Titanium dioxide prepolymer and preparation method thereof as well as photocatalyst ultraviolet light curing paint with same

A technology of titanium dioxide and prepolymer, which is applied in the field of photocatalyst UV curing paint, can solve the problems of poor scratch resistance, poor storage stability of titanium dioxide, and poor dirt resistance of UV curing paint, and achieve uniform dispersion and dirt resistance good staining ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] One aspect of the present invention provides a kind of preparation method of titanium dioxide prepolymer, comprises the following steps:

[0024] (1) Carboxylation reaction of n-butyl titanate in ethanol to obtain carboxylated titanium dioxide;

[0025] (2) After dissolving polyurethane acrylic resin in an organic solvent, carry out a hybrid reaction with carboxylated titanium dioxide to obtain a titanium dioxide prepolymer.

[0026] The present invention aims at the problems of poor storage stability and easy migration of titanium dioxide in the existing preparation of titanium dioxide photocatalyst coatings. Titanium dioxide is prepared into titanium dioxide prepolymer, and titanium dioxide is grafted into polyurethane acrylic resin through condensation and hybridization reactions. Since polyurethane acrylic resin can be combined with The other components in the UV curable paint are well mixed. The titanium dioxide and polyurethane acrylic resin are prepared into a pr...

Embodiment

[0038] When the paint surface provided by the present invention is cured, the required curing energy is 1200-2000mJ / cm 2 , specifically provided by a UV lamp.

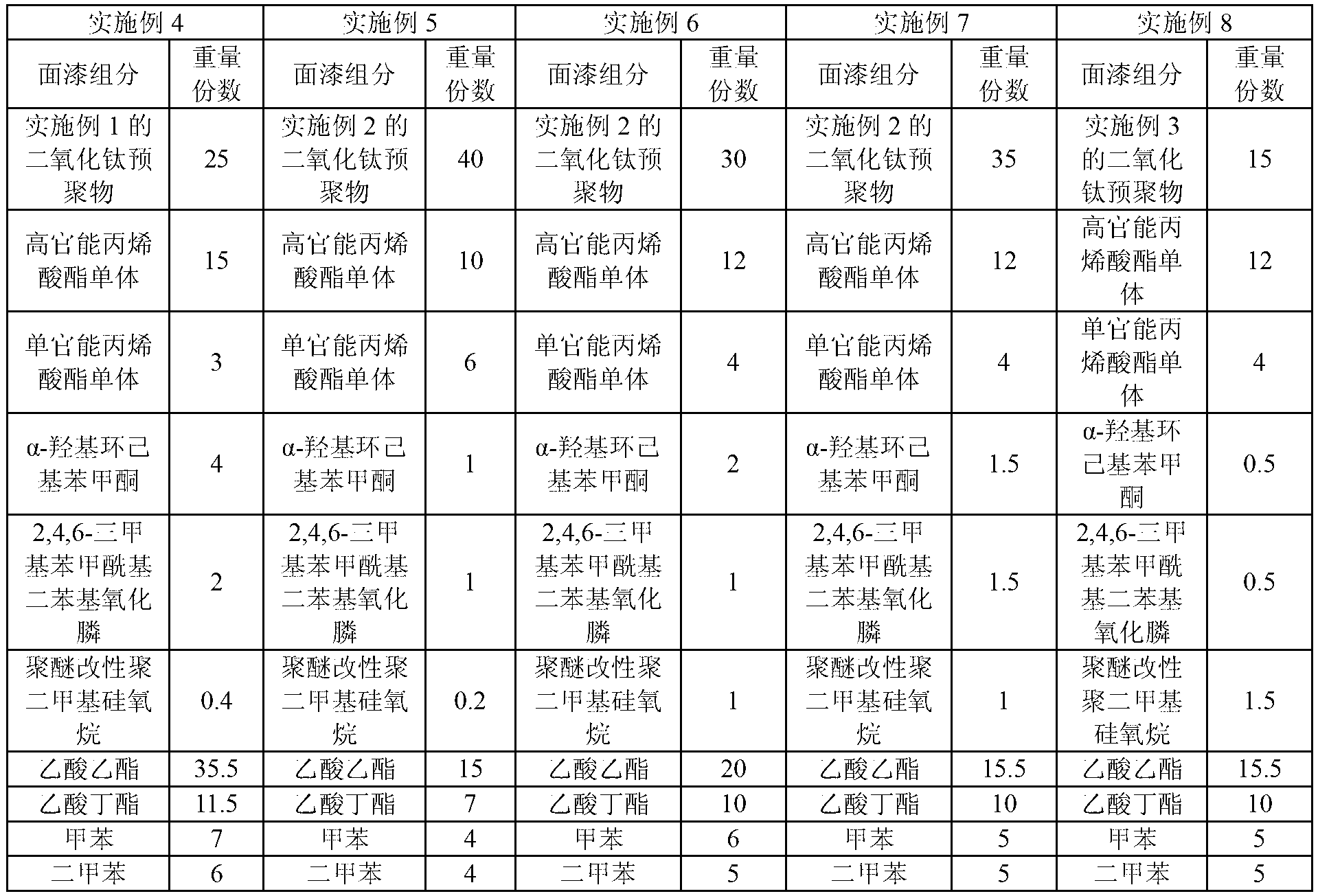

[0039] The monofunctional acrylate monomer used in Examples 4-8 is isobornyl acrylate, and the high-functional acrylate monomer is dipentaerythritol hexaacrylate. The model of the monofunctional acrylate monomer is EM70; the model of the high-functional acrylate monomer is EM266, both of which were purchased from Taiwan Changxing Chemical.

[0040] The auxiliary agent is polyether-modified polydimethylsiloxane, purchased from BYK Chemical Company in Germany, with the brand name BYK-333.

[0041] High-functional aliphatic polyurethane acrylic resin was purchased from EBECYRL 1290 of Cytec Corporation of the United States and 6195-100 of Taiwan Changxing Chemical.

[0042]The model of α-hydroxycyclohexyl benzophenone in the photoinitiator is Irgacure 184 purchased from Ciba Company in Switzerland, and the model of 2,4,...

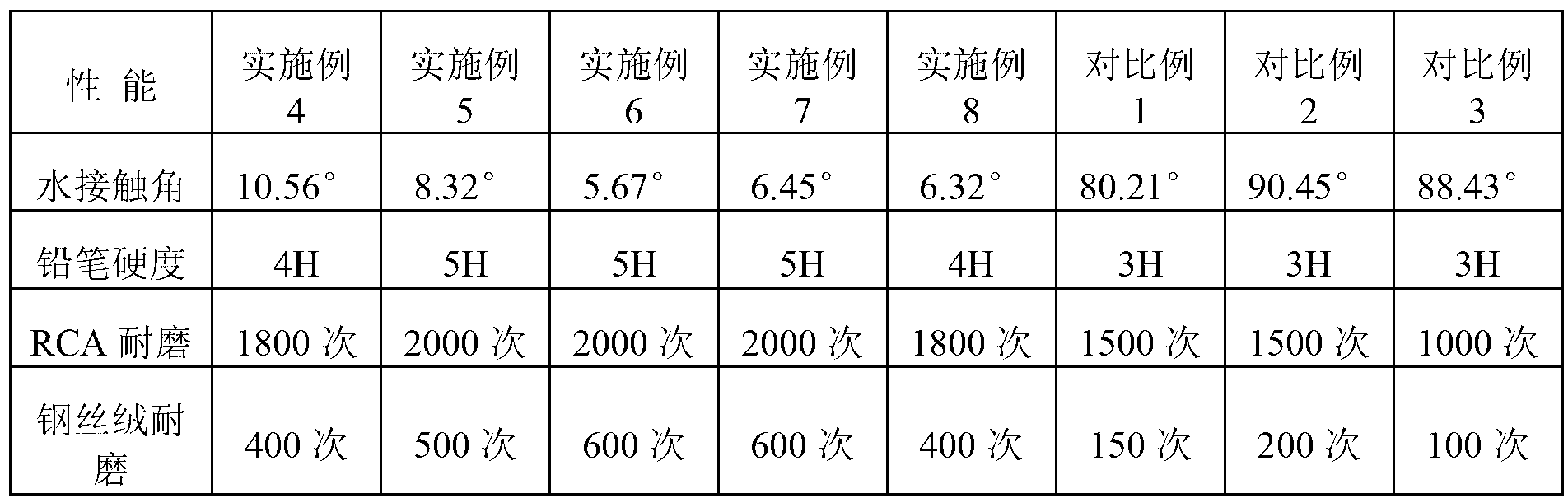

Embodiment 4~8

[0044] Preparation method of photocatalyst ultraviolet light curing paint in embodiment 4~8:

[0045] a) preheating the acrylic group-containing resin in the UV-curable paint of Examples 4-8 at 40-50°C for 1-2 hours, and dissolving it with 2 / 3 volume of diluent to obtain the first solution;

[0046] b) Add the acrylic monomers and photoinitiators in the UV-curable paints of Examples 4-8 to the first solution, and stir at 500-600 r / min at 40-50°C for 20-30 minutes to obtain the second solution ;

[0047] c) Add the additives in the UV-curable paints of Examples 4-8 and the remaining 1 / 3 volume of diluent to the second solution, stir at 900-1200r / min for 10-20min, and use a 400-mesh filter cloth Filter to obtain a UV-curable primer.

[0048] Coating and curing method in Examples 4 to 8: Spray the photocatalyst UV curable paint prepared in Examples 4 to 8 on the substrate, the coating film thickness is 20 μm, infrared leveling: 65°C / 8min, curing energy: 1500mJ / cm 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com