Process method for modifying preservative treatment material based on nanometer silicon dioxide and emulsified wax

A technology of nano-silica and process methods, applied in wood treatment, pretreatment equipment, wood processing appliances, etc., to achieve the effects of simple treatment process, improved flame retardancy and weather resistance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

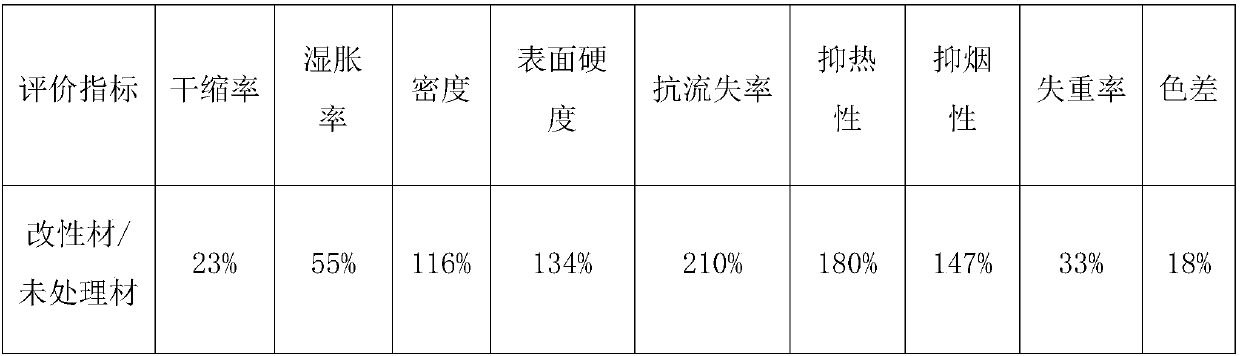

Embodiment 1

[0028] First of all, pre-treatment: after peeling and sawing the southern pine into required size specifications, dry it at 40°C and 40% relative humidity for 24 hours to control the moisture content of the wood to 8-10%.

[0029] Secondly, prepare nano-silica modifier: sodium hexametaphosphate (SHMP), trisodium phosphate (TSP), disodium ethylenediaminetetraacetic acid (EDTA-2Na), sodium polyphosphate and Dissolve 3 parts by mass of sodium pyrophosphate (TSPP) in 500 parts by mass of distilled water under the action of a magnetic stirrer, then add 1 part by mass of nano-silica, stir at 200r / min for 60min, and then disperse by ultrasonic at 20°C After 60 minutes, the nano-silicon dioxide modifier used was prepared, and the particle diameter of the nano-silicon dioxide was 20nm.

[0030] Again, prepare emulsified wax / amine-dissolved quaternary ammonium copper (ACQ) preservative modified solution: 2 mass parts of emulsified wax solution are dissolved in 800 mass parts of ACQ pres...

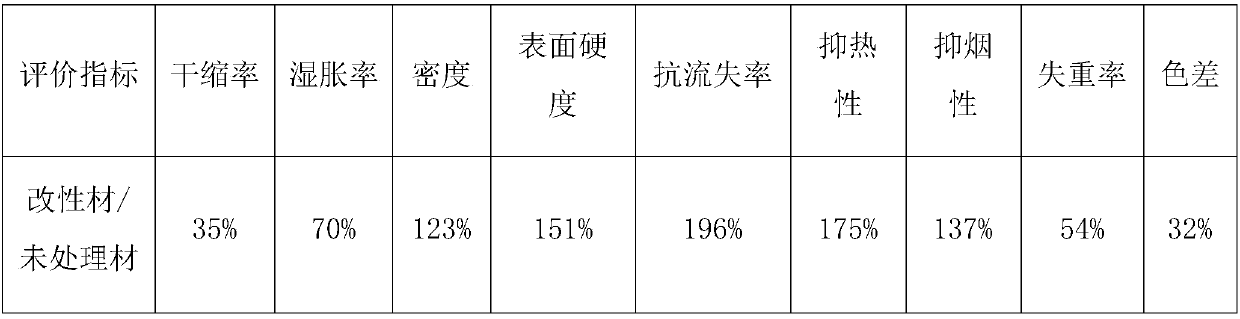

Embodiment 2

[0040] First of all, pre-treatment: Peel the Pinus sylvestris sylvestris, saw and cut it into the required size specifications, then dry it at 50°C and 50% relative humidity for 12 hours, and control the moisture content of the wood to 8-10%;

[0041] Secondly, prepare nano-silica modifier: sodium hexametaphosphate (SHMP), trisodium phosphate (TSP), disodium ethylenediaminetetraacetic acid (EDTA-2Na), sodium polyphosphate and Dissolve 6 parts by mass of sodium pyrophosphate (TSPP) in 600 parts by mass of distilled water under the action of a magnetic stirrer, then add 3 parts by mass of nano-silica, stir at 220r / min for 90min, and then disperse by ultrasonic at 40°C 15min, the nano-silicon dioxide modifier used is prepared, and the particle diameter of the nano-silicon dioxide is 30nm;

[0042] Again, prepare emulsified wax / preservative modified solution: 4 mass parts of emulsified wax solution are dissolved in 900 mass parts of amine-dissolved quaternary ammonium copper (ACQ) p...

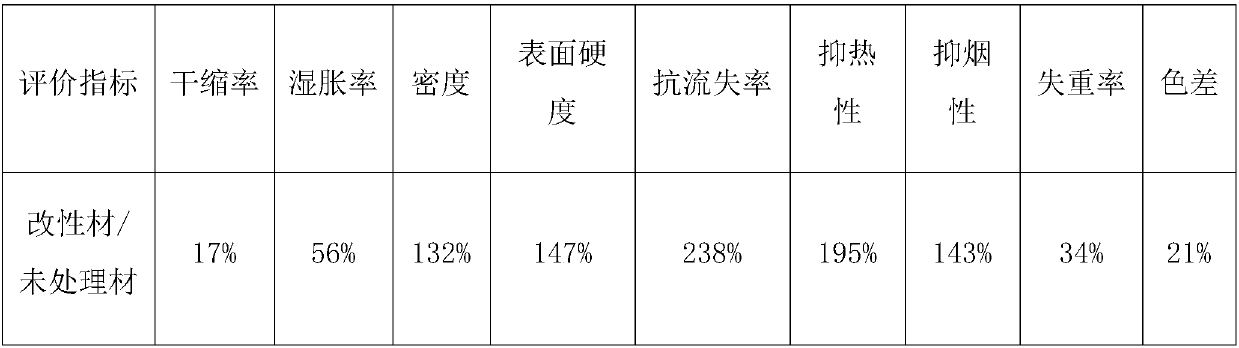

Embodiment 3

[0054] First of all, pre-treatment: after peeling and sawing the Chinese fir to the required size, dry it for 8 hours at 60°C and 60% relative humidity to control the moisture content of the wood to 8-10%;

[0055] Secondly, prepare nano-silica modifier: sodium hexametaphosphate (SHMP), trisodium phosphate (TSP), disodium ethylenediaminetetraacetic acid (EDTA-2Na), sodium polyphosphate and Dissolve 10 parts by mass of sodium pyrophosphate (TSPP) in 600 parts by mass of distilled water under the action of a magnetic stirrer, then add 2 parts by mass of nano-silica, stir at 300r / min for 150min, and then disperse by ultrasonic at 50°C 40min, the nano-silicon dioxide modifier used is prepared, and the particle diameter of the nano-silicon dioxide is 40nm;

[0056] Again, prepare emulsified wax / preservative modified solution: 6 parts by mass of emulsified wax solution are dissolved in 1000 parts by mass of copper azole (CA) preservative solution, and stirred for 30 min with a rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com