Patents

Literature

249results about How to "Insect-resistant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment protecting wood wax oil

InactiveCN101550316ANo pollution in the processMeet environmental protection requirementsCoatingsWood impregnation detailsWaxVegetable oil

The present invention relates to an environment protecting wood wax oil which comprises the following main components by weight: 75-85 parts of vegetable oil, 0.1-1 part of vegetable wax or animal wax, 11-22 parts of rosin resin, 1-2 parts of drier and 0.1-1 part of cosolvent. The preparing method of the wood wax oil comprises the following steps: heating and melting the vegetable oil and wax mixing system, reducing the temperature and adding other materials, and mixing to uniform for obtaining the wood wax oil. The wood wax oil related to the invention can totally penetrate into the wood. The wood wax oil of the invention is remarkably different with the traditional paint with the existence of paint skin. The surface of wood wax oil has an open texture effect. The different woods can represent different real tactile sensation. Furthermore the wood with the environment protecting wood wax oil can be partially restored and retrofitted without mark. The wood wax oil can preserve various excellent performances of wood and effectively prevent the seasoning cracking of wood. The wood is caused to possess the excellent performances of ventilation, drying, corrosion resistance, worm resistance, flame resistance, etc. The using quality of wood can be increased comprehensively.

Owner:TIANJIN XIANDAIREN RE EMPLOYMENT SERVICE

Wood wax oil for protecting lumber and preparation technique thereof

InactiveCN101407068AStay flexibleKeep greenCoatingsWood impregnation detailsVegetable oilHazardous substance

The invention discloses wood wax oil for protecting wood and a method for preparing the same. The raw materials of the wood wax oil comprise vegetable oil and wax, and the wood wax oil is characterized in that the compositions of the raw materials of the wood wax oil comprise vegetable oil, animal or vegetable wax, ferric oxide and a catalyst. The wood wax oil and the preparing process can protect the wood completely, can keep the elasticity and environmental protection performance of wood, can prevent the wood from cracking effectively and enable the wood to have various comprehensive properties such as drying, as well as corrosion, insects, moisture, mildew, termite, anti-cracking, and fire-retardant resistance, and the like, and meet all requirements of environmental protection, and does not to release any harmful substance during long-term use. The preparing process of the wood wax oil is simple and no organic solvent is needed to be added, thereby avoiding the incorporation of harmful substances.

Owner:张海林

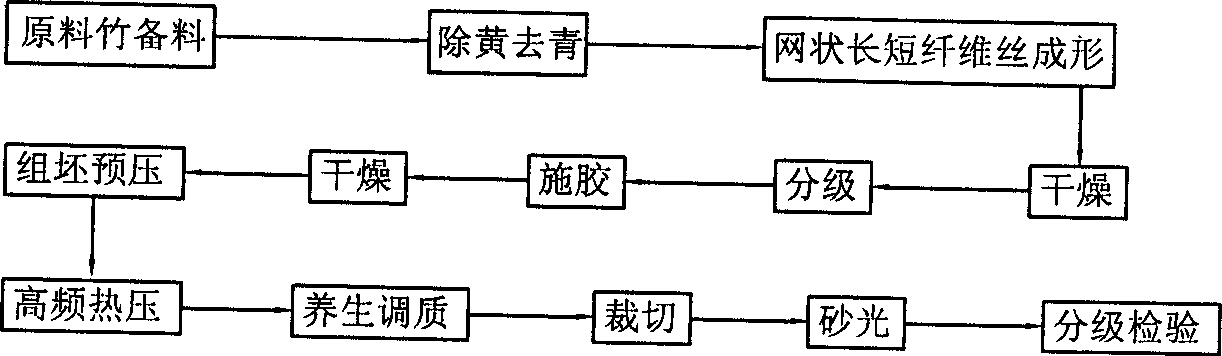

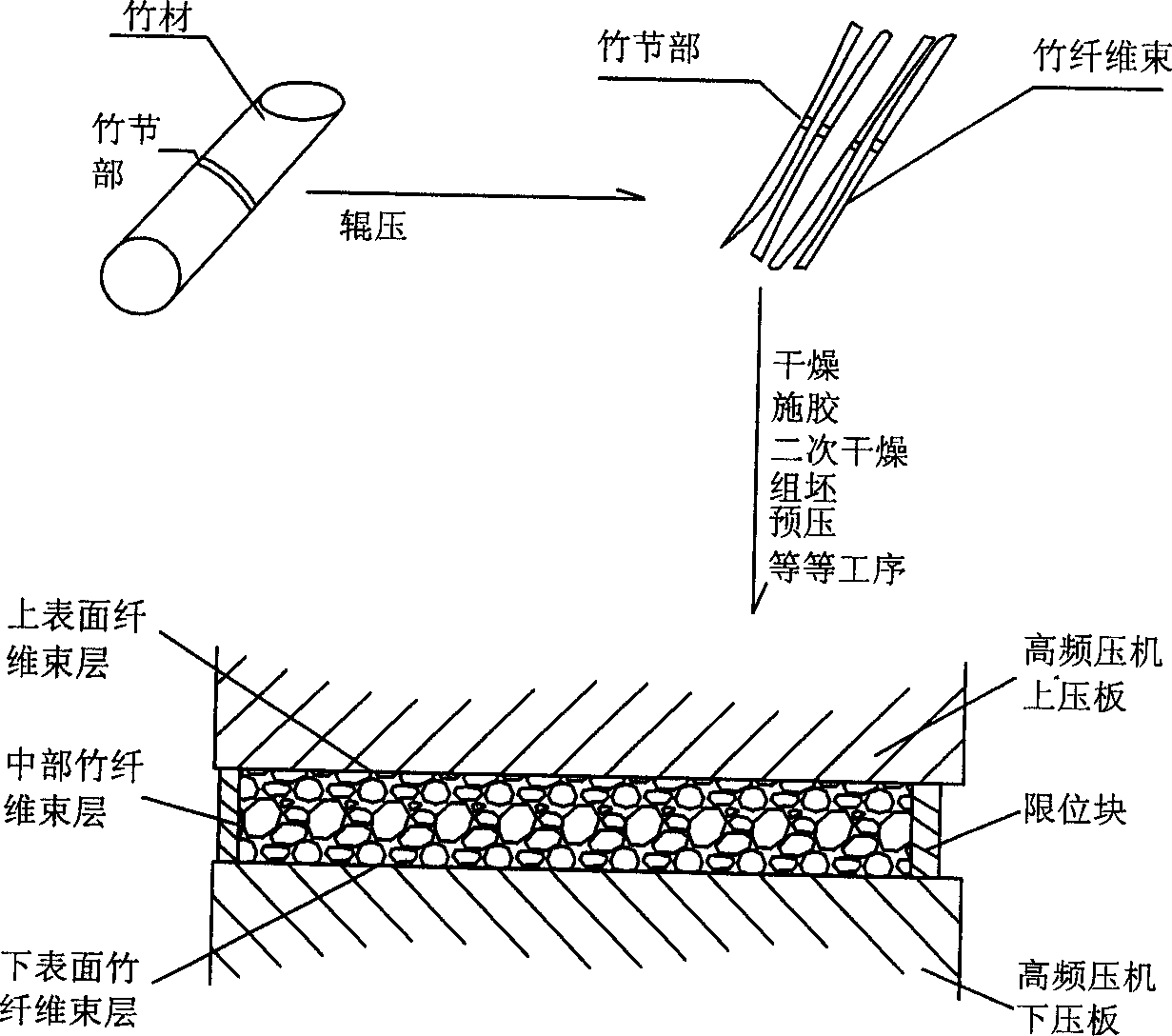

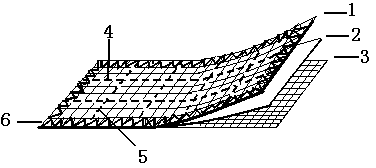

Reinforced composite bamboo board and its manufacturing method

InactiveCN1769621ALight weightEnvironmentally friendlyWood working apparatusDomestic articlesSurface layerFiber bundle

The invention discloses a strengthening composite bamboo board and preparing method, which consists of net bamboo fiber bundle layer and surface layer, wherein the net bamboo fiber bundle layer is composed of parallel grain and cross grain. The invention is prior to wood fiber board, which prevents the common bamboo board (bar structure of multiple-layer parallel adhesion) from deforming and uneven strength.

Owner:SICHUAN SHENGDA FOREST PROD IND GRP CO LTD

Flame retardant polystyrene foamed hard wood-imitating material and preparation method thereof

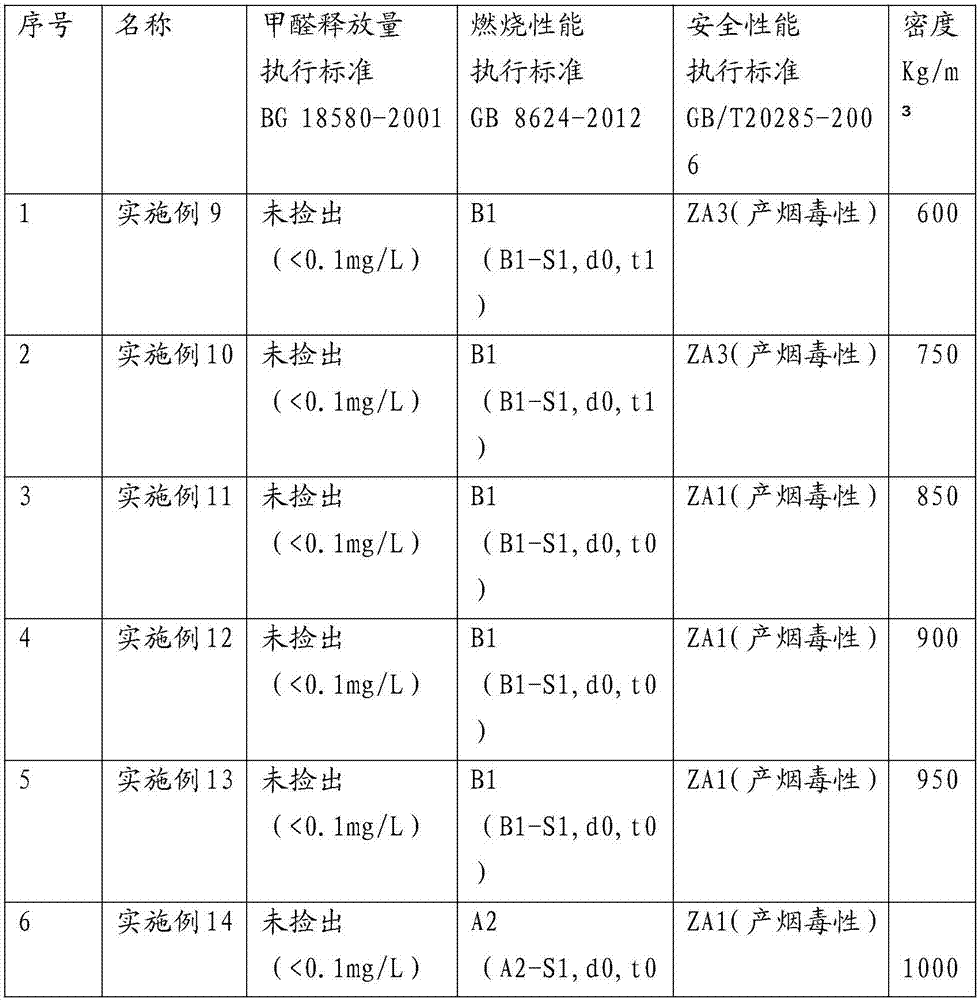

The invention discloses a flame retardant polystyrene foamed hard wood-imitating material and a preparation method thereof. The hard wood-imitating material comprises, by weight, 50-70 parts of recovered polystyrene, 55-75 parts of high impact polystyrene, 35-45 parts of flame retardant masterbatch for a core layer, 30-40 parts of special flame retardant masterbatch for a surface layer, 0.5-0.9 parts of a foaming agent, 1-4 parts of a flexibilizer, 0.1-0.5 parts of a plasticizer, and 0.5-0.9 parts of a coloring agent. The flame retardant polystyrene foamed hard wood-imitating material of the present invention has high intensity flame retardation, is a hard foamed wood-imitating material with certain toughness and low density, and simultaneously has the advantages of fireproofing, waterproofing, oil resistance, insect prevention, mildew resistance, weatherproofing, light weight and the like.

Owner:SHANGHAI INTCO INDUSTRIES CO LTD +1

Production method of kapok fiber spunlaced nonwoven fabric

InactiveCN103205862AKeep natural propertiesMaintain propertiesNon-woven fabricsVegetal fibresKapok fiberPulp and paper industry

The invention belongs to the technical field of weaving, in particular to a production method of kapok fiber spunlaced nonwoven fabric. The method includes: pretreating kapok fiber to improve spinnability; using a weighing curtain feeder to feed kapok fiber into a blowing-carding device for opening, blending and purification; using an induced fan to collect web in a blowing-carding machine to feed into a tiny dust removing device for further dust removing and opening; connecting the tiny dust removing device with a spunlaced line carding machine, carding the fiber into web on the spunlaced line carding machine, cross lapping, spunlacing to form fabric, coiling, degreasing and bleaching, drying and slitting to obtain the finished product. The method is safe, environment-friendly, energy-saving, efficient, high in automation level, and advanced in spunlaced kapok nonwoven fabric weaving, and various characteristics of fiber raw materials are protected effectively.

Owner:蒋海彦

Flame retardant environmentally friendly adhesive and producing method of plant fiberboard

ActiveCN105331294ARaw materials are easy to getFlame retardantNon-macromolecular adhesive additivesWood working apparatusFire retardantFiberboard

The present invention provides a flame retardant environmentally friendly adhesive, and the raw materials comprise magnesium sulfate, magnesium chloride, water, magnesium oxide, sodium dihydrogen phosphate, boric acid, and methyl cellulose. The flame retardant environmentally friendly adhesive is a formaldehyde-free environmentally friendly inorganic adhesive, not only has flame-retardant effect, but also can make a plant fiberboard highly stable in fiber structure and high in mechanical properties, and also allows the plant fiberboard to have waterproof, moistureproof, fireproof, rot-resistant, pest control and other functions; in addition, the flame retardant environmentally friendly adhesive has readily available raw materials, and cheap in price, so that the production cost of the flame retardant environmentally friendly adhesive is relatively low. The present invention also provides a producing method of the plant fiberboard by use of the flame retardant environmentally friendly adhesive.

Owner:河南国信联投环保科技有限公司

Wood protecting agent and method of producing the same

The invention discloses a wood additive and making method to solve the problem of low solubility and bad penetrability of boron system compound as wood protective in the water, which is made of 100wt% borate and 0. 1-5wt% composite surface activator. The making method comprises the following steps: 1. blending boric acid and borax evenly to place in the 25-75 deg. c environment to do solid-phased reaction; drying; obtaining the borate; 2. blending the composite surface activator and borate evenly to obtain the wood protective. The invention has the function of preservation, insect protection, termite-resistant, flame-proof and smoke inhibition, which doesn't harm human and animals without influencing the appearance, dynamics and manufacturing property of the wood.

Owner:NORTHEAST FORESTRY UNIVERSITY

Sterilization processing method of rattan plaited article materials

InactiveCN104476639ASimple processing methodInsect-resistantBiocideWood treatment detailsMildewSoftening

The invention provides a sterilization processing method of rattan plaited article materials, and belongs to the technical field of rattan plaited article production. The sterilization processing method comprises following steps: rattan is harvested, and each 10 to 20 strips are bonded with a consistent direction so as to obtain one bouquet of rattan; the bonded rattan bouquets are immersed in a processing solution with the end tip of rattan upward, and are exposed to sunlight for 3 to 6 h; leaves of the rattan bouquets are removed, the rattan bouquets are dried with hot air, wherein at a first stage, the rattan bouquets are dried to medium dry, and are subjected to moisture retention for 30 to 50 min for a first time with softening steam, at a second stage, the rattan bouquets are dried to be sixty percent dry, and are subjected to moisture retention for 1 to 3 h for a second time with softening steam, and at a third stage, the rattan bouquets are dried to be eighty percent dry; and the processed rattan bouquets are stored at shade places for natural air drying. According to the sterilization processing method, the fresh rattan is processed firstly; the sterilization processing method is simple, is capable of realizing sterilization, insect prevention, moth prevention, and mildew and rot prevention, and prolonging service life of rattan plaited articles; the obtained steam used for softening is capable of realizing rattan softening, and volatile substances contained by the steam is capable of realizing sterilization and fragrance improvement of rattan.

Owner:ANHUI HONGFU CRAFTS

Bamboo chopstick processing method

InactiveCN105291238ASave energyGuaranteed anti-corrosion performanceWood treatment detailsReed/straw treatmentSulfurMildew

The invention discloses a bamboo chopstick processing method. The bamboo chopstick processing method comprises the following steps: a bamboo is sawn to a bamboo cylinder; the bamboo cylinder is processed to a bamboo piece, and is processed to a bamboo chopstick blank; one end of the bamboo chopstick blank is sharpened; the wet disinfection and the blenching are performed; the preservative treatment is performed; the carbonizing treatment is performed; the drying and the disinfection are performed; the polishing is performed; and the sorting and the packing are performed. Compared with the mildew prevention and the disinfection of chopsticks smoked by sulfur and boiled by hydrogen peroxide, the bamboo chopstick processing method is safer and more reliable; as ozone cannot leave any poisonous substances on the chopsticks, and an ozone disinfection method saves more energy, the excellent mould preventing, bleaching and disinfecting effects can be obtained only by consuming less electric energy without needing heating; bamboo chopsticks are dip in paraffin liquid or tung oil under high temperature, so that the corrosion preventing effect of the chopsticks in later use is effectively guaranteed; the bamboo chopsticks prepared by the method has such performances as corrosion prevention, insect prevention, mildew prevention and damp prevention, and such natural colors as faint yellow and brown are given to the bamboo chopsticks; and the bamboo chopstick processing method increases the mechanical degree, quickens the production speed, and improves the production efficiency.

Owner:安徽泓浩竹科技股份有限公司

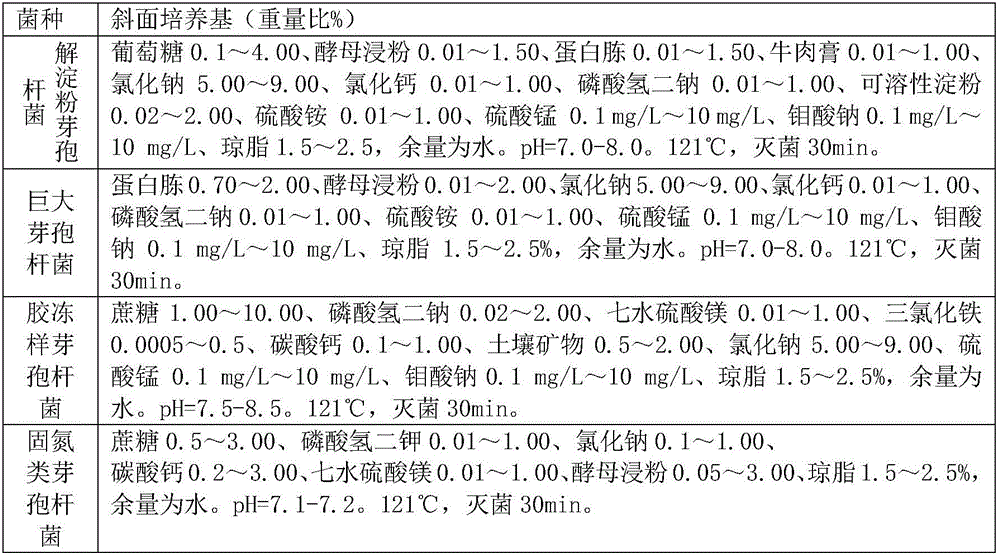

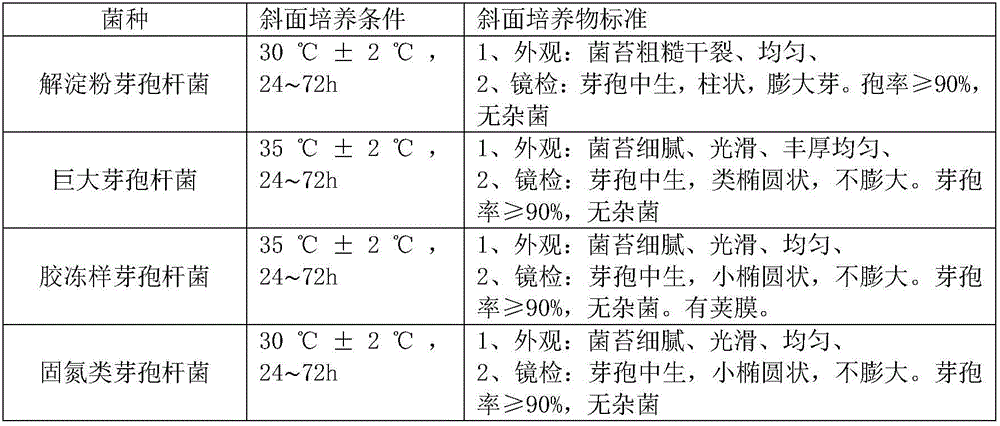

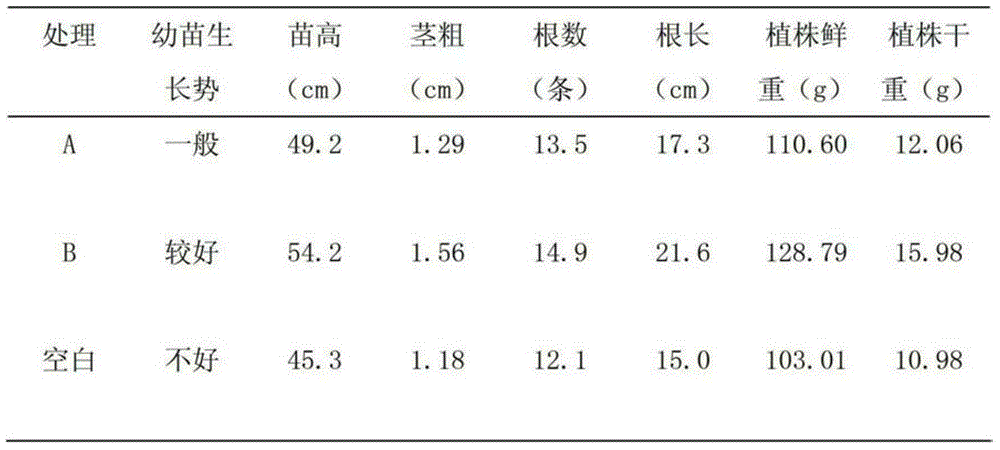

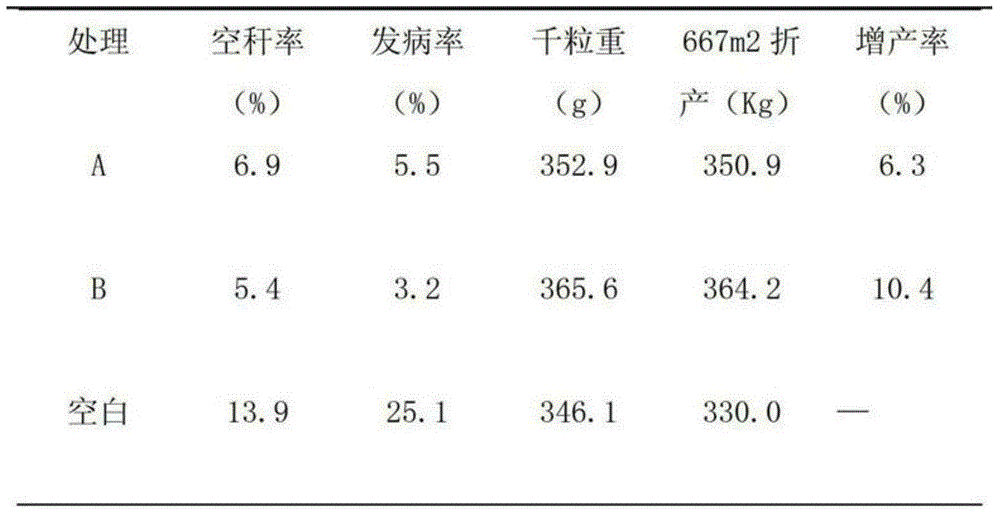

Compound inoculant for improvement of saline-alkali soil and preparation and application of same

InactiveCN106367074AFully differentiatedIncrease fruitingBiocideAgriculture tools and machinesAlkali soilFarmyard manure

The invention relates to a compound inoculant for improvement of saline-alkali soil and particularly provides a novel compound inoculant for improvement of saline-alkali soil, and preparation and applications of same. Bacillus amyloliquefaciens, bacillus megatherium, bacillus mucilaginosus and paenibacillus azotofixans are fermented respectively to obtain fermentation liquids, which are then mixed with a carrier respectively according to certain volume-weight ratio (V / kg); the mixtures are dried at low temperature and finally are compounded according to ratio. The compound inoculant is a powder agent, wherein the microorganisms therein are functional bacteria, and the inoculant is high in living bacteria number and especially contains high-activity metabolic products, so that the compound inoculant is suitable for being mixed with a base fertilizer, especially high-quality farmyard manure, for use. When being applied in soil, high environment adaption capability and high reproduction speed are achieved. The compound inoculant can increase beneficial microbial flora in rhizosphere and rapidly decompose organic substances for absorption and utilization by plants, can reduce the alkalinity of soil, improve fertility of soil and improve the water permeability and retention and breathability properties of the soil, and can accelerate growth of root system and prevent spreading of soil-borne diseases, thereby maintaining ecological balance, reducing cost and improving the saline-alkali soil.

Owner:北京康缘益生生物科技有限公司

Biological compound seed coating agent and application

InactiveCN105494446AMitigate the problem of pathogen resistance and environmental pollutionHigh efficiencyBiocidePlant growth regulatorsBacillus amyloliquefaciensInsecticide resistance

The invention discloses a biological compound seed coating agent and an application. The biological compound seed coating agent comprises bacillus amyloliquefaciens YN2010-KC CGMCC No.5722 fermentation liquor, insecticide, bactericide, a dispersing agent and a film-forming agent. The biological compound seed coating agent has multiple functions of preventing diseases, preventing insects, enduring drought, promoting growth and increasing the yield, and the problem of pathogenic bacterium insecticide resistance and environmental pollution caused by a traditional chemical seed coating agent can be relieved. The preventing effect of the traditional biological seed coating agent and stability under the adverse conditions can be improved. The biological compound seed coating agent is good in suspension property and dispersing performance, does not precipitate, is even in coating, does not fall off and is safe for operators and environment.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

Efficient seed coating agent, preparation method and applications thereof, and method using same to process seeds

InactiveCN105052933AStrong targetingImprove versatilityBiocideFungicidesEnvironmental resistanceFruit tree

The invention belongs to the technical field of seed processing, and especially relates to an efficient seed coating agent, a preparation method and applications thereof, and a method using the same to process seeds. The efficient seed coating agent comprises the following components: amino-oligosaccharin, a dispersant, an adhesive, a surfactant, vigilance dye, and water. The preparation method comprises the following steps: weighing all raw materials other than amino-oligosaccharin according to a certain ratio, evenly mixing the weighed raw materials, then adding amino-oligosaccharin, and grinding the mixture until the particles of each component is less than 5 mm. The efficient seed coating agent is mixed with seeds according to a mass ratio of 1:50 to coat the seeds. The efficient seed coating agent can be used to prevent and treat diseases of fruit trees, vegetables, underground roots, tobaccos, traditional Chinese herbals, grain crops, cotton, and the like. The seed coating agent has the advantages of strong pertinence, good universality, sustain-released property, and fertilizer-retaining performance, and is capable of preventing the diseases and pests. Moreover, the raw materials are easily-available and cheap, so the production cost is low. Besides the raw materials are environment-friendly and harmless, and meet the nuisance-free requirements.

Owner:山东亿嘉农化有限公司

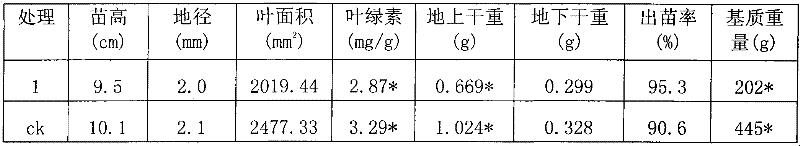

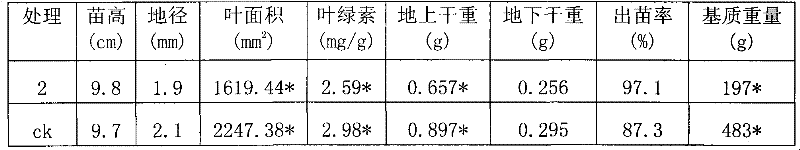

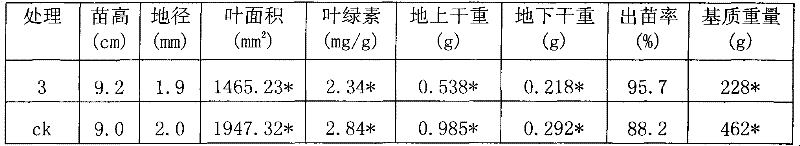

Soilless culture matrix for castanopsis fissa container seedling, and preparation method of soilless culture matrix

ActiveCN102351594ALow costRelieve stressAgriculture gas emission reductionCultivating equipmentsDiseasePlant roots

The invention provides soilless culture matrix for a castanopsis fissa container seedling, and a preparation method for the soilless culture matrix. The soilless culture matrix is characterized by comprising the following components in part by weight: 10 to 15 parts of stacked sawdust of which water content is 40 percent, 0.5 to 1 part of stacked tung bran, 2 to 6 parts of carbonized sawdust, 2 to 4 parts of tanning extract residue, or / and 2 to 4 parts of inorganic matrix, namely one or more of pearlite, vermiculite, and rock wool powder. The preparation method comprises the following steps of: adding the stacked sawdust, the stacked tung bran, the carbonized sawdust, the tanning extract residues or / and the inorganic matrix into a mixing machine respectively, and stirring or manually mixing uniformly to obtain the soilless culture matrix. In the soilless culture matrix, sawdust and tanning extract resources are fully utilized, and the matrix has better physical behavior, is more suitable for growth and development of plant root systems, and has the effects of controlling insects and diseases; the weight of the matrix is half all mud matrix; and transportation cost and forest planting cost are reduced, and the soilless culture matrix has good market application prospect.

Owner:GUANGXI FORESTRY RES INST

Sterilizing processing liquid for processing rattans

InactiveCN104397071ASimple processing methodInsect-resistantBiocidePest repellentsBiotechnologyOyster

The invention provides a sterilizing processing liquid for processing rattans, and relates to the technical field of rattan-weaved product production. The processing liquid is composed of the following raw materials in parts by weight: 3 to 7 parts of andrographis paniculata, 2 to 4 parts of cordate houttuynia, 1 to 3 parts of basil, 2 to 4 parts of wild chrysanthemum, 3 to 7 parts of tribulus terrestris, 2 to 4 parts of prunella vulgaris, 3 to 6 parts of santal, 4 to 8 parts of honeysuckle flower, 3 to 7 parts of purslane, 2 to 4 parts of perilla leaf, 2 to 5 parts of Chinese magnoliavine, 2 to 5 parts of hairyvein agrimony, 1 to 3 parts of tabasheer, 2 to 4 parts of fructus forsythiae, 2 to 4 parts of yellow gentian, 2 to 4 parts of rhizoma atractylodis, 2 to 4 parts of eupatorium, 1 to 3 parts of cyrtomium rhizome, 1 to 3 parts of common cnidium fruit, 1 to 3 parts of rheum officinale, 1 to 3 parts of stemona, 2 to 4 parts of smoke stalk, 1 to 3 parts of oyster, and 3 to 7 parts of tree peony bark. In the processing method, live rattans are processed by the provided liquid. The processing method is simple. The processed rattans are sterilized and have the functions of insect resistance, mothproof property, and mold resistance. The service life of rattan-weaved products can be prolonged. The prepared softening steam can soften the rattans, and the volatile substances in the steam can sterilize the rattans and increase the aroma of the rattans.

Owner:ANHUI HONGFU CRAFTS

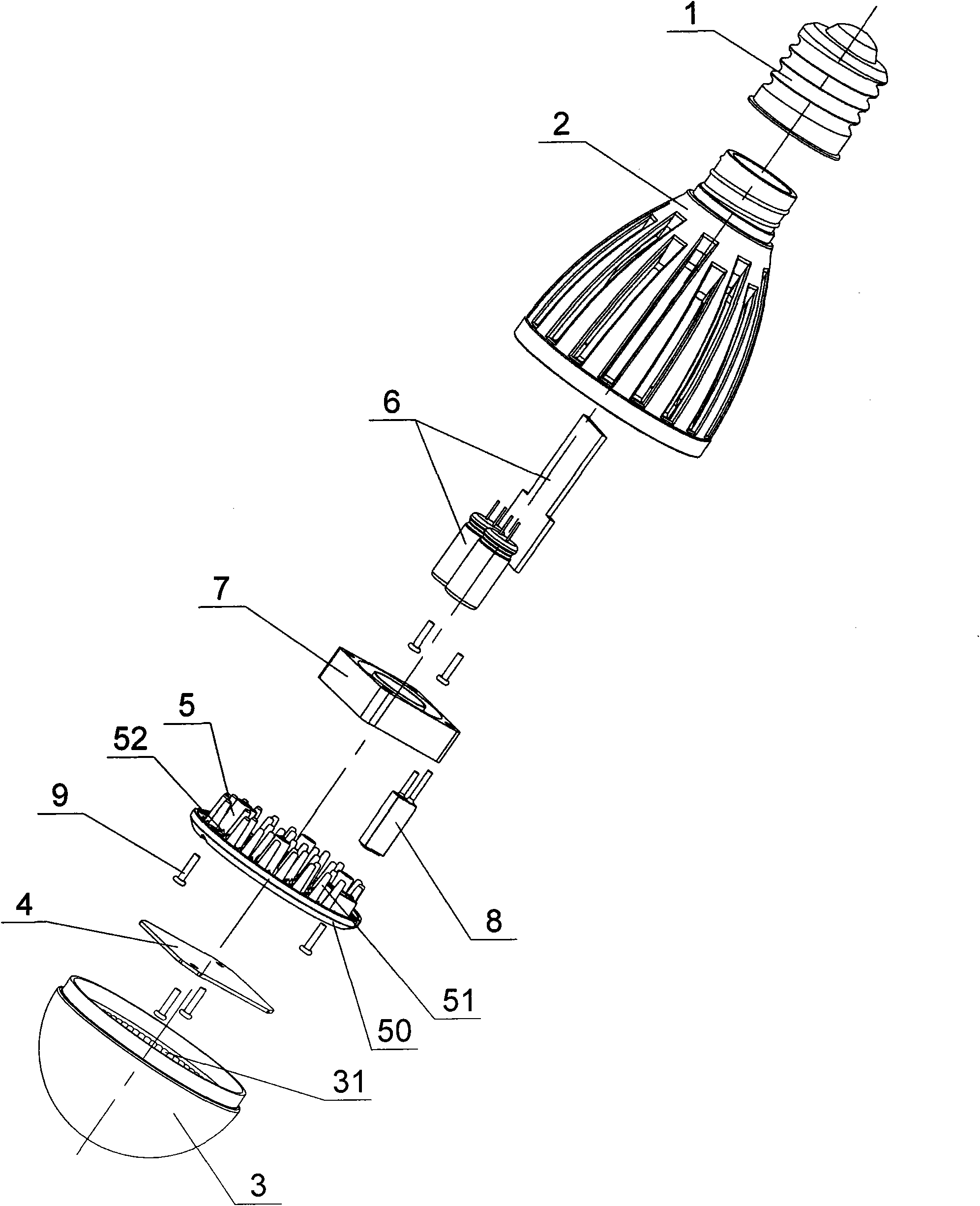

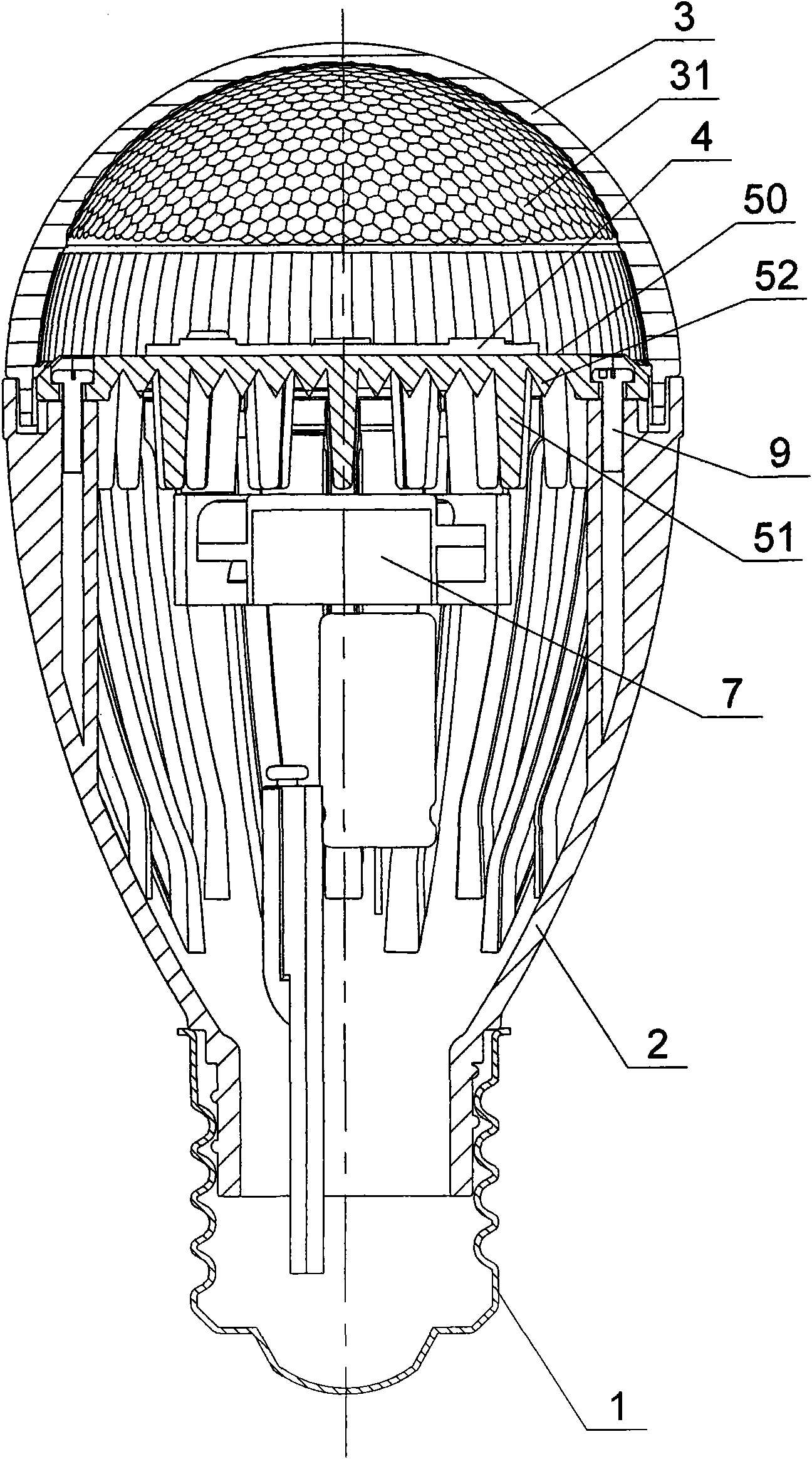

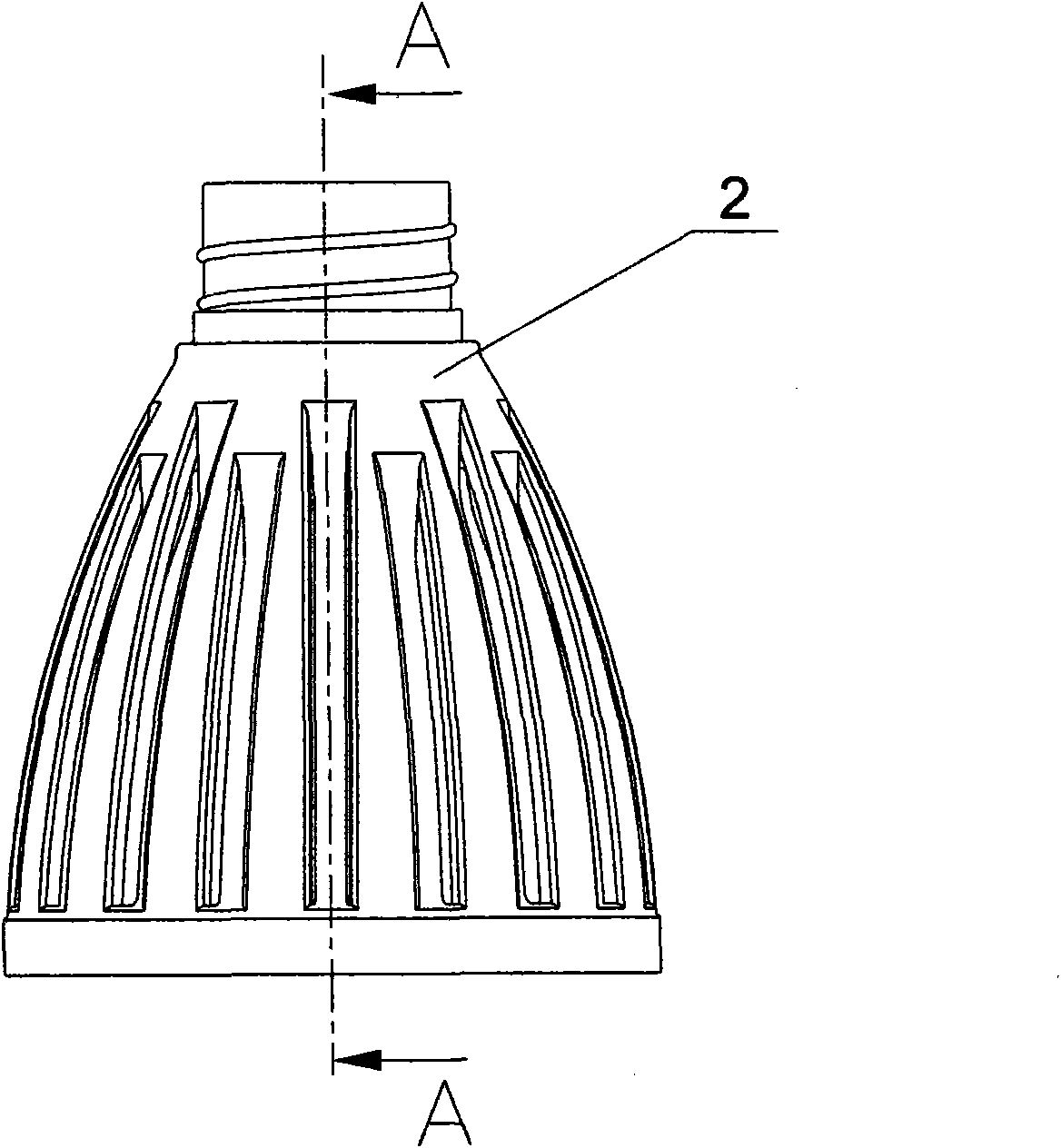

High-power LED bulb

InactiveCN102109104AIncrease cooling areaAvoid safety hazardsPoint-like light sourceLighting heating/cooling arrangementsElectric shockHigh power leds

The invention discloses a high-power LED bulb with electric shock preventing performance, high safety and long service life. The high-power LED bulb comprises a bulb cap (1), an insulating casing (2), an insulating light-transmitting front bulb shade (3), a light source plate (4) integrated with an LED chip, a radiator (5), a power supply drive component (6) and a thermo-sensitive switch (8), wherein the thermo-sensitive switch (8) is used for cutting off a power supply when the bulb is under high temperature; the front end of the insulating casing (2) is fixedly connected with the insulating light-transmitting front bulb shade (3), so as to form an accommodating cavity; all the light source plate (4), the radiator (5), the power supply drive component (6) and the thermo-sensitive switch (8) are arranged in the accommodating cavity; the radiator (5) comprises a baseplate (50); the bottom surface of the baseplate (50) is a plane surface part tightly clung to the light source plate (4); a heat radiation pillar (51) is arranged on the top surface of the baseplate (50); a lug boss (52) or sunken part which is used for enlarging the radiation area is arranged on the top surface of the baseplate (50); and a plurality of heat radiation grooves (21) communicated with the inner cavity of the insulating casing (2) are formed on the side wall of the insulating casing (2). The high-power LED bulb can be extensively applied to the field of LED illumination.

Owner:NANKER GUANGZHOU SEMICON MFG

Environment-friendly plant fiber wood-plastic composite material and preparation method thereof

The invention provides an environment-friendly plant fiber wood-plastic composite material and a preparation method thereof. The environment-friendly plant fiber wood-plastic composite material is prepared from the following components serving as base stock by weight percent: 50-90% of plant fibers, 5-40% of waste polystyrene plastic recovery particles and 5-10% of styrene butadiene styrene (SBS), as well as a proper amount of an assistant-silane coupling agent and stearic acid, wherein the use amount of the silane coupling agent accounts for 1-10wt% of the plant fibers while the use amount of the stearic acid accounts for 2-5wt% of the plant fibers. The environment-friendly plant fiber wood-plastic composite material has the advantages of insect prevention, moth resistance, chemical corrosion resistance, large additive amount of cellulose, high physical and mechanical strength, low cost, easy decomposition and wide application, and is environment-friendly.

Owner:广东普科特粉末涂料有限公司

Morchella cultivation material and method for cultivation of Morchella

InactiveCN107098768AWell mixedPromote absorptionCalcareous fertilisersBio-organic fraction processingAdditive ingredientMomordica grosvenori

The invention discloses a Morchella cultivation material, which comprises the following components by weight: 25-35 parts of corn stalk, 25-35 parts of poplar sawdust, 20-30 parts of rape straws, 10-20 parts of peanut shell, 15-25 parts of sunflower seed meal, 8-15 parts of coconut shell, 3-6 parts of chestnut shell, 7-12 parts of Momordica grosvenori dregs, 5-8 parts of vinasse, 3-6 parts of Chinese Honeylocust Fruit shell, 4-7 parts of Gentiana apiata, 3-6 parts of dandelion and 2-5 parts of honeysuckle and the like. The method for cultivation comprises the following steps: (1) preparation of the Morchella cultivation material, (2) seed mixing, (3) seed sowing, (4) mycelial growth management and (5) fruitbody growth management. The waste raw materials are used, and scientifically and reasonably matched, nutrients are fully complementary, the Morchella cultivation material is environmentally-friendly and economic, herbal ingredients are added, the beneficial functions of Morchella are improved, the Morchella cultivation material has antibacterial and antiviral effect; the method for cultivation is simple and practical, low-cost and high-yield, and quality is good.

Owner:CHENGDU TIANLU FUNGI

Manufacturing method of thick and light straw wall material

InactiveCN101899883AFireproofInsect-resistantConstruction materialSolid waste managementHot pressAdhesive

The invention discloses a manufacturing method of a thick and light straw wall material. Wheat straw, straw and corn straw serve as raw materials. The moisture content of the raw materials is controlled to be 6-18%; after the raw materials are cut, applied with MDI adhesive and / or applied with anti-corrosion preservative and fire retardant, paved and assembled, the raw materials are sent into an injecting and steaming press; the upper surface and the lower surface of a slab are heated by contacting with a heating platen; meanwhile, the slab is injected by upper and lower high-temperature steam; the integral thickness direction of the slab can be quickly heated; and meanwhile, water vapor catalysis and excitation causes MDI glue in the slab to be quickly puffed to foam, thus preparing the heat reservation straw wall material with the thickness of 35-150 mm and the density of 0.15-0.5 g / cm<3>. The invention has the advantages that the heat reservation straw wall material has large thickness and light weight, has the performances of insect prevention, anticorrosion and fire protection and has simple manufacturing technology. Hot-pressing time is 1 / 5-1 / 10 of the traditional hot-pressing time. The manufacturing method of the thick and light straw wall material has short product manufacturing time, favourable shape stability, energy saving and low cost.

Owner:NANJING FORESTRY UNIV

UHMWPE (Ultra High Molecular Weight Poly Ethylene) fiber composite summer sleeping mat and manufacturing method thereof

InactiveCN104287537AImprove thermal conductivityLightweight is obviousSynthetic resin layered productsWoven fabricsFiberSurface layer

The invention discloses a UHMWPE (Ultra High Molecular Weight Poly Ethylene) fiber composite summer sleeping mat and a manufacturing method thereof. The summer sleeping mat comprises a mat surface layer, a sweat absorption layer and a mat bottom coating layer, wherein the mat surface layer is prepared from UHMWPE, or is prepared by arranging the UHMWPE and higher-water-absorption common textile materials at intervals or is prepared by using the UHMWPE and higher-water-absorption fiber composite yarns as warp and weft yarns, and is subjected to anti-bacterial and insect-preventing treatment; the sweat absorption layer is made of a high-water-absorption fabric and is arranged between the mat surface layer and the mat bottom coating layer; the mat bottom coating layer is a common hydrophilic fabric with certain abrasion resistance, is sewn in an edge coating manner, covers the sweat absorption layer and the mat surface layer and is sewn around the mat surface layer. The mat has an obvious and ensuring contact feeling of coolness, is easy to fold and carry, is light in weight, and has the anti-bacterial and insect-preventing functions; the mat surface is dry and comfortable for a long time.

Owner:PAP LOGISTICS EQUIP RES INST +1

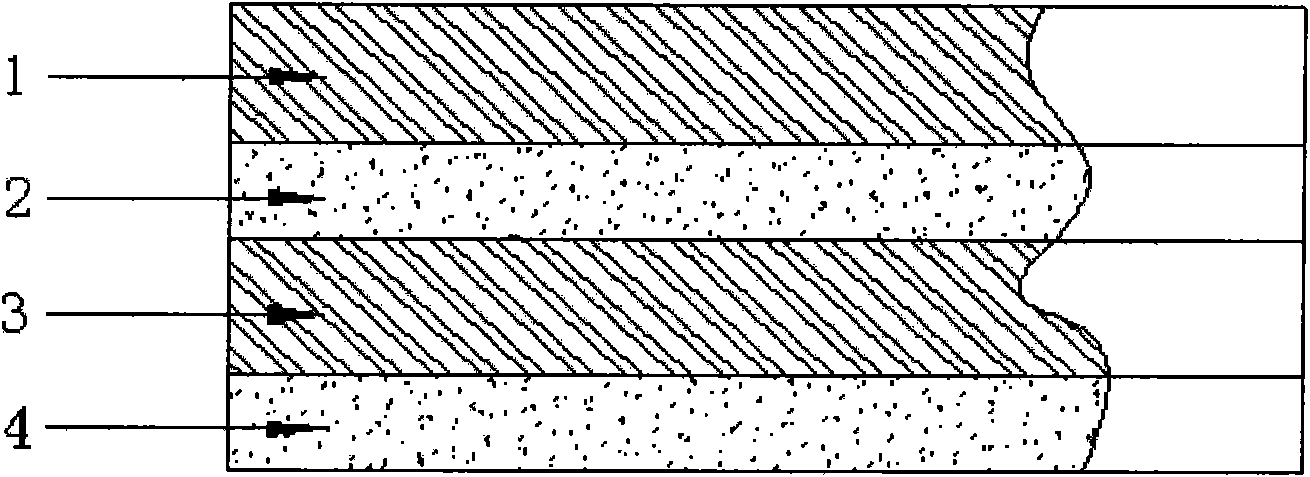

Formula of carbonized solid-wood high-density fiber composite board and producing and recycling process

ActiveCN104308947AFireproof hasFire retardant withConstruction materialWood working apparatusFiberSolid wood

The invention discloses a formula of a carbonized solid-wood high-density fiber composite board and a producing and recycling process. The raw materials are carbonized wood fiber powder and highly dehydrated carbonized materials, the characters of plastic fusion has been improved, hydrophilic factors in the carbonized wood are recombined, the balance point (commonly known as moisture line) of moisture absorption of the wood is lowered and is not easy to be affected by the surrounding, and quality of the products can be guaranteed. The formula thoroughly overcomes the defects of similar products in the market and has the advantages of water resistance, insect prevention, corrosion prevention, flame retarding and the like. Meanwhile, the formula can be used for decorations such as sculpture, veneering and spraying, is free of formaldehyde and can be recycled and reused completely.

Owner:GUANGDONG HUANGTIAN ENVIRONMENTAL PROTECTION TECH CO LTD

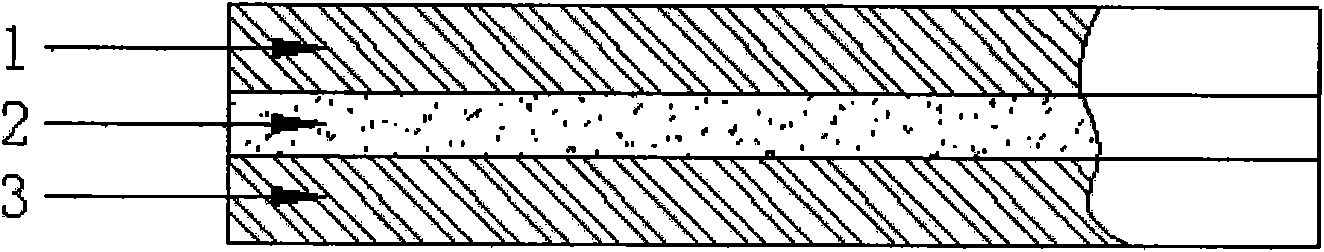

Novel low-carbon veneer and manufacture method thereof

InactiveCN101941218AAddress resource scarcityImprove protectionWood veneer joiningWood layered productsEnvironmental resistanceFiber

The invention discloses a novel low-carbon veneer formed by the lamination of at least one wood layer and at least one magnesite gelation flame-retardant layer. The magnesite gelation flame-retardant layer mainly comprises the contents of magnesium chloride and magnesium oxide, plant fibers, such as sawdust or peanut shell powder, as well as glass fibers, modifiers and other mineral extractives are also added, and the wood layer and the magnesite gelation flame-retardant layer are laminated and adhered through an adhesive or cemented by a cementing material. The invention also discloses a manufacture method of the veneer. The novel low-carbon veneer of the invention is fireproof, moistureproof, non-toxic, environment-friendly without inducing insect pests, high-temperature-resistant, sound-absorbing, shockproof, light-quality and antiseptic, can be sawed, planed, nailed or processed otherwise and can favorably solve the problem of wood shortage and protect the environment.

Owner:庄启程 +2

Flame-retardance formaldehyde-free industrial hemp straw fiberboard and manufacturing method thereof

InactiveCN107322745AWith flame retardant functionClear componentsDomestic articlesFlat articlesSolventFiberboard

The invention provides a flame-retardance formaldehyde-free industrial hemp straw fiberboard. The fiberboard comprises raw materials of industrial hemp straw all-straw core fragments and flame-retardance adhesive being 18-48 weight% of the fragments; and the fiberboard is prepared by such steps as cold pressing and curing. Aiming at a hot pressing process and a method for applying solvent adhesive in traditional fiberboard manufacturing, the flame-retardance formaldehyde-free industrial hemp straw fiberboard is prepared by using a cold pressing process and special flame-retardance formaldehyde-free adhesive. Compared with a traditional fiberboard preparation method, the method has the advantages of simple process, low energy consumption and no environmental pollution; and compared a wood fiberboard, the obtained product has such characteristics as flame retardance, low smoke, no irritation, no poison, no formaldehyde, bacteria resistance, insect resistance, water resistance, high strength and possession of both medium density and high density.

Owner:洪家敏

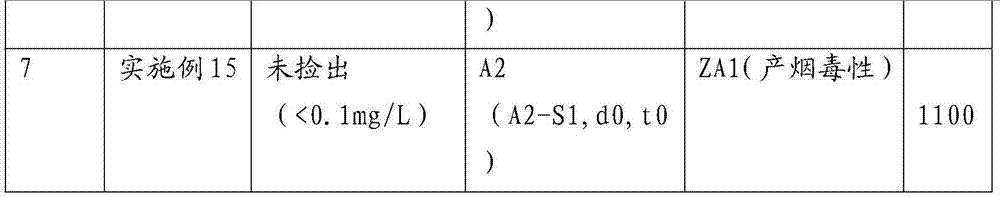

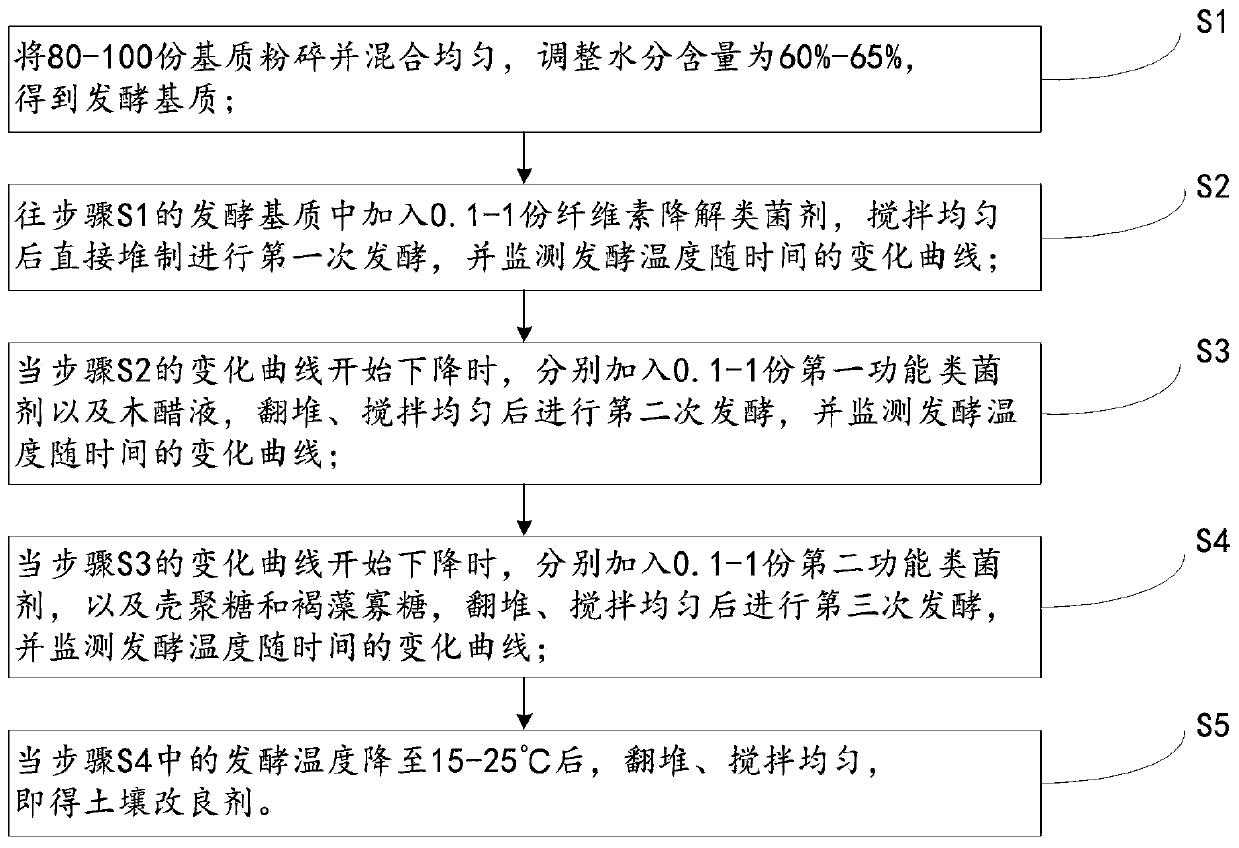

Preparation method of soil amendment and soil amendment

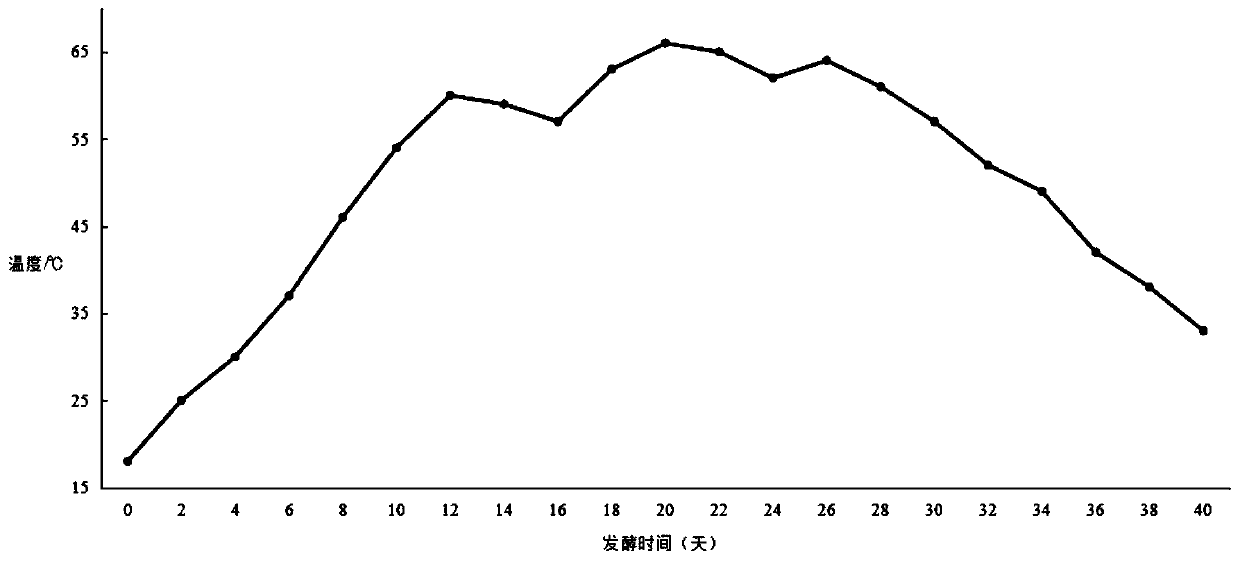

ActiveCN110330977AMake full use of biomass resourcesPromote degradationBiocidePlant growth regulatorsGrowth promotionThree stage

The invention provides a preparation method of a soil amendment and a soil amendment. The method includes: mixing a cellulose degradation inoculant with a fermentation substrate evenly and performingcomposting fermentation, and in the first fermentation process, rapidly heating a pile body to quickly degrade lignocelluloses substances in the substrate; when the temperature of the pile body startsto drop, using a first functional inoculant and wood vinegar for second fermentation of the pile body; rapidly heating the pile body subjected to second fermentation again, when the temperature of the pile body starts to drop again, adding a second functional inoculant, chitosan and alginate oligosaccharide, and carrying out third fermentation in cooperation with pile turning and stirring. The method carries out substrate fermentation in three stages, can improve the fermentation efficiency and make the fermentation more sufficient, the pile body is heated repeatedly, and grass seeds, parasite eggs and pathogenic microorganisms can be killed thoroughly. After application of the soil amendment, the utilization efficiency of soil nutrient elements is increased, and the soil quality is improved, the soil amendment also has growth promotion, insect resistance and other functions, and is economical and environment-friendly.

Owner:MICROBIOLOGY INST OF SHAANXI

Processing method before imbedding biological specimen

InactiveCN101180958AGood embedding effectMildew proofDead animal preservationEducational modelsMildewMoisture

The invention relates to a processing method of biological specimens before embedment. The method is that the biological specimens is dipped into a processing solution prepared with formaldehyde withthe concentration of 37 to 40 percent per 37.5 to 42.5ml and 57.5 to 62.5g of carbamide for 1 to 3 days and then the specimens are transferred to place in an incubator of 30 to 40 DEG C for 1 to 4 hours and then the specimens are embedded with transparent urea-formaldehyde resin. The processing method has the advantages of effectively moisture removing, lower cost, simple operation, better embedment effect and anti-mildew, anti-pest and color preserving, and is especially applicable to the embedment of biological specimens with more water content, such as Flammulina, Craspedacusta, earthworms,small mollusks and fish, etc.

Owner:CHONGQING NORMAL UNIVERSITY

Method for embedding biological specimen with high water content

InactiveCN101162190AStay transparentNo peelingPreparing sample for investigationPolyethylene glycolSpecimen preparation

The invention relates to an encapsulating method for a biological specimen. The technical proposal adopted is that: a biological specimen is fixed, sterilized, antisepticised and cleaned, polyoxyethylene (PEG six hundred) is used to plasticize the specimen, the plasticized specimen is placed in a porcelain dish which is provided with absorbent paper, is then put into an incubator of thirty degrees to forty degrees for twelve to twenty-four hours and are finally fully integrated with a prepared transparent Lauxite until the preparation of specimen is completed. The encapsulating method has the advantages of a good encapsulating effect, mould proofing, insect prevention and color retention, which is particularly applicable to encapsulating the biological specimen with more water content, such as Craspedacusta, earthworms, mollusks and small-sized fishes.

Owner:CHONGQING NORMAL UNIVERSITY

Compound fertilizer and preparation method thereof

ActiveCN106946619AChange compactionChange air permeabilitySuperphosphatesBio-organic fraction processingDiseaseSludge

The invention discloses a compound fertilizer. The compound fertilizer is prepared from the following raw materials in parts by weight: 50 to 55 parts of fishpond sludge, 10 to 18 parts of brewer's grain, 25 to 40 parts of animal dung, 22 to 28 parts of lignin, 12 to 20 parts of oil meal, 20 to 25 parts of straw, 5 to 8 parts of waste edible fungus culture medium, 5 to 8 parts of ammonium sulfate, 3 to 7 parts of monopotassium phosphate, 6 to 10 parts of calcium superphosphate, 3 to 5 parts of traditional Chinese medicinal composition, and 3 to 6 parts of trace elements. The invention further provides a preparation method for the compound fertilizer. The compound fertilizer has the advantages of reasonable formula, low cost, scientific and practical production process, can increase organic matters of soil and improve the defective conditions of soil hardening, poor air permeability and the like, has a long-lasting fertilizer effect, has the effects of resisting pests, dispelling pests and resisting diseases, is particularly suitable for tuberous root plants and tuberiferous plants, and can effectively improve the yield and quality of the tuberous root plants and tuberiferous plants.

Owner:广州肇基生物科技有限公司

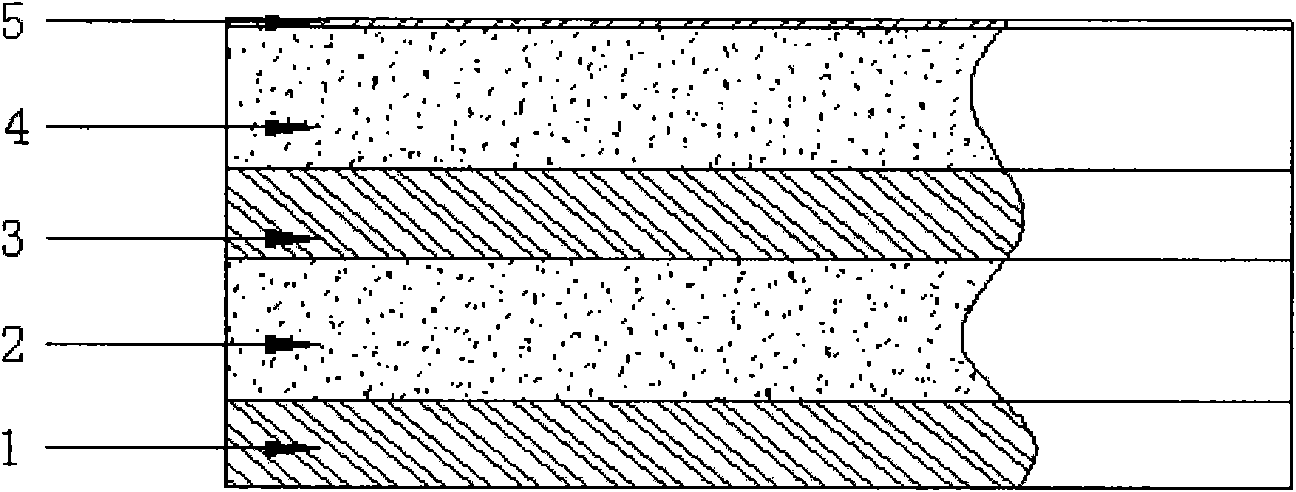

Biomass flame-retardant thermal-insulating panel and preparing method thereof

The invention aims to provide a biomass flame-retardant thermal-insulating panel and a preparing method thereof. By the biomass flame-retardant thermal-insulating panel, the environmental-friendly straw panel which integrates high strength and flame retardation and is low in energy consumption is produced. The biomass flame-retardant thermal-insulating panel consists of biomass raw materials and an adhesive in a mass ration of 1:0.3- 1. The biomass raw materials comprise crop straw, shells, core wood and carbides; the adhesive is prepared from silica sol or sodium silicate, aluminium chloride, filler, curing agent and stabilizer; the filler is a composite consisting of aluminium oxide, zinc oxide and magnesium oxide; the curing agent is one of aluminium hydroxide, magnesium hydrate or zinc hydroxide; and the stabilizer is carboxymethylcellulose sodium.The preparing method comprises the following steps of: the pretreatment of biomass raw materials; dosing; and hot press molding. The biomass flame-retardant thermal-insulating panel is abundant in raw materials, and the preparing is simple, energy-saving and environment-friendly. The product has the advantages of flame retardance, water prevention, insect prevention, high mechanical property and heat-insulating property, low cost and the like, and has the huge economic and social benefits.

Owner:河南省高新技术实业有限公司

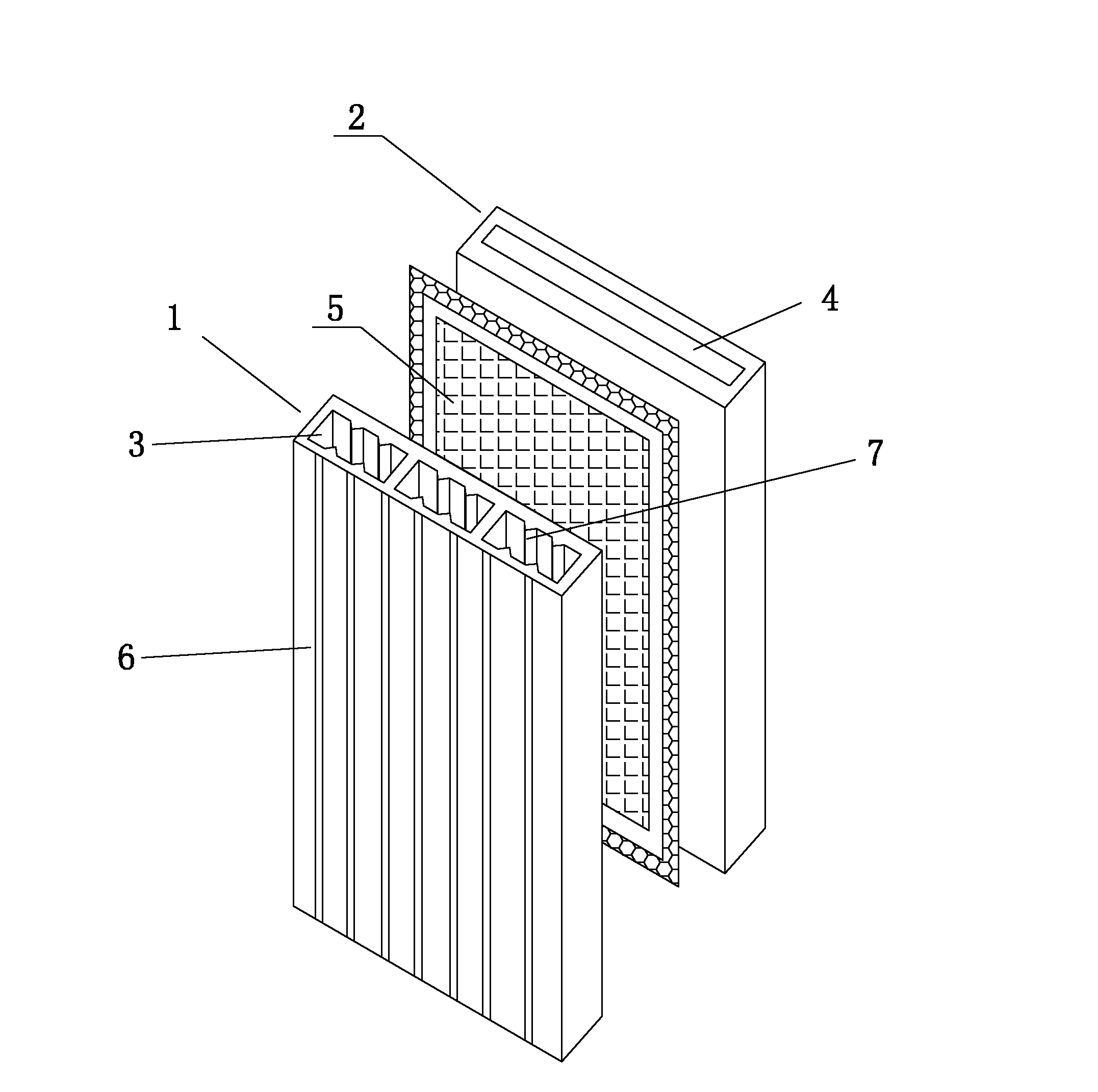

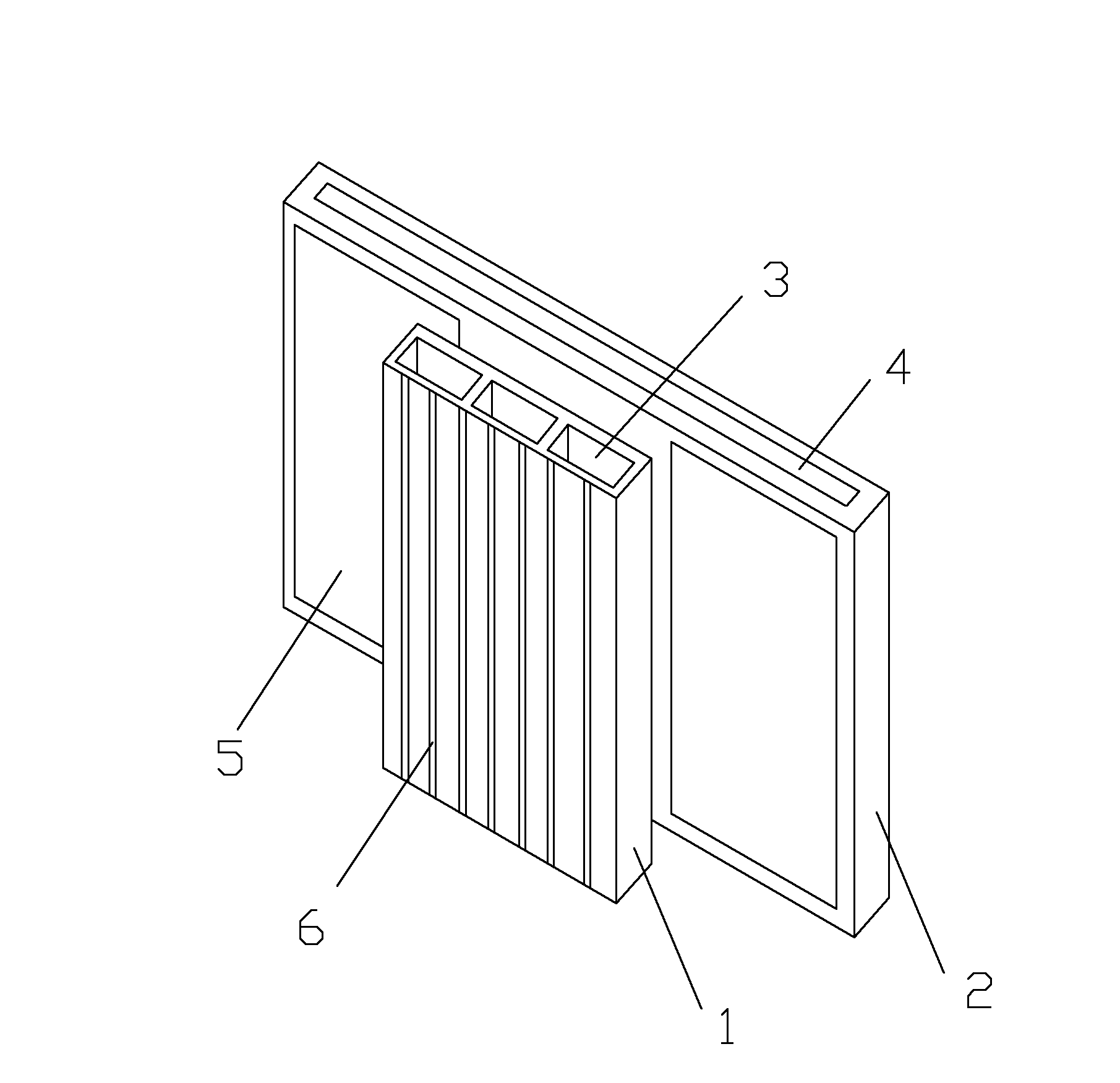

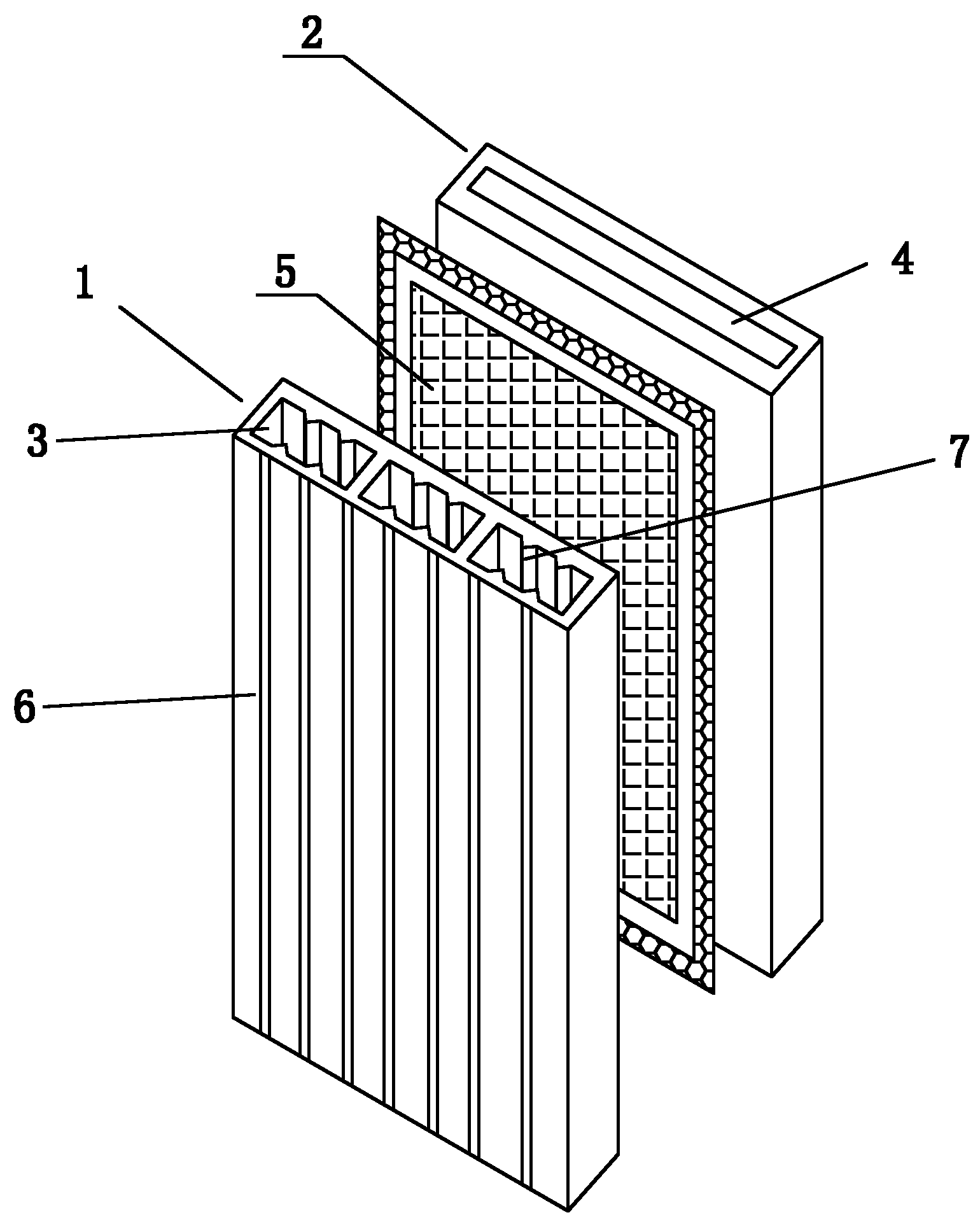

Composite curtain wall for multifunctional building

The invention discloses a composite curtain wall for a multifunctional building. The curtain wall is divided into an outer layer unit and an inner layer unit, one or more tubular hollow cavities that are through from one end to the other end are arranged inside the outer layer unit, and insulation materials are arranged inside the inner layer unit. In hot areas, the tubular hollow cavities inside the outer layer unit are vertically installed and are through from top to bottom. An air inlet and an air outlet are respectively reserved at the upper end and the lower end of the outer layer unit. As each tubular hollow cavity in the outer layer unit is independently closed, air outside the curtain wall and air inside the tubular hollow cavities form a strong hot pressure difference, due to the hot pressure difference, air flows freely from bottom to top inside the tubular hollow cavities, a Chimney effect is formed to take heat away from the outer layer unit of the curtain wall, in order to play functions of saving energy and cooling; in cold areas, the tubular hollow cavities inside the outer layer unit can be mounted horizontally, so that outdoor cold air is prevented by air both inside the outer layer unit and hollow cavities therein from directly contacting the inner layer unit in order to play the thermal insulation function.

Owner:马勇

Hard PVC floor production technology

The invention discloses a hard PVC floor production process, which comprises the following steps: 1) mixing materials; 2) banburying; 3) opening practice; 4) cutting; 5) hot pressing; Fire; 8) health preservation; 9) cutting board slotting; 10) health preservation; 11) packaging. In the hard PVC floor production process of the present invention, the PVC base plate is made of hard PVC foam material, which can effectively prevent deformation, increase strength and prevent collapse while effectively controlling the shrinkage rate.

Owner:JIANGSU RUISHENG NEW MATERIALS CO LTD

Ecological total-effect organic fertilizer and preparation method thereof

InactiveCN104761321AAbundant resourcesLow costBio-organic fraction processingOrganic fertiliser preparationPhosphatePotassium

The invention belongs to the technical field of organic fertilizer processing, and specifically relates to an ecological total-effect organic fertilizer and a preparation method thereof. The preparation method comprises the following steps: mixing the following raw materials: 50-60% of edible mushroom dregs, 20-25% of soybean sauce dregs or wine lees, 5-10% of ground phosphate rock, 5-10% of waste smoke residues or grass charcoal or peat soil, 1-3% of potassium sulphate, 1-3% of urea and 3-5% of trace elements, then adding a special organic fertilizer fermentation stock solution accounting for 0.005-0.01% of the raw materials in mass, uniformly stirring and then preparing a product in a deep-groove fermentation machine through anaerobic and aerobic fermentation and composting, turning and throwing a product by a double-screw turning-throwing machine during a fermentation process, and controlling a water content and an oxygen supply amount.

Owner:CHANGSHA XIANGFEI FERTILIZER SCI & TECHCO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com