A bismuth phosphate thin film with photoresponse properties and its preparation method and application

A technology of bismuth phosphate and photoresponse, which is applied in the direction of phosphate, phosphorus oxyacid, chemical instruments and methods, etc., can solve the problem of small powder particle size, achieve good uniformity, overcome difficulties in recycling, Equipment requires simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

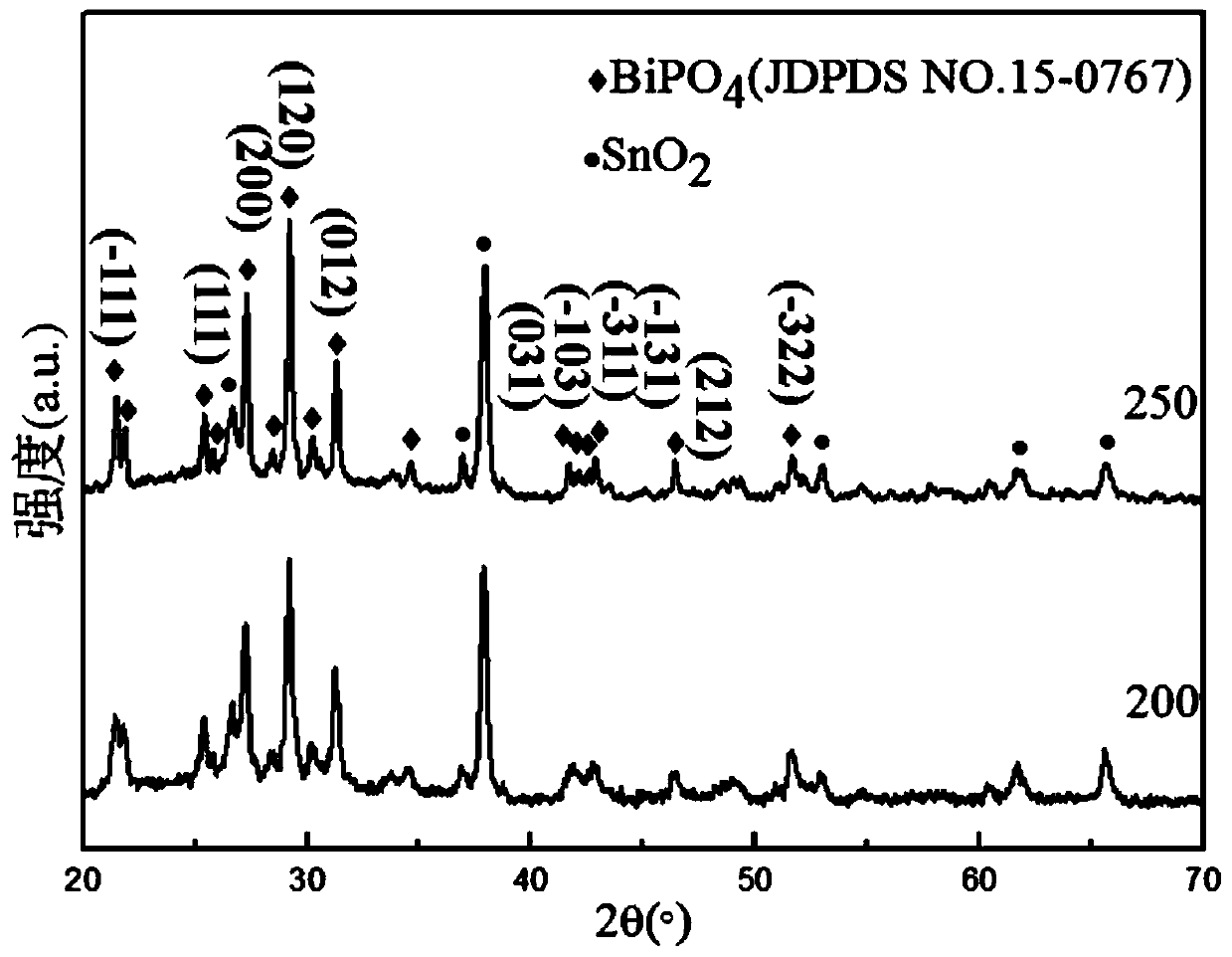

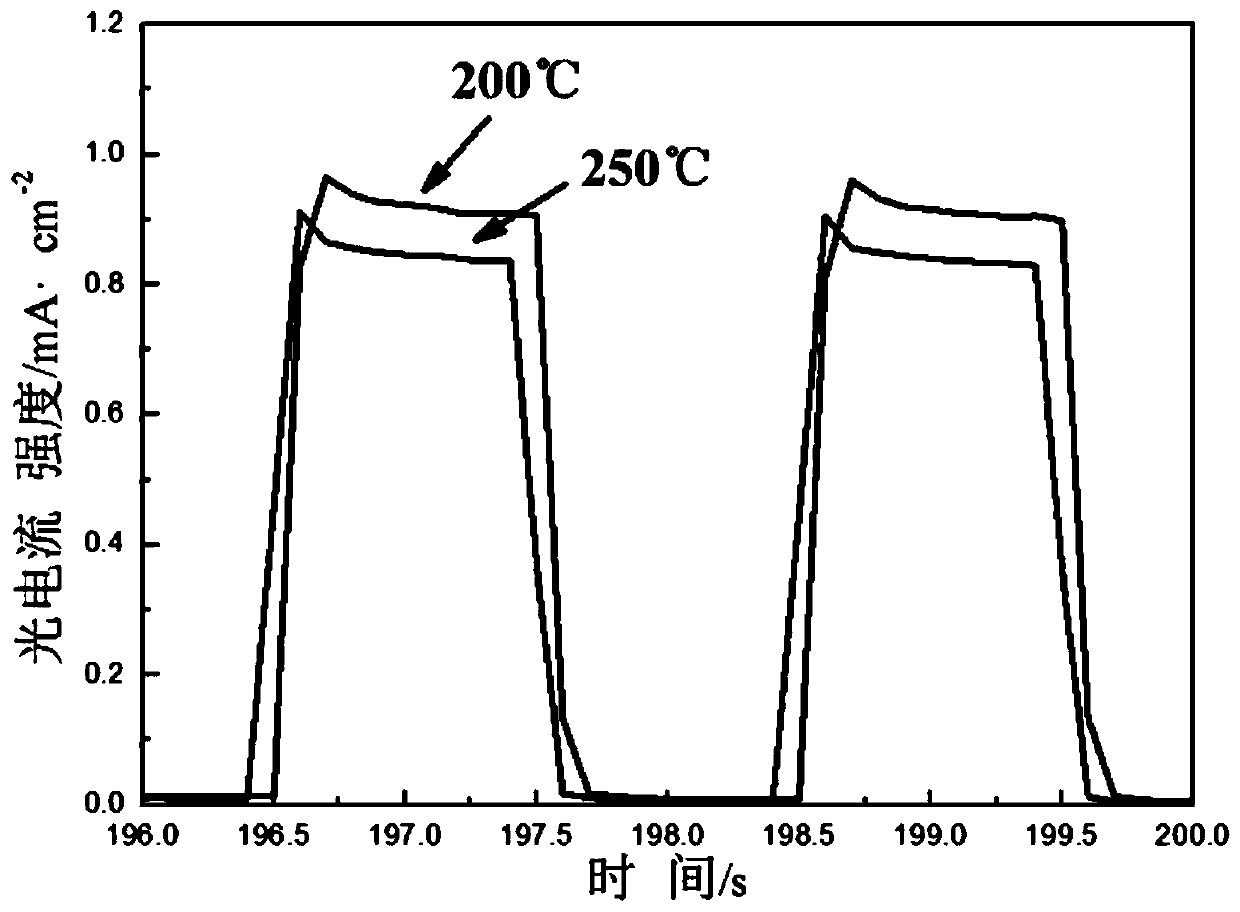

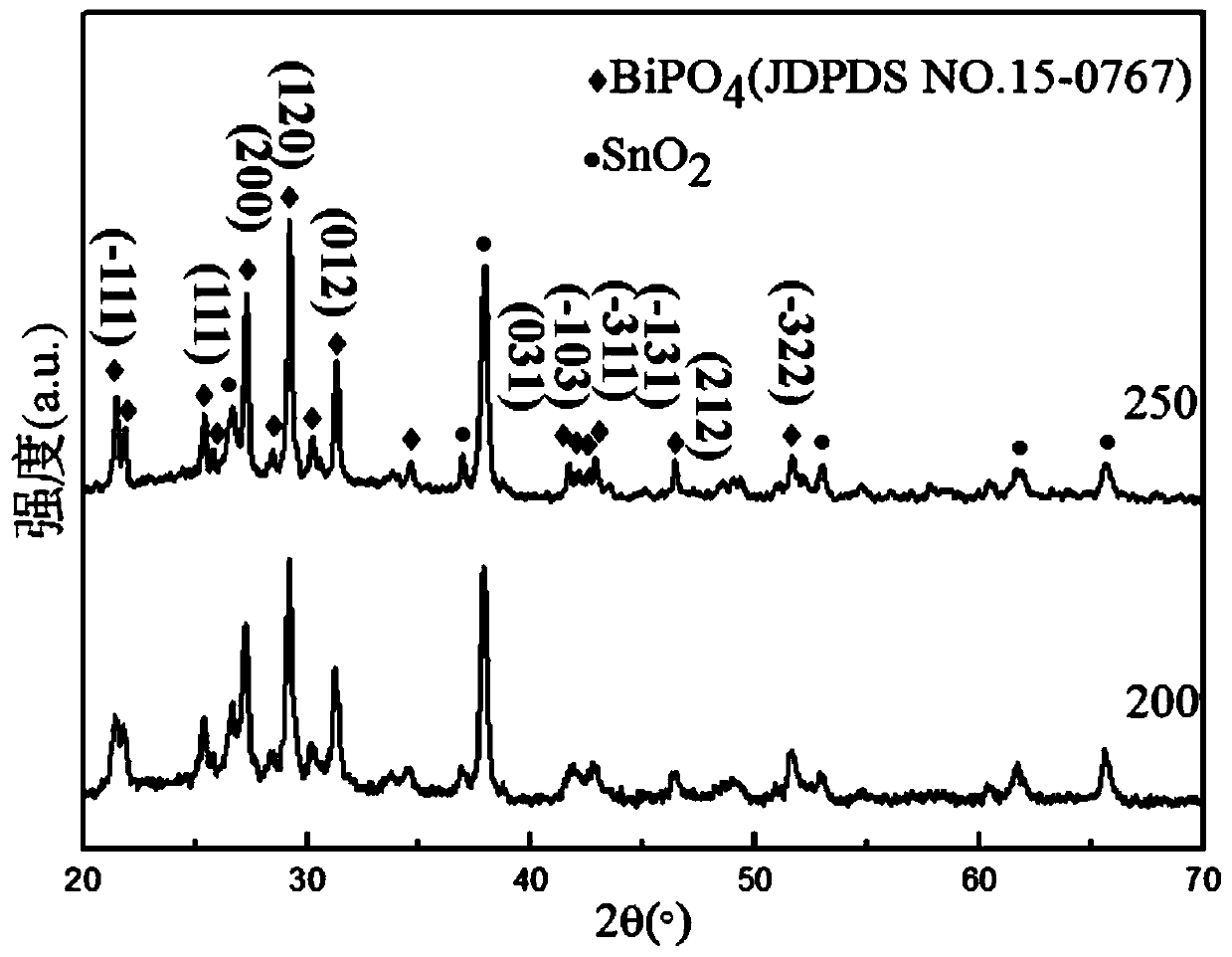

Embodiment 1

[0028] Step 1: The raw material Bi(NO 3 ) 3 Dissolve in ethylene glycol, make a 0.2mol / L solution, record it as solution A, add Na 3 PO 4 Dissolve it in ethylene glycol and prepare it as a 0.2mol / L solution, denoted as solution B; according to the molar ratio of Bi to P as 1:1, slowly drop solution B into solution A and stir vigorously. White precipitate, dropwise add concentrated nitric acid with a concentration of 1mol / L to it until the precipitate is eliminated and the configuration becomes colorless and clear BiPO 4 Solution, continue to stir for 1h to make it evenly mixed to obtain BiPO 4 Precursor solution; BiPO 4 The precursor solution is allowed to stand for 12 hours to obtain colorless and clear BiPO 4 Sol (it remains colorless and clear after aging for 12 hours);

[0029] Step 2: Clean the cut FTO glass substrate and irradiate it under ultraviolet light to make the surface of the FTO glass substrate achieve atomic cleanliness;

[0030] Step 3: Use a spinning rate of 4000r / ...

Embodiment 2

[0033] Step 1: The raw material Bi(NO 3 ) 3 Dissolve in ethylene glycol, make a 0.2mol / L solution, record it as solution A, add Na 3 PO 4 Dissolve it in ethylene glycol and prepare it as a 0.2mol / L solution, denoted as solution B; according to the molar ratio of Bi to P as 1:1, slowly drop solution B into solution A and stir vigorously. White precipitate, dropwise add concentrated nitric acid with a concentration of 1mol / L to it until the precipitate is eliminated and the configuration becomes colorless and clear BiPO 4 Solution, continue to stir for 1h to make it evenly mixed to obtain BiPO 4 Precursor solution; BiPO 4 The precursor solution is allowed to stand for 12 hours to obtain colorless and clear BiPO 4 Sol (it remains colorless and clear after aging for 12 hours);

[0034] Step 2: Clean the cut FTO glass substrate and irradiate it under ultraviolet light to make the surface of the FTO glass substrate achieve atomic cleanliness;

[0035] Step 3: Use a spinning rate of 4000r / ...

Embodiment 3

[0038] Step 1: The raw material Bi(NO 3 ) 3 Dissolve in ethylene glycol, make a 0.19mol / L solution, record it as solution A, add Na 3 PO 4 Dissolve in ethylene glycol and prepare it as a 0.19mol / L solution, denoted as solution B; according to the molar ratio of Bi to P as 1:1, slowly drop solution B into solution A and stir vigorously. White precipitate, dropwise add concentrated nitric acid with a concentration of 1mol / L to it until the precipitate is eliminated and the configuration becomes colorless and clear BiPO 4 Solution, continue to stir for 1.1h to make it evenly mixed to obtain BiPO 4 Precursor solution; BiPO 4 The precursor solution is allowed to stand for 12 hours to obtain colorless and clear BiPO 4 Sol (it remains colorless and clear after aging for 12 hours);

[0039] Step 2: Clean the cut FTO glass substrate and irradiate it under ultraviolet light to make the surface of the FTO glass substrate achieve atomic cleanliness;

[0040] Step 3: Use a spin coating rate of 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| photoelectricity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com