Magnetic mesoporous silica core-shell structure affinity microsphere based on metal ion modification as well as preparation method and application thereof

A technology of metal ion modification and mesoporous silica, which is applied in the fields of peptide preparation, microsphere preparation, chemical instruments and methods, etc., can solve the problems of complicated process, large loss, limited desalination capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

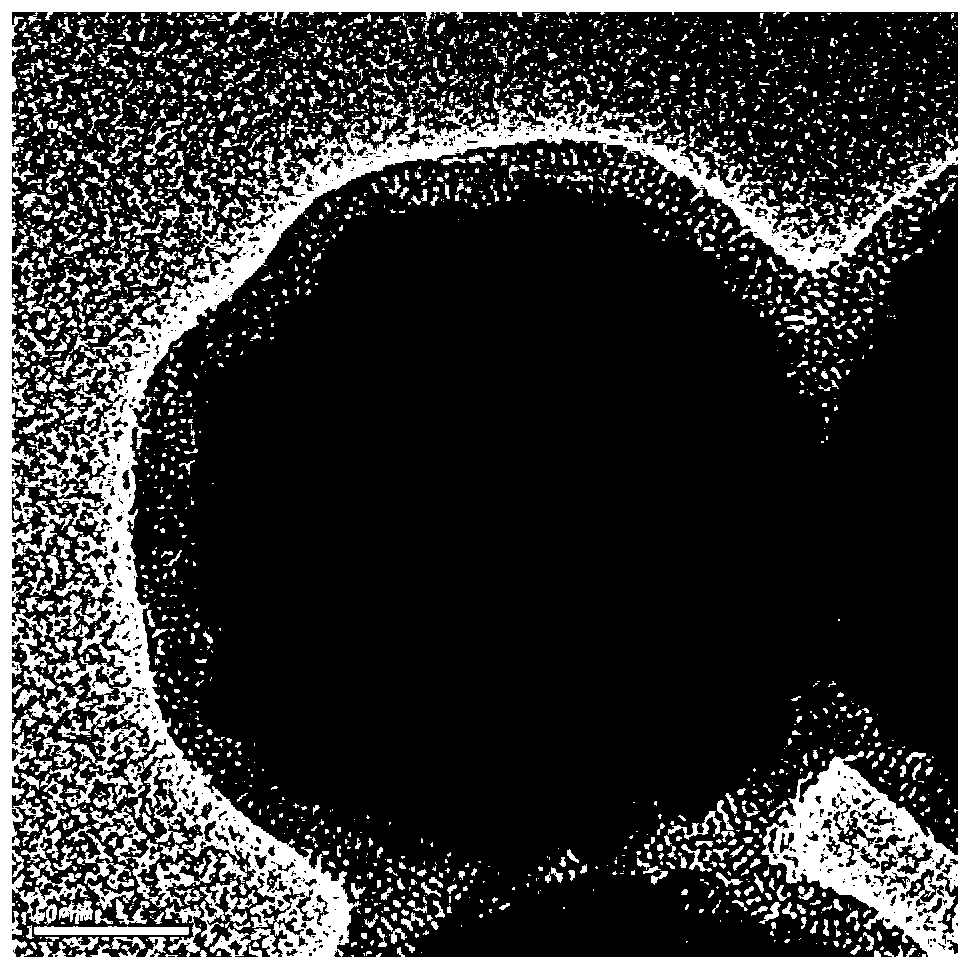

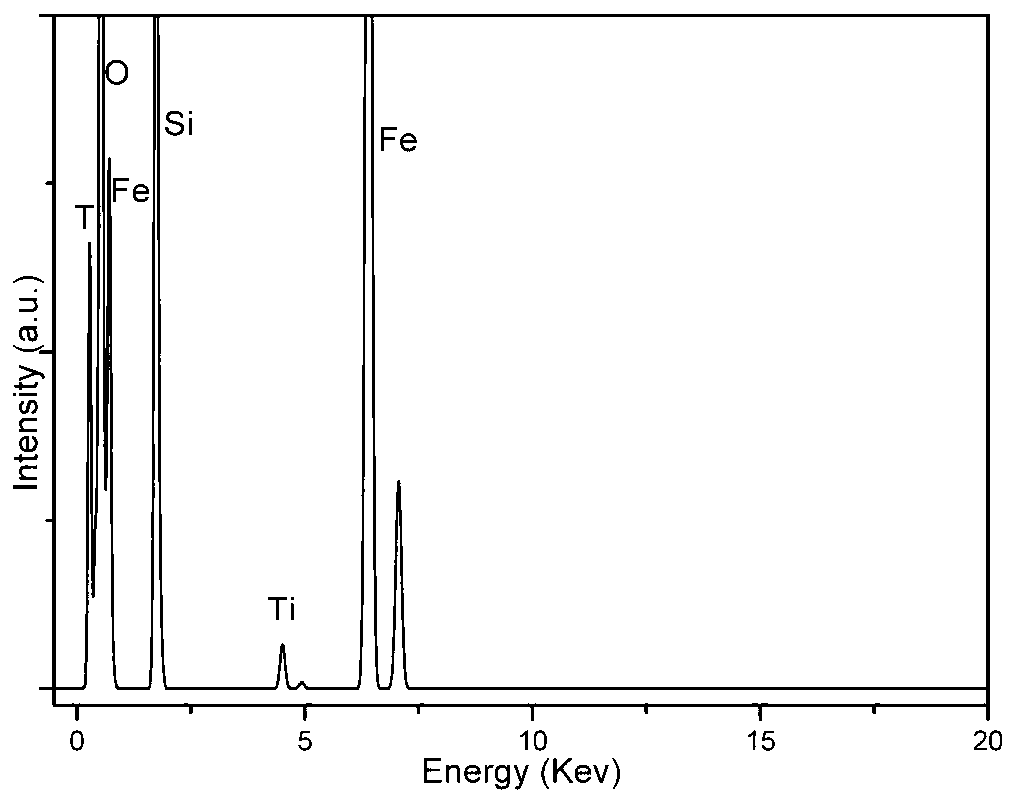

[0030] Example 1 Preparation of magnetic mesoporous silica core-shell affinity microspheres based on metal ion modification

[0031] 1. Fe 3 o 4 Magnetic particle preparation

[0032] Prepared by solvothermal method, the specific steps are as follows: Weigh 5.13g of ferric chloride hexahydrate (FeCl 3 ·6H 2 O) Uniformly disperse into 80mL ethylene glycol to make a solution, and add 1.25g of surfactant PEG and 5.00g of anhydrous sodium acetate in turn under magnetic stirring, and stir to form a uniform system. The mixture was transferred to a 120mL autoclave with a polytetrafluoroethylene liner and sealed, and finally the autoclave was placed in a constant temperature box and heated to 200°C for 6 hours of constant temperature reaction. After the reaction system was naturally cooled, the resulting suspension was magnetically separated to obtain a black powdery substance. After washing with deionized water and ethanol several times alternately, and drying at 60°C for 8 hou...

Embodiment 2

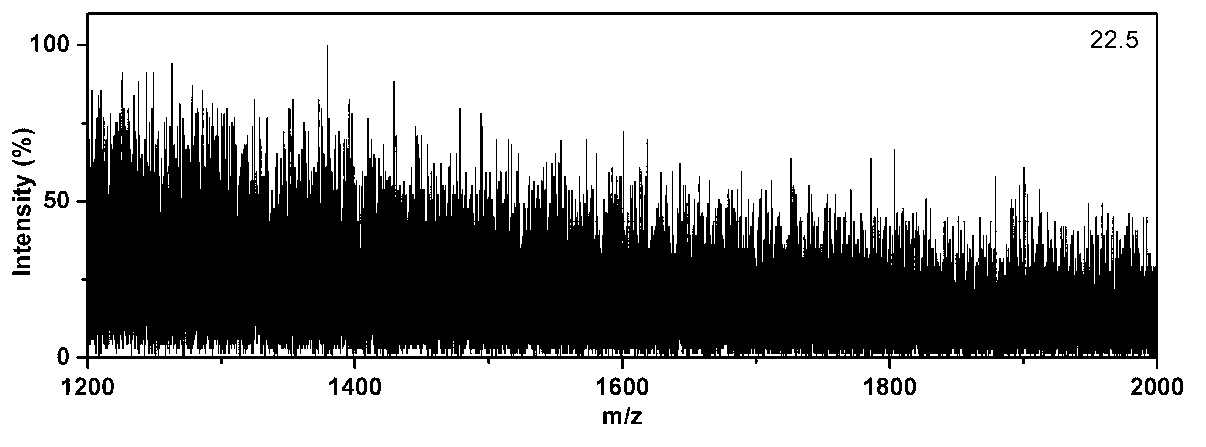

[0036] Example 2 Enrichment of low-abundance standard peptides using magnetic mesoporous SiO2 core-shell structure affinity microspheres based on metal ion modification

[0037] 1. Preparation of sample solution: Prepare 50mL of 5nM synthetic polypeptide MW=1533.6 solution.

[0038] 2. Enrichment and mass spectrometry analysis of synthetic peptides: Take 500 μL of the above peptide solution and add 100 μg of magnetic mesoporous SiO 2 Affinity microspheres, disperse evenly, shake for 10min. Remove the supernatant after magnetic separation, 5 μL of 80% acrylonitrile (CAN), 0.5% trifluoroacetic acid (TFA) (v / v), shake for 5 minutes, and magnetically separate. Collect the supernatant, take 0.7uL sample, mix with 0.7 matrix, and spot on the MALDI-TOF target plate to form co-crystals for mass spectrometry analysis.

[0039] 3. Analysis results: Figure 3A It is the result of direct mass spectrometry detection before 5nM standard peptide enrichment. Because the peptide concentr...

Embodiment 3

[0040] Example 3 Utilizes Magnetic Mesoporous SiO Based on Metal Ion Modification 2 Enrichment of low-abundance peptides in complex samples using core-shell affinity microspheres

[0041] 1. Preparation of sample solution: Weigh 1 mg of bovine serum albumin BSA and dissolve it in 1 mL of 50 mM ammonium bicarbonate solution (pH 8.0), add trypsin to enzymatically digest it for 16 hours according to the mass ratio of trypsin to 50:1 , the enzymolysis temperature was controlled at 37°C, and 1% formic acid was finally added to terminate the reaction. Take 50uL of the polypeptide solution, dilute it to 5nM with an aqueous solution containing 4M urea, and set aside.

[0042] 2. Enrichment and mass spectrometry analysis of peptides: take 500uL of the above peptide solution, add 100ug of magnetic mesoporous SiO 2 Affinity microspheres, disperse evenly, shake for 10min. After magnetic separation, remove the supernatant, wash the affinity microspheres with 500uL deionized water, mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com