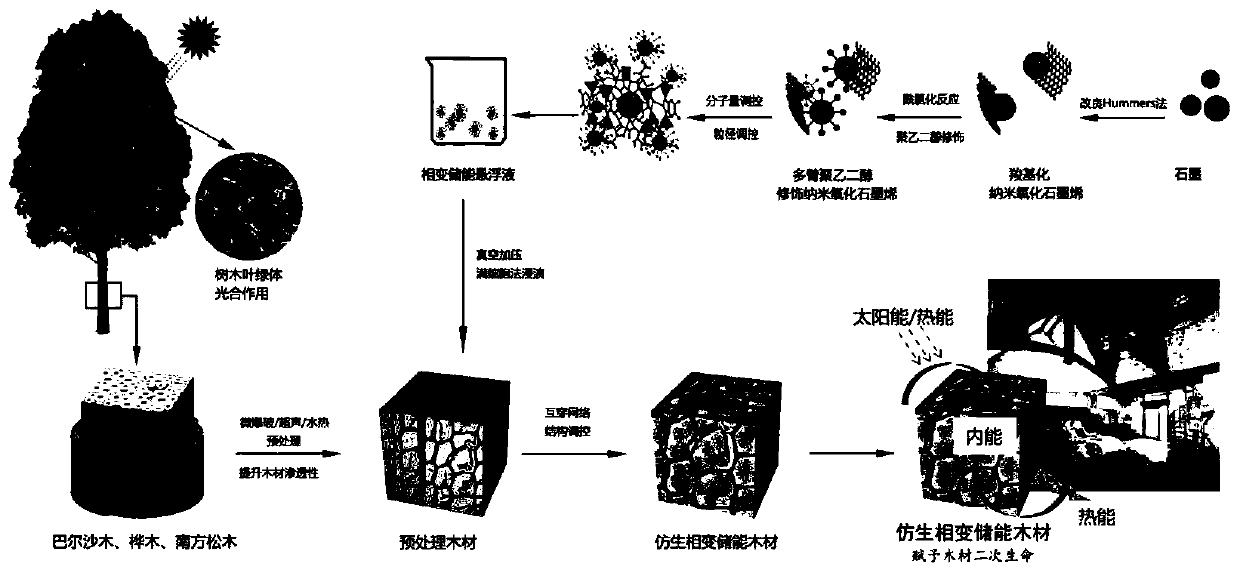

Method for preparing thermal conduction enhanced phase change energy storage wood based on photothermal response

A technology of phase change energy storage and heat conduction enhancement, which is applied in the direction of heat exchange materials, wood treatment, wood heating, etc., to achieve the effect of improving energy utilization and energy storage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Measure 250 mg of graphene oxide powder and ultrasonically disperse in 50 mL of deionized water to prepare a 5 mg / ml graphene oxide dispersion. Then add 1g of sodium hydroxide and 1g of chloroacetic acid, ultrasonicate at 400W for 3h, then centrifuge at 8000r / min for 10min, wash with deionized water 2-3 times, use dialysis bags to dialyze until neutral to obtain well-dispersed carboxylated oxidation Graphene aqueous dispersion.

[0025] (2) Use polyethylene glycol-800 as the phase change material, put 21g polyethylene glycol-800 in a beaker, put it in a water bath at 50°C, wait until the polyethylene glycol-800 becomes molten, add 9g Absolute ethanol, magnetically stirred for 1 h, and prepared a polyethylene glycol solution with a concentration of 70%, called A, for later use. Measure 200mg of carboxylated graphene oxide aqueous dispersion and 2g of aminated polyethylene glycol-800, magnetically stir for 20min, then ultrasonic for 10min, then add 1mg of 1-(3-dimeth...

Embodiment 2

[0029] (1) Measure 500 mg of graphene oxide powder and ultrasonically disperse in 100 mL of deionized water to prepare a 5 mg / ml graphene oxide dispersion. Then add 2g of sodium hydroxide and 2g of chloroacetic acid, ultrasonicate at 400W for 3h, then centrifuge at 8000r / min for 10min, wash with deionized water 2-3 times, and dialyze to neutral with a dialysis bag to obtain a well-dispersed carboxylated oxidation Graphene aqueous dispersion.

[0030] (2) Use polyethylene glycol-800 as the phase change material, put 42g polyethylene glycol-800 in a beaker, put it in a water bath at 50°C, wait until the polyethylene glycol-800 becomes molten, add 18g Absolute ethanol, magnetically stirred for 1 h, and prepared a polyethylene glycol solution with a concentration of 70%, called A, for later use. Measure 400mg of carboxylated graphene oxide aqueous dispersion and 4g of aminated polyethylene glycol-800 magnetically stir for 20min and then ultrasonic for 10min, then add 2mg of 1-(3-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com