Wet oxidation catalyst and preparation method thereof

A catalyst and oxidant technology, applied in the field of catalytic wet oxidation catalyst and its preparation, can solve the problems of high working temperature, high price, gap in activity, etc., and achieve the effects of high anti-bleeding performance, stable catalytic performance, and good low-temperature activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a kind of preparation method of catalyst, comprises the following steps:

[0027] 1) Dissolving the manganese precursor salt in water to obtain a manganese salt solution, adjusting the pH value of the manganese salt solution to 8-10 with an alkaline solution to obtain an alkaline manganese salt solution;

[0028] 2) mixing the alkaline manganese salt solution with an oxidizing agent to perform an oxidation reaction to obtain a primary oxidation product;

[0029] 3) mixing the primary oxidation product with a peroxidant to carry out a hydrothermal reaction, and separating the obtained reaction product from solid to liquid to obtain a solid;

[0030] 4) drying and calcining the obtained solid in an oxygen atmosphere to obtain a catalyst.

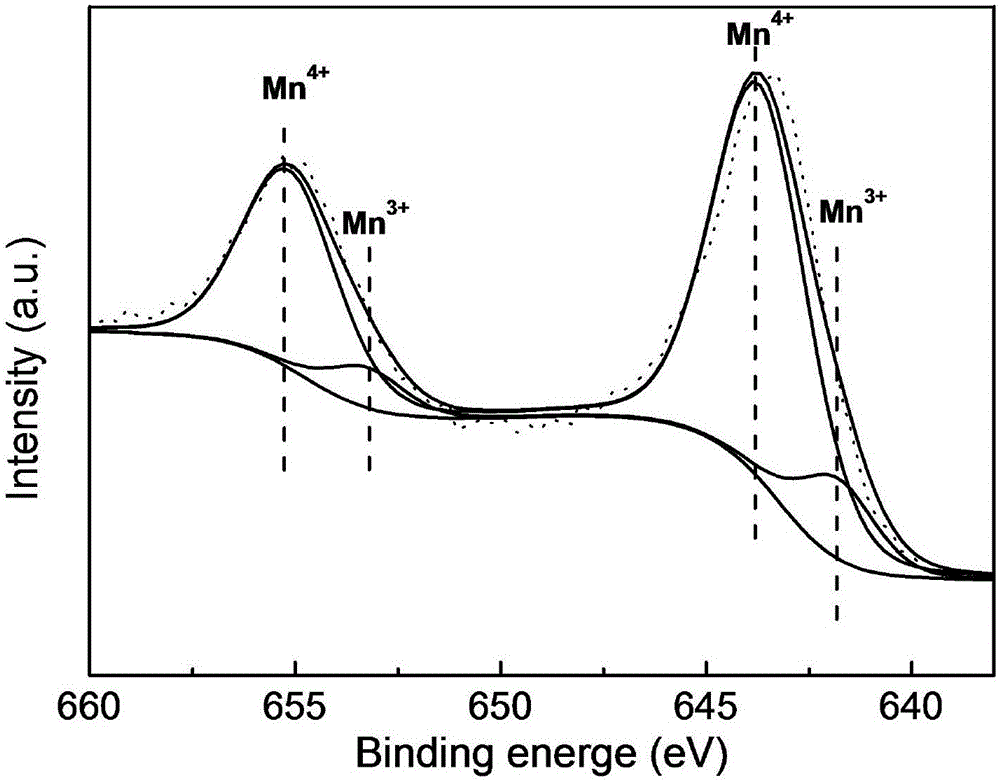

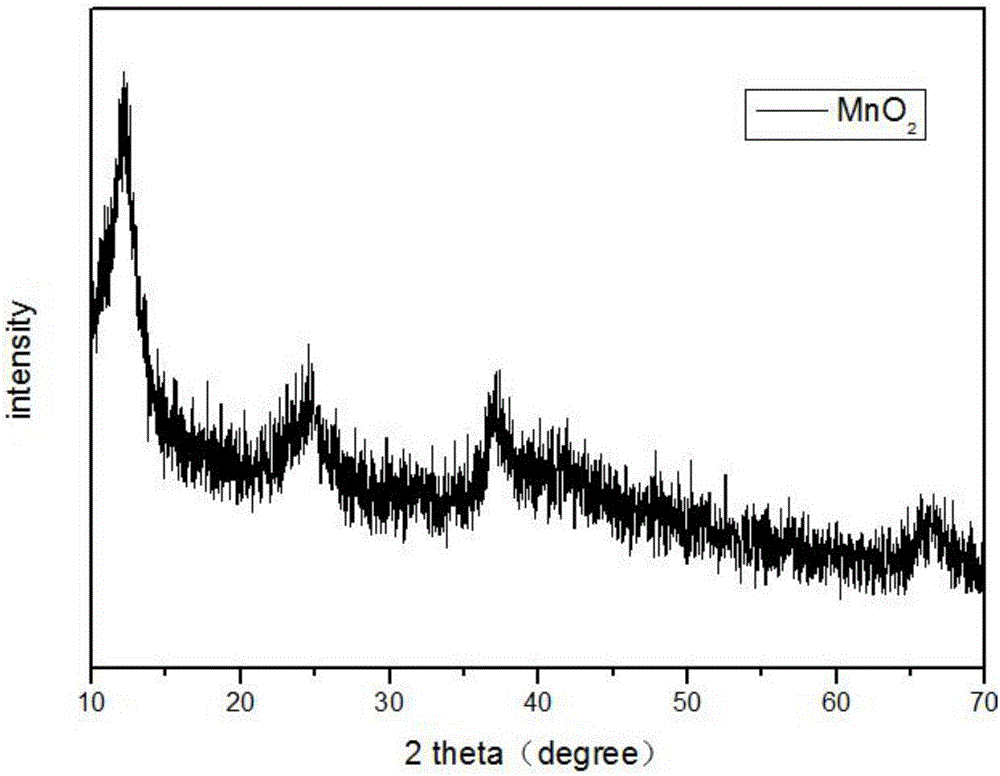

[0031] This method combines redox and hydrothermal. Precipitation of manganese precursor from alkaline solution to generate Mn(OH) 2 precipitation. After high temperature water heating, Mn(OH) 2 decomposes in...

Embodiment 1

[0043] MnCl 2Dissolve in water, prepare a solution with a concentration of 0.3mol / L, take 500mL of the solution, and add dropwise 0.2mol / L sodium hydroxide solution to adjust the pH value to 9, then add 7.51g of 20% hydrogen peroxide, and then mix the resulting mixture Put it in a constant temperature water bath at 80°C, and after the oxidation reaction for 3 hours, transfer the mixed solution into a high-pressure reactor, rapidly raise the temperature to 150°C, and continue the reaction for 6 hours, during which time, 2.15g of 20% hydrogen peroxide was added every half hour. Then, the obtained mixture was filtered and washed, and the obtained solid was dried at 80° C., and finally calcined at 450° C. in an oxygen atmosphere to obtain a catalyst.

[0044] Add 0.1g catalyst to 20mL phenol wastewater (TOC=1000ppm), reaction pressure=2.0Mpa, reaction temperature 60°C, 70°C, 80°C, 90°C, react in autoclave for 3h, the results are shown in Table 1.

[0045] Catalyst activity at dif...

Embodiment 2

[0048] MnCl 2 Dissolve in water, prepare a solution with a concentration of 0.5mol / L, take 500mL of the solution, and add dropwise 0.2mol / L sodium hydroxide solution to adjust the pH value to 10, then add 7.79g of 30% hydrogen peroxide, and then mix the resulting mixture Put it in a constant temperature water bath at 100°C, and after the oxidation reaction for 4 hours, transfer the mixed solution into a high-pressure reactor, rapidly raise the temperature to 180°C, and continue the reaction for 8 hours, during which time, 2.23g of 30% hydrogen peroxide was added every half hour. Then, the obtained mixture was filtered and washed, the obtained solid was dried at 100° C., and finally calcined at 600° C. in an oxygen atmosphere for 8 hours to obtain a catalyst.

[0049] Add 0.1g catalyst to 20mL phenol wastewater (TOC=1000ppm), reaction temperature=70°C, reaction pressure 1.5MPa, 2.5MPa, 3.0MPa in the autoclave for 3h, the results are shown in Table 2.

[0050] The activity of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com