Method for preparing simply regulated and controlled different-crystal-form bismuth-titanium composite oxide photocatalysts and application of method

A technology of titanium composite oxide and photocatalyst, which is applied in the fields of physical/chemical process catalysts, chemical instruments and methods, catalyst activation/preparation, etc. It can solve the problems of difficult to effectively use sunlight, large band gap, and low quantum yield, etc. problem, achieve good application prospects, simple equipment, and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

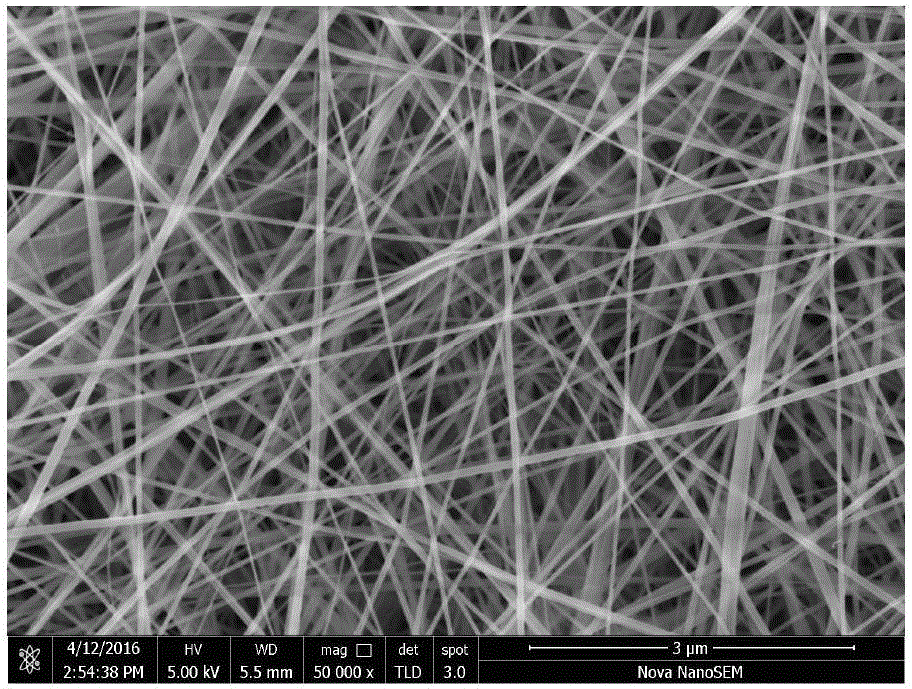

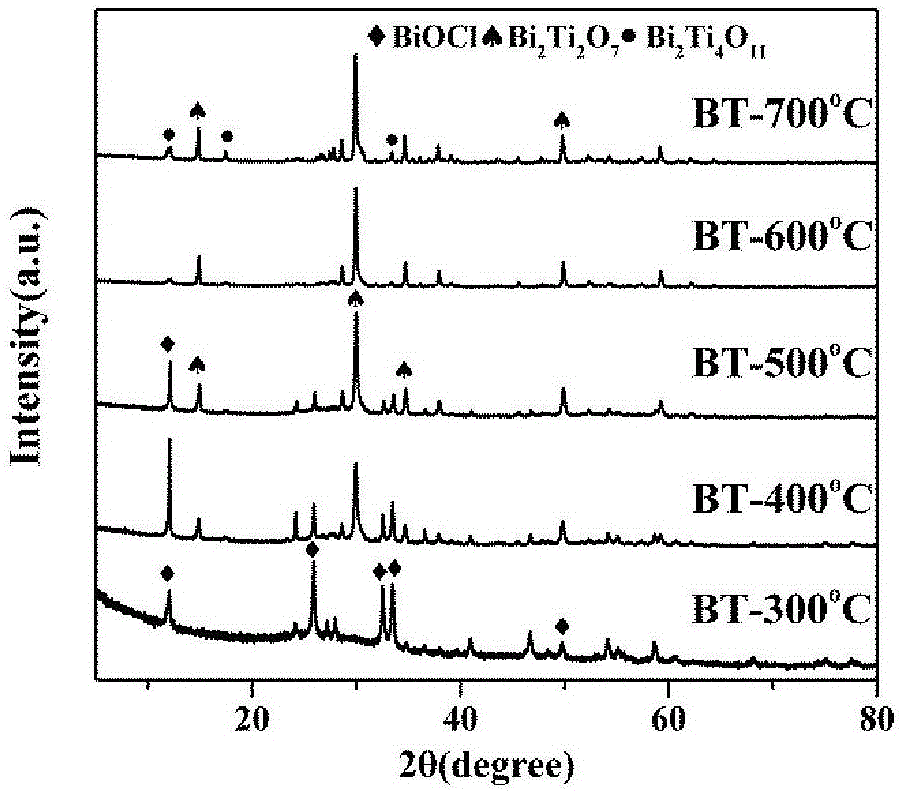

[0022] Embodiment 1: bismuth chloride (BiCl 3 ) in 20 ml N,N dimethylformamide and 5 ml acetic acid; add 2 g polyvinylpyrrolidone (PVP), stir until the solution is clear; drop n-butyl titanate (Ti(OiPr) 4 ) solution, stirred for 2 h to form a uniform yellow and transparent spinning precursor solution. Take the precursor solution into the syringe, put it into the electrospinning equipment, and perform spinning. The obtained fibers are calcined at a temperature of 300 o C-700 oC , and finally cooled to room temperature in air to obtain bismuth titanate composite oxides of different crystal forms.

[0023] The specific steps are:

[0024] 1. Dissolve 0.315 g of bismuth chloride in 20 ml of N,N dimethylformamide and 5 ml of acetic acid, and stir until clear.

[0025] 2. While stirring, add 2 g of polyvinylpyrrolidone to the above solution, and stir until clear.

[0026] 3. Add 0.34 ml of n-butyl titanate solution dropwise to the above solution, and stir for 2 hours to form a...

Embodiment 2

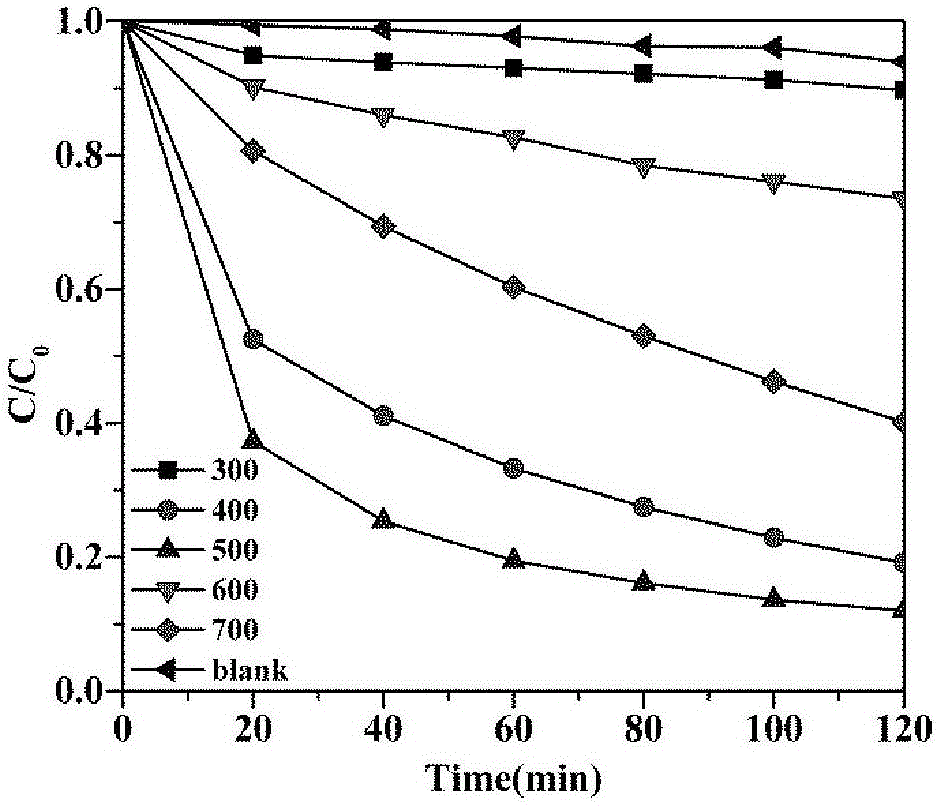

[0030] Under simulated sunlight irradiation, the photocatalyst prepared by the preparation method in Example 1 was used to photocatalyze the 50 mg / L tetracycline hydrochloride solution respectively.

[0031] 1. Weigh 100 mg of the photocatalyst obtained by the preparation method in Example 1 and place it in a photocatalytic reactor.

[0032] 2. Add 100 ml tetracycline hydrochloride solution (50 mg / L).

[0033] 3. Before light exposure, the mixture was magnetically stirred for 1 h in the dark in the dark to allow the system to reach adsorption / desorption equilibrium, and samples were taken and centrifuged.

[0034] 4. Then irradiate with simulated sunlight (xenon lamp) as the excitation light source of the photocatalyst, sample every 20 min and centrifuge.

[0035] The obtained supernatant is measured absorbance (wherein the maximum absorption peak wavelength of the tetracycline hydrochloride solution is 364 nm) with a UV spectrophotometer, and the degradation situation compar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com