Surface treatment process for oak work boards and fumigation device thereof

A surface treatment and fumigation device technology, which is applied in wood treatment, wood treatment details, wood processing equipment, etc., can solve the problems of poor wood floor processing and finishing effects, increased oak cost, and prone to defective products, etc., to achieve rich benefits, The effect of reducing production cost and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: A surface treatment process for oak slabs. The method is to erect the oak slab above the ammonia water, and the ammonia water volatilizes to generate ammonia gas, and the ammonia gas fumigates the oak slab. The concentration of the ammonia water is 30%, the ambient temperature is kept at 30-50 degrees Celsius, and the fumigation time is 15-30 hours.

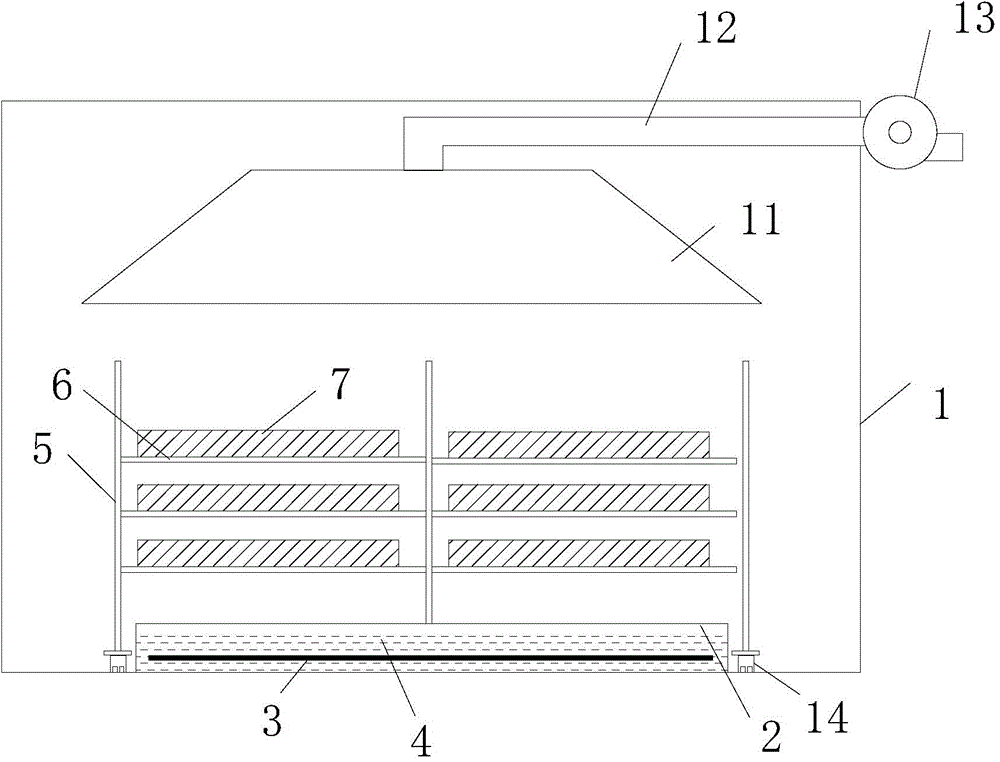

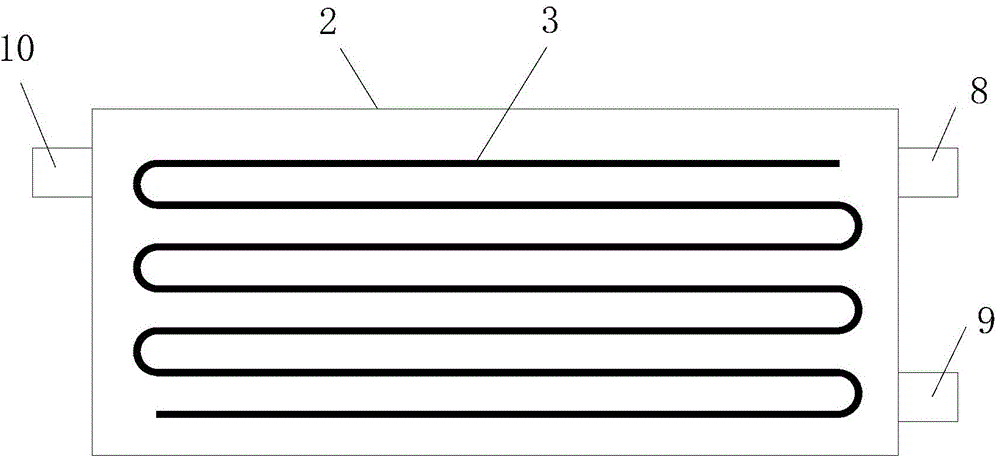

[0016] The fumigation device using the above process, if attached figure 1 And attached figure 2 As shown, it includes a box body 1, a water tank 2 is provided at the bottom of the box body 1, a heating wire 3 and ammonia water 4 are arranged in the water tank 2, a blank frame 5 is arranged above the water tank 2, and a grid shelf is arranged on the blank frame 5 Board 6, oak blank board 7 is arranged on grid shelf 6. The water tank 2 is provided with a liquid inlet pipe 8 and a liquid outlet pipe 9 through which the ammonia water enters and exits, and a regulating pipe 10 for adjusting the concentration o...

Embodiment 2

[0017] Embodiment 2: A surface treatment process for oak slabs. The method is to erect the oak slabs above the ammonia water, the ammonia water volatilizes to generate ammonia gas, and the ammonia gas fumigates the oak slabs. The concentration of the ammonia water is 45%, the ambient temperature is maintained at 40 degrees centigrade, and the fumigation time is 25 hours.

Embodiment 3

[0018] Embodiment 3: A surface treatment process for oak slabs. The method is to erect the oak slab above the ammonia water, the ammonia water volatilizes to generate ammonia gas, and the ammonia gas fumigates the oak slab. The concentration of the ammonia water is 20%, the ambient temperature is maintained at 35 degrees centigrade, and the fumigation time is 20 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com