Method adopting microbe microbial enhanced oil recovery (MEOR) technology for water-based extraction of bitumen in oil sands

A technology for microbial oil flooding and asphalt oil is applied in the field of using microbial oil flooding technology (MEOR) water-based extraction of asphalt oil from oil sands and water-based oil sands to extract asphalt oil, which can solve problems such as inapplicability and improve the recovery rate. , high recovery rate, the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

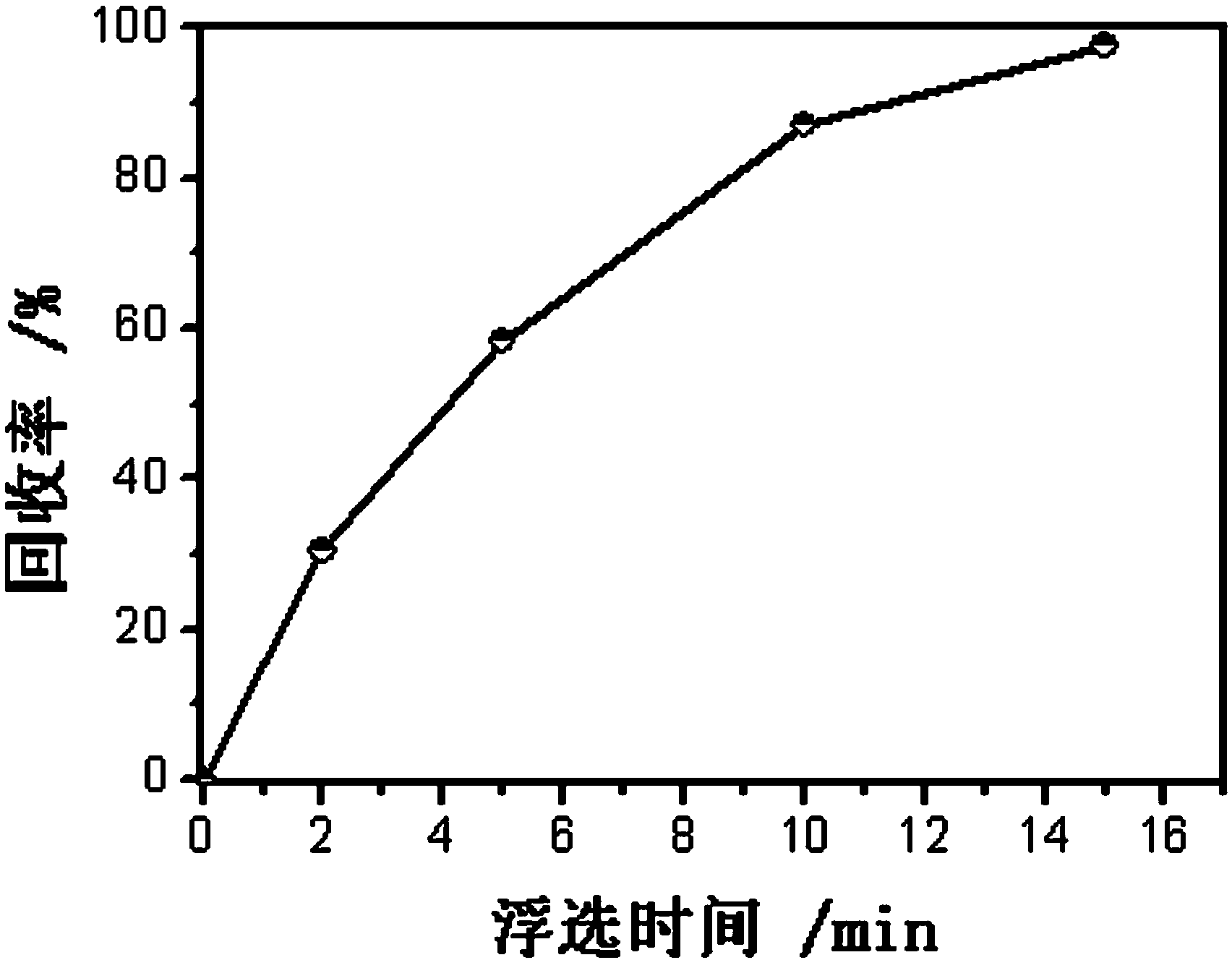

Embodiment 1

[0017] Selection of oil sands: weathered oil sands, taken from Zhalaite Banner, Inner Mongolia, its basic composition and content are as follows: solid components (sand, clay) 89 wt%, asphalt 10.4 wt%, water 0.6 wt%. Because the surface of the solid components (sand, clay) in the oil sand is strongly hydrophobic, this type of oil sand produces little or no bitumen foam during normal flotation, so water-based extraction of bitumen oil cannot be performed.

[0018] Process for water-based extraction of asphalt oil from oil sands:

[0019] (1) Accurately weigh 300 g of oil sand, transfer it to a 500ml Erlenmeyer flask, and then add 300ml of culture system, which is composed of inorganic medium and aqueous solution of trace elements, and per liter of culture system, inorganic medium: Na 2 HPO 4 12H 2 O: 3g, KH 2 PO 4 : 11 g, NaNO 3 : 5 g, NaCl: 1 g, CaCl 2 : 0.1 g, MgSO 4 : 0.25 g; trace elements: FeCl 3 ·6H 2 O: 0.08 g, ZnSO 4 ·7H 2 O: 0.75 g, CuSO 4 ·5H 2 O: 0.075...

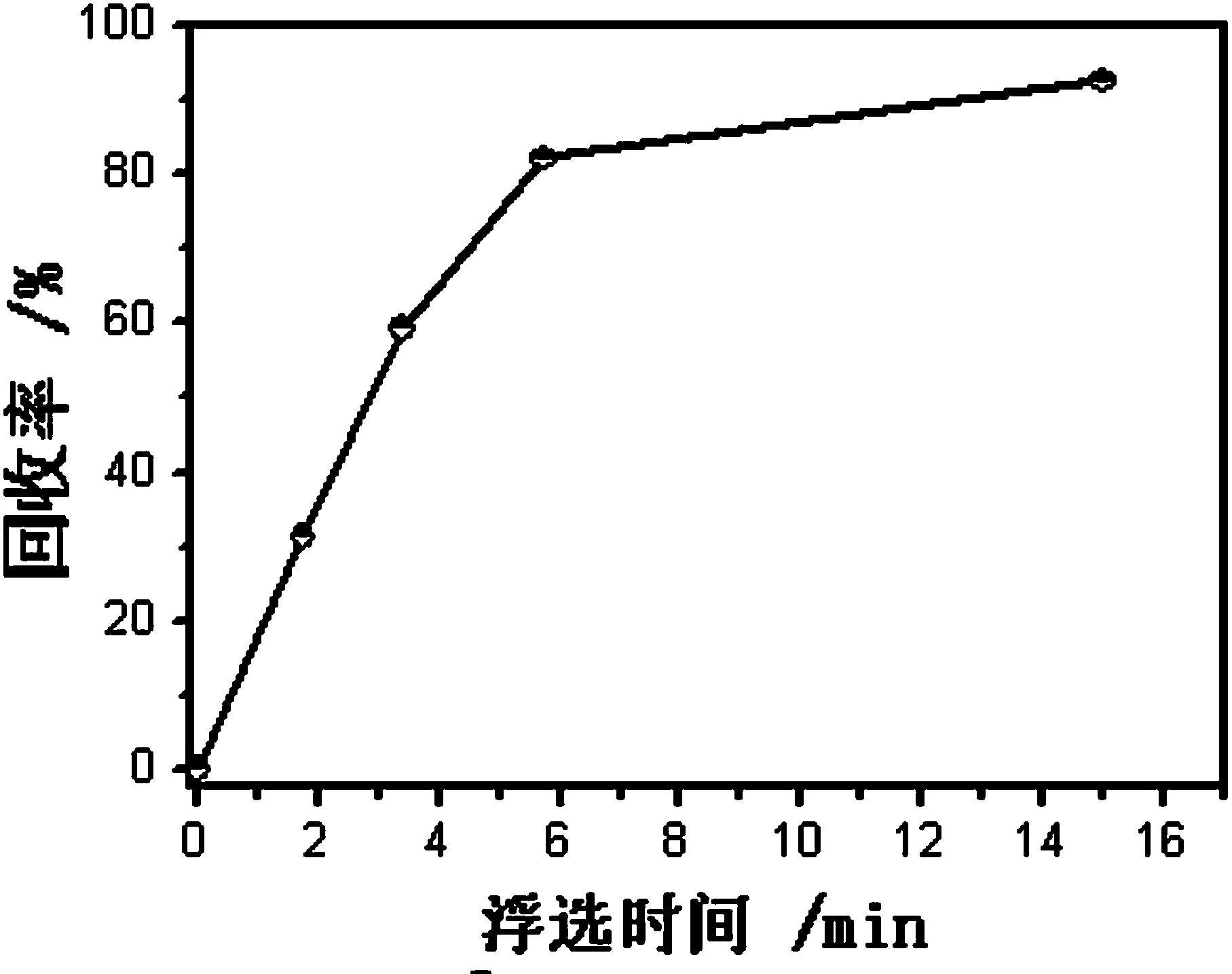

Embodiment 2

[0023] Selection of oil sand: Oil sand ore with high electrolyte and high clay content is taken from Heiyoushan, Xinjiang. Its basic composition and solid components (sand, clay) are 92.3 wt%, asphalt 5.3 wt%, and water 2.4 wt%. Because the surface of the solid components (sand, clay) in the oil sand is strongly hydrophobic, this type of oil sand produces little or no bitumen foam during normal flotation, so water-based extraction of bitumen oil cannot be performed.

[0024] Process for water-based extraction of asphalt oil from oil sands:

[0025] (1) Accurately weigh 300 g of oil sand, transfer it to a 500ml Erlenmeyer flask, and then add 300ml of culture system, which is composed of inorganic medium and aqueous solution of trace elements, and per liter of culture system, inorganic medium: Na 2 HPO 4 12H 2 O 4 g, KH 2 ·PO 4 : 12 g, NaNO 3 : 6 g, NaCl: 1.5 g, CaCl 2 : 0.15 g, MgSO4 : 0.3 g; trace elements: FeCl 3 ·6H 2 O: 0.1 g, ZnSO 4 ·7H 2 O: 0.8 g, CuSO 4 ·5H ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com