Processing technology of mildew-proof insect-proof rattan- plaited handicraft

A processing technology and handicraft technology, applied in wood processing utensils, sugarcane machining, manufacturing tools, etc., can solve the problems of unsatisfactory anti-mildew effect, affecting the health of users, poor softening and humidifying effect, etc., so as to improve the anti-mildew effect. Anti-insect effect, high effective utilization rate, good penetration uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

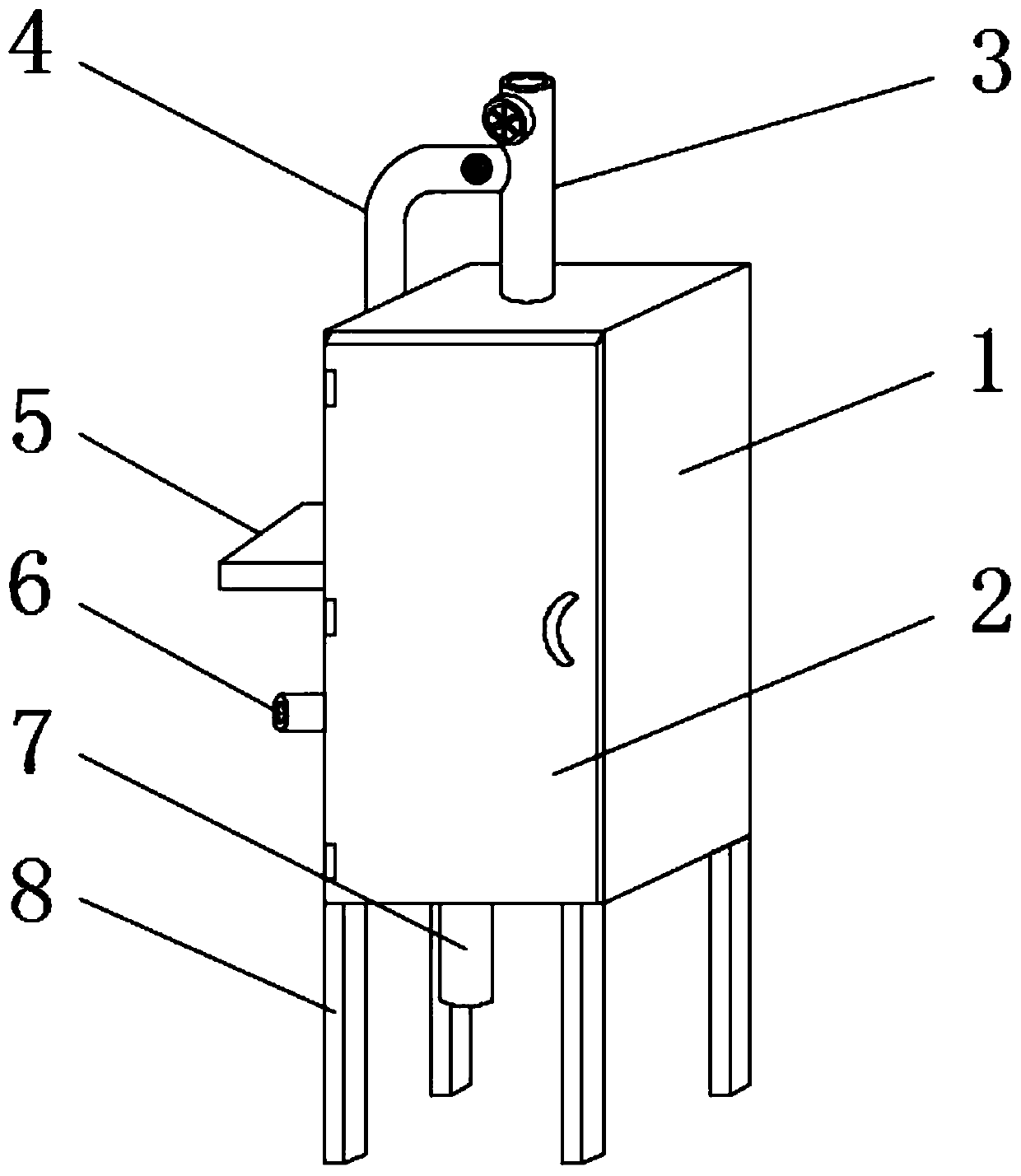

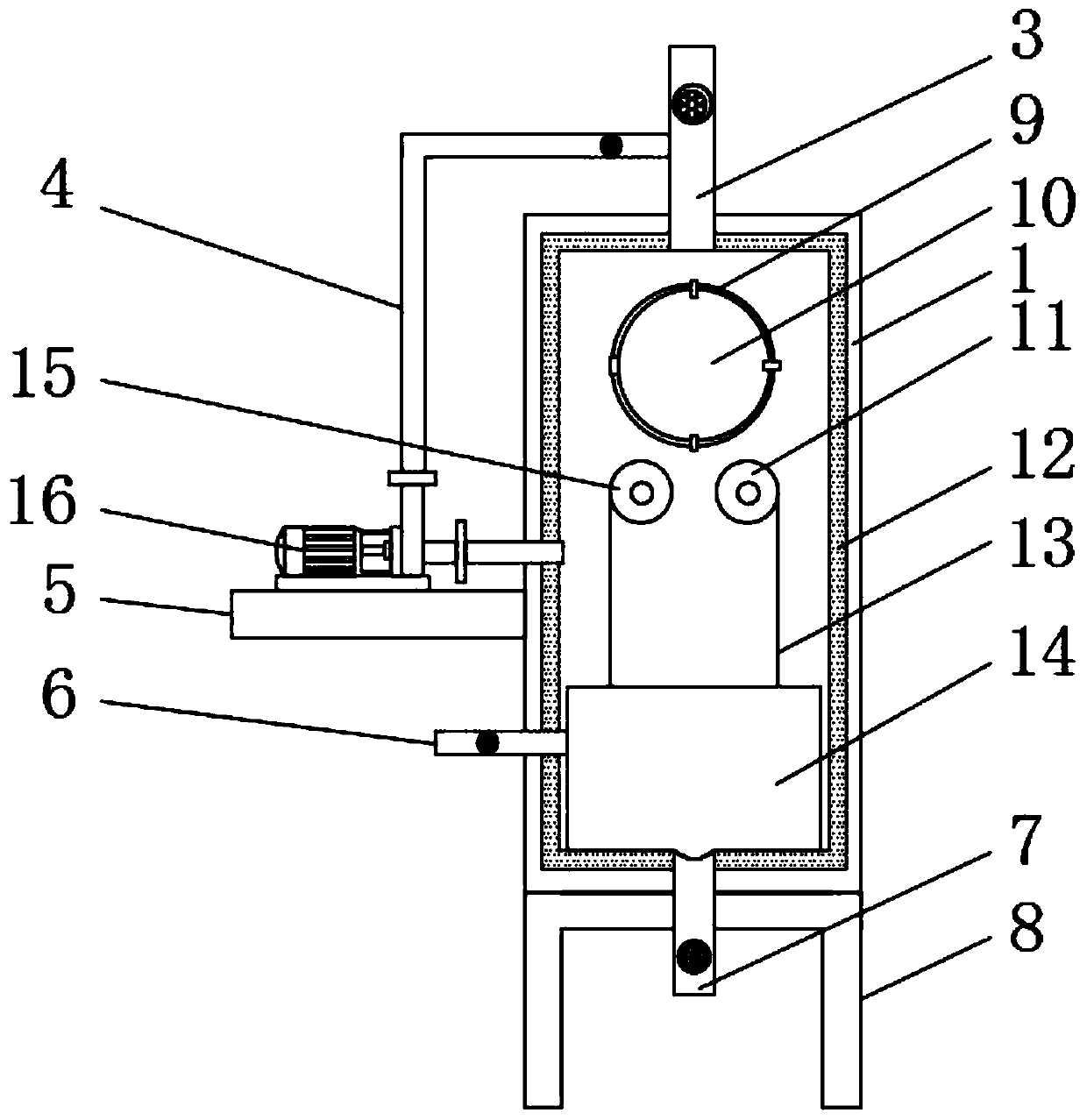

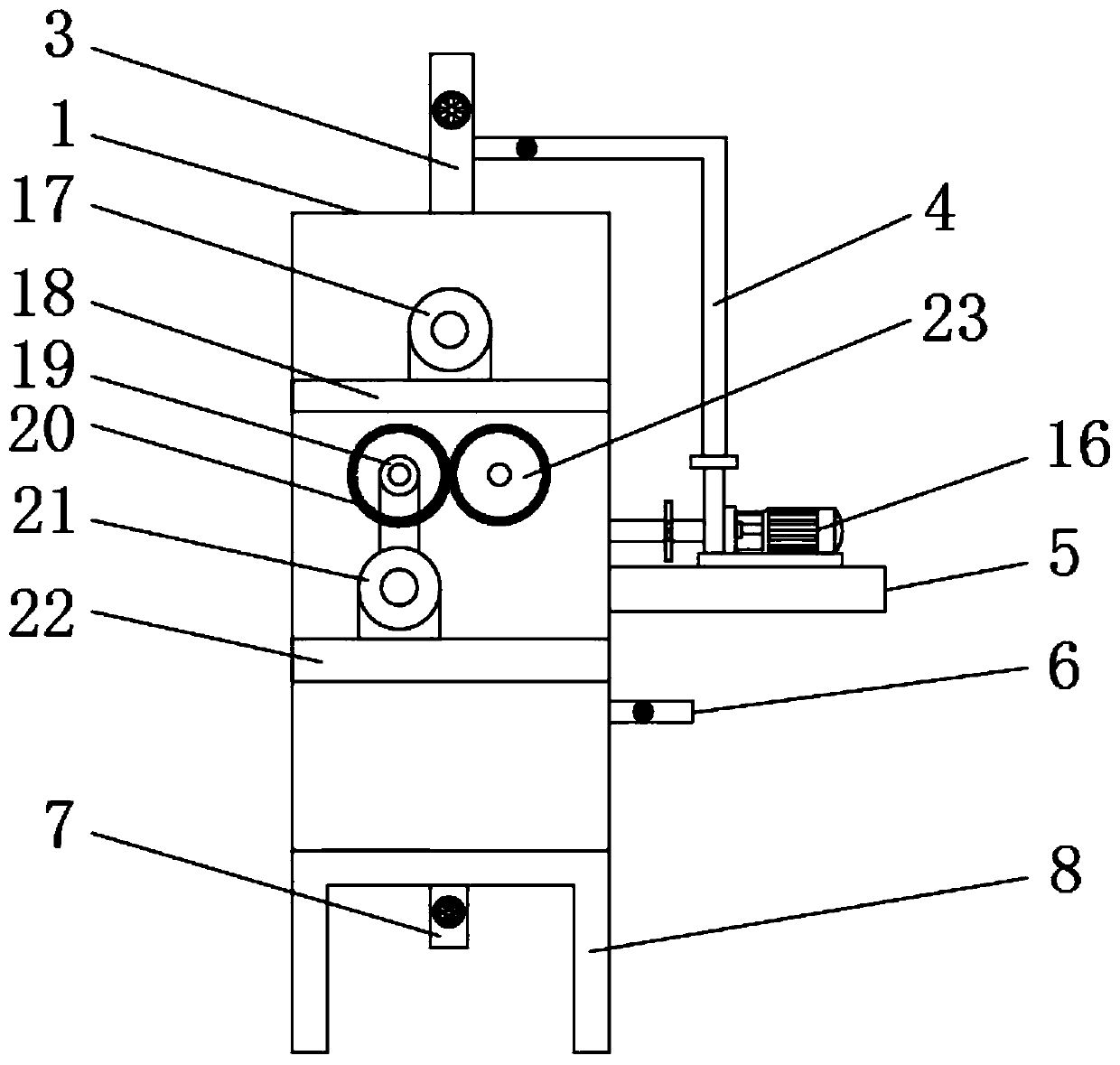

[0052] see Figure 1-8 As shown, the present embodiment is a processing technology of mildew-proof and insect-proof rattan handicraft, which is prepared by the following steps:

[0053] Step 1: Rattan treatment:

[0054] The rattan is felled, and the rattans that are felled are consistent from end to end, and 10-20 are bundled to obtain rattan bundles;

[0055] Insert the rattan bundles into the treatment solution, with the ends of the rattan facing upwards, and place them in the sun to dry for 3-6 hours;

[0056] After removing the leaves of the rattan, dry them with hot air. The drying is divided into three stages. In the first stage, the rattans are dried until they are 50% dry, and then put into the steam drum 9 in the steam softening device to keep the fragrance The liquid components in the mixture are directly added to the cooking tank 14, and the solid components in the fragrant mixture are placed in the hanging basket 26, and then moved to the cooking tank 14, and fr...

Embodiment 2

[0071] see Figure 1-8 As shown, the present embodiment is a processing technology of mildew-proof and insect-proof rattan handicraft, which is prepared by the following steps:

[0072] Step 1: Rattan treatment:

[0073] The rattan is felled, and the rattans that are felled are consistent from end to end, and 10-20 are bundled to obtain rattan bundles;

[0074] Insert the rattan bundles into the treatment solution, with the ends of the rattan facing upwards, and place them in the sun to dry for 3-6 hours;

[0075] After removing the leaves of the rattan, dry them with hot air. The drying is divided into three stages. In the first stage, the rattans are dried until they are 50% dry, and then put into the steam drum 9 in the steam softening device to keep the fragrance The liquid components in the mixture are directly added to the cooking tank 14, and the solid components in the fragrant mixture are placed in the hanging basket 26, and then moved to the cooking tank 14, and fr...

Embodiment 3

[0090] see Figure 1-8 As shown, the present embodiment is a processing technology of mildew-proof and insect-proof rattan handicraft, which is prepared by the following steps:

[0091] Step 1: Rattan treatment:

[0092] The rattan is felled, and the rattans that are felled are consistent from end to end, and 10-20 are bundled to obtain rattan bundles;

[0093] Insert the rattan bundles into the treatment solution, with the ends of the rattan facing upwards, and place them in the sun to dry for 3-6 hours;

[0094] After removing the leaves of the rattan, dry them with hot air. The drying is divided into three stages. In the first stage, the rattans are dried until they are 50% dry, and then put into the steam drum 9 in the steam softening device to keep the fragrance The liquid components in the mixture are directly added to the cooking tank 14, and the solid components in the fragrant mixture are placed in the hanging basket 26, and then moved to the cooking tank 14, and fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com