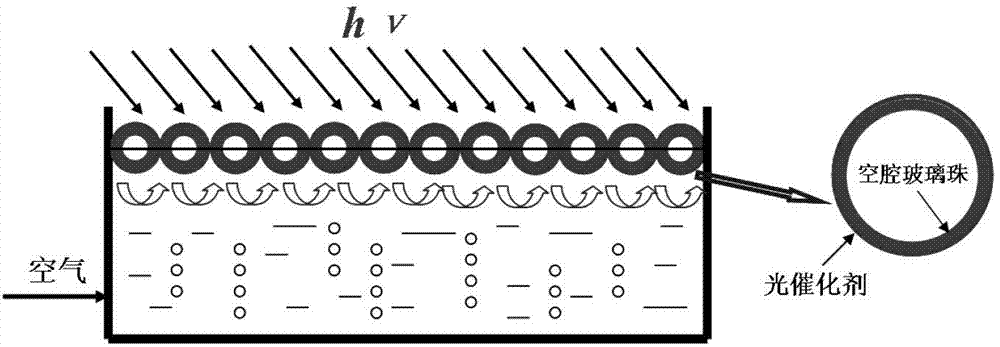

Process for coating Bi2O3/TiO2 photocatalysis film on surface of hollow lightweight glass sphere

A technology of photocatalytic thin film and glass spheres, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve low mass transfer efficiency and low utilization rate of irradiated light and other problems, to achieve the effect of high mass transfer efficiency, high utilization rate and simple coating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

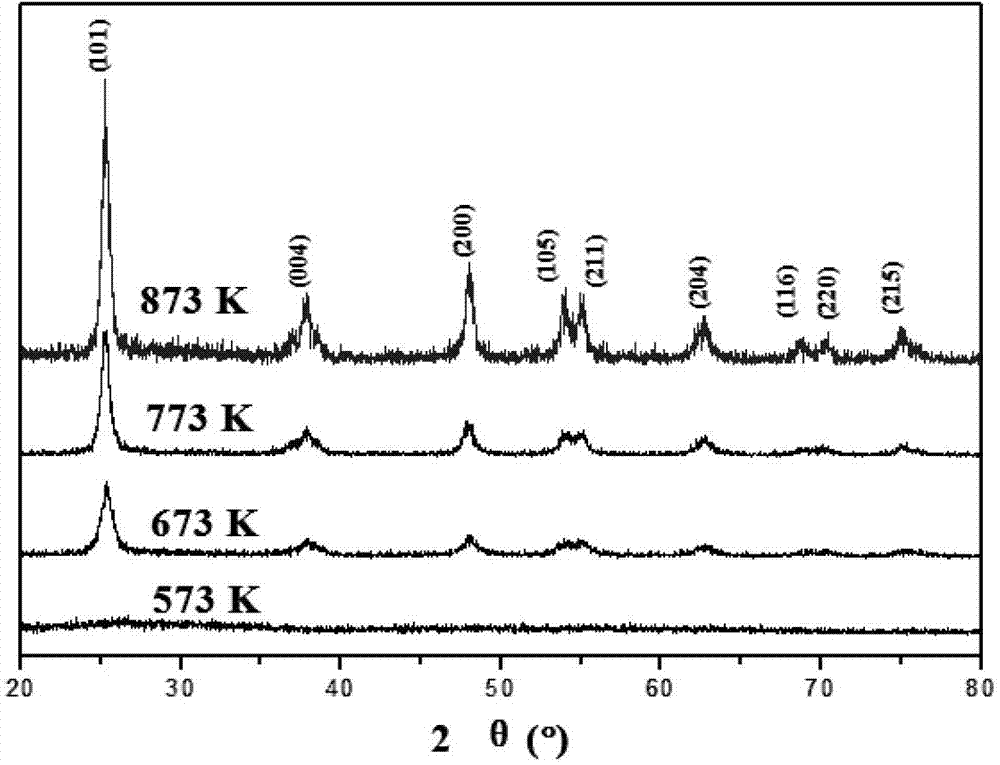

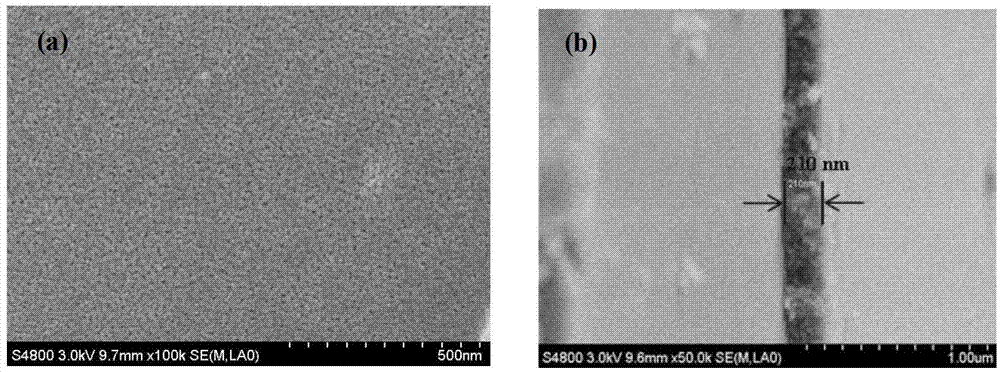

[0034] After surface treatment of glass spheres, make solution A with 0.25g pentanediol, 0.7g water, 1.0g polyethylene glycol and 100mL ethanol and stir for 30min. into B solution. Add solution A to solution B, mix well, add 2mL concentrated nitric acid to adjust the pH to 3-4, then add bismuth nitrate pentahydrate to the solution so that the Bi / Ti molar ratio is 1.0%, and the precursor solution can be obtained. Put the glass ball in the precursor solution and rotate it to make the surface fully contact with the precursor solution. Take out the ball and blow it dry quickly with a hair dryer to obtain a uniform film, then put it in an oven to dry at 100°C for 1 hour. Repeat the above operation 2 times, that is, after the number of coating times is 3 times, place the glass ball in a muffle furnace at 500 ° C for 4 hours to obtain the surface coated with Bi 2 o 3 / TiO 2Glass spheres with photocatalytic films. Place the coated glass balls in a suspension reactor with a diamete...

Embodiment 2

[0041] No bismuth nitrate was added during the preparation, that is, the Bi / Ti molar ratio was 0, and the rest of the content was the same as that described in Example 1. Figure 4 The UV-vis DRS spectrum in shows that TiO in the present embodiment 2 The film has no obvious absorption in the visible region.

Embodiment 3

[0043] During the preparation process, the Bi / Ti molar ratio was controlled to be 0.5%, and the remaining content was the same as that described in Example 1. Figure 4 The UV-vis DRS spectrum in shows that due to Bi 2 o 3 The modification effect makes this embodiment more pure TiO in the visible light region 2 The thin film has a stronger light absorption intensity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com