Wood preservative modification treatment method and application thereof

A treatment method and wood preservative technology, applied in the direction of wood treatment, wood treatment details, impregnated wood, etc., can solve problems such as threatening the environment and pollution, and achieve the effects of improving the resistance to loss, durability, and resistance to loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

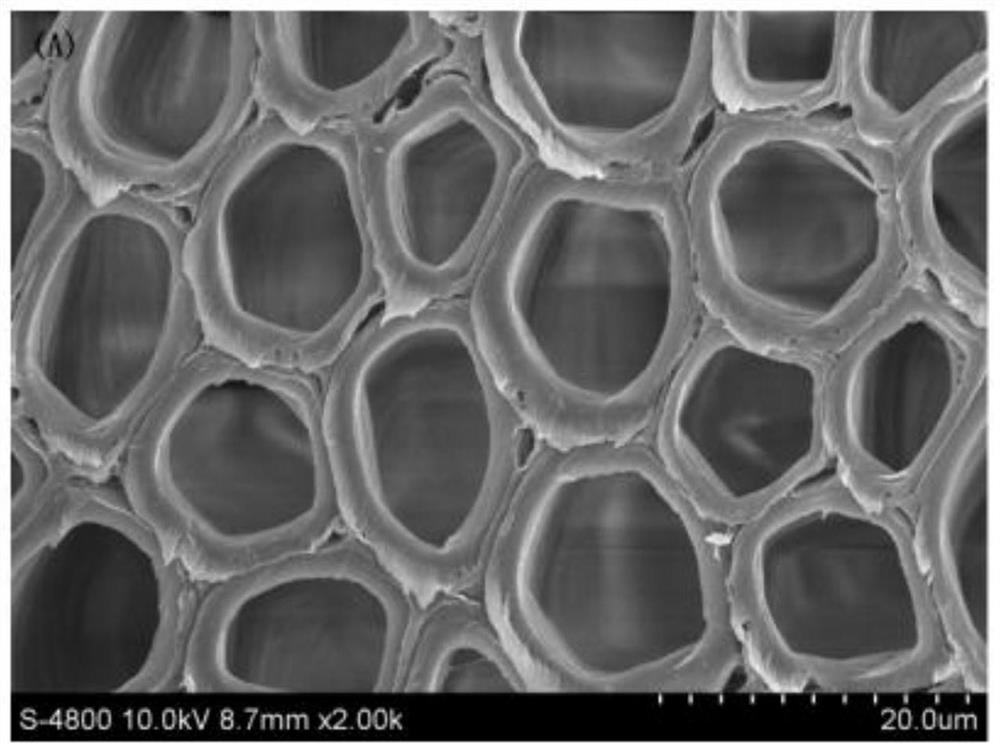

[0028] Weigh 17g of quercetin and 7.1g of oxalic acid dihydrate and dissolve them in 188mL of absolute ethanol to prepare a solution with a molar ratio of quercetin and oxalic acid dihydrate of 1:1, add 1.54g of p-toluenesulfonic acid to the solution, After stirring evenly, put in Populus tomentosa wood blocks.

[0029] The above system was impregnated under the vacuum condition of 525-600mmHg (0.07-0.08Mpa) for 15 minutes, then pressurized to 0.8Mpa and maintained for 24 hours. After impregnation, the wood blocks were put into an oven at 120°C for 8 hours after the ethanol solvent evaporated completely, and the modified wood grafted with quercetin was obtained.

Embodiment 2

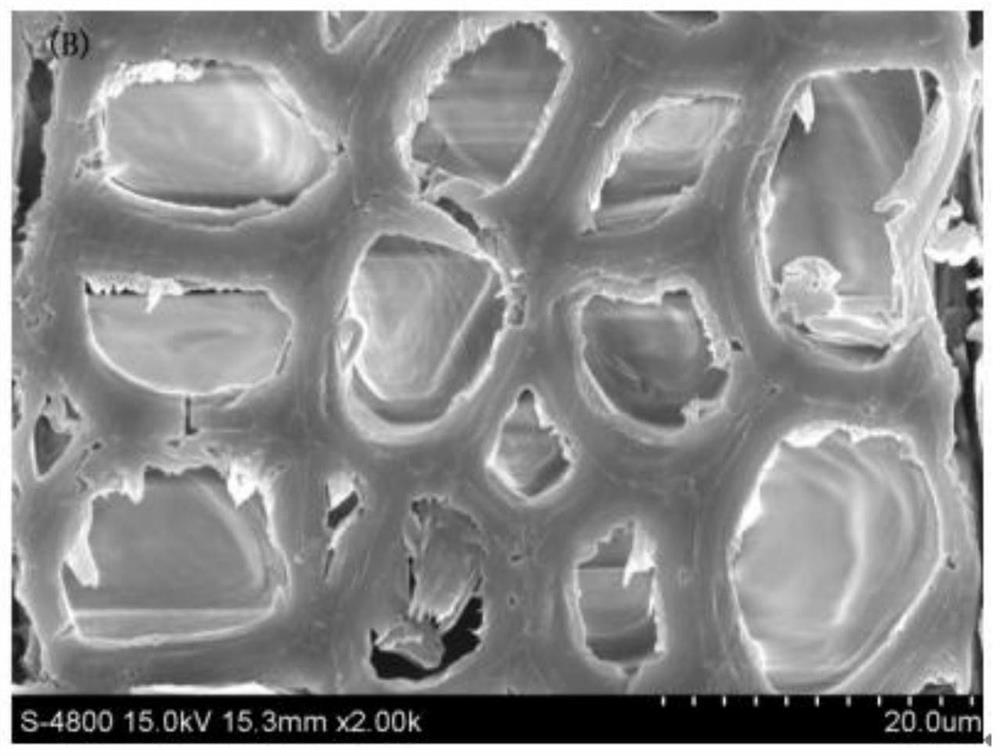

[0031] Weigh 12g of quercetin and 10g of oxalic acid dihydrate and dissolve them in 188mL of absolute ethanol to prepare a solution with a molar ratio of quercetin and oxalic acid dihydrate of 1:2, add 1.54g of p-toluenesulfonic acid to the solution, and stir Evenly put into poplar wood block.

[0032] The above system was impregnated under the vacuum condition of 525-600mmHg (0.07-0.08Mpa) for 15 minutes, then pressurized to 0.8Mpa and maintained for 24 hours. After impregnation, the wood blocks were put into an oven at 120°C for 6 hours after the ethanol solvent evaporated completely, and the modified wood grafted with quercetin was obtained.

Embodiment 3

[0034] Weigh 15g of quercetin and 18.8g of oxalic acid dihydrate and dissolve them in 188mL of absolute ethanol to prepare a solution with a molar ratio of 1:3 between quercetin and oxalic acid dihydrate, add 1.54g of p-toluenesulfonic acid to the solution, Stir well and put in poplar wood pieces. The system was impregnated for 48 hours under vacuum conditions of 525-600mmHg (0.07-0.08Mpa). After impregnation, the wood blocks were put into an oven at 120°C for 4 hours after the ethanol solvent evaporated completely, and the modified wood grafted with quercetin was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com