Method of treating wood by means of impregnation in compounded mildewproof preservative liquid and high-temperature thermal treatment

A technology of high-temperature heat treatment and preservative solution, which is applied in the direction of impregnation of wood, wood treatment, gas phase impregnation, etc., can solve the problems of being easily eroded by wood decay fungus, ecological environment hazards, and affecting performance, etc., to inhibit the growth of mold and resist loss. Good performance, good anti-mildew effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

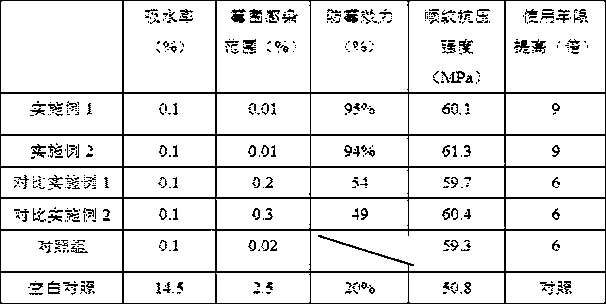

Examples

Embodiment 1

[0028] A method for impregnating and heat-treating wood with a compound anti-mildew preservative solution, comprising the following steps:

[0029] (1) Compounding of anti-mold and anti-corrosion liquid:

[0030] The copper-containing compound impregnating solution is uniformly mixed with the antifungal agent chitosan copper complex solution, camphor tree leaf extract solution, burdock leaf extract medicinal solution and nano-titanium dioxide-Chinese herbal medicine composite antiseptic solution to obtain a compound anti-mold antiseptic solution;

[0031] (2) Pressure impregnation treatment of wood:

[0032] Immerse the wood in distilled water, ultrasonically clean it for 20 minutes, put it in an oven at 60-70°C and dry it to constant weight, and then immerse it in the compound anti-mold and anti-corrosion solution obtained in (1). The gauge pressure under vacuum is - Treat at 0.09MPa for 30min, then impregnate at 1MPa for 40min, take it out, and put it in an oven at 60-70℃ t...

Embodiment 2

[0046] A method for impregnating and heat-treating wood with a compound anti-mildew preservative solution, comprising the following steps:

[0047] (1) Compounding of anti-mold and anti-corrosion liquid:

[0048] The copper-containing compound impregnating solution is uniformly mixed with the antifungal agent chitosan copper complex solution, camphor tree leaf extract solution, burdock leaf extract medicinal solution and nano-titanium dioxide-Chinese herbal medicine composite antiseptic solution to obtain a compound anti-mold antiseptic solution;

[0049] (2) Pressure impregnation treatment of wood:

[0050] Immerse the wood in distilled water, ultrasonically clean it for 25 minutes, put it in an oven at 70-80°C and dry it to constant weight, and then immerse it in the compound anti-mold and anti-corrosion solution obtained in (1). The gauge pressure under vacuum is - Treat at 0.09MPa for 35min, then impregnate at 2MPa for 45min, take it out, and put it in an oven at 70-80℃ t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com