Patents

Literature

75results about "Vapor phase impregnation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Modifying method for wood elements

InactiveUS6632326B1Good dimensional stabilityReduce processing timeCellulosic pulp after-treatmentLiquid surface applicatorsManufacturing cost reductionAcetic acid

The present invention's modifying method for wood elements includes a step for soaking wood elements in one or a mixture of acetic anhydride, acetic acid, or chloroacetic acid; and a step for acetylating the impregnated wood elements in a gaseous phase. This method makes it possible to reduce the time required for the step of acetylating the wood elements, simplifies the process, reduces fabrication costs, and enables fabrication of a wood fiberboard having high dimensional stability.

Owner:YAMAHA CORP

Methods of conferring fire retardancy to wood and fire-retardant wood products

ActiveUS20150352744A1Radiation/waves wood treatmentVacuum evaporation coatingFire retardantEngineered wood

A process is provided for treating wood products including lumber, plywood and other engineered wood products comprising the steps of applying an aqueous fire-retardant impregnate and applying a coating to the surface of the wood product. In one embodiment, said process confers fire-retardant properties to the wood products sufficient to pass the extended burn test of ASTM E-84. The present invention also provides fire retardant wood products.

Owner:KOPPERS PERFORMANCE CHEM

Modification treatment method of salix integra for weaving

ActiveCN107088941AHigh hardnessHigh strengthWood treatment detailsPretreatment apparatusSolution treatmentHardness

The invention discloses a modification treatment method of salix integra for weaving, and belongs to the technical field of wickerwork processing. The method comprises the following steps of (1) salix integra pretreatment, (2) steam treatment, (3) acid-base solution treatment, (4) soaking modification treatment and (5) drying treatment. According to the method, salix integra branches are subjected to special modification treatment, the contents and compositions of inner material compositions are effectively adjusted, the flexibility of the salix integra branches is improved, the weaving yield is guaranteed, the hardness and strength of the salix integra can be recovered and improved in time after weaving, and the service life of a wickerwork product is prolonged. In addition, the salix integra branches treated through the method can be recycled again through high temperature softening treatment, and the problem that existing wickerwork products cannot be reused effectively is solved.

Owner:阜南佳利工艺品股份有限公司

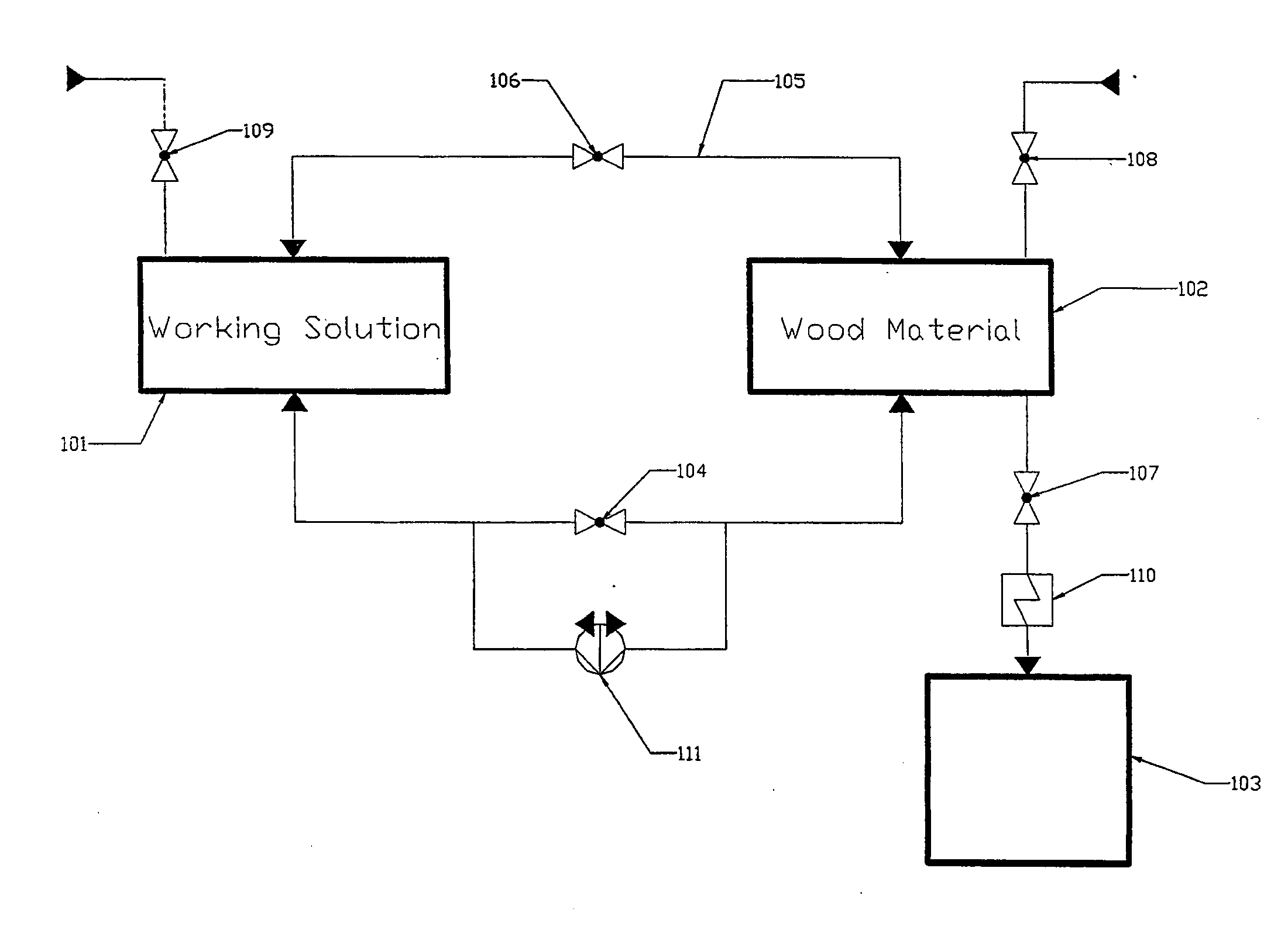

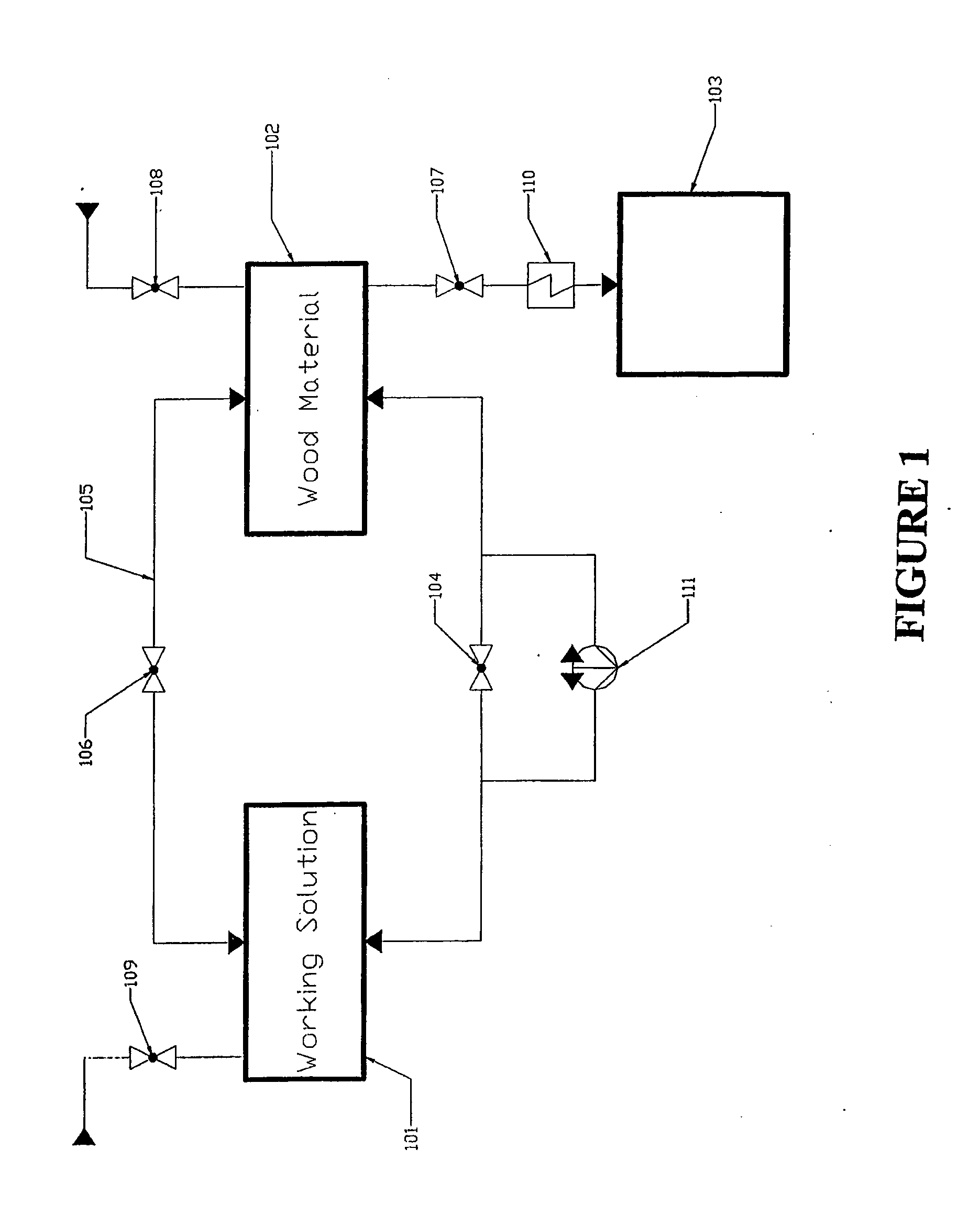

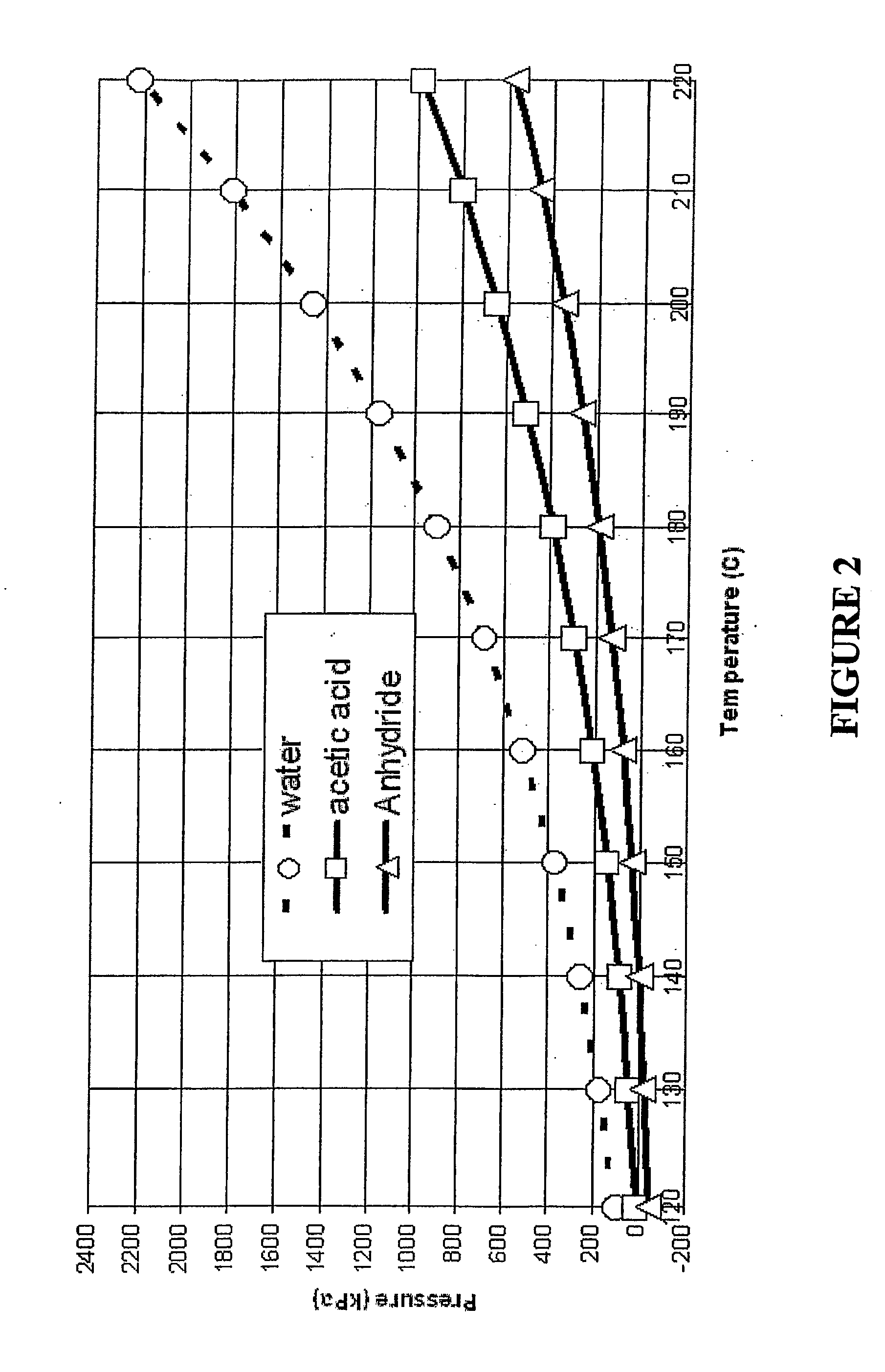

Impregnation process

ActiveUS20070128422A1Reduce pressurePromote recoveryFibreboardPretreated surfacesBoiling pointHigh pressure

The invention relates to a process for impregnating wood or wood based material. A working solution is preheated to a temperature above the atmospheric boiling point (“a super hot temperature”) above the atmospheric boiling point (“a super hot temperature”) of the working solution, at an elevated pressure sufficient to maintain the working solution in the liquid phase. The working solution is contacted with a wood or wood based material at a super hot temperature and an elevated pressure to cause impregnation of the solution into the wood or wood based material. The impregnated wood or wood based material and any remaining working solution, waste material and / or by-products are then separated.

Owner:TITAN WOOD LTD +1

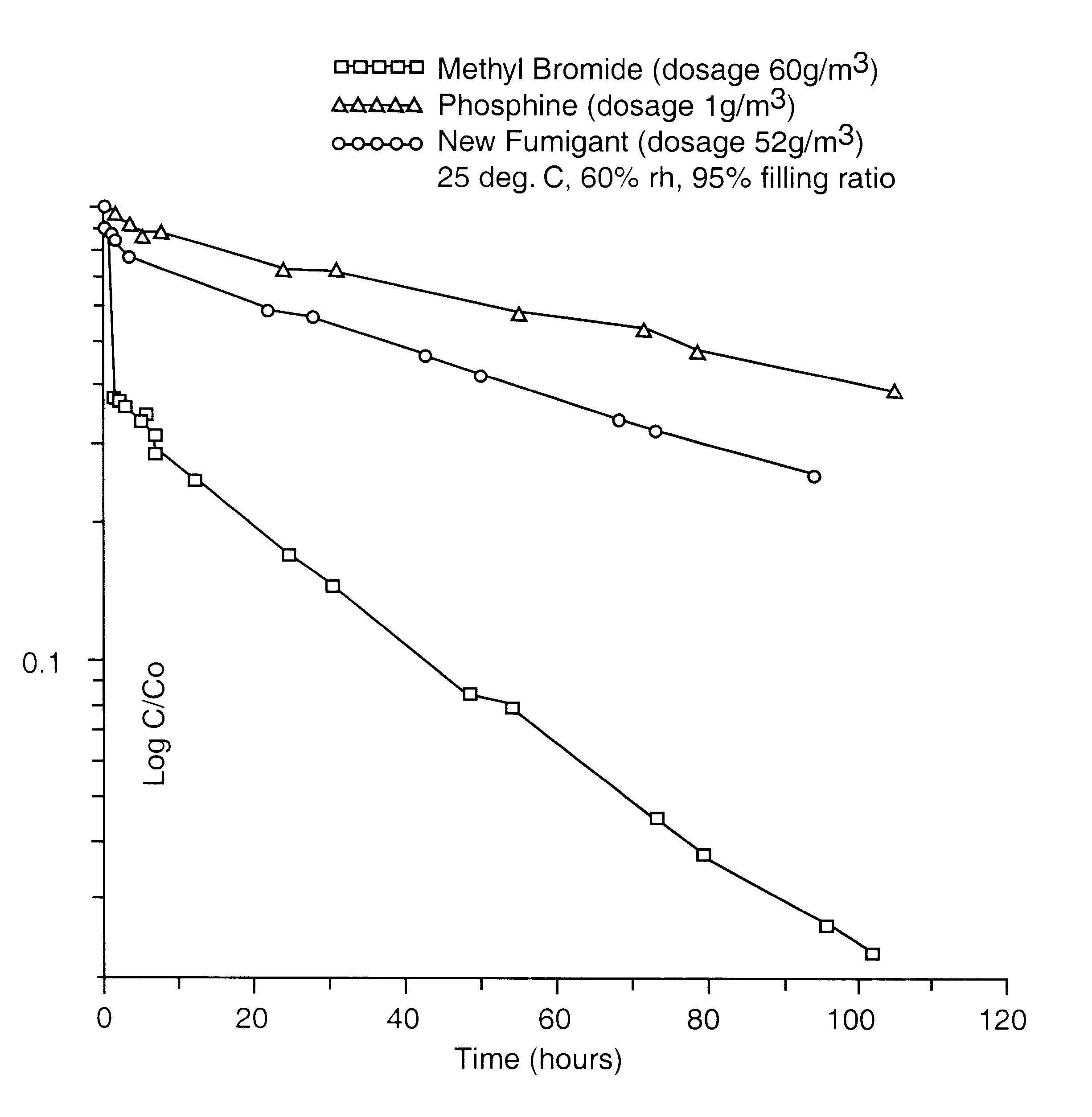

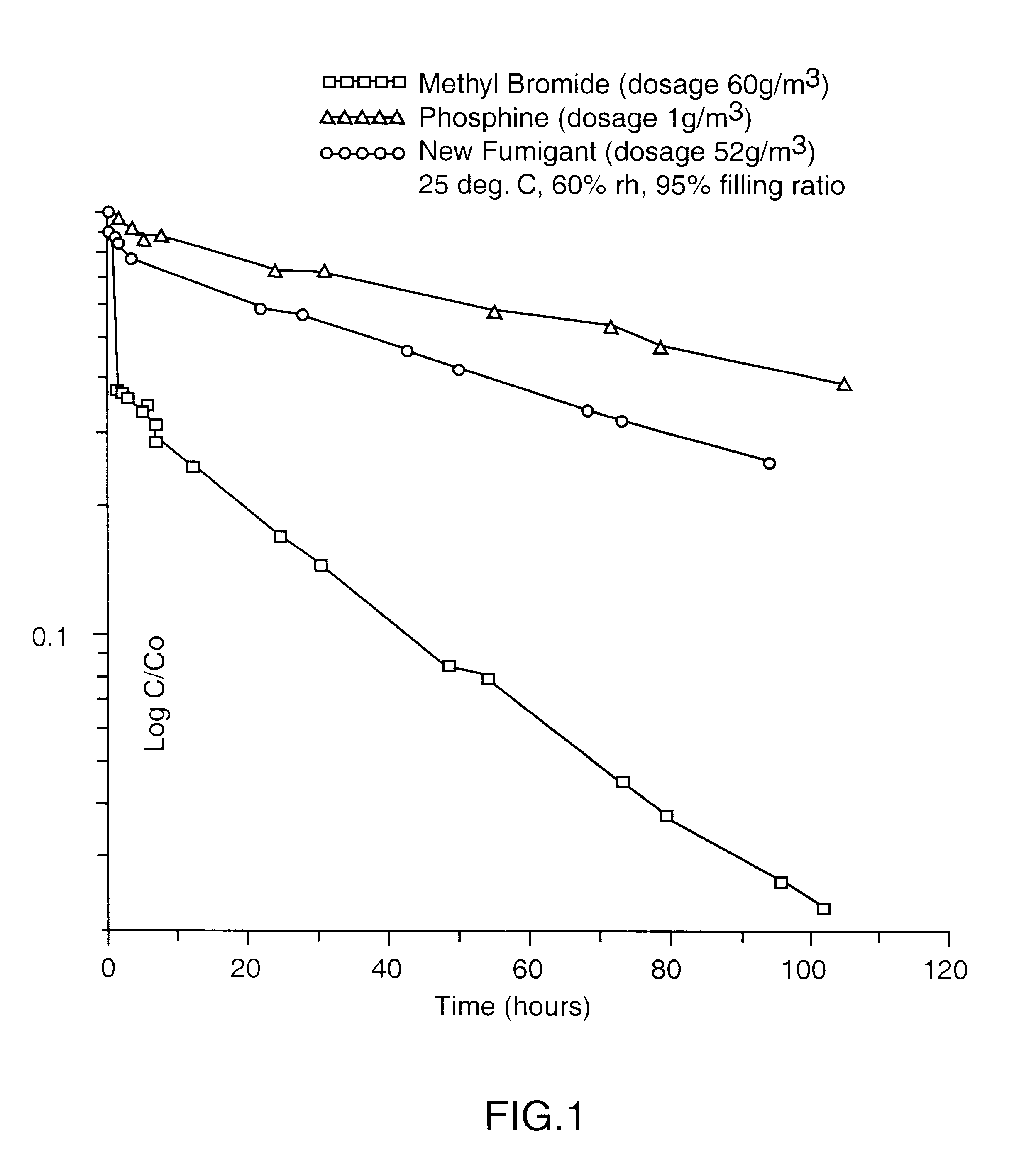

Fumigant for wood parasitic nematode and method of wood fumigation

The invention provides a wood parasitic nematode fumigant, which is characterized in that methyl iodide dissolved in liquefied carbon dioxide gas is used instead of destructive matters from an ozonosphere, to use bromomethane limited in the world range; or, the methyl iodide is used together with any, or two or more compound of the sulfuryl fluoride, the methyl isothiocyanate, the phosphine, the ethylene oxide, the carbonyl sulfide and the propylene oxide; the invention also provides a wood fumigating method, which can kill the wood parasitic nematode by using the fumigant.

Owner:SUMIKA GREEN +2

Process for machining antiquing floors by using low-grade boards

InactiveCN107116656AIncrease sales valueConsistent colorBelt grinding machinesCoating impregnationMaterial defectEngineering

The invention relates to a process for machining antiquing floors by using low-grade boards. The process comprises the following steps: low-grade board blanks are machined as plain plates; the surface polishing and the defect port rounding are performed on material defects by using an angle grinding piece, a steel wire disc and a grinding wheel in sequence; then, putty is coated in cracks to fill and level up the cracks; the plain plates are machined by adopting more than two antiquing treatment processes of scraping, wire drawing, dimpling, dull knife machining, relief machining, carbon combustion machining and chemical change machining; and natural oil or wax oil is brushed on the surfaces of the plain plates for airing to obtain finished products. The process uses the boards with such material defects as dead knots, bark pockets, insect holes, mineral lines and cracks and discarded by the industry as raw materials to prevent the wood wastes, finishes natural material defects, and fills the putty to form an artistic effect; and the antiquing treatment process is used for forming the natural antiquing effect on the surfaces of the floors to improve the floor sale additional value.

Owner:湖北燕加隆木制品有限公司

Carbonyl sulphide insecticide

The gaseous chemical compound, carbonyl sulphide, has hitherto been unknown as a fumigant for the control of insects and mites. Experiments have shown conclusively that carbonyl sulphide can be used as such a fumigant, with fumigation properties comparable to those of phosphine and methyl bromide. The effectiveness of carbonyl sulphide against insects (both adult and immature stages), mites, termites and moulds is demonstrated. In addition, its low absorbtion by grain, lower flammability than phosphine, lack of influence on seed germination, and apparent environmental safety make carbonyl sulphide particularly beneficial as a fumigant of stored grain. It may also be used to fumigate other stored produce (including perishable foodstuff), soil, timber and spaces (such as buildings) and any material likely to be infested by insects or mites, or act as a source of such infestation.

Owner:COMMONWEALTH SCI & IND RES ORG

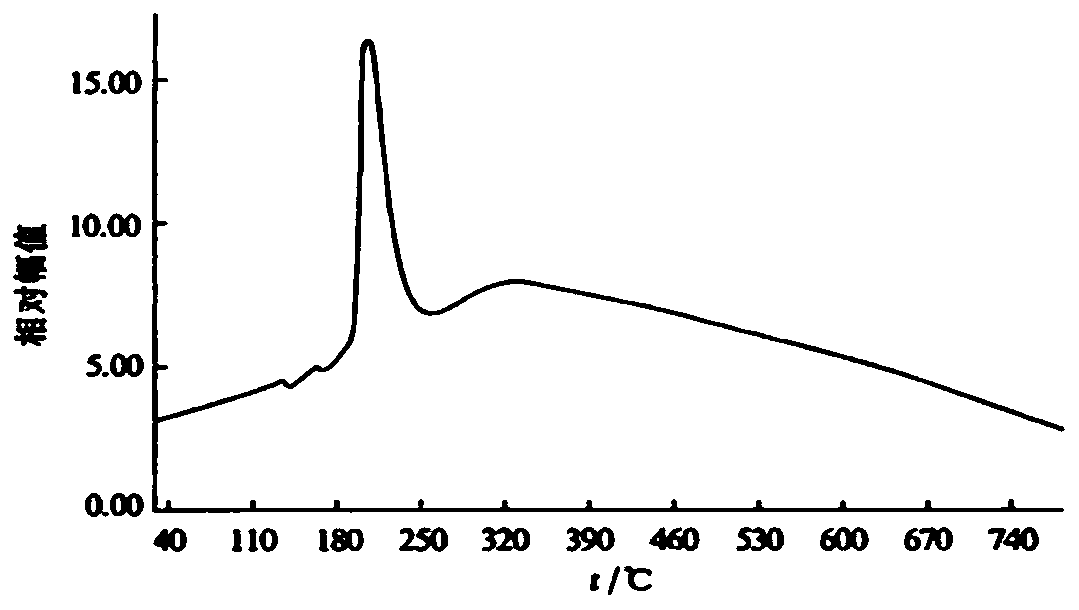

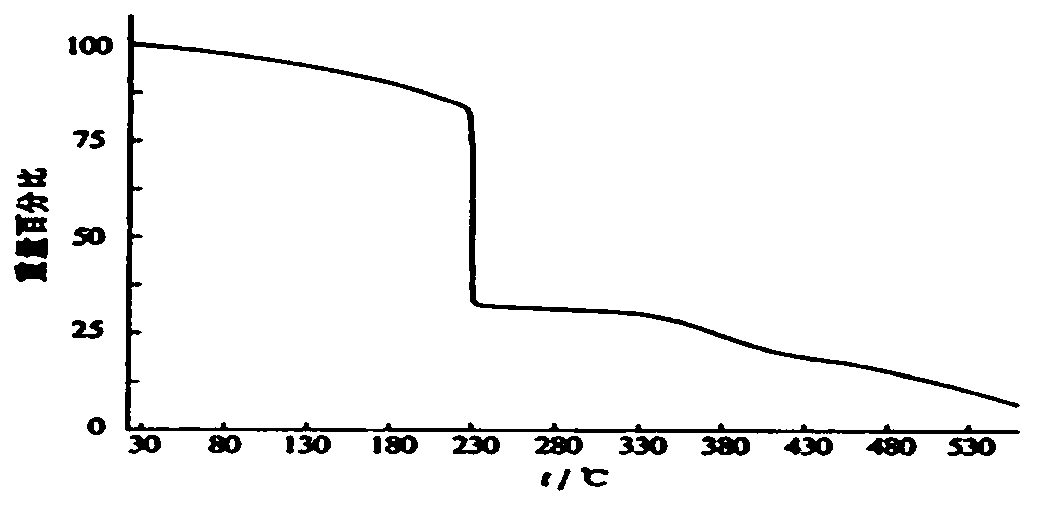

Processing method for sequoias product

InactiveCN107471356AUniform colorAvoid deformationRadiation/waves wood treatmentWood treatment detailsForeign matterWater vapor

The invention relates to the technical field of processing wooden handicrafts, and discloses a processing method of metasequoia wood products. The chemical composition of the treated metasequoia wood changes, the free hydroxyl functional groups are greatly reduced, and the hygroscopicity and water absorption of the wood are significantly reduced. Cellulose is degraded into free acid, which cuts off the food chain of decaying bacteria, improves antisepsis, compressive strength, and hardness, volatilizes the content of wood, facilitates processing and finishing, and is easy to maintain. During the production process of pressure and high temperature heat treatment wood Only water vapor and temperature are involved, no chemicals are added, and no foreign substances are added. Therefore, the use of pressure and high temperature heat treatment of wood is environmentally friendly and will not pollute the environment. At the same time, because the equilibrium moisture content of treated wood decreases during use, Dimensional stability is greatly improved. After finishing, Metasequoia wood products are uniform in color, durable, stable in material and not easy to deform.

Owner:FUNAN YONGXING ARTS & CRAFTS

Esterified lignocellulosic materials and methods for making them

Owner:EASTMAN CHEM CO

Methods of conferring fire retardancy to wood and fire-retardant wood products

ActiveUS9669564B2Radiation/waves wood treatmentLiquid surface applicatorsFire retardantEngineered wood

A process is provided for treating wood products including lumber, plywood and other engineered wood products comprising the steps of applying an aqueous fire-retardant impregnate and applying a coating to the surface of the wood product. In one embodiment, said process confers fire-retardant properties to the wood products sufficient to pass the extended burn test of ASTM E-84. The present invention also provides fire retardant wood products.

Owner:KOPPERS PERFORMANCE CHEM

Method for preparing ultraviolet-aging-resistant functional type wood through physical vapor deposition method

ActiveCN109291182AImprove product added valueLow costRadiation/waves wood treatmentWood treatment detailsUltravioletNitrogen gas

The invention discloses a method for preparing ultraviolet-aging-resistant functional type wood through a physical vapor deposition method. The method mainly aims at solving the problems that the woodsurface is aged under ultraviolet radiation, and the high-temperature condition of a conventional physical vapor deposition method is not applicable to the construction of a coating structure on thewood surface. The method comprises the steps that firstly, a tube type resistance furnace is refitted, and a high-temperature area and a deposition area are defined through division; a g-C3N4 precursor and the wood are placed in the different areas of the tube type resistance furnace; after air in a quartz tube is exhausted through nitrogen gas, the temperature is raised at the set technological parameters; and after the certain temperature is reached, physical vapor deposition operation is started, and the surface of the wood is uniformly loaded with g-C3N4, so that a protective coating capable of absorbing ultraviolet rays is formed. After an accelerated ultraviolet aging test lasting for 15 days is completed, compared with the condition before treatment, the total color difference of the product is less than 8% which is far less than the value, namely 25%, of wood which is not subjected to modification treatment; and the surface of the wood is well protected. The method has the advantages of being simple in preparation technological process, low in raw material cost, environmentally friendly and the like.

Owner:NORTHEAST FORESTRY UNIVERSITY

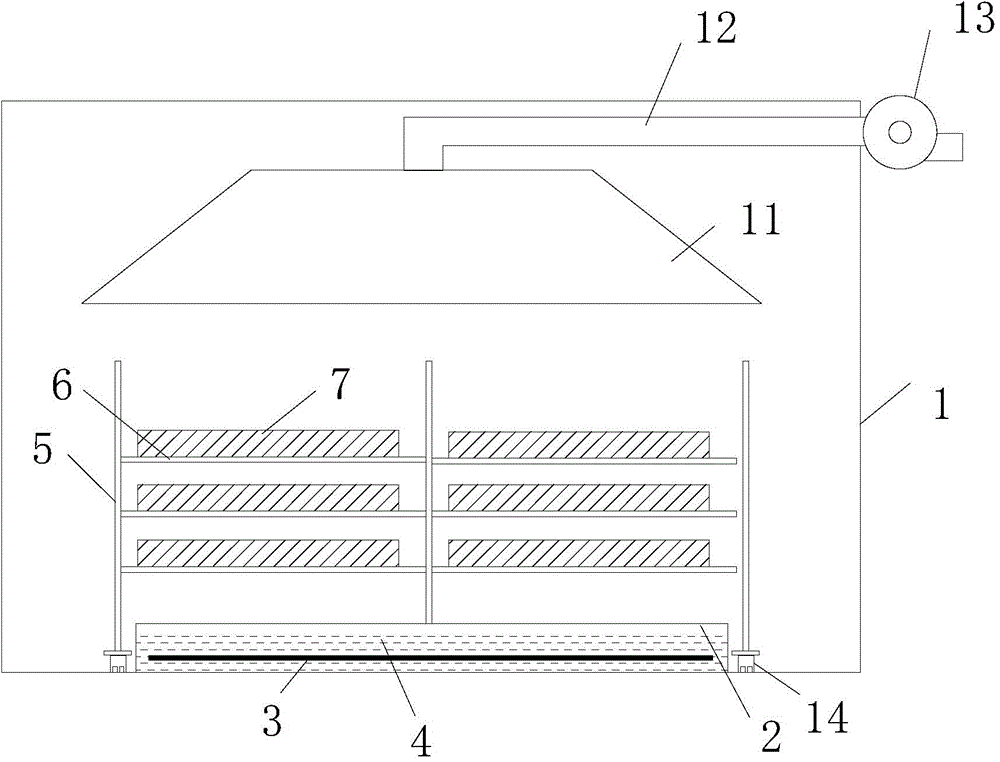

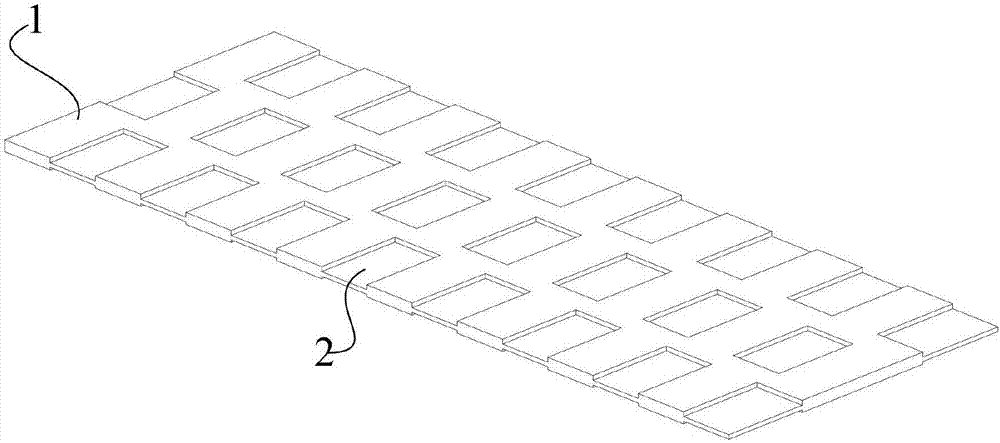

Fir furniture board processing device

ActiveCN107379168AIntermittent periodic rotation fully uniformFully and evenly smokedCoating impregnationVapor phase impregnationEngineeringMechanical engineering

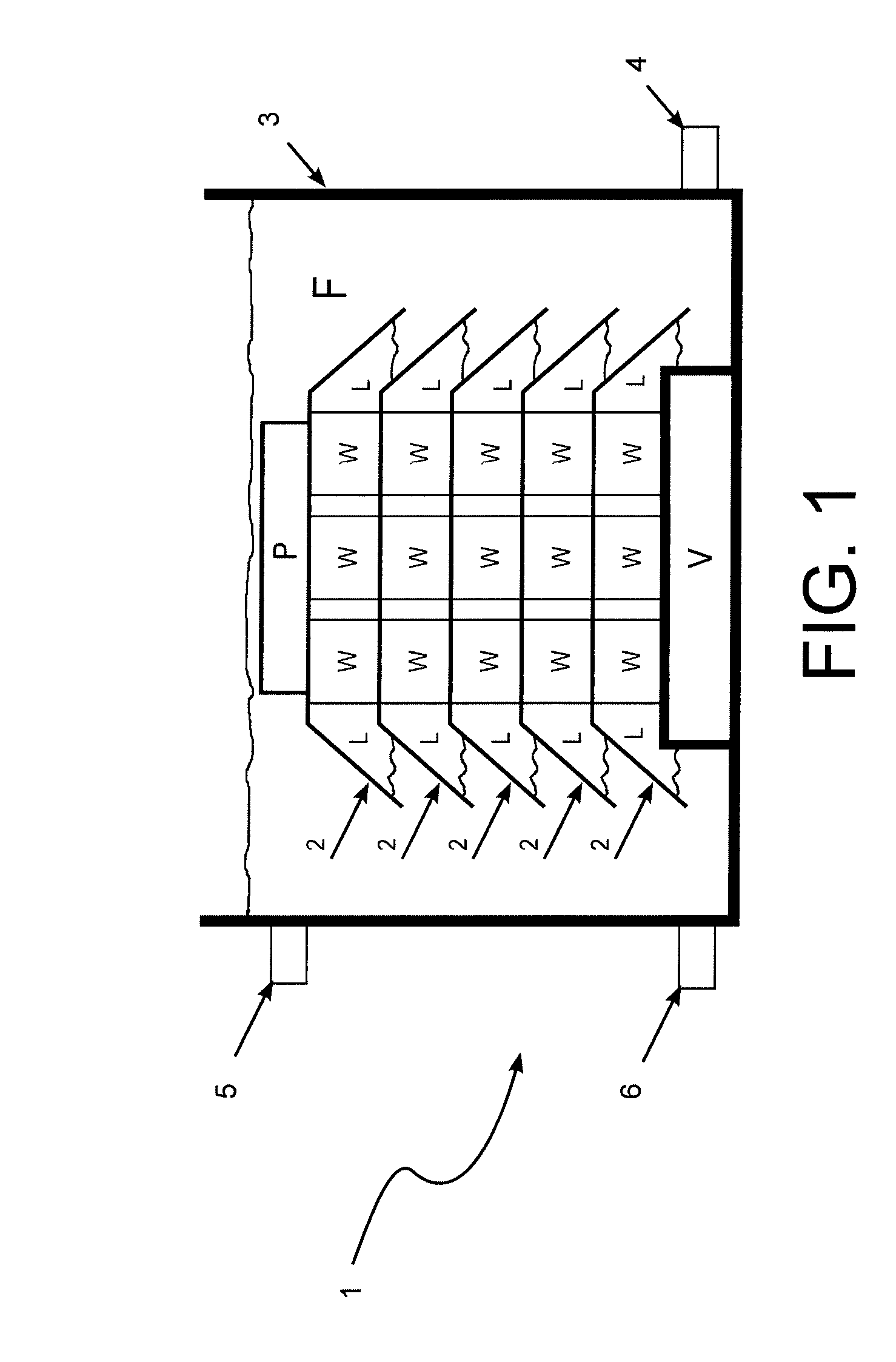

The invention relates to a fir furniture board processing device. The processing device comprises a spraying-steaming box, a fumigating box and a board frame; two sides of the spraying-steaming box and two sides of the fumigating box are provided with openings, the two sides of the spraying-steaming box and the two sides of the fumigating box are provided with end doors, and the front and rear sides of the bottom surface of the spraying-steaming box and the front and rear sides of the bottom surface of the fumigating box are fixedly connected with the bottom surfaces of wheel rails; the cross sections of the wheel rails are of U-shaped structures, and two ends of the wheel rails extend out of the spraying-steaming box and the fumigating box respectively; and rollers are fixedly arranged at four corners of the bottom surface of the board frame respectively, the rollers are provided with a power device, the power device is a motor, and the rollers can be located in the corresponding wheel rails at the same time. According to the processing device, the untreated fir board only needs to be installed in the board frame by an operator, then the fir board is detached after the processing is completed, and therefore the physical labor of operators can be reduced to the maximum extent, and the processing efficiency of the fir board is greatly improved; and a burning furnace and the fumigating box are arranged separately so that the fire caused by the fact that the lower fir board is too close to a fire source in the fumigating process can be avoided.

Owner:HUNAN INSTITUTE OF ENGINEERING

Processing technology of mildew-proof insect-proof rattan- plaited handicraft

InactiveCN111015865AGood penetration uniformityImprove effective utilizationWood treatment detailsCane mechanical workingBiotechnologySolid component

The invention discloses a processing technology of a mildew-proof insect-proof rattan-plaited handicraft, which comprises the following steps: putting rattans into a treatment solution, drying with hot air, plaiting the rattans into a handicraft, air-drying, polishing the surface of the rattan-plaited handicraft, brushing a protective paint, and drying to obtain the rattan-plaited handicraft. Themain components of the treatment liquid, the softening steam and the protective paint in the process are natural materials, the health of a user is not influenced, the safety is high, and the rattan is treated by adopting a method of combining soaking, steam softening and protective paint coating, so that the mildew-proof and insect-proof effects are good; according to the process, a steam softening device is used for softening and humidifying rattans uniformly and has a good effect through the rotation of the steaming barrel and the extraction and return of steam at the top of the inner cavity of the steam box to the lower part of the steaming barrel; solid components in the fragrance-remaining mixture are placed in the hanging basket and then placed in the cooking pool to be cooked, so that the device is convenient to clean.

Owner:阜南县利民工艺品有限公司

Anti-corrosion and anti-fade dyeing method for rattan

InactiveCN107379165ABright colorImprove aestheticsPressure wood treatmentWood treatment detailsEngineeringMildew

The invention belongs to the technical field of rattan processing, in particular to an anti-corrosion and anti-fade dyeing method for rattan. The anti-corrosion and anti-fade dyeing method for the rattan specifically comprises the following steps that (1) steam treatment and dyeing treatment are conducted; and (2) vacuum treatment and air blast drying treatment are conducted; specifically, steam treatment is conducted before dyeing, so that opening of hydrogen bond between aspirated pit membrane and pit border is effectively promoted, with the help of a method for reducing pit aspiration through the principle that self elasticity of the pit membrane is restored to the original position, infiltration of a dyeing agent is promoted accordingly; and vacuum treatment is conducted after dyeing, pressure difference of the inside and outside of the rattan is formed by removing air in the rattan, further diffusion and infiltration of the dyeing agent is effectively promoted, the dyeing agent is closely combined with rattan molecules, so that the coloring and fixation effects are improved. According to the anti-corrosion and anti-fade dyeing method for the rattan, not only is the rattan bright and distinct in color, are attractiveness and the visual effect improved, but also breeding of harmful bacteria can be effectively inhibited, rot and mildew of the rattan can be effectively inhibited, and the service life of the rattan is prolonged.

Owner:阜南县宏达工艺品厂

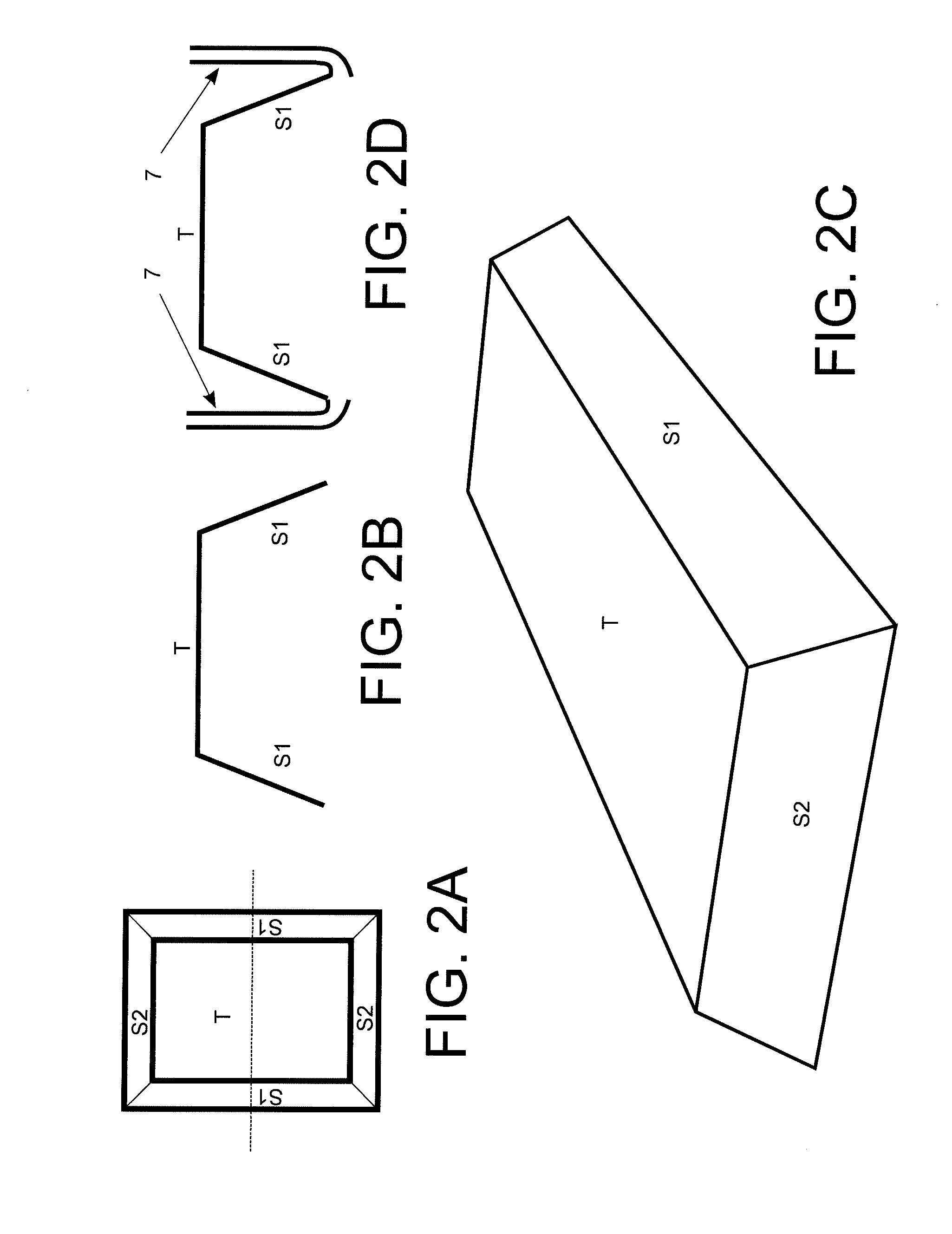

Surface treatment process for oak work boards and fumigation device thereof

InactiveCN104985656AIncrease profitReduce manufacturing costWood treatment detailsPressure impregnationAmmonia gasUtilization rate

The invention discloses a surface treatment process for oak work boards and a product thereof. According to the method, the oak work boards are erected above ammonia water, the ammonia water volatilizes to generate ammonia gas, and the ammonia gas is used for fumigating the oak work boards. By the adoption of the method, the oak work boards with miscellaneous surface colors or whitish surface colors can be effectively changed into products with qualified colors similar to yellow of teak, so that the utilization rate of oaks is greatly increased, the production cost of the oaks is lowered, and abundant benefits are brought to enterprises.

Owner:JIUSHENG WOOD

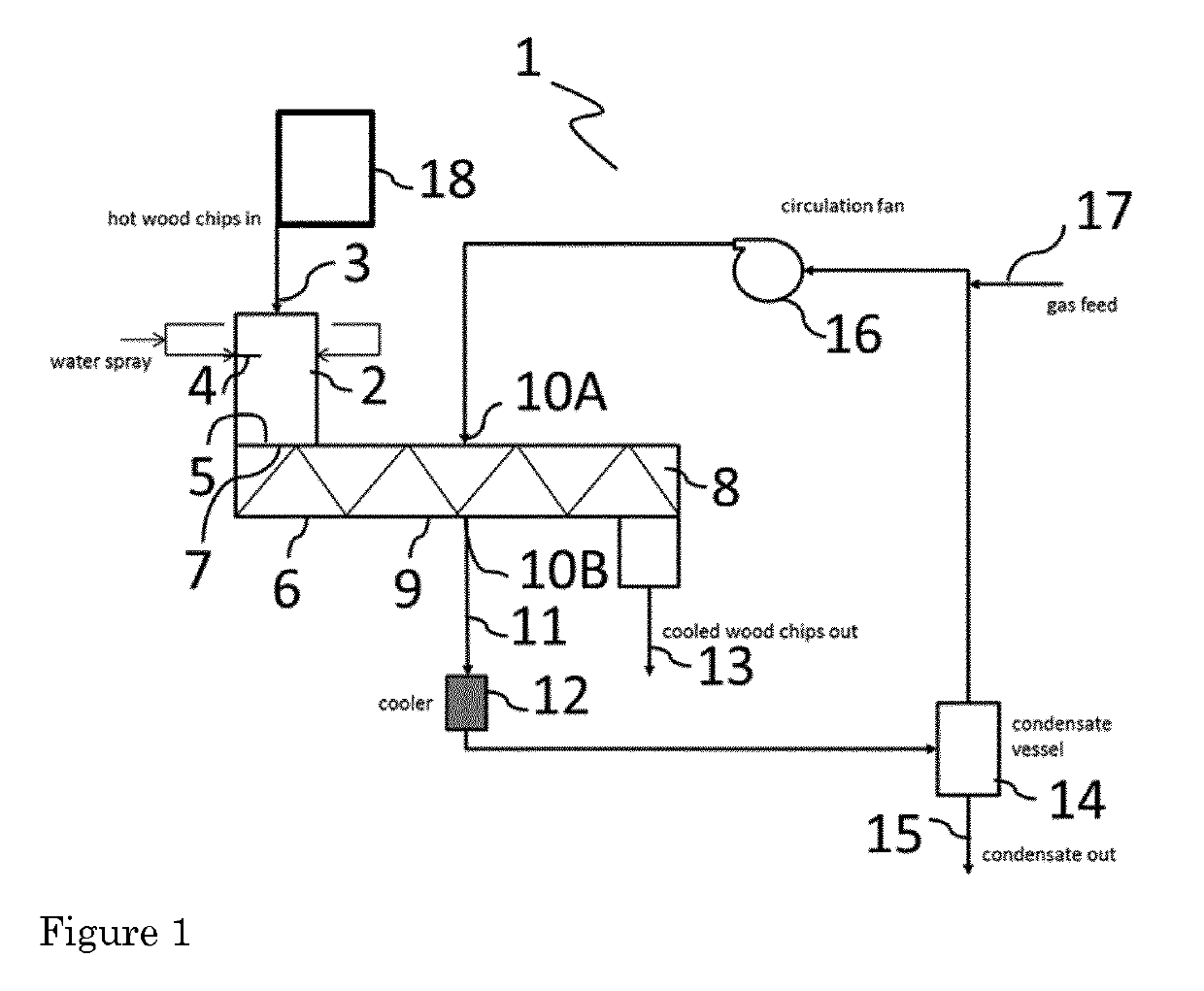

Cooling acetylated wood elements

A process for the production of acetylated wood elements, a cooling system and a wood acetylation plant are described. A process for the production of acetylated wood elements comprises acetylating wood elements and cooling the acetylated wood elements wherein the cooling comprises supplying liquid water to the acetylated wood elements to provide wetted wood elements and exposing the wetted wood elements to a gas flow.

Owner:TRICOYA TECH

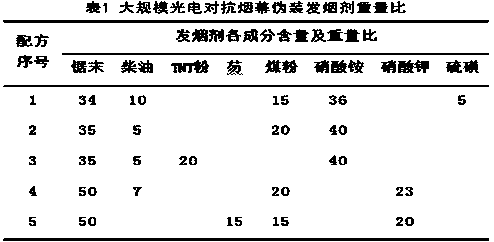

Smoke producing agent capable of being massively applied and preparing and igniting method

ActiveCN110260717AEasy to reinforceLow costIncandescent ignitionWood treatment detailsPotassium nitrateHigh energy

The invention relates to a smoke producing agent which is easily collected and suitable for massive applying, and a preparing and igniting method. The smoke producing agent comprises saw dust, diesel oil or fluorine, pulverized coal or TNT powder, potassium nitrate or ammonium nitrate; and 5% of sulphur is added while the smoke producing agent is treated as insecticidal smoke. According to the smoke producing agent, a high-energy electric igniting tool replaces a safety fuse for igniting, so that the distant operation is realized. According to the smoke producing agent and the igniting method, the main components are easily collected and nontoxic; the igniting is fast; the success rate is high; and the damage of toxic substances to human body is avoided.

Owner:中国人民解放军69080部队

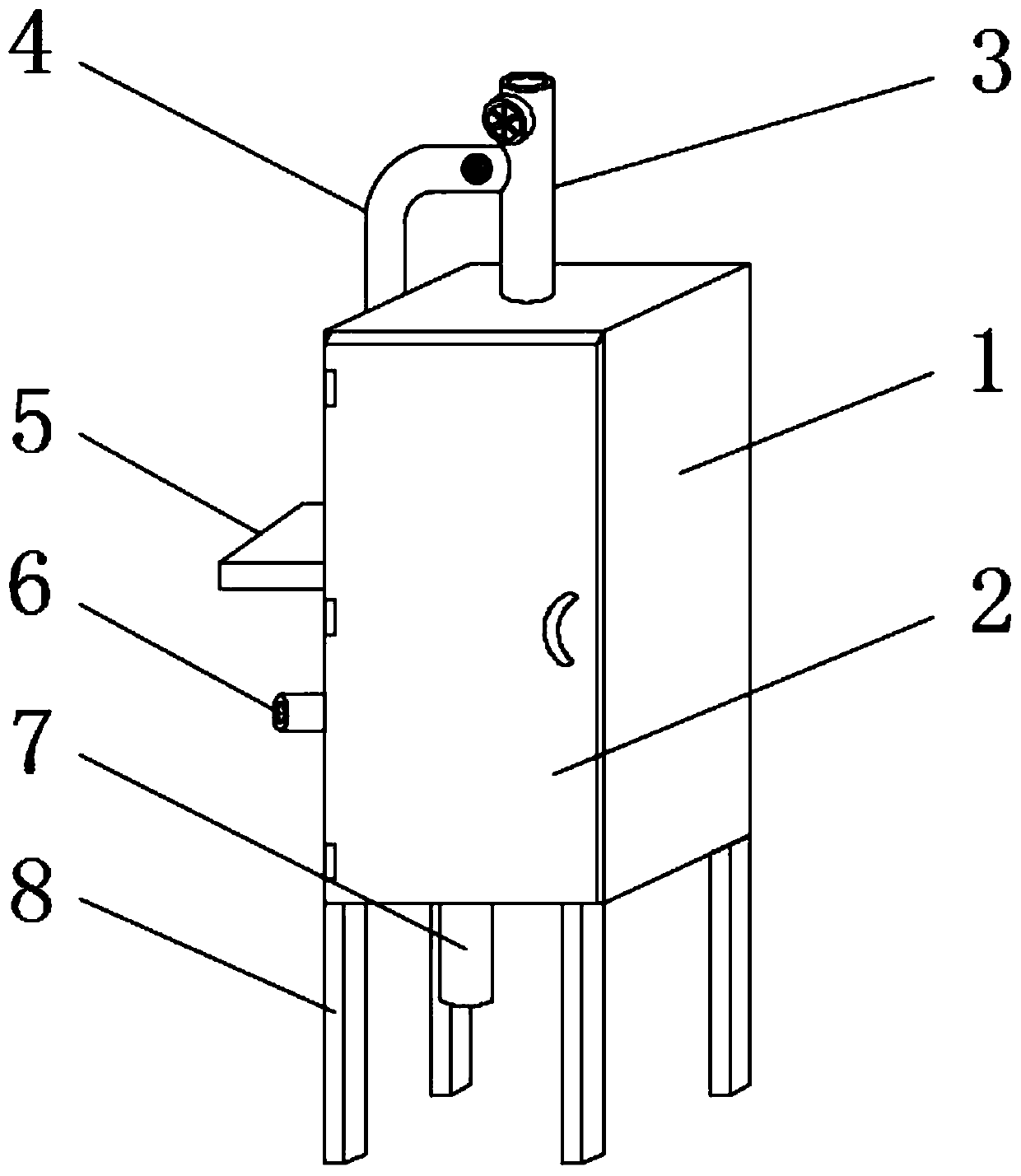

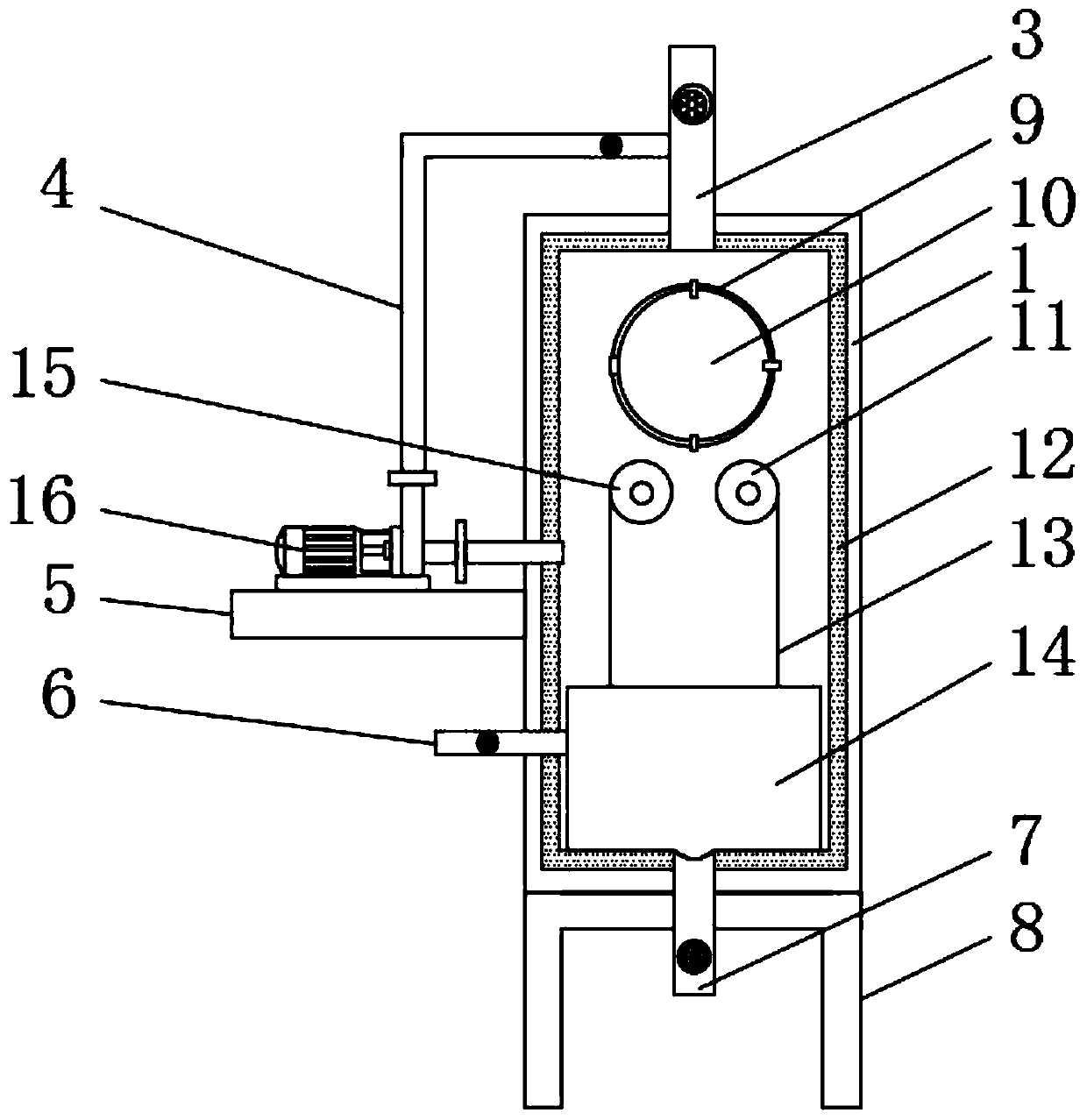

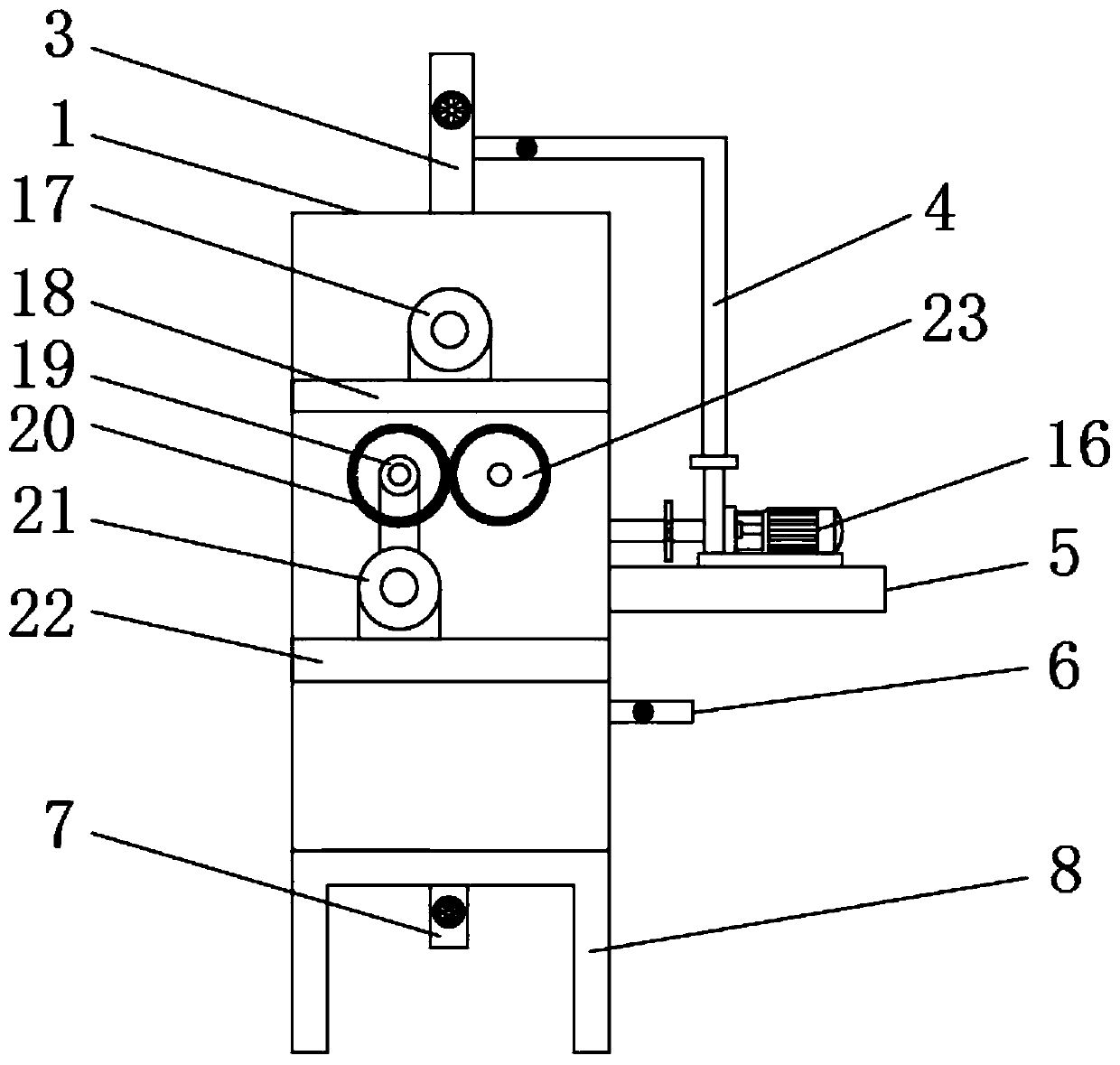

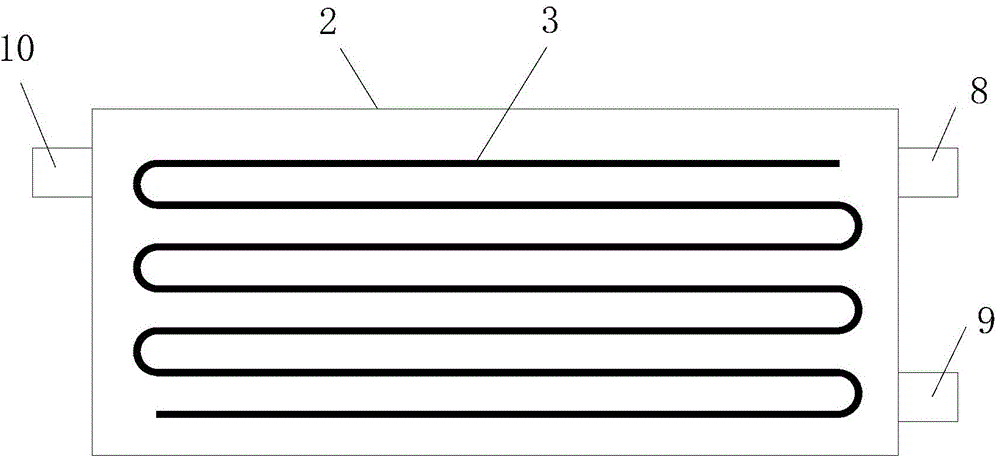

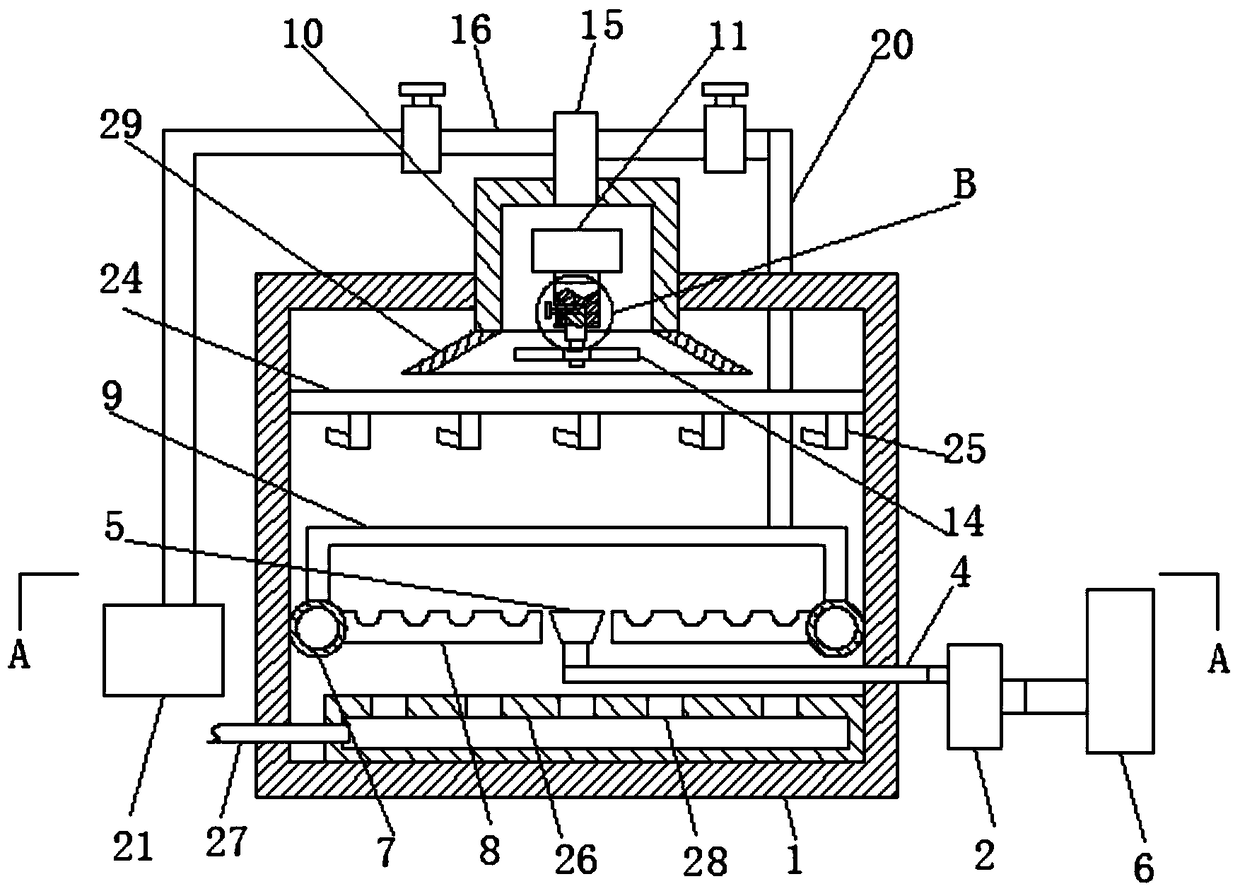

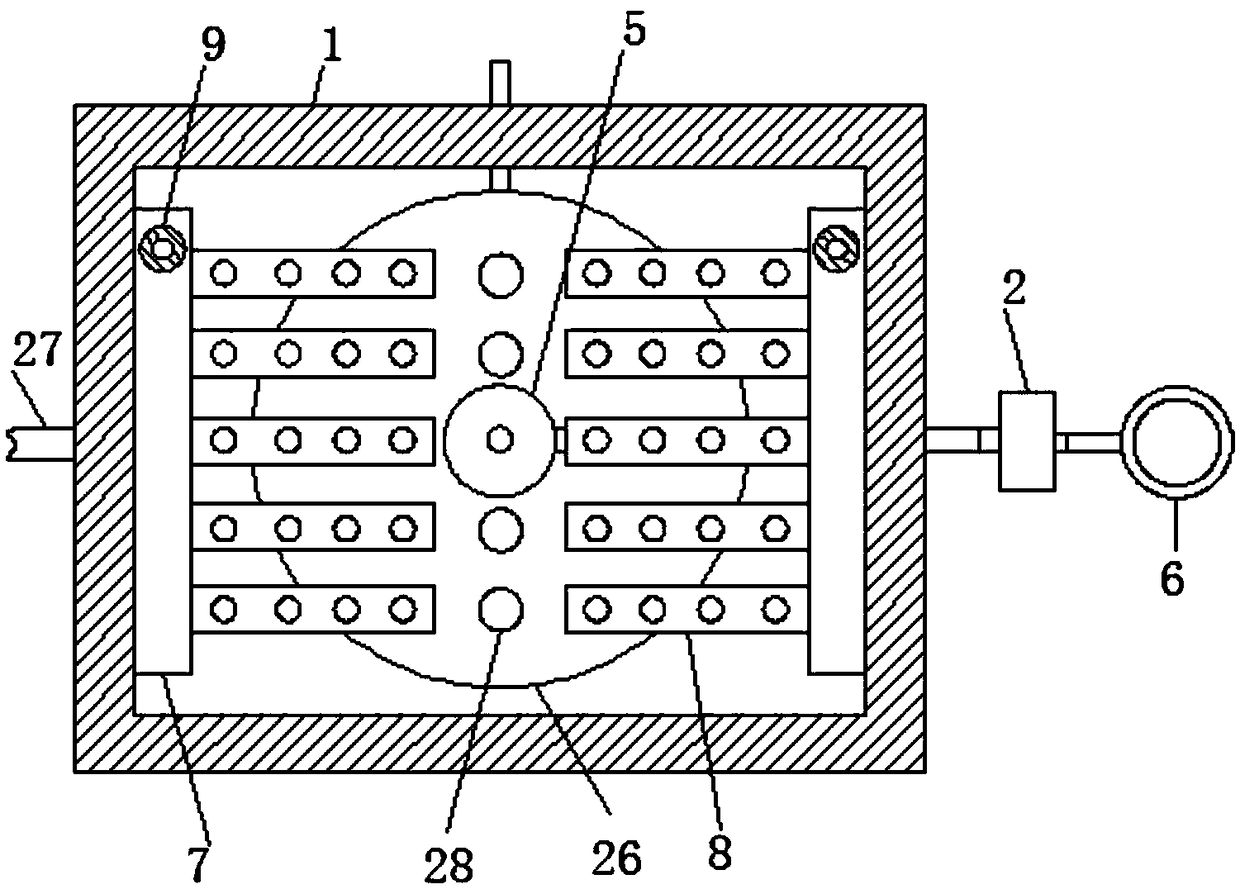

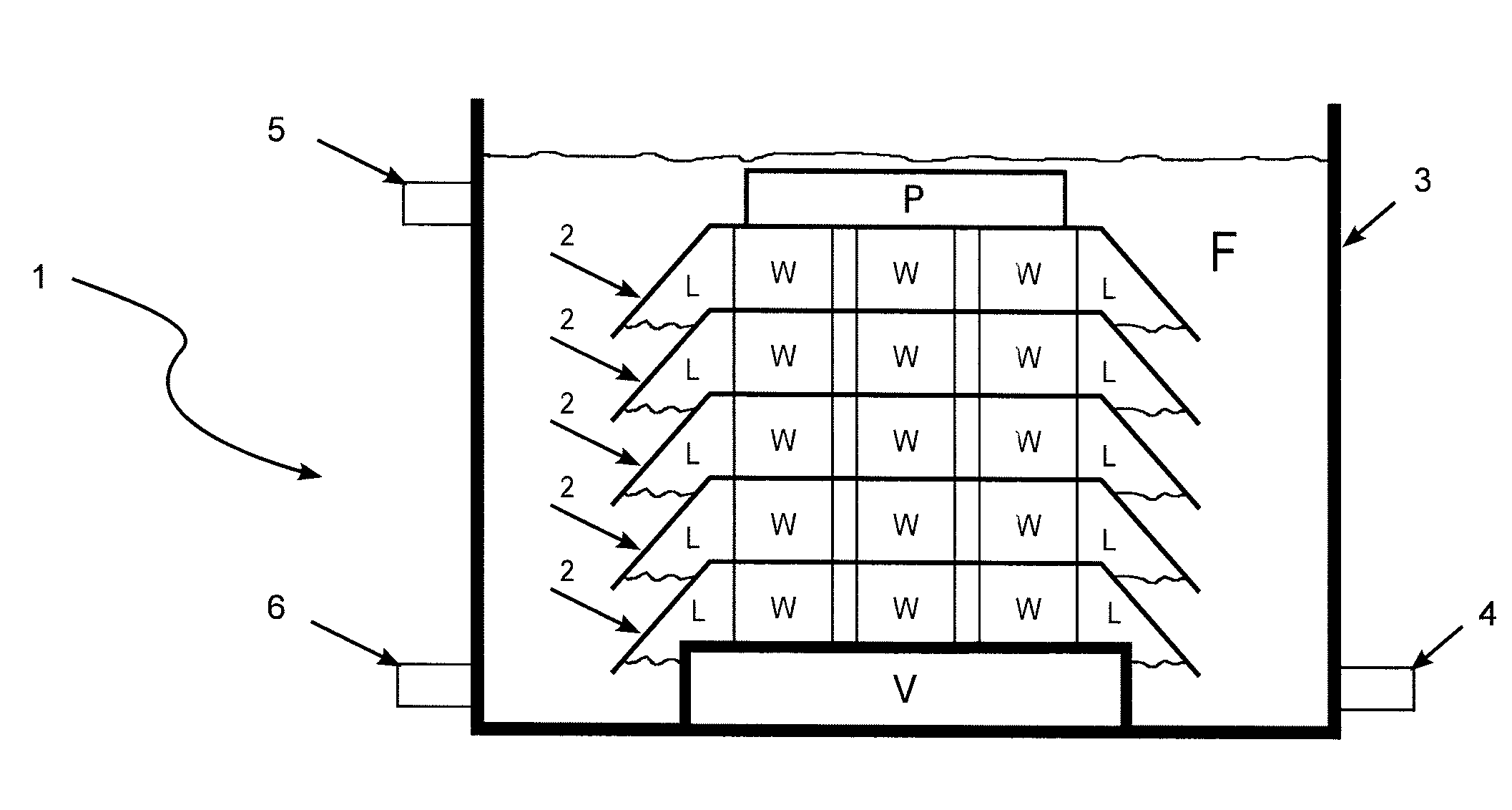

Air circulation system and waste gas recovery device of wood veneer smoking device

ActiveCN109015983AImprove the smoke effectFully contactedVapor phase impregnationWood impregnation detailsWood veneerSpray nozzle

The invention relates to the technical field of wood veneer dyeing and discloses an air circulation system and a waste gas recovery device of a wood veneer smoking device. A box with an open end and awater pump are involved. One side of the box is rotationally connected with a box door matched with a box opening through hinges. One side of the box fixedly communicates with a reagent feed pipe. One end of the reagent feed pipe extends into the box and is fixedly connected with a spray nozzle. An opening of the spray nozzle faces upwards. The other end of the reagent feed pipe extends to the outside of the box and is fixedly connected with a water outlet end of the water pump. A reagent barrel is arranged on one side of the water pump. A water inlet end of the water pump is fixedly connected with a reagent guide pipe. One end of the reagent guide pipe fixedly communicates with the reagent barrel. Two opposite vertical inner side walls of the box are fixedly connected with first ventilation pipes correspondingly. The two first ventilation pipes are arranged symmetrically. According to the air circulation system and waste gas recovery device of the wood veneer smoking device, a smoking reagent can fully react with wood veneer, the working efficiency is improved, and waste gas can be recovered conveniently.

Owner:JIASHAN JIUSHUN WOOD CO LTD

Modified wood fibres for manufacture in composites

InactiveUS20160122440A1Reduce materialQuality improvementVapor phase impregnationWood impregnation detailsCelluloseWood fibre

Owner:CC WOOD

Construction technology for steel plate modified fast-growing poplar

ActiveCN107363956AChange compressive strengthChange modulus of elasticityWood treatment detailsThermal wood treatmentSheet steelAdhesive

The invention belongs to the technical field of fast-growing wood modification and especially relates to a construction technology for steel plate modified fast-growing poplar. The construction technology comprises the following steps: a) selecting materials; b) cutting; c) deeply processing; d) airing; e) thermally modifying; f) drying; g) shearing; h) preparing a structural adhesive; i) dipping; j) combining; k) maintaining. Compared with the prior art, the construction technology for steel plate modified fast-growing poplar, provided by the invention, has the advantages and positive effects that the methods for processing, bonding, maintaining, pre-pressing and post-processing the fast-growing wood through the steel plate, structural adhesive and a series of construction technologies are adopted for modifying, so that the mechanical properties, such as compressive strength, elasticity modulus, deformation rate and anti-seismic property, of the fast-growing poplar can be changed and the fast-growing poplar can meet the use requirement of the architectural structure components (columns, beams, plates and walls).

Owner:SHANDONG XIEHE UNIV

Method for treating lignocellulosic material

InactiveUS20060013957A1Easy to fixAvoid leachingPretreated surfacesThermal wood treatmentCellulosePreservative

A method for heat treating lignocellulosic material with a water-soluble preservative, such as preferably borate, involves the modification of the lignocellulosic material by heat to a moisture content of 0 to 5%, and preferably as close as possible to 0%. The thermo-treatment of the lignocellulosic material drives out not only free extra cellular water but also the intercellular and intracellular water. The process of modification by heat effectively kills the cells, permanently altering their cellular structure, and locking or fixing the preservative in the lignocellulosic material so that the water-soluble preservative does not leach out of the treated lignocellulosic material in the presence of rain water.

Owner:ROY JACQUES

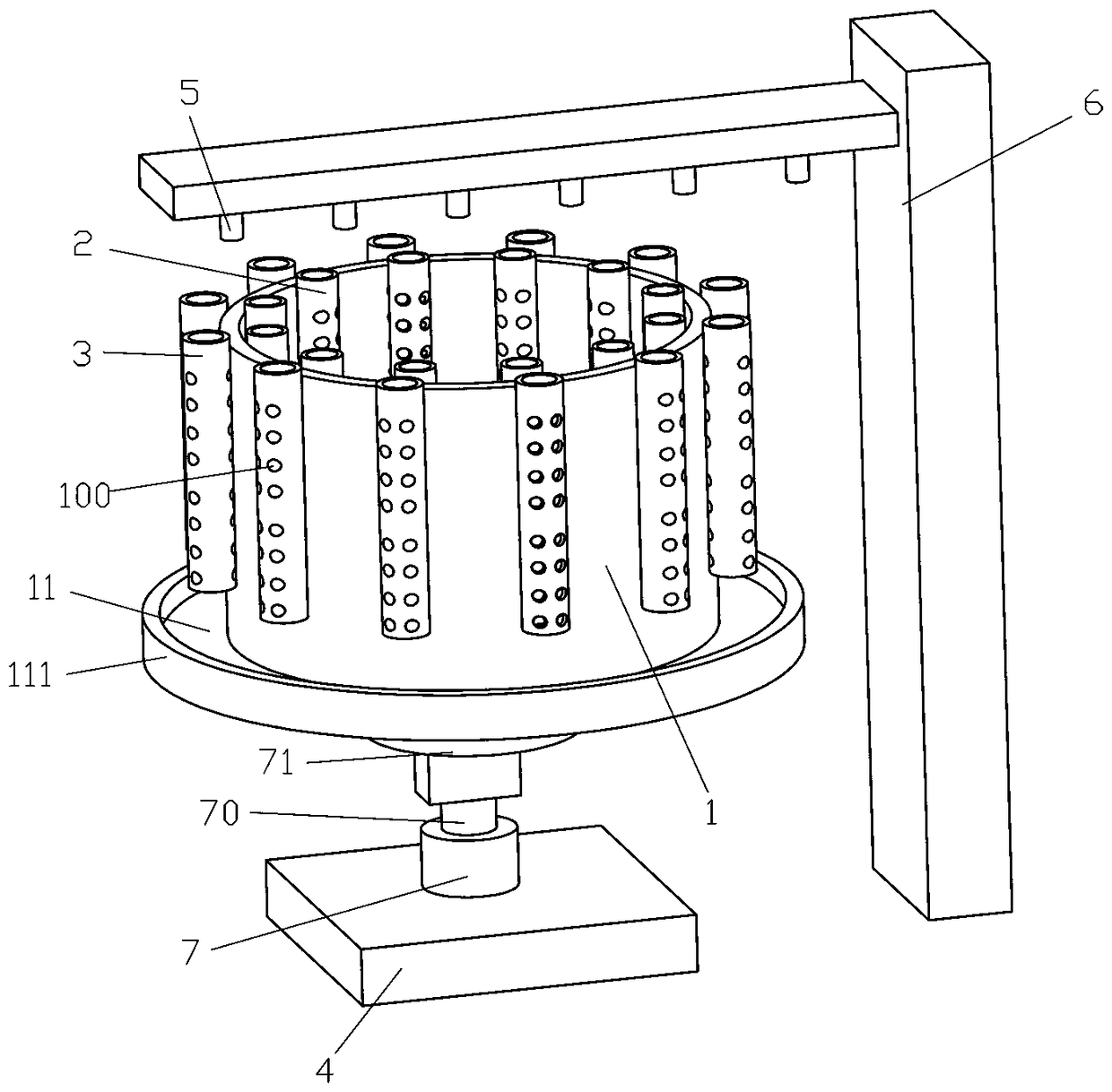

Bamboo batten stewing device

InactiveCN108189182AImprove efficiencyStable internal performancePlant material mechanical workingVapor phase impregnationBattenBiomedical engineering

The invention relates to the technical field of processing of bamboo products, in particular to a bamboo batten stewing device. The bamboo batten stewing device comprises a cylindrical cylinder body provided with an upward opening; the inner wall of the cylinder body is equipped with a plurality of inner cylinders, wherein each inner cylinder is used for placing bamboo battens and is provided withan upward opening; the outer wall of the cylinder body is equipped with a plurality of outer cylinders, wherein each outer cylinder is used for placing the bamboo battens and is provided with an upward opening; the cylinder body is installed on a base plate; and steam injection pipes are arranged above the cylinder body. The bamboo batten stewing device is high in efficiency and greatly improvesthe performances of the bamboo battens.

Owner:柯华平

Environmentally-friendly antiseptic wood manufacturing method with biomass gas as heating medium

InactiveCN104942946AImprove anti-corrosion performanceLow rate of decay and weight lossWood treatment detailsWood dampingMixed gasHeat treated

The invention provides an environmentally-friendly antiseptic wood manufacturing method with biomass gas as a heating medium, and relates to the antiseptic wood manufacturing method. The method mainly solves the problems that an existing wood corrosion prevention method is harmful to the environment, and a traditional heat processing corrosion prevention method contaminates the environment and is higher in cost. The method includes the steps that 1, air seasoning is conducted on wood; 2, the dried wood is placed in a heat processing chamber; 3, biomass materials are placed in a combustor; 4, a heat processing kiln door is closed, an air inlet hole and an air outlet hole are opened; 5, the biomass materials are ignited; 6, the temperature rises, and steam is sprayed; 7, when the temperature rises and reaches the designated temperature, ternary mixed gas is kept in a kiln to make the biomass materials to be burned weakly; 8, heat preservation is conducted for 2.5 hours to 3.5 hours; 9, the temperature drops, steam is sprayed, and hydrating is conducted; 10, when the difference between the indoor temperature and the outdoor temperature of the heat processing chamber ranges from 25 DEG C to 35 DEG C, the wood is taken out, air seasoning is conducted on the wood, and the obtained dried wood is the environmentally-friendly antiseptic wood. According to the method, the biomass gas is adopted as the heating medium, no chemical preservative is added, the manufactured antiseptic wood is environmentally friendly, and environment protection is facilitated.

Owner:孙伟伦

Method for treating lignocellulosic material

InactiveUS7754284B2Easy to fixAvoid leachingPretreated surfacesThermal wood treatmentCellulosePreservative

Owner:ROY JACQUES

Method and device for drying, modelling and/or thermally modifying wooden parts

InactiveUS20140349012A1Improve thermal conductivityAvoid contactDrying solid materials with heatWood compressionEngineeringAmbient air

The invention relates to a method for drying, modelling and / or thermally modifying wooden parts, comprising the steps of: a) arranging the wooden parts in a bath; b) filling the bath with a liquid, for instance paraffin or (linseed) oil, wherein the wooden parts are sealed from the ambient air by the liquid; c) the liquid being heated for some time, preferably between 100° C. and 300° C., for the purpose of drying, modelling and / or thermally modifying the wooden parts; d) removing the wooden parts from the bath. The invention also relates to a device for performing the method according to the invention for drying, modelling and / or thermally modifying wooden parts, comprising:—a bath adapted to receive the wooden parts, which bath is intended to receive a liquid such as paraffin or (linseed) oil—heating means for heating the liquid. Finally, the invention relates to a covering and rack as parts of the device according to the invention.

Owner:LANGKAMP JAN

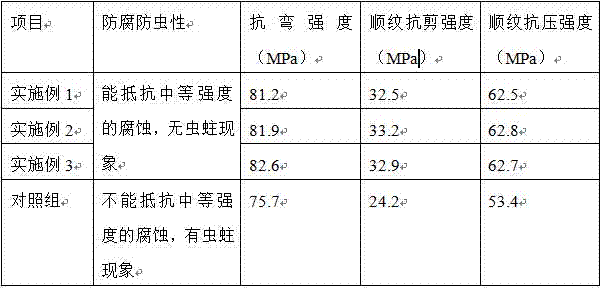

Processing method of pinus sylvestris wood

InactiveCN107297800ASolve the problem of large decline in mechanical propertiesImprove flexural strengthWood treatment detailsThermal wood treatmentPinus contortaHardness

The invention relates to the technical field of woodwork processing and manufacturing, and discloses a processing method of pinus sylvestris wood. The method comprises the following steps that (1) pinus sylvestris log is naturally aired to remove partial moisture, and then a degreaser acts on the wood to improve a degreasing effect, wherein the used degreaser is good in permeability, can bring out internal grease of pinus sylvestris, and minimizes an influence of further processing; (2) the wood is treated by a fumigant after grease cleaning, so that vermin-proof and moth-proof effects of the wood can be improved, and what is important is that effects of improving the bending strength, the bending elastic modulus and the parallel-to-grain compressive strength of the pinus sylvestris wood are exerted; and (3) the wood stabilized by steam is treated under high-temperature pressurization, so that an inclusion of the wood is volatilized, the equilibrium moisture content is reduced, the dimensional stability is greatly improved, the parallel-to-grain shear strength is improved to some extent, the possibility of deformation is low, the compressive strength and the hardness are improved, and an environmental protection property is good.

Owner:安徽三和工艺品有限公司

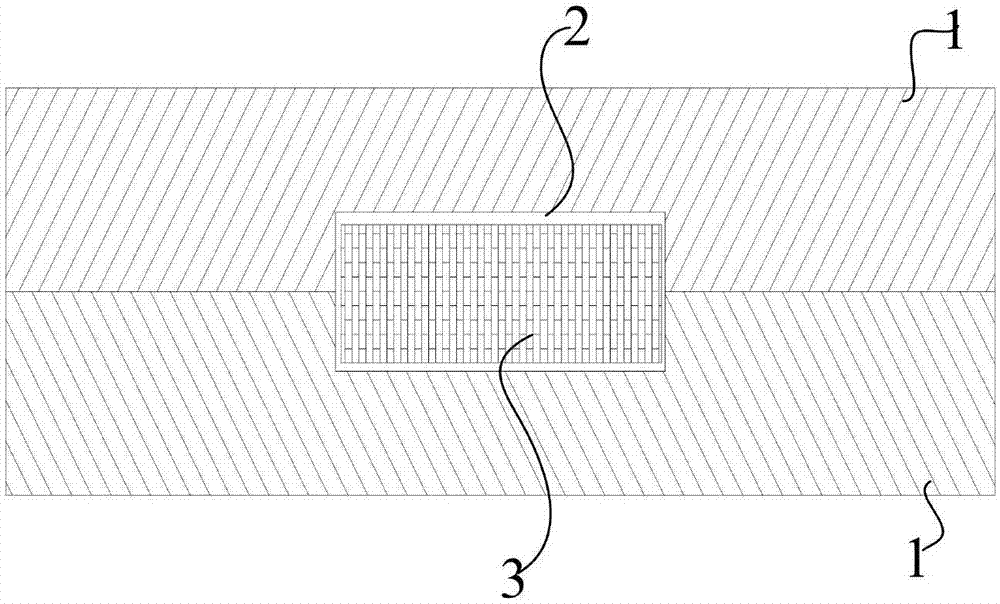

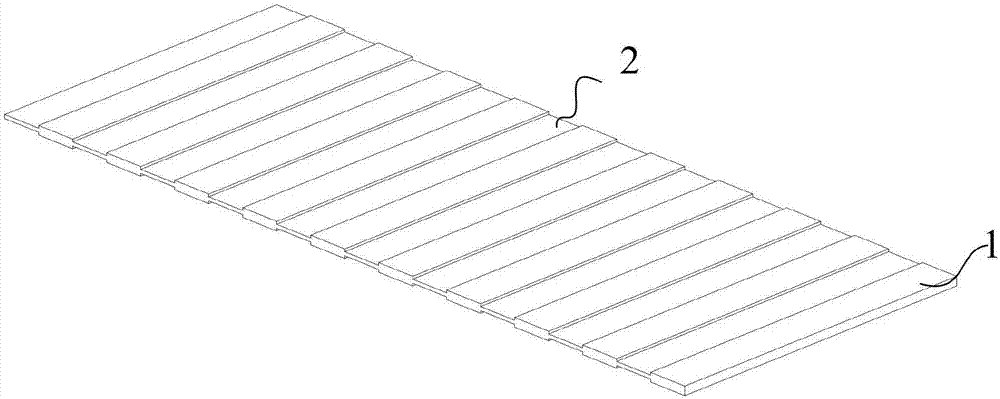

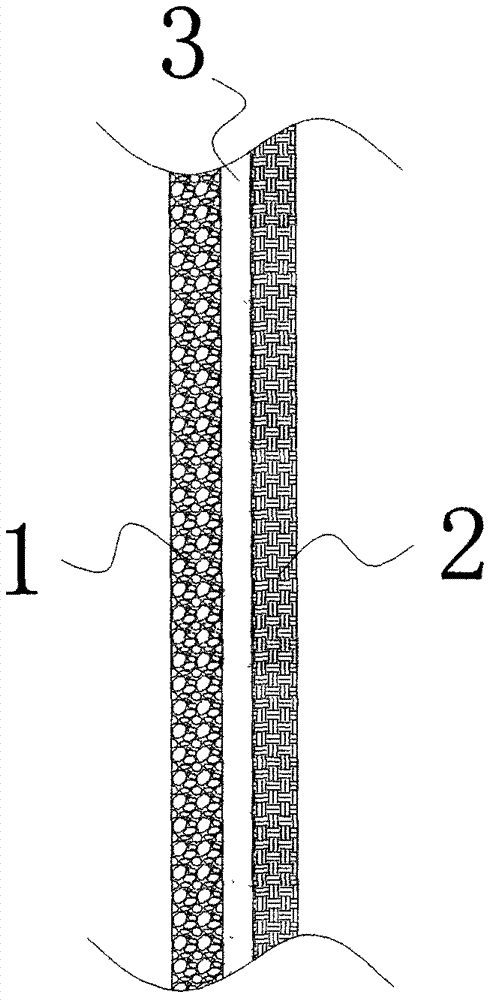

Indoor thermal-insulated and sound-insulated plate and preparation method thereof

PendingCN107081833ALow costEffective insulationCovering/liningsProfiling/shaping machinesEngineeringAcoustic board

Owner:黄达尔

Processing technique of amorpha fruticosa branches for wicker products

InactiveCN106078976ADoes not damage smoothnessHigh tensile strengthWood treatment detailsVapor phase impregnationFiberWrinkle skin

The invention provides a processing technique of amorpha fruticosa branches for wicker products. The processing technique of the amorpha fruticosa branches for the wicker products comprises the following steps that firstly, the cut fresh amorpha fruticosa branches are soaked in a liquor tank containing liquor at the temperature of 40-45 DEG C for 30-50 minutes, then completely washed with deionized water and then placed in the burning sun for 2-3 days; secondly, the amorpha fruticosa branches are placed in a steaming room to be fumigated for 1-2 hours with steam and then cooled to the temperature of 5-10 DEG C; thirdly, the amorpha fruticosa branches are placed in a closed container, vacuumization is conducted in the container till the pressure reaches 2-4 kPa, the pressure is increased to 2-3 MPa with nitrogen 2-3 days later, vacuumization is conducted till the pressure reaches 0.5-1 kPa 2-3 days later, and the closed container is opened 3-5 days later; and fourthly, the amorpha fruticosa branches are covered with plant ash at the temperature of 50-60 DEG C for heat preservation for 40-60 minutes, and then the amorpha fruticosa branches are taken out and blown clean with hot air at the temperature of 30-35 DEG C. According to the processing technique, the smoothness of the surfaces of the branches is not destroyed, crude fibers of the branches can be made compact and crossed to form wrinkles, and the tensile strength and yield strength of the branches are greatly improved; and in addition, the surfaces of the processed branches are free of shrinkage and pits, and the attractiveness is not affected.

Owner:阜南县黄岗利达工艺品有限公司

Mildew-proof processing method of wood slabs

ActiveCN107225639AImprove stabilityGood anti-mildew effectWood treatment detailsPretreatment apparatusFiberPulp and paper industry

The invention belongs to the technical field of processing of wood slabs, and particularly relates to a mildew-proof processing method of wood slabs. The method comprises the following steps: processing wood raw materials into the wood slabs with corresponding thicknesses; drying to ensure that the moisture is 30 to 35 percent; putting the wood slabs on a support frame; then putting the support frame into a sealed container to carry out treatment under a high-temperature high-pressure condition; then carrying out treatment by utilizing a vacuum condition. Compared with the prior art, the invention has the following advantages that the wood slabs are treated for a period of time under the high-temperature high-pressure condition, vacuum treatment is further carried out, moisture and oil grease inside the wood slabs are separated out, and proteins, starch and a structure of fibers are changed; moreover, mildew inhibitor is applied to the surface of the wood slabs, so that the stability of the wood slabs is greatly improved, the mildew-proof effect is good, the time is long, and the wood slabs are easily popularized and used.

Owner:安徽宏润工艺品有限公司

Manufacturing method for bamboo laminated timber

InactiveCN107088939AAvoid missingImprove rigidityRadiation/waves wood treatmentWood treatment detailsMaterials preparationEngineering

The invention discloses a manufacturing method for bamboo laminated timber. The manufacturing method comprises the process steps of material preparation, dark color mould-proof treatment, microwave treatment, drying, gluing, glue splicing, preservation, cutting and dividing, examining and grading, and repairing and packaging. The manufacturing method has the advantages that the through the bamboo laminated timber manufactured by the manufacturing method, the problems that the market lacks the bamboo laminated timber, and large-size eucalyptus wood is liable to cracking and distortion and is low in physical and mechanical performance are also solved, the good rigidity of bamboo is achieved, decorative boards and furniture materials are enriched, and the requirements of recycle or circular economy and environmental protection performance are met; and additional value of the bamboo and eucalyptus wood is increased, and good economic benefits and social benefits are achieved.

Owner:FUJIAN AGRI & FORESTRY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com