Heat treatment and chemical treatment method for improving mildew-proof and antibacterial effects of bamboo strips

A chemical treatment, anti-mildew and anti-bacterial technology, applied in wood treatment, wood treatment details, reed/straw treatment, etc. The effect of spraying and brushing, inhibiting mildew and increasing relative content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

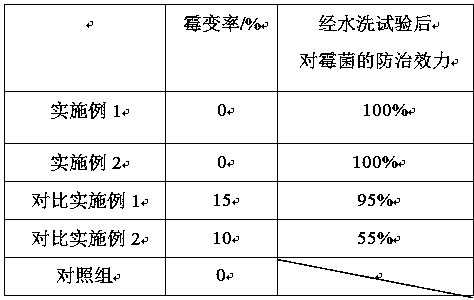

Examples

Embodiment 1

[0030] A method for heat treatment and chemical treatment to improve the anti-mildew and antibacterial properties of bamboo strips, comprising the steps of:

[0031] (1) Heat treatment and chemical treatment of moso bamboo strips:

[0032] Select three-year-old Moso bamboo strips with good appearance and no mildew, remove bamboo green and bamboo yellow, soak them in a water bath at 58-62°C for 5 hours, take them out, soak them in hydrogen peroxide solution, and treat them at 68-72°C for 5 hours. Take it out, wash it with water and soak it in clear water, then put it into boric acid solution, and treat it at 58-62°C for 5 hours to obtain chemically treated moso bamboo strips; then dry heat treatment at 165-175°C for 110 minutes to obtain heat-treated bamboo strips;

[0033] (2) Spray anti-mildew and anti-bacterial treatment:

[0034] Mix nano-zinc oxide modified by silane coupling agent, 4 parts of cinnamyl alcohol and ethanol at a solid-to-liquid ratio of 1:10, ultrasonically...

Embodiment 2

[0047] A method for heat treatment and chemical treatment to improve the anti-mildew and antibacterial properties of bamboo strips, comprising the steps of:

[0048] (1) Heat treatment and chemical treatment of moso bamboo strips:

[0049]Select three-year-old moso bamboo strips with good appearance and no mildew, remove bamboo green and bamboo yellow, soak in a water bath at 58-62°C for 6 hours, take it out, soak in hydrogen peroxide solution, and treat at 68-72°C for 6 hours, Take it out, wash it with water and soak it in clear water, then put it into boric acid solution, and treat it at 58-62°C for 6 hours to obtain chemically treated moso bamboo strips; then dry heat treatment at 165-175°C for 130 minutes to obtain heat-treated bamboo strips;

[0050] (2) Spray anti-mildew and anti-bacterial treatment:

[0051] Mix nano-zinc oxide modified by silane coupling agent, 8 parts of cinnamyl alcohol and ethanol at a solid-to-liquid ratio of 1:15, and after ultrasonic dispersion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com