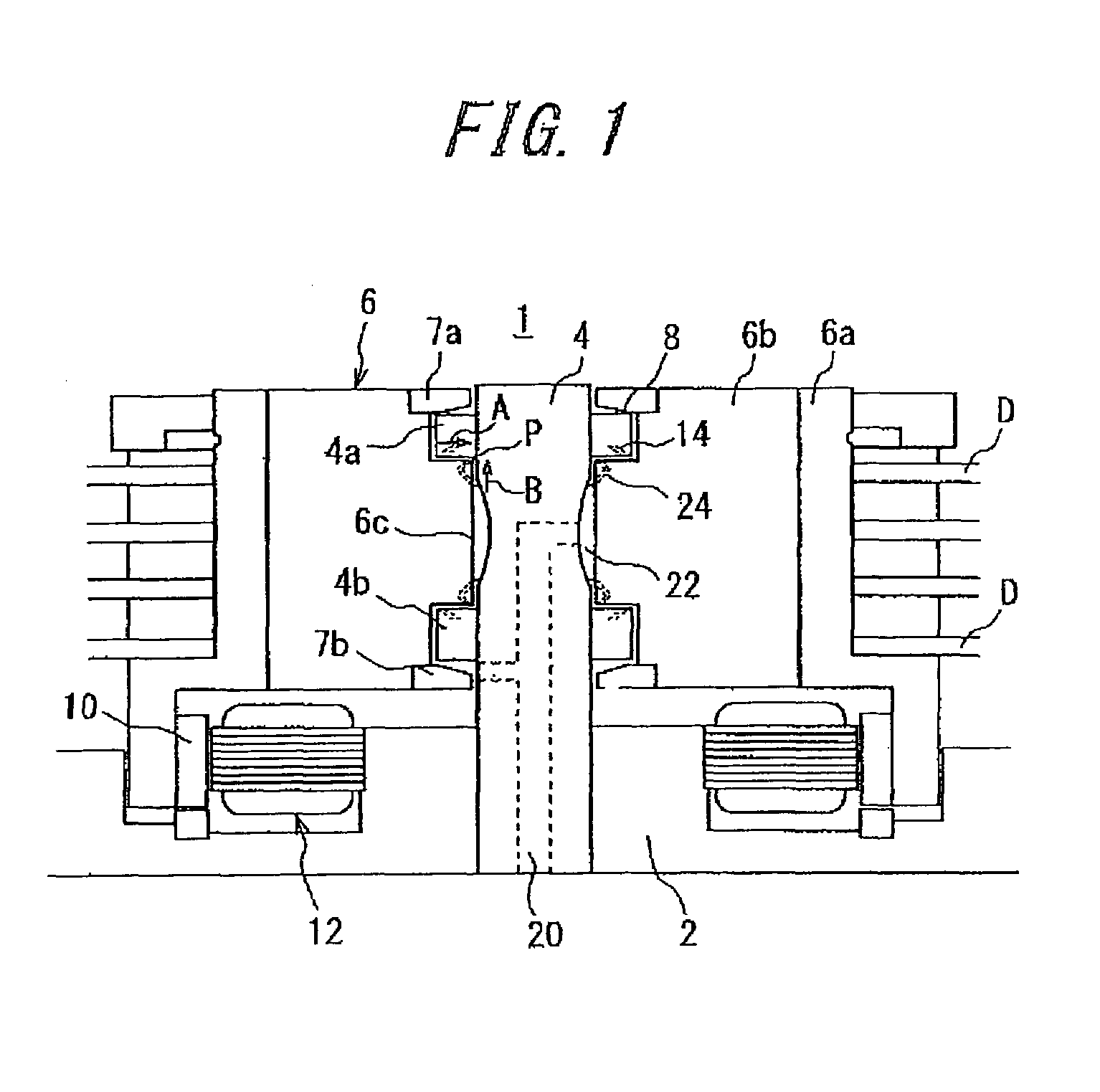

Polyphenylene sulfide resin composition

Owner:TORAY IND INC

Resin composition and molded article composed of the same

ActiveUS8829099B2Excellent in flowabilityIncrease resistanceLiquid surface applicatorsSpecial tyresGlass transitionPolymer chemistry

Owner:TORAY IND INC

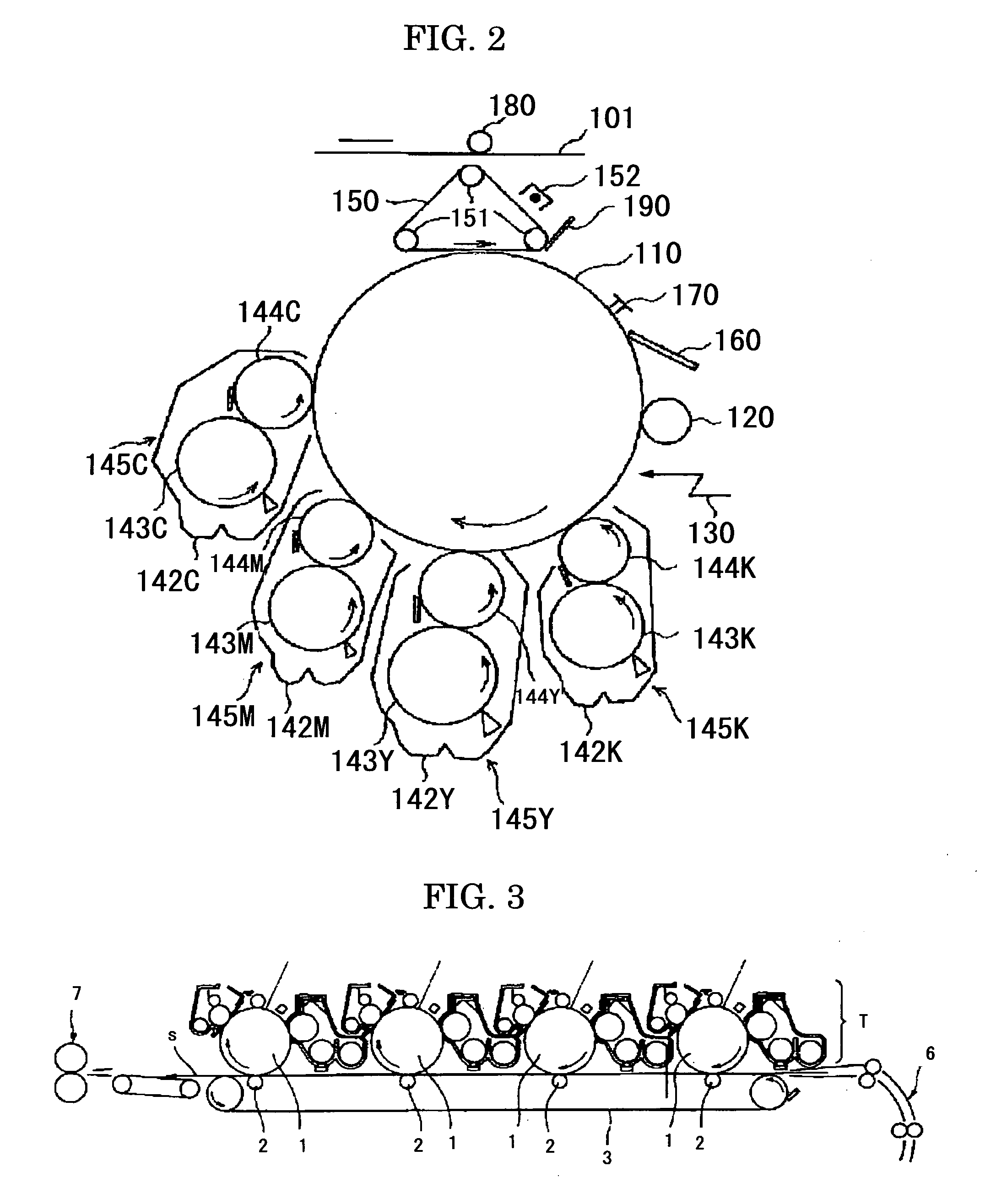

Lubricating oil composition and lubricating oil for fluid dynamic bearing as well as fluid dynamic bearing and method for lubricating fluid dynamic bearing using the same

InactiveUS20090318316A1Improve hydrolytic stabilityImprove oxidation stabilityOrganic chemistryShaftsChemistryOxidation stability

This invention relates to a lubricating oil composition being excellent in oxidation stability and low-temperature flowability, and more particularly to a lubricating oil composition characterized by using as a base oil a diester obtained from a straight-chain dihydric alcohol having a carbon number of 6 to 12 and having a hydroxyl group at both terminal carbon atoms respectively and a branched-chain saturated monovalent fatty acid having a carbon number of 6 to 12.

Owner:JAPAN ENERGY CORP

Thermoplastic resin composition and molded article thereof

ActiveUS8193264B2Excellent in flowabilityMaintain good propertiesOrganic chemistryInksTransmittancePolyester resin

A thermoplastic resin composition and a molded article thereof, respectively excellent in flowability and mechanical properties, and, in a preferred mode, also excellent in low warping property, laser transmittance and laser weldability, is obtained by mixing (B) 0.1 to 4 parts by weight of a polyfunctional compound having three or more functional groups, in which at least one of the terminal structures having the functional groups is a structure containing alkylene oxide units, with (A) 100 parts by weight of a thermoplastic resin, and further provides a molded particle thereof. It is preferred that the (A) thermoplastic resin is one or more selected from a polyester resin and polycarbonate resin.

Owner:TORAY IND INC

Transparent Thermoplastic Resin Composition

Owner:LOTTE ADVANCED MATERIALS CO LTD

Resin composition for automotive parts

InactiveUS7553887B2Excellent in flowabilityMaintain good propertiesFilm/foil adhesivesOrganic dyesElastomerPolymer science

To provide a resin composition comprising a polypropylene resin composition and an aluminum flake pigment for use as an automotive resin composition, which is excellent in mechanical strength, physical properties and flowability, and enables to produce molded products showing good metallic appearance.A composition comprising a crystalline propylene / ethylene block copolymer, an elastomeric polymer and an inorganic filler is a preferred example of the polypropylene resin composition, and aluminum flakes surface-coated with a polymer containing as constituent units acrylic acid, an acrylic acid ester, epoxylated polybutadiene and divinylbenzene are preferred examples of the aluminum flake pigment.

Owner:PRIME POLYMER CO LTD

Monoazo lake pigment composition and gravure ink using the same

InactiveUS6989055B2Excellent in flowabilityGood printabilityCoupling reaction in azo dyesDye lakesWater solubleSlurry

A monoazo lake pigment composition containing a monoazo lake pigment obtained from a laked pigment aqueous slurry prepared by conducting coupling of a diazo component obtained by diazotizing an aromatic amine having a soluble group and a coupler component and conducting laking after or simultaneously with the coupling, wherein the laking is carried out in the presence of a water-soluble acrylic polymer in an amount of 0.1 to 40 parts by weight per 100 parts of the above coupler component, and a gravure ink containing the above pigment composition and a gravure ink vehicle.

Owner:TOYO INK SC HOLD CO LTD

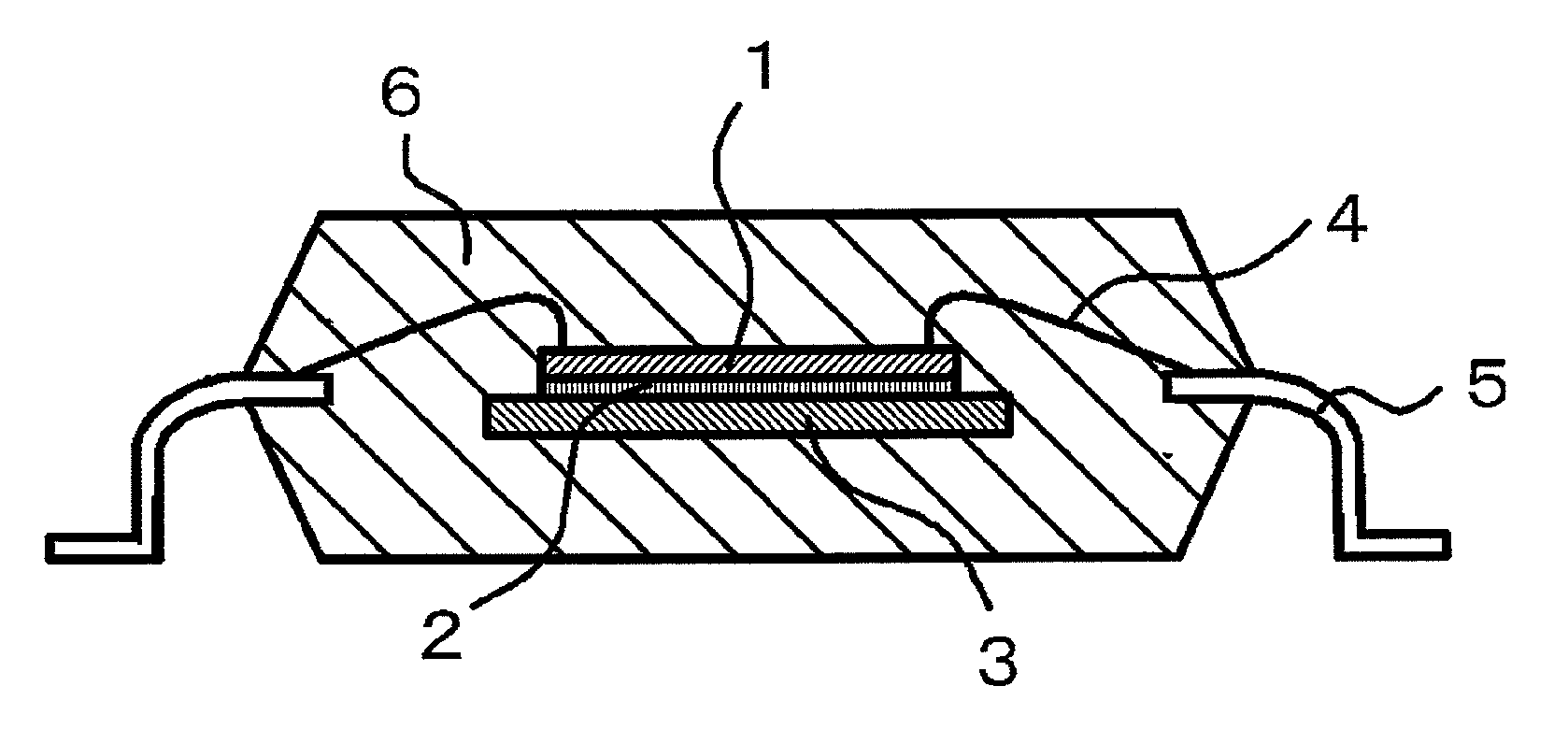

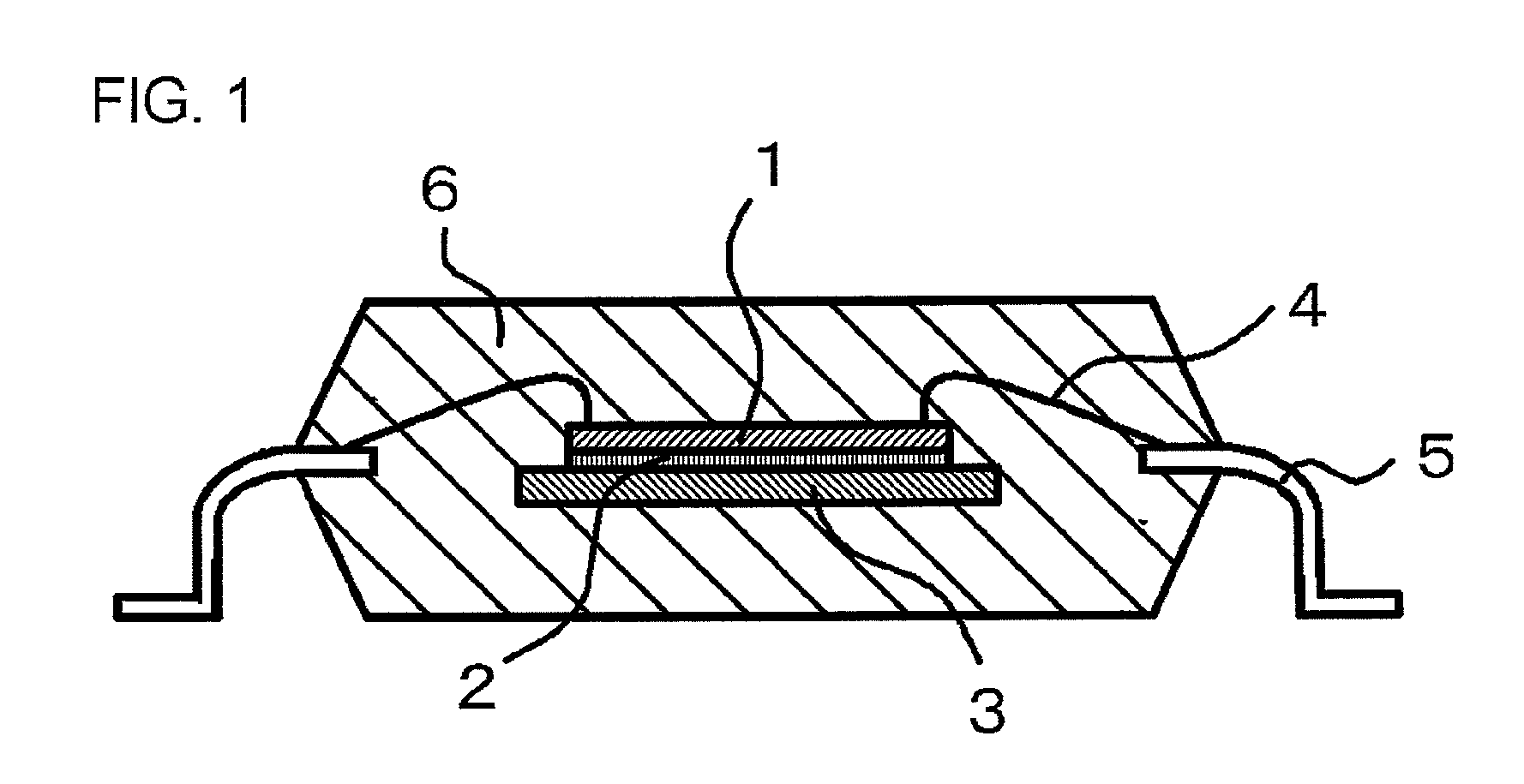

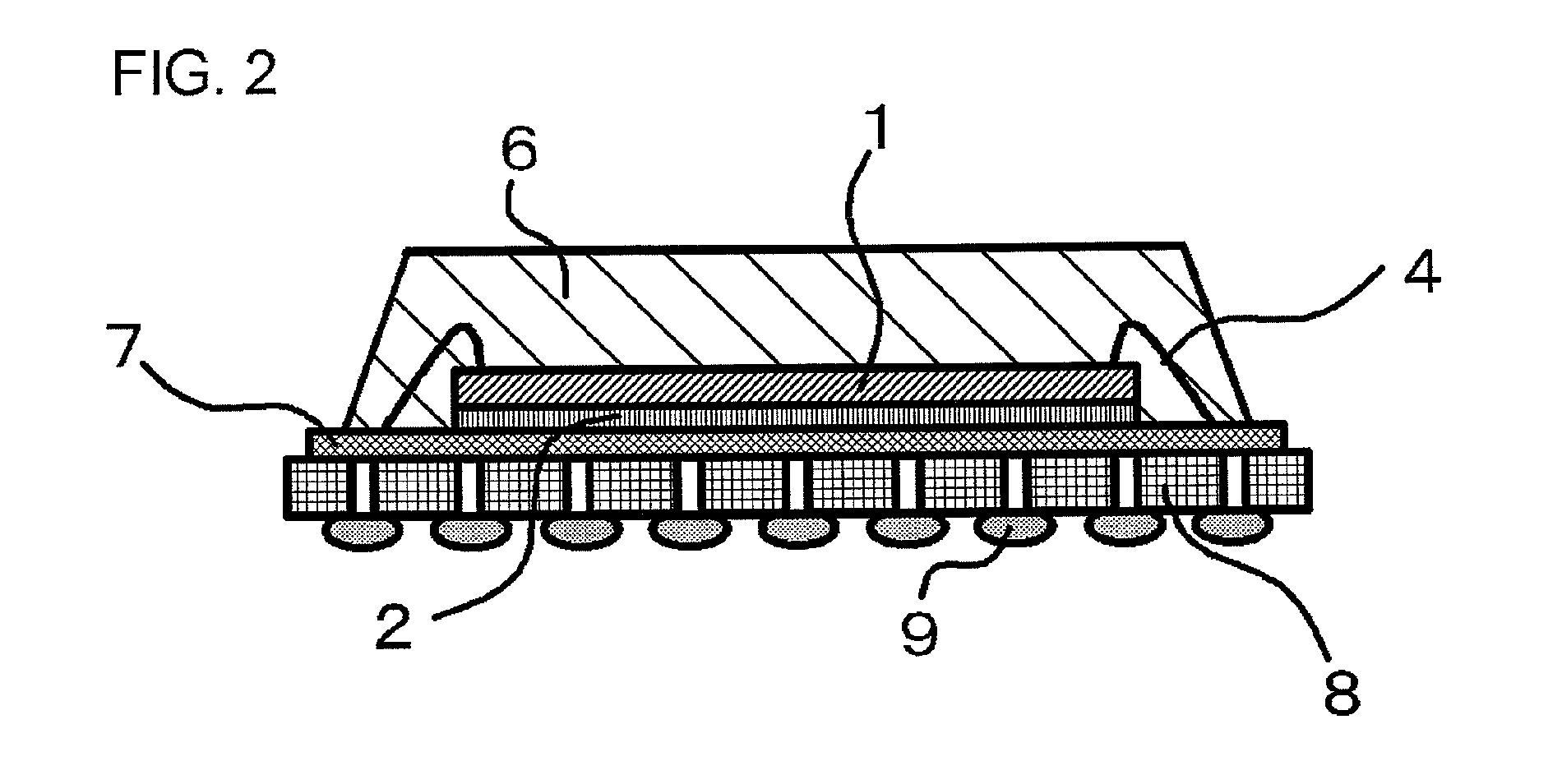

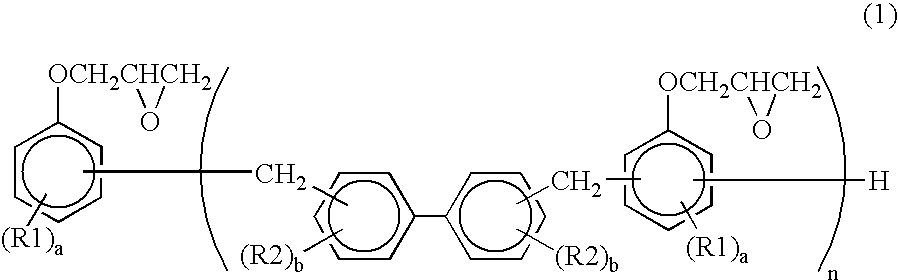

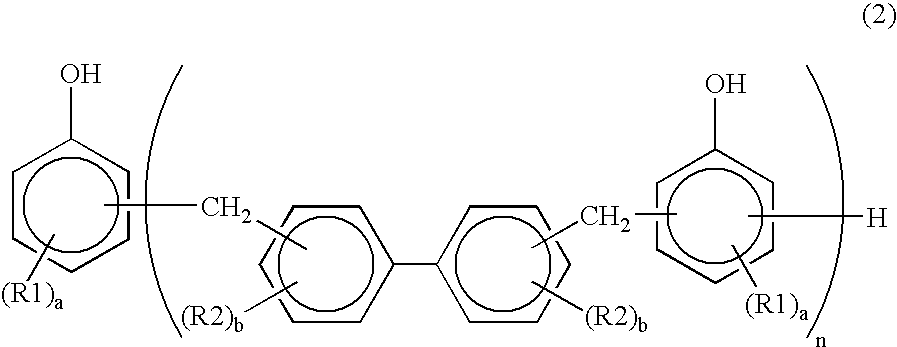

Resin composition for encapsulating semiconductor and semiconductor device

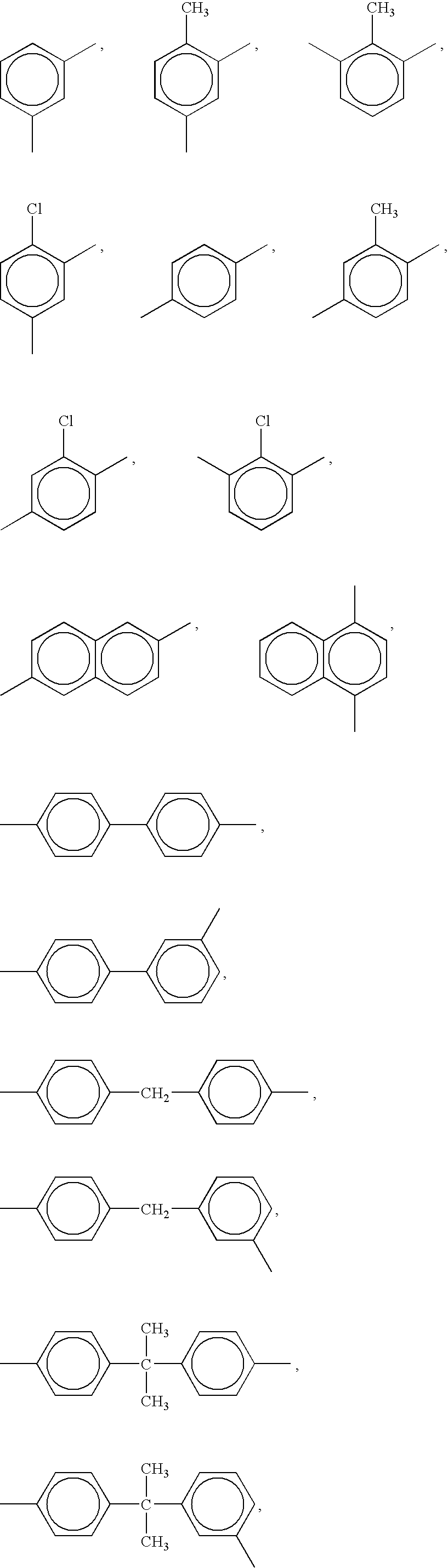

InactiveUS20120001350A1Excellent in flowabilityGood moldabilitySemiconductor/solid-state device detailsSolid-state devicesPolymer scienceDevice material

Disclosed is a resin composition for encapsulating a semiconductor containing an epoxy resin (A), a curing agent (B), and an inorganic filler (C), wherein the epoxy resin (A) includes an epoxy resin (A1) having a predetermined structure, and the curing agent (B) includes a phenol resin (B1) having a predetermined structure, wherein the content of a c=1 component included in the total amount of the phenol resin (B1) is not less than 40% in terms of area percentage and the content of a C≧4 component is not more than 20% in terms of area percentage, as measured by the area method of gel permeation chromatography. Also disclosed is a semiconductor device obtained by encapsulating a semiconductor element with a cured product of the resin composition for encapsulating a semiconductor.

Owner:SUMITOMO BAKELITE CO LTD

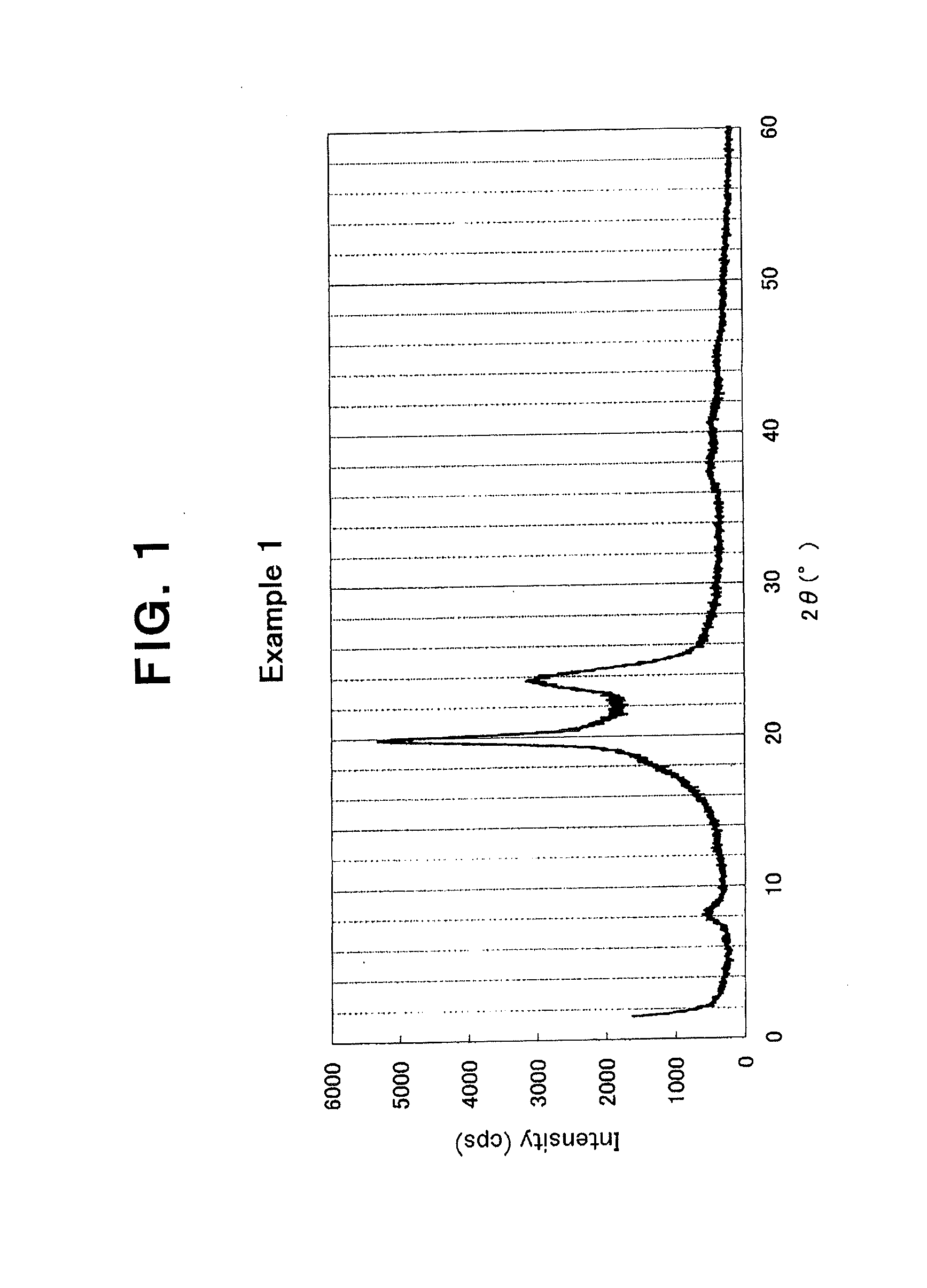

Polyamide 1010 polymer particles and method for producing same

ActiveUS20140349113A1High crystallinityHigh chemical resistanceSynthetic resin layered productsCellulosic plastic layered productsSolventChemistry

The production of polyamide 1010 polymer particles, in which polyamide 1010 resin, a different polymer B and an organic solvent are dissolved and mixed and thereupon an emulsion is formed within a system for phase separation into two phases, being a solution phase having the polyamide 1010 resin as the main component and a solution phase having the polymer B as the main component, and thereafter a poor solvent of the polyamide 1010 resin is brought into contact therewith to precipitate the polyamide 1010 resin, wherein the formation of the emulsion is carried out at a temperature of 100° C. or higher, thereby making it possible to obtain highly crystalline polyamide 1010 particles having a high sphericity.

Owner:TORAY IND INC

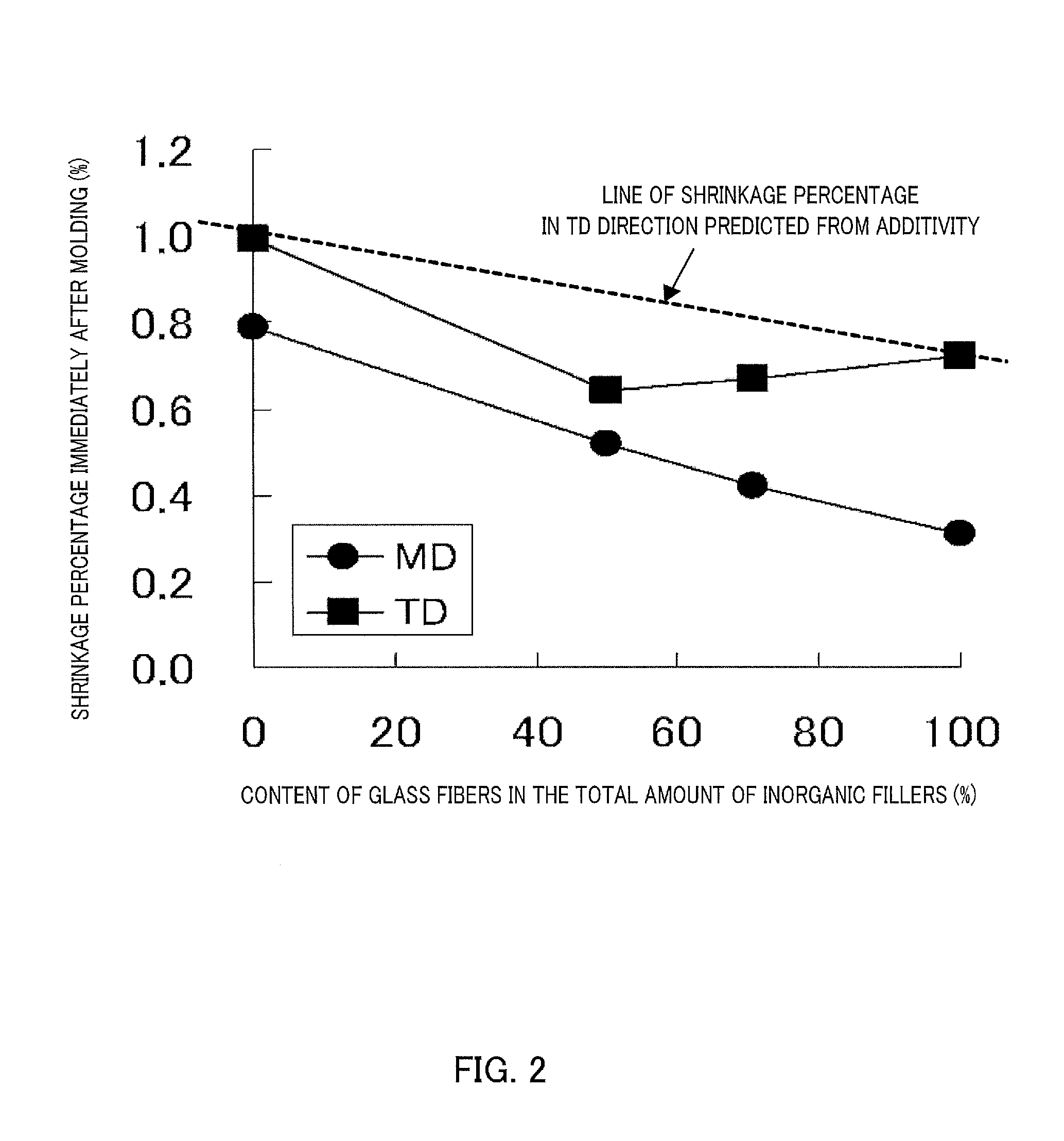

Thermoplastic resin composition for reflector, reflector plate, and light-emitting diode element

ActiveUS20140097737A1High mechanical strengthExcellent in flowability and moldabilityIncadescent screens/filtersVehicle headlampsReflectivityStructural unit

The purpose of the present invention is to provide a thermoplastic resin composition for a reflector plate with which it is possible to obtain a molded article having excellent moldability, high mechanical strength, excellent heat resistance and a high reflectance that is stable over time, and it is possible to obtain a reflector plate with which there is little reduction in reflectance due to heating. The thermoplastic resin composition for a reflector of the invention comprises 30 to 80 weight % of a thermoplastic resin (A) having structural units containing carbonyl groups and a melting point or glass transition temperature of 250° C. or higher, 10 to 50 weight % of an inorganic filler (B) containing an inorganic filler (B-1) that comprises a carbonyl structure and has an aspect ratio of 10 to 100, and 5 to 50 weight % of a white pigment (C).

Owner:MITSUI CHEM INC

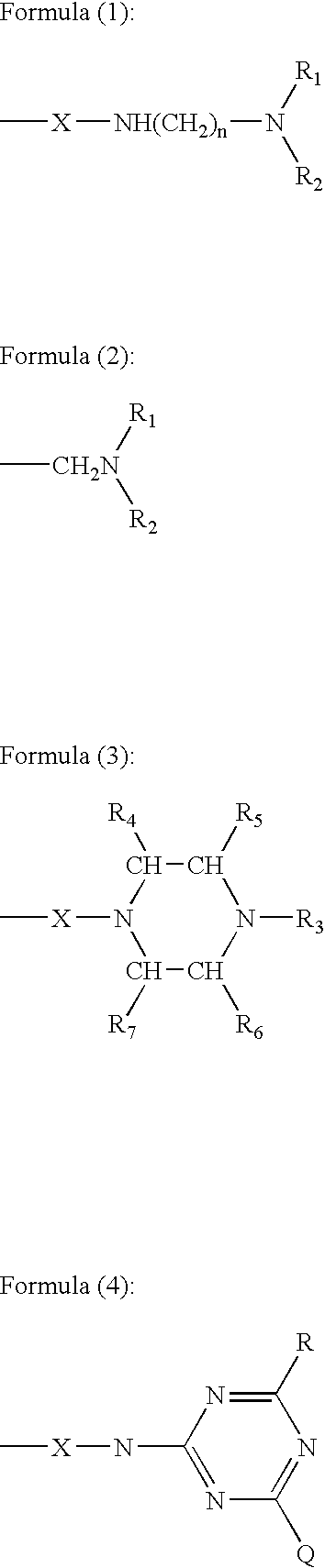

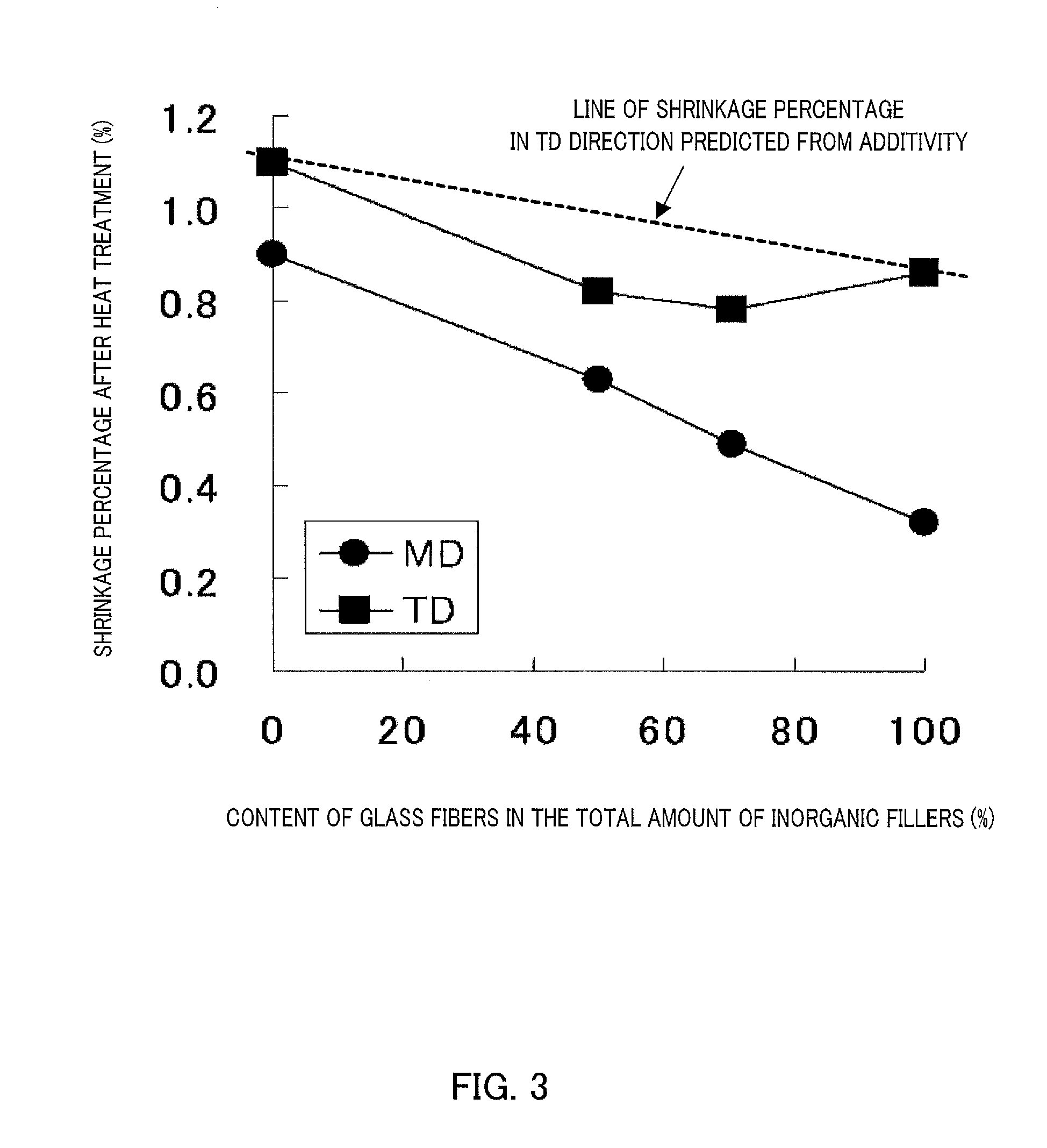

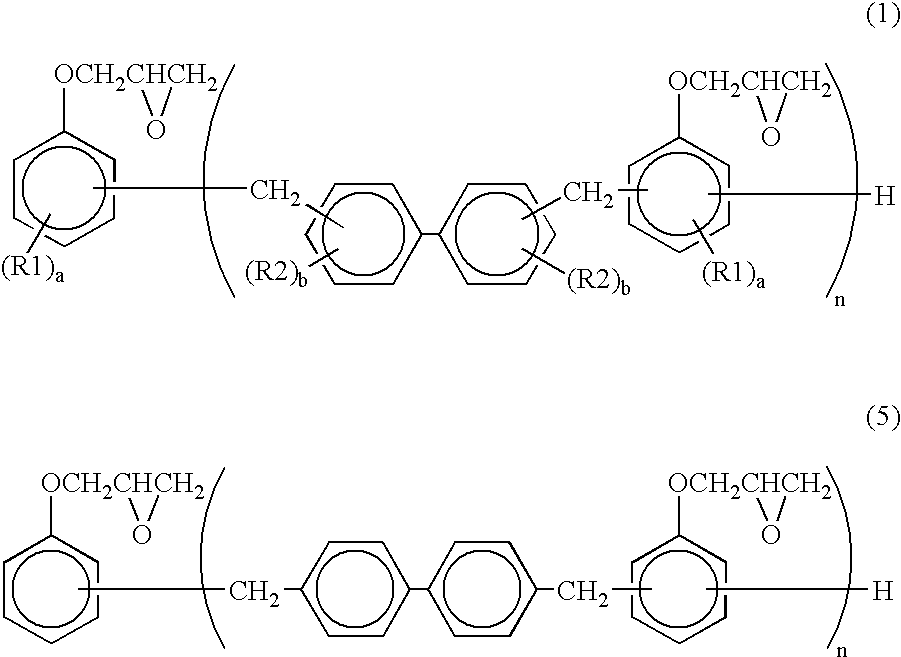

Epoxy resin composition and semiconductor device

InactiveUS20060154079A1Excellent in flowabilityExcellent in solder crack resistanceSemiconductor/solid-state device detailsSynthetic resin layered productsEpoxyCrack resistance

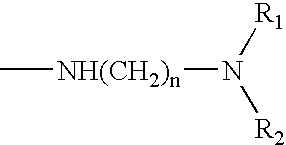

The object of the present invention is to provide an epoxy resin composition for semiconductor encapsulation which is excellent in flowability, adhesion to substrates, flame retardancy and solder crack resistance without using bromine-containing organic compounds and antimony compounds. According to the present invention, there is provided an epoxy resin composition for semiconductor encapsulation characterized by including, as essential components, a phenolic aralkyl type epoxy resin having a biphenyl structure, a phenolic aralkyl resin having a biphenyl structure, a curing accelerator, an inorganic filler, a specific silane coupling agent having a secondary amine, and a specific silane coupling agent having a mercapto group.

Owner:SUMITOMO BAKELITE CO LTD

Polycarbonate resin composition with excellent scratch resistance and impact strength

A polycarbonate resin composition according to the present invention comprises a polycarbonate resin and an ultra-high molecular weight branched acrylic copolymer resin and can have excellent transparency, appearance, and flowability, as well as scratch resistance and impact strength.

Owner:LOTTE ADVANCED MATERIALS CO LTD

Thermally expanded microspheres and a process for producing the same

ActiveUS20120121907A1Improve efficiencyImprove liquiditySynthetic resin layered productsCellulosic plastic layered productsMicrometerBoiling point

The present invention provides heat-expanded microspheres having high packing efficiency, and a production method thereof. The heat-expanded microspheres are produced by expanding heat-expandable microspheres, which comprise shell of thermoplastic resin and a blowing agent encapsulated therein having a boiling point not higher than the softening point of the thermoplastic resin and have an average particle size from 1 to 100 micrometer, at a temperature not lower than their expansion initiating temperature, and the heat-expanded microspheres result in a void fraction not higher than 0.70.

Owner:MATSUMOTO YUSHI SEIYAKU

Epoxy resin composition for semiconductor encapsulation and semiconductor device using the same

InactiveUS20090281225A1Good adhesivenessImprove flame retardant performanceSolid-state devicesSemiconductor devicesEpoxyDevice material

The present invention relates to an epoxy resin composition for semiconductor encapsulation, the epoxy resin composition including the following ingredients (A) to (C) and further including the following ingredient (D) as a flame retardant: (A) an epoxy resin; (B) a phenolic resin; (C) an inorganic filler; and (D) an aluminum hydroxide powder having a 50% volume cumulative diameter D50 (μm) of 1.5 to 5 μm and a BET specific surface area S (m2 / g) of 3.3 / D50≦S≦4.2 / D50, and having a ratio D50 / D10 of 1.5 to 4 wherein D10 is a 10% volume cumulative diameter thereof.

Owner:NITTO DENKO CORP

Resin composition and molded article composed of the same

InactiveUS20140155534A1Excellent in flowabilityIncrease resistanceOrganic dyesGlass transitionPolymer chemistry

A resin composition comprising a polylactic acid-based resin (A) and methacrylic resins (B), wherein the methacrylic resins having at least (a) a difference of 10° C. or more in glass transition temperature or (b) a difference of 3% or more in syndiotacticity; it is preferred that at least one of the methacrylic resins (B) is a methacrylic resin having a weight average molecular weight of 50,000 to 450,000, a glass transition temperature of 110° C. or higher and a syndiotacticity of 40% or more, and that the resin composition further contains a multilayer structure polymer formed as particles each consisting of a core layer and one or more shell layers covering it (C). A molded article made of said resin composition.

Owner:TORAY IND INC

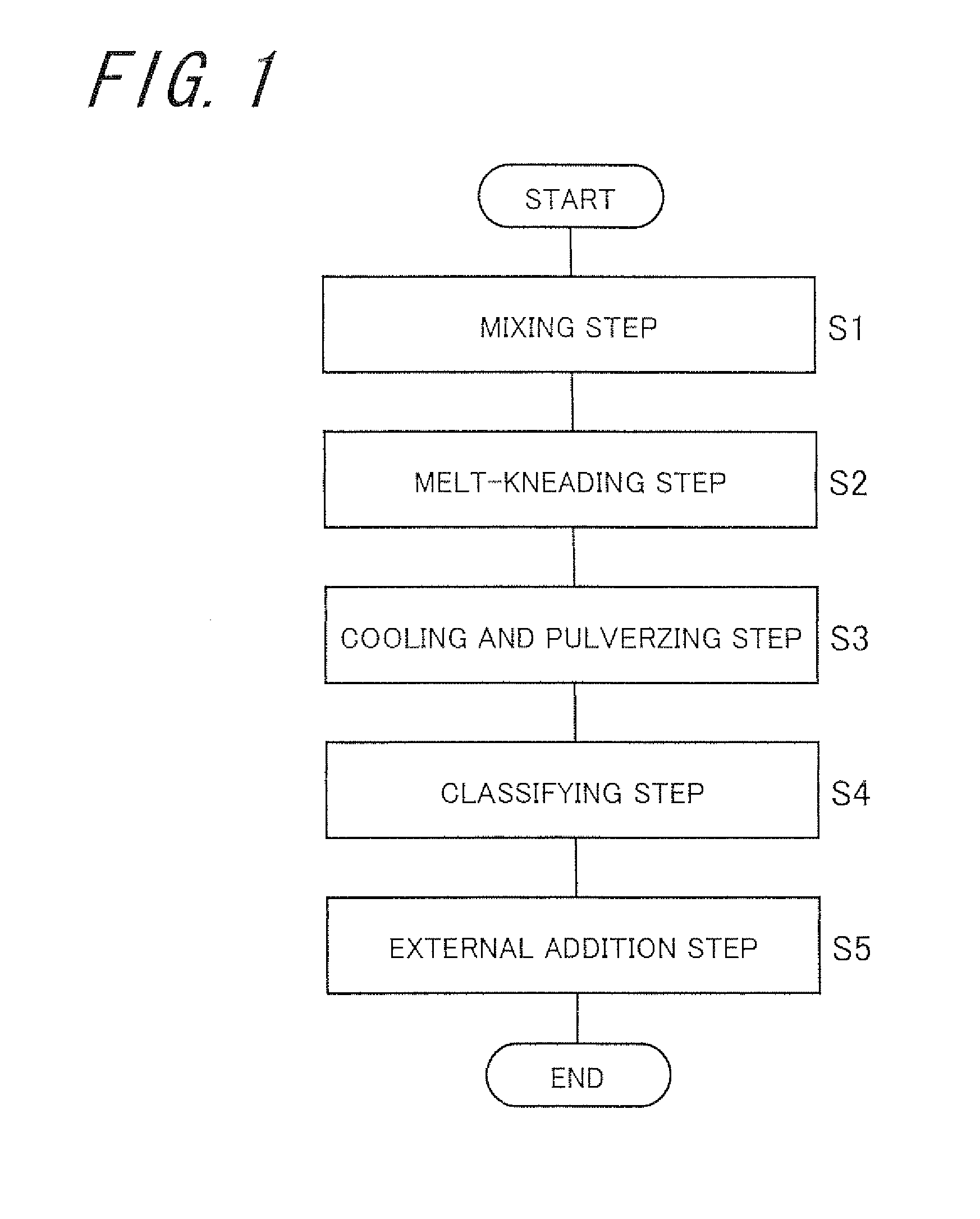

Toner and method for manufacturing the same

InactiveUS20110305982A1Improve charge stabilityExcellent in powder flowabilityDevelopersPolyolAlcohol

A toner includes a binder resin containing a polyester resin A obtained by subjecting aromatic dicarboxylic acid, rosin, and trivalent or higher-valent alcohol as starting materials to polycondensation, a content of the rosin in a sum of the starting materials being 60% by weight or more, and a polyester resin B obtained by subjecting aromatic dicarboxylic acid and polyalcohol as starting materials to polycondensation; a dispersing aid for dispersing the polyester resin A into the polyester resin B; and a colorant.

Owner:SHARP KK

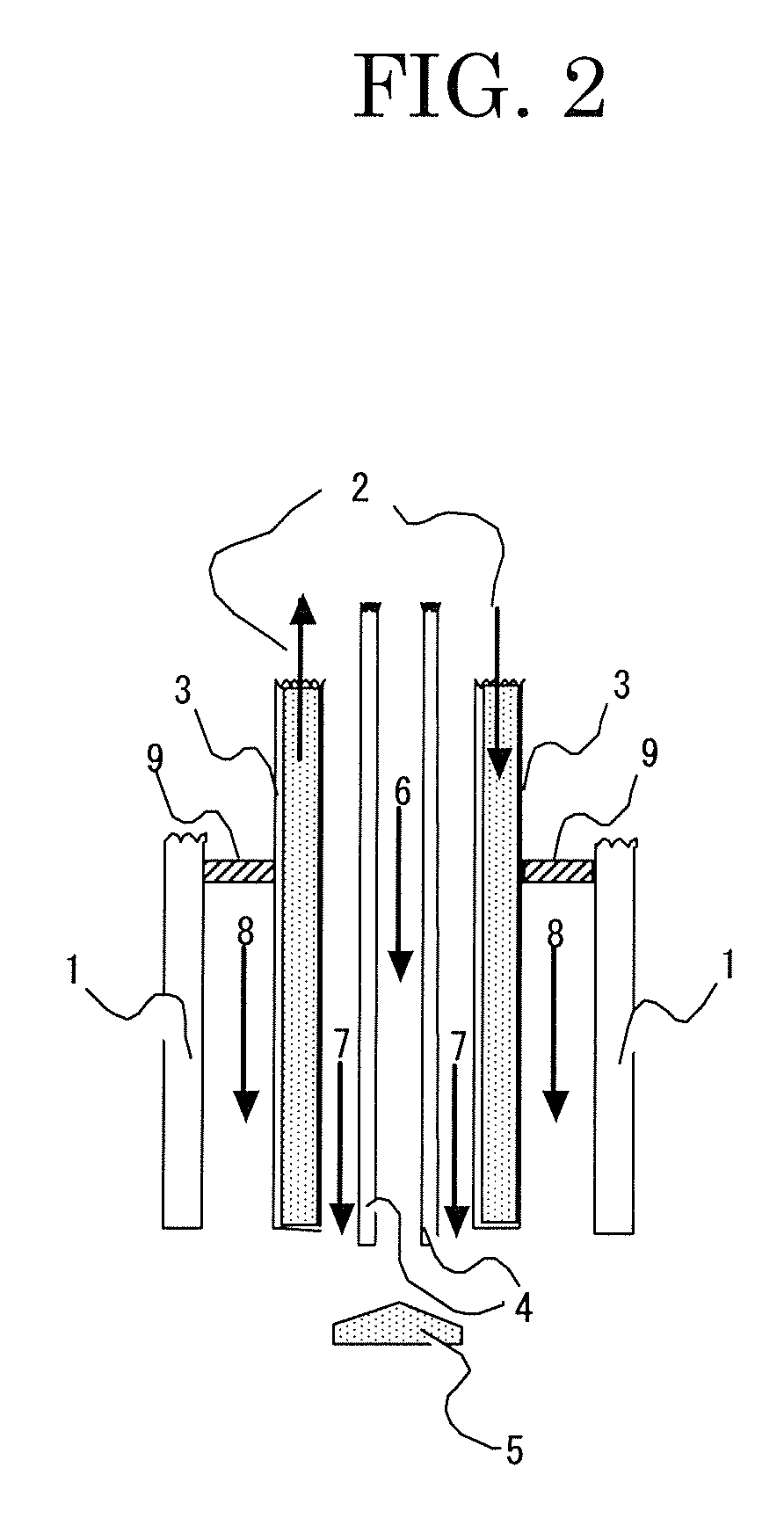

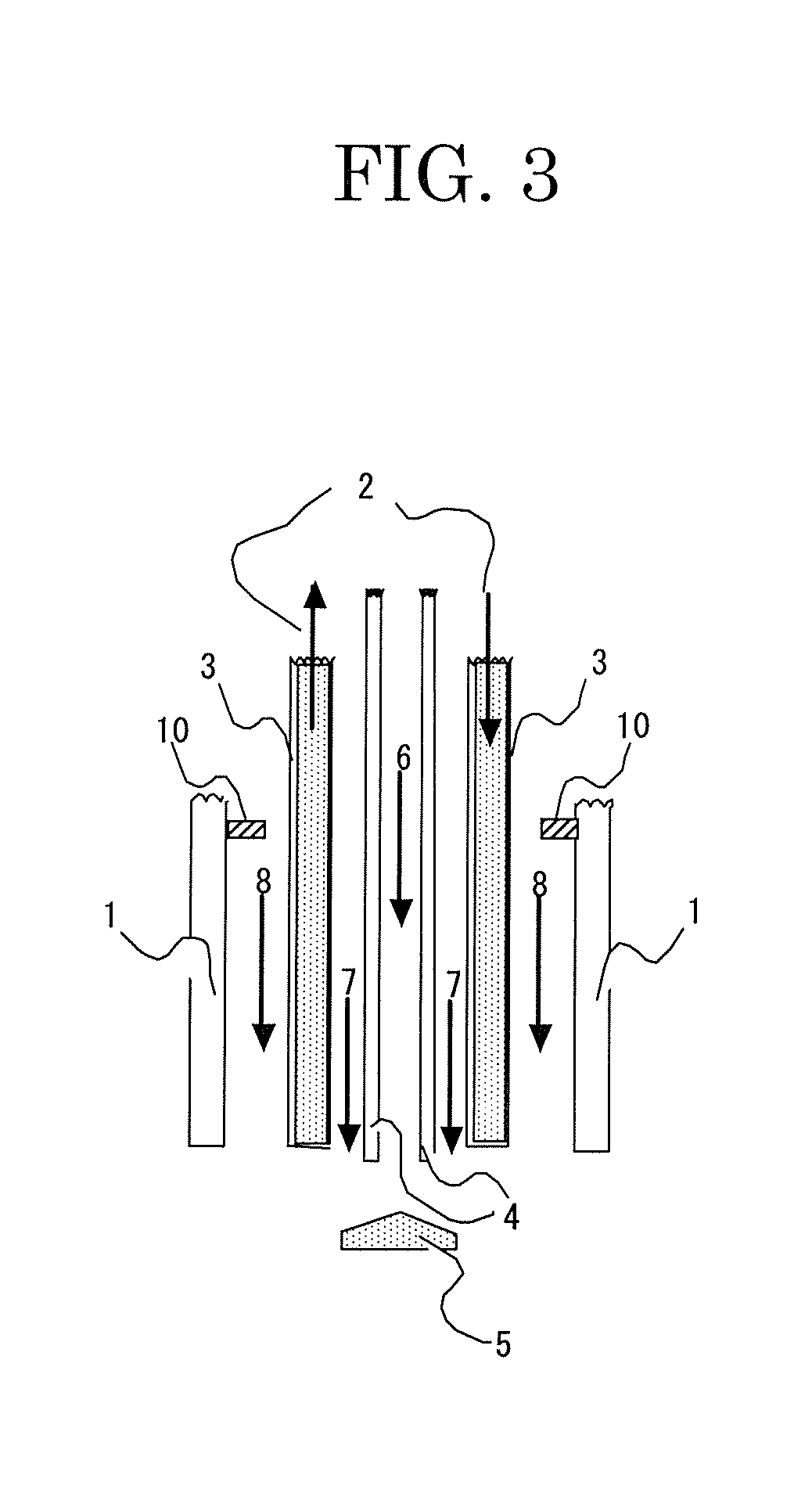

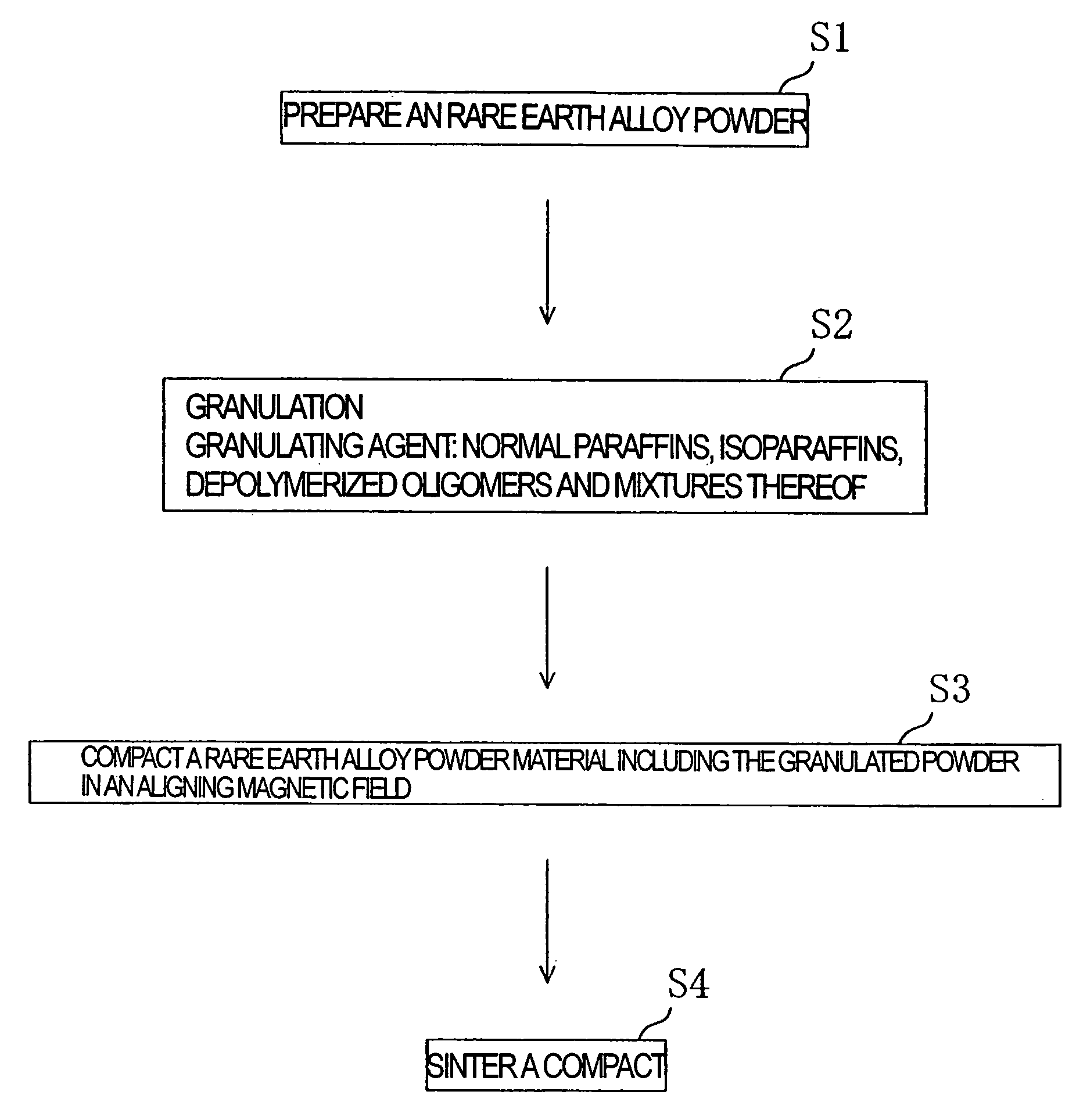

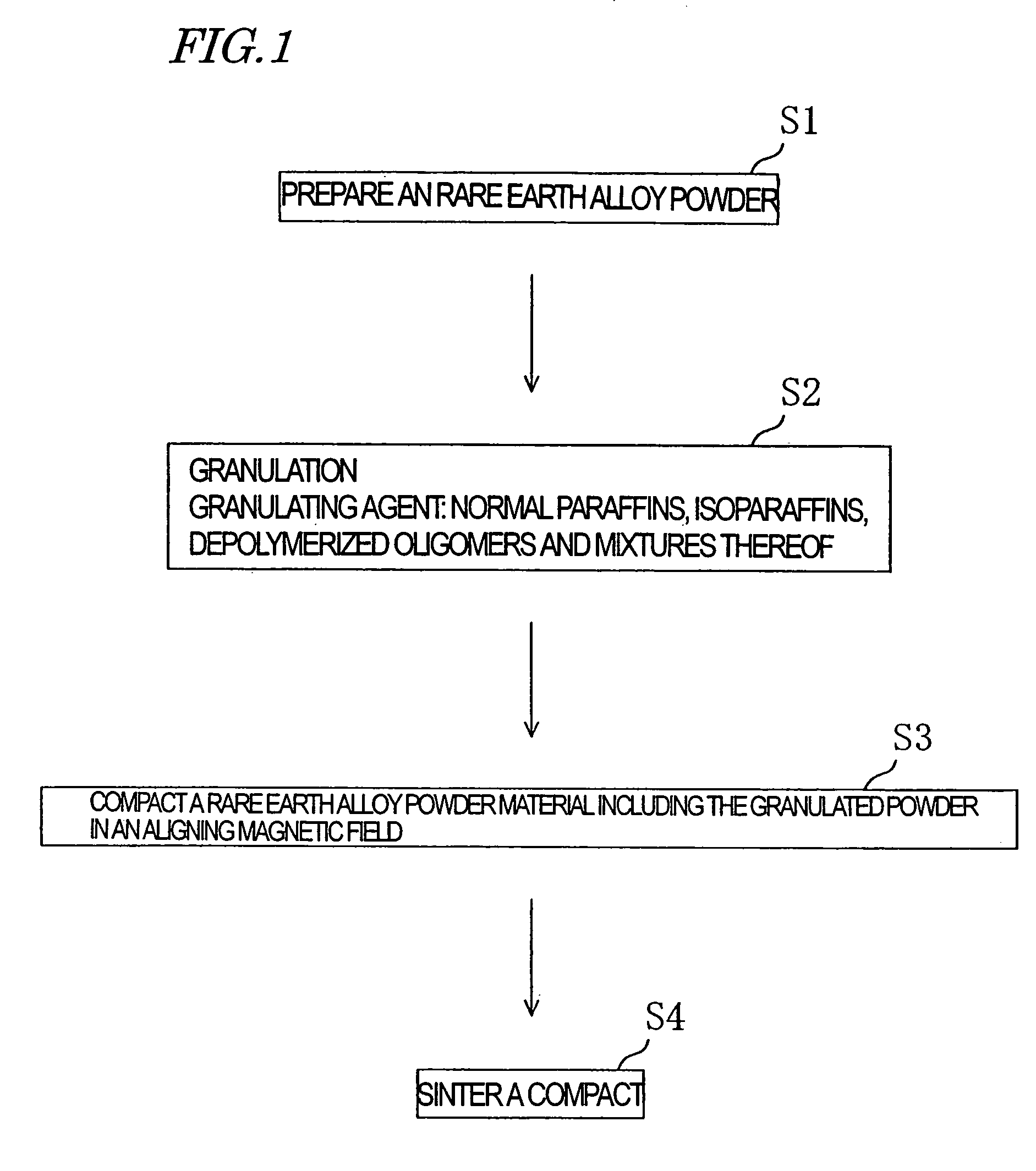

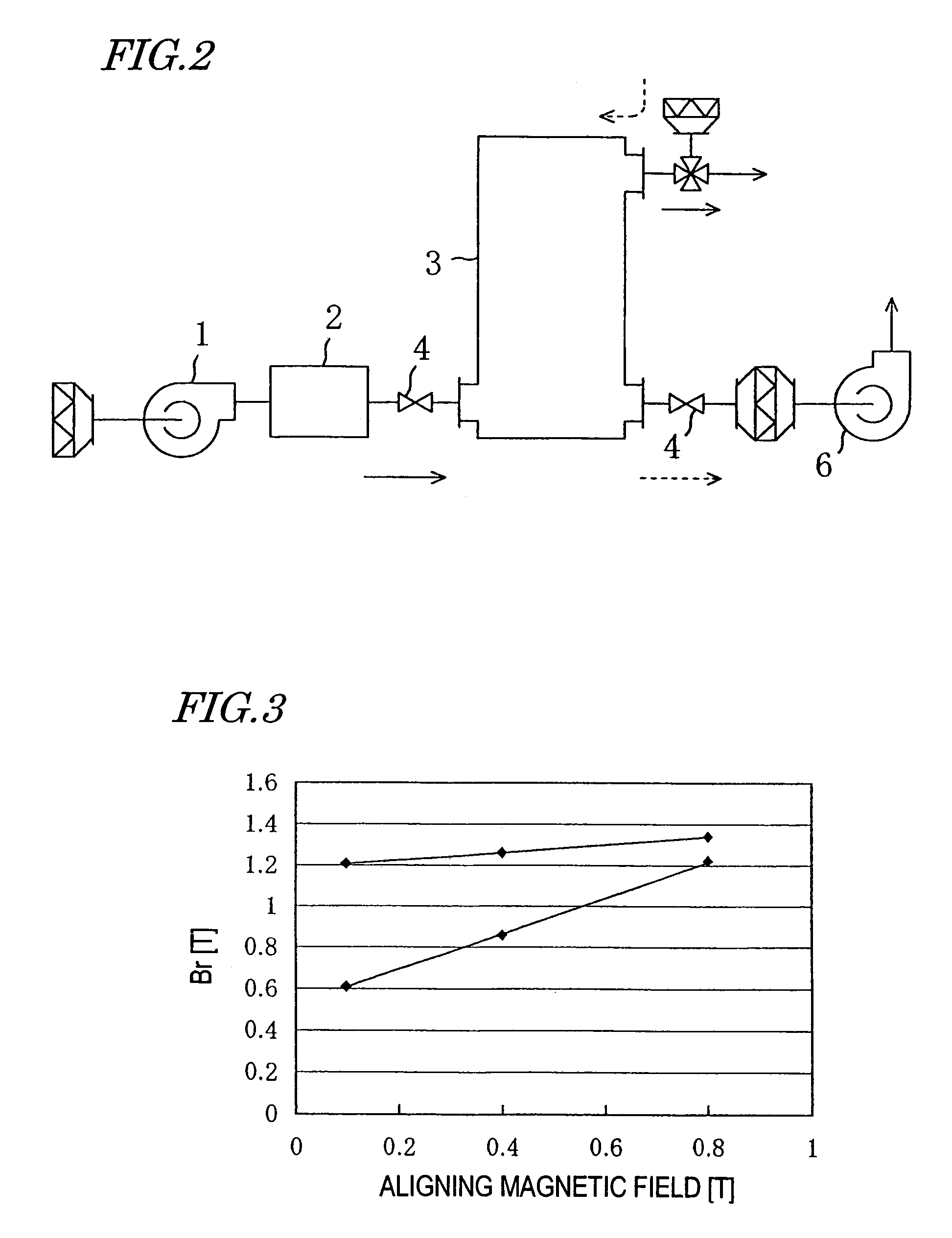

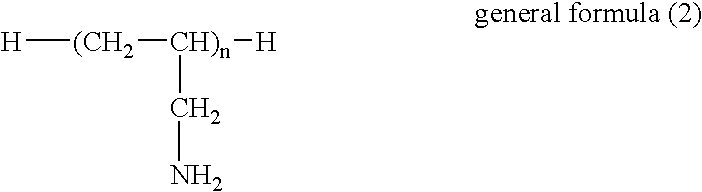

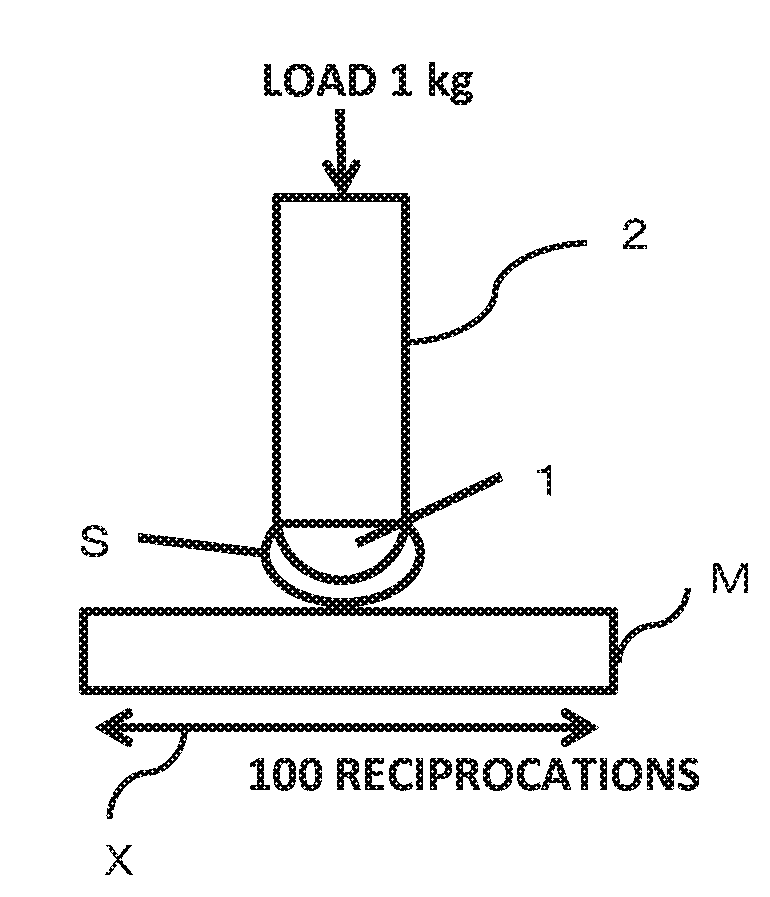

Method for producing granulated powder of R-FE-B type alloy and method for producing R-FE-B type alloy sintered compact

InactiveUS7214343B2Excellent in compactibilityExcellent in flowabilityTransportation and packagingMetal-working apparatusOligomerAlloy

The method for producing a granulated powder of the present invention includes the steps of: preparing an R—Fe—B alloy powder; and granulating the alloy powder using at least one kind of granulating agent selected from normal paraffins, isoparaffins and depolymerized oligomers, to prepare a granulated powder. The produced R—Fe—B alloy granulated powder is excellent in flowability and compactibility as well as in binder removability.

Owner:HITACHI METALS LTD

Pigment dispersion and use thereof

The invention relates to a pigment dispersion comprising: a condensate of or a salt between a polyallylamine and a polyester having a free carboxylic acid or the salt; a pigment derivative represented by the following general formula (1); a pigment; and an organic solvent,(P−X)−[N(R1, R2, R3, R4)]+ general formula (1)wherein p represents an organic dyestuff residue; X represents a sulfonic acid group or a carboxylic acid group; R1 represents an alkyl group having 5 to 20 carbon atoms; and R2, R3 and R4 each independently represents a hydrogen atom or an alkyl group having 1 to 20 carbon atoms.

Owner:TOYO INK SC HOLD CO LTD

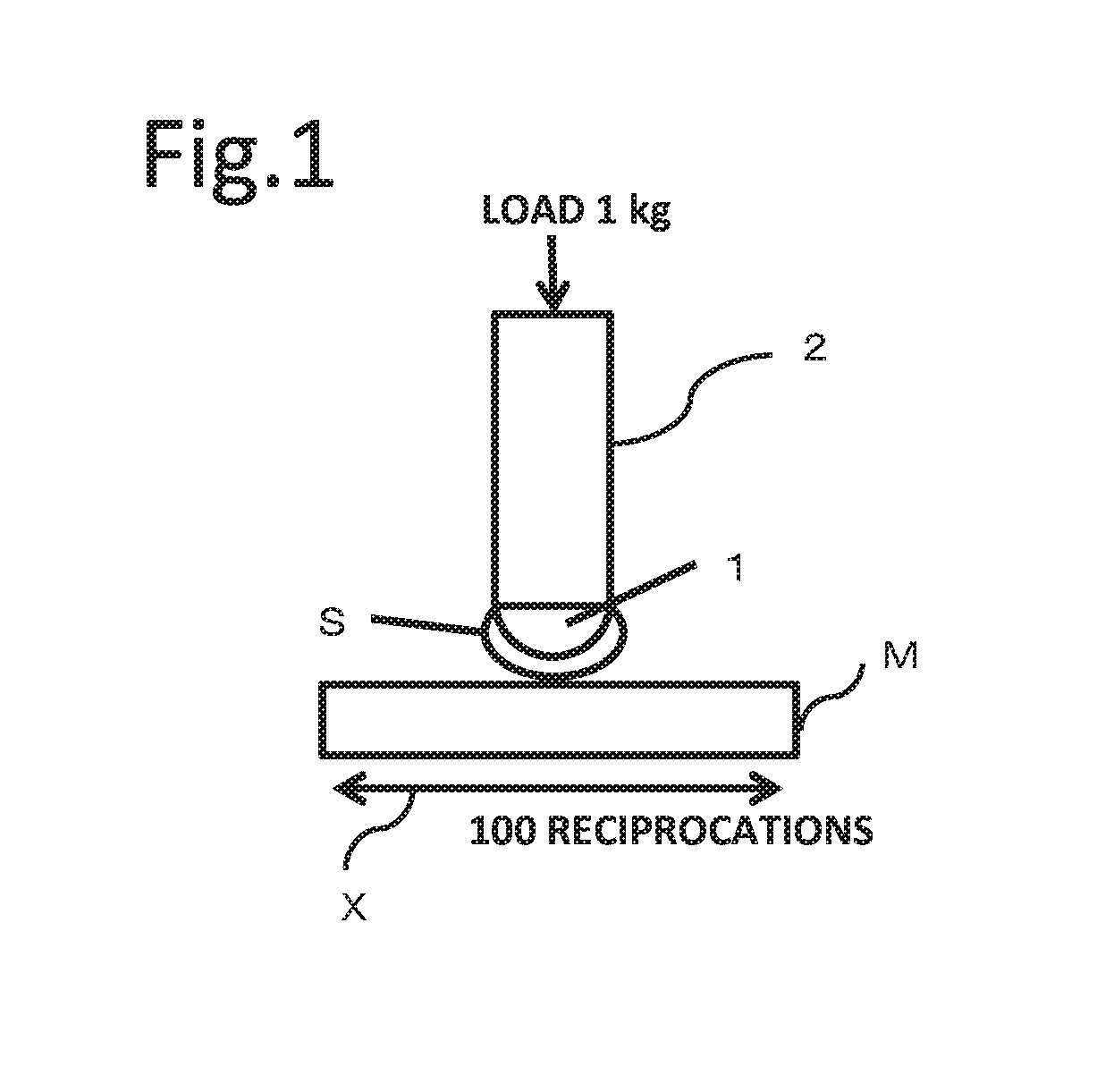

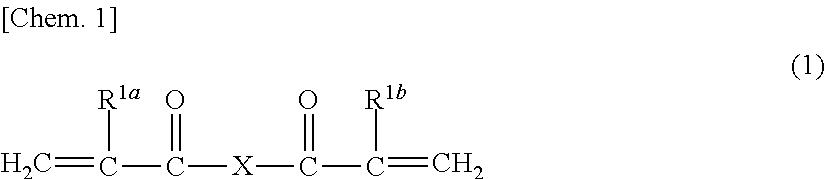

Graft copolymer, crosslinked particles, graft crosslinked particles, rubbery polymer, and thermoplastic resin composition using same

InactiveUS20180312693A1Excellent in weather resistance and color developabilityFlowability , impact resistance and abrasion resistance of be improveSolventMiniemulsion

Provided is a graft copolymer that has an excellent impact-resistance-imparting effect and that can provide a thermoplastic resin composition excellent in weather resistance and color developability. A graft copolymer (C) obtained by graft-polymerizing one or two or more monomers (B), which are selected from (meth)acrylic acid esters, aromatic vinyls, vinyl cyanides, N-substituted maleimides, and maleic acid, onto a composite rubber-like polymer (A), which is obtained by polymerizing a mixture (Ac) containing a polyorganosiloxane (Aa) and an acrylic acid ester (Ab) after forming a miniemulsion in water solvent. A thermoplastic resin composition that contains the graft copolymer (C) and a thermoplastic resin (D).

Owner:TECHNO UMG CO LTD

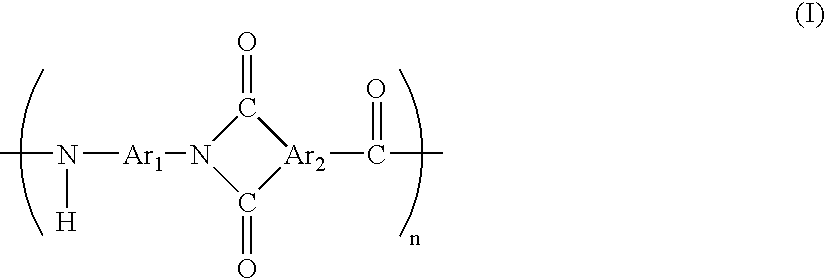

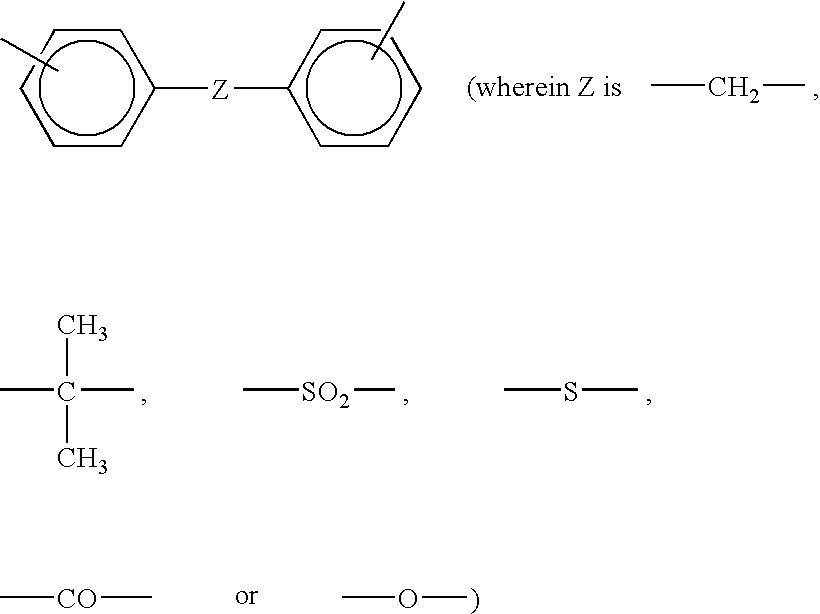

Resin composition

An object of the present invention is to improve the compatibility of the resin composition comprising the PAI resin and the PAS resin so as to provide a resin composition which is excellent in flowability when molten, strength, tenacity and heat resistance.A resin composition comprising:(1) 5 to 60 parts by weight of aromatic polyamide imide resin (A) having a weight average molecular weight (Mw) of 1,000 to 100,000 and having an amino group in an amount of 0.00002 to 0.002 mol / g in a molecule,(2) 95 to 40 parts by weight of polyarylene sulfide resin (B), and(3) 0.01 to 10 parts by weight of episulfide compound (C) based on 100 parts by weight of the total of (A) and (B).

Owner:MITSUBISHI GAS CHEM CO INC

Powdered Resin Composition For Slush Molding And Molded Product

ActiveUS20070287793A1Excellent in flowabilityImprove stabilityCoatingsPolymer science(Hydroxyethyl)methacrylate

A powdered resin composition for slush molding comprising a thermoplastic polyurethane resin powder (B) as the main component and a fine particle powder (A) of a vinyl type copolymer comprising a copolymer of a monomer (a01) having one vinyl group such as methyl methacrylate and a monomer (a02) having two or more vinyl groups such as ethylene glycol dimethacrylate and having a cross-linked structure; or a fine particle powder (E) of a vinyl type copolymer comprising the (a01) and a monomer (a03) having one or more vinyl groups and one or more functional groups other than a vinyl group such as hydroxyethyl (meth)acrylate and having a cross-linked structure. The fine particle powder is a powder flowability improver which does not cause die stains and the powdered resin composition for slush molding containing the fine powder do not cause staining of molds.

Owner:SANYO CHEM IND LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com