Reinforced composite bamboo board and its manufacturing method

A manufacturing method, bamboo-based technology, applied in the direction of manufacturing tools, flat products, building structures, etc., can solve the problems of actual production difficulties, high requirements for production equipment, low material utilization rate, etc., and achieve favorable rational utilization of raw materials The effect of high utilization rate and huge market potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

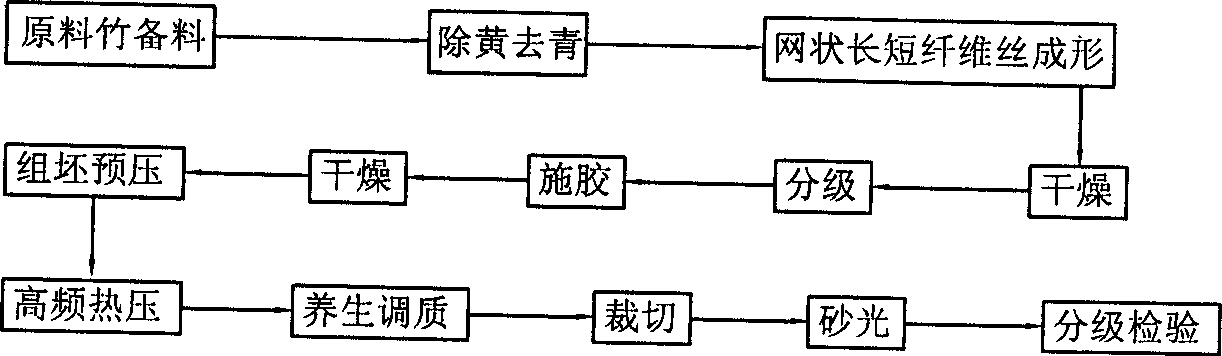

Method used

Image

Examples

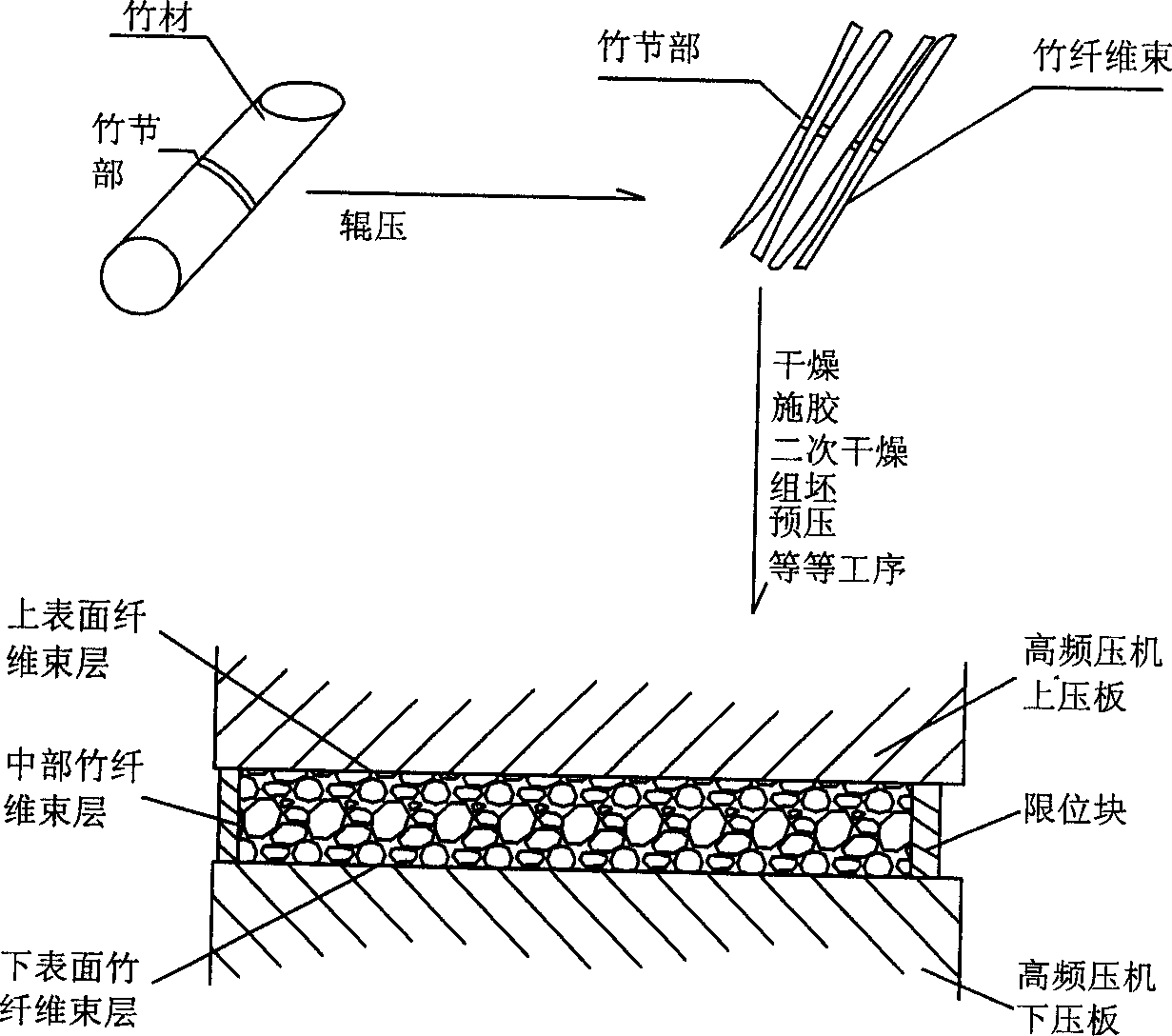

Embodiment 1

[0046] A reinforced composite bamboo board, which has the texture characteristics of ordinary bamboo flooring, is characterized in that it includes an outer bamboo fiber layer made of bamboo fiber bundles, and a bamboo fiber layer between the two outer bamboo fiber layers consisting of along-grain and horizontal-grain bamboo fibers. Bamboo fiber layers made of bundles. The outer bamboo fiber layer is the upper and lower surface layers of the reinforced composite bamboo board. The diameter of the bamboo fiber is 0.001mm-3mm, especially preferably 0.01-1mm. The bamboo fiber is a reticular bamboo fiber bundle, which is firstly disentangled from the bamboo into long, cross-linked and maintains the original arrangement of the fibers. The loose net-like fiber bundles in the way, the bamboo fibers are not completely separated into an individual, forming interconnected bamboo fiber groups. The bamboo fiber bundles can be assembled by using leftover materials from processing the bambo...

Embodiment 2

[0065] The reinforced composite bamboo board processed by the present invention has the advantages of high strength, high hardness, good toughness, etc., and the reinforced composite bamboo board is fine and dense, not easy to crack and deform, and its various performance indicators are higher than those of commonly used wood. etc., and can solve the deformability problem of existing bamboo floor (multi-layer parallel glued strip structure).

[0066] The manufacturing process of the reinforced composite bamboo board of the present invention has low requirements on the selection of bamboo materials, not only can use high-intensity moso bamboo, but also bamboo materials such as small-diameter bamboos (such as Cizhu), and the processing residues of bamboo flooring can be widely used. Utilization is conducive to the rational use of resources.

[0067] The production of the reinforced composite bamboo board product of the present invention has the advantages of less energy consumpt...

Embodiment 3

[0075] The diameter of the bamboo fiber is about 0.01mm, and the sizing amount of the bamboo fiber is 6%. For the first drying, the temperature is 80°C, and the moisture content of the bamboo fiber is controlled between 4%. When sizing, add 0.05% of the interface coupling agent between the bamboo fiber and the rubber material, 0.05% of the penetrating wetting agent, and 0.1% of the modifier. The moisture content of the second drying control bamboo fiber is 6%. 3 billet.

[0076] The billet is pre-pressed to a density of 0.5g / cm 3 After that, enter the heat press machine for heat pressing. If the bamboo floor is produced, the density of the slab needs to be compressed to 0.9g / cm 3 , the pressure of the slab needs to reach 50MPa to meet the requirements of bonding strength. The hot-pressing temperature adopts different hot-pressing temperatures according to different rubber materials, and the temperature is roughly controlled at 200°C; the hot-pressing time is 0.8min / mm.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com