Patents

Literature

328results about How to "Guaranteed anti-corrosion performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-based primer-topcoat braking paint and preparation method thereof

The invention relates to a water-based primer-topcoat braking paint and a preparation method thereof. The braking paint comprises the following materials by weight percentage: 30-40 of water-based acrylic resin, 2-10 of amino resin, 1-3 of neutralizing agent, 2-5 of compound rustproofing pigment, 1-3 of tinting pigment, 10-20 of filling agent, 0.1-0.5 of defoaming agent, 0.1-0.5 of flatting agent and 25-40 of deionized water, wherein the water-based acrylic resin is a free radical polymerization resultant which comprises the following materials by weight percentage: 10-30 of monomer containing hydroxy acrylic acid, 5-20 of monomer containing carboxyl acrylic acid, 2-8 of internal crosslinking monomer, 20-40 of other acrylic acid monomer, 15-30 of phenyl ethylene monomer, 1-5 of evocating agent and 40-50 of alcohol ether latent solvent. When the paint is prepared, the dispersion and the abrading condition of the pigments and the filling agents are reasonably controlled to ensure that each component of the paint fully plays the respective function. The paint ensures the corrosion prevention effect and the decoration of a coating and realizes the combination of a primer and a topcoat.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +1

Double-component graphene anticorrosive coating

ActiveCN105086754AImprove anti-corrosion performanceExtended service lifeAnti-corrosive paintsEpoxy resin coatingsEpoxySolvent

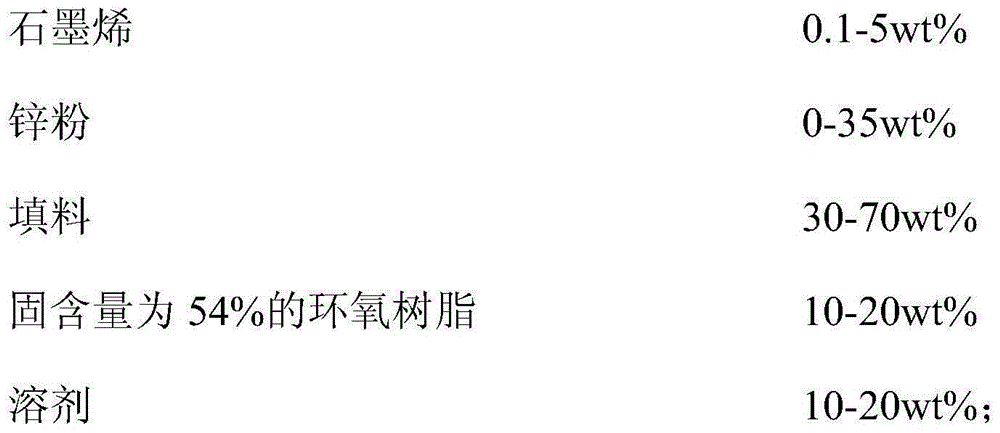

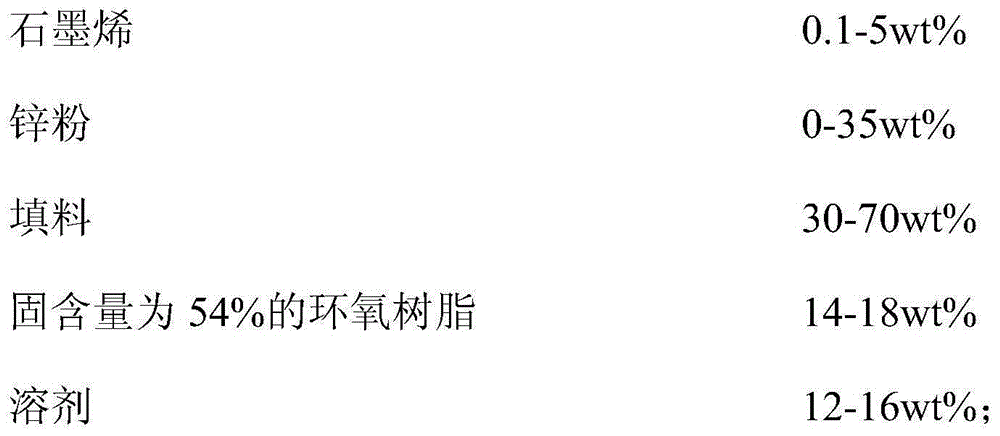

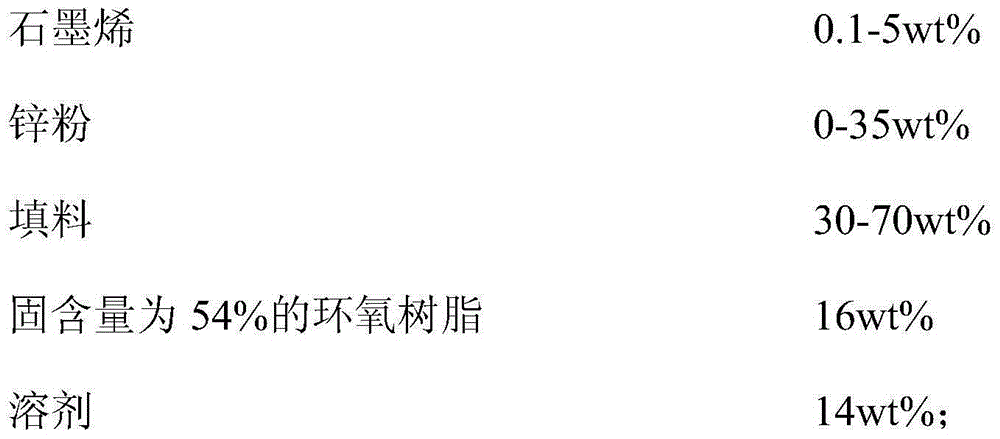

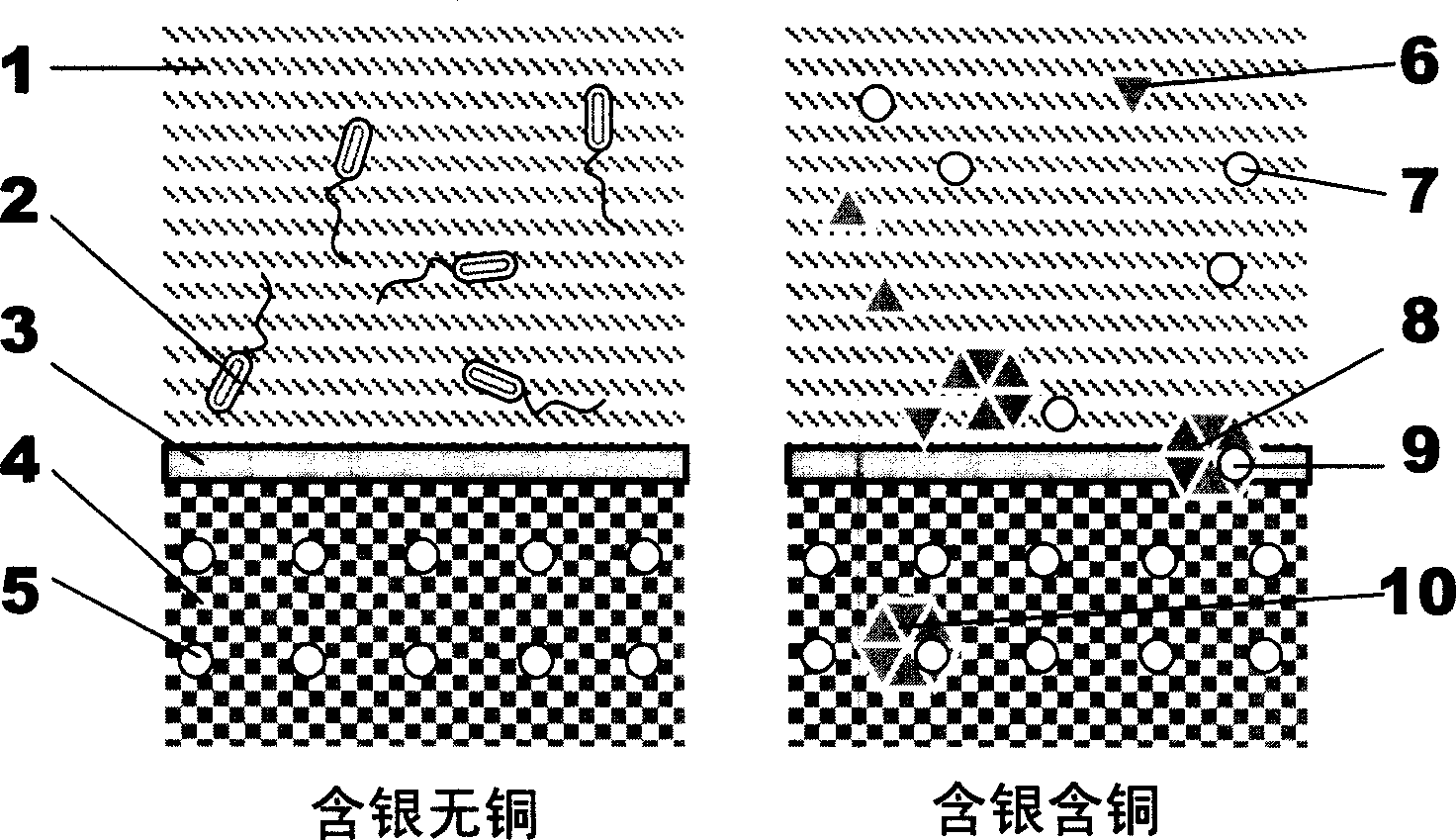

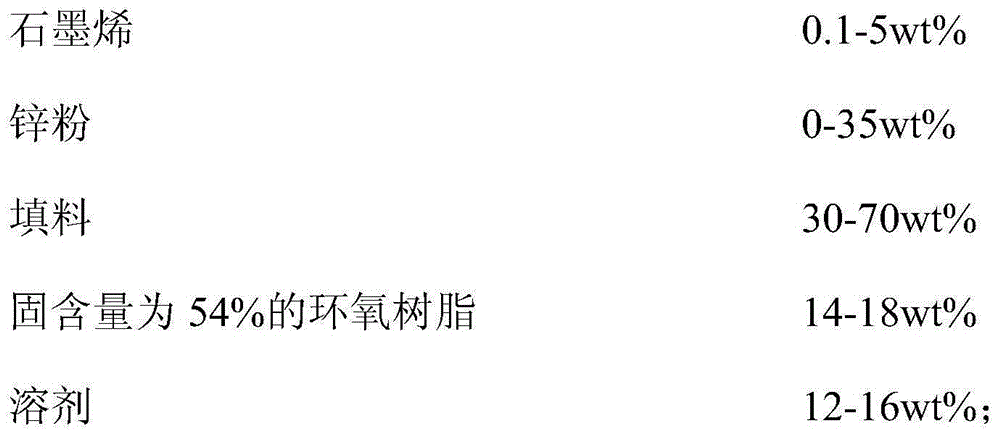

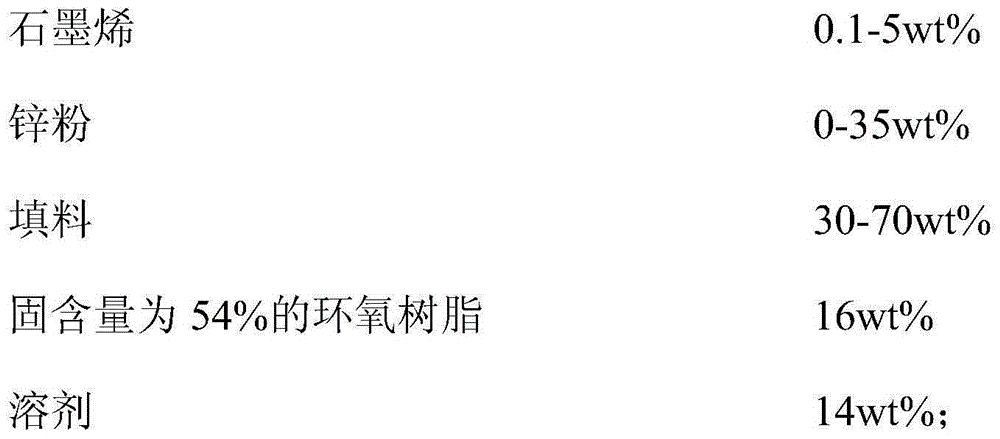

A zinc-rich epoxy anti-corrosion coating, including a component A, capable of being cured into a film, and a component B containing a curing agent; component A contains, by weight percentage, graphene (0.1-5wt%), zinc powder (0-35wt%), filler (30-70wt%), 10-20wt% epoxy resin having 54wt% solids content, and solvent (10-20wt%), wherein the sum of the weight percentages of the graphene, zinc powder and filler is 60-80wt% and the sum of the weight percentages of all components of compenent A is 100wt%. The present invention adds graphene into an anti-corrosion coating, thus decreasing the thickness of the coating film, increases the anti-corrosion effect while decreasing zinc powder contents, reduces the amount of zinc oxide vapor generated during welding, and is environmentally friendly.

Owner:THE SIXTH ELEMENT CHANGZHOU MATERIALS TECH

Epoxy resin-graphene-zinc powder anticorrosive coating and preparation method thereof

InactiveCN105623471AReduce contentWays to overcome corruptionAnti-corrosive paintsEpoxy resin coatingsEpoxyPolyamide

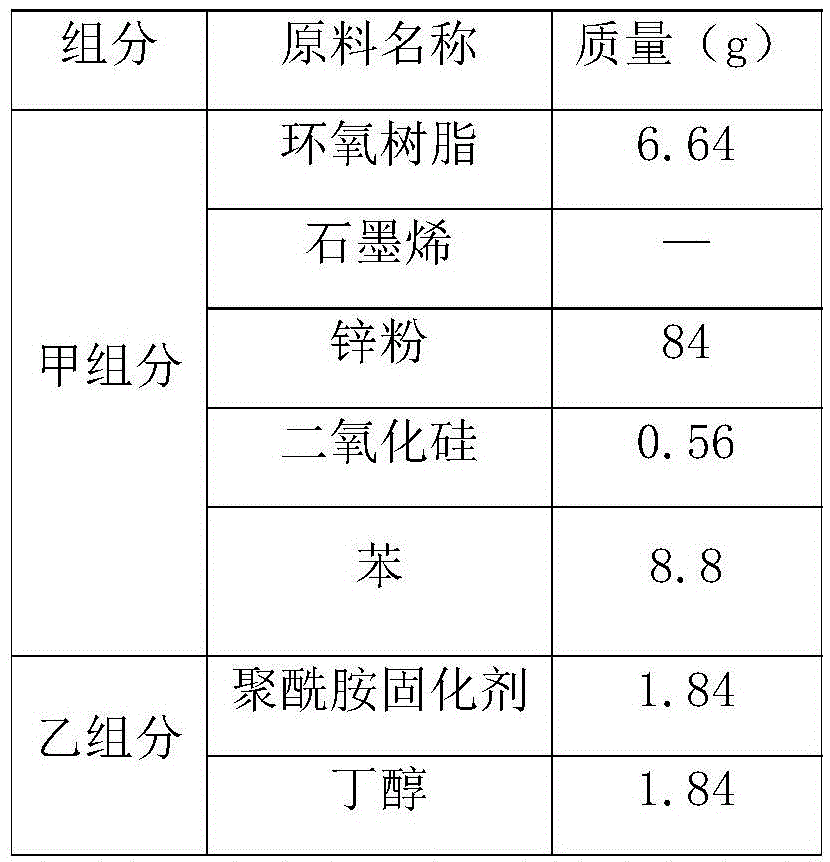

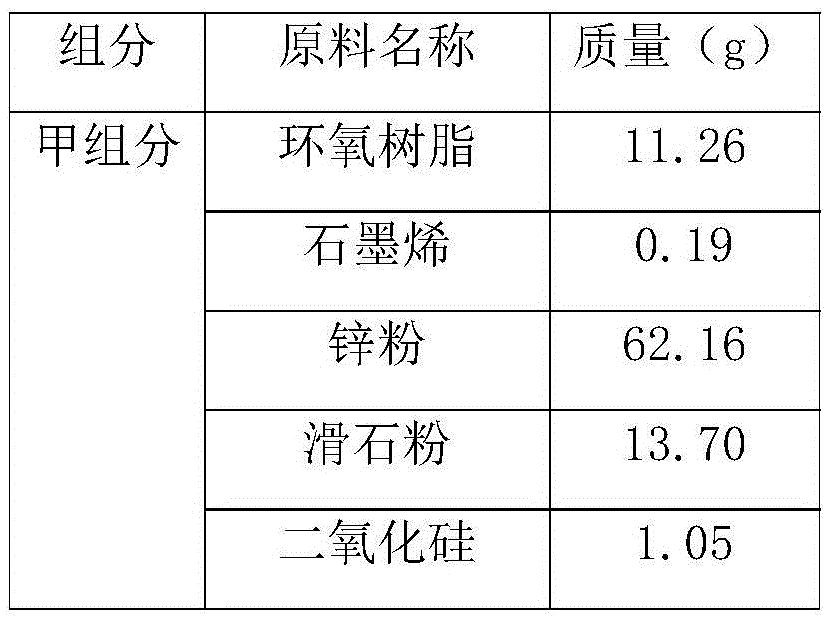

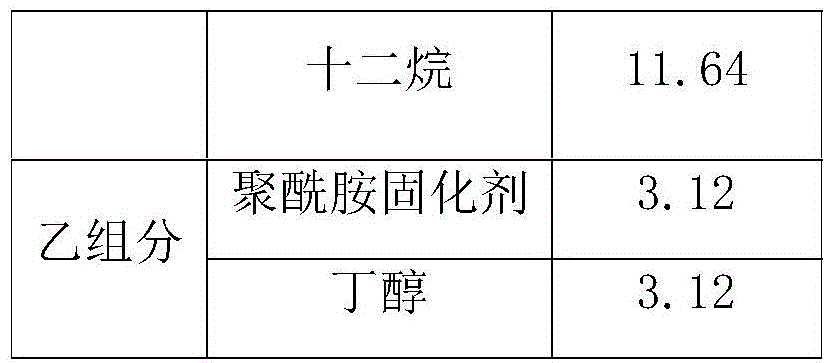

The invention relates to epoxy resin-graphene-zinc powder anticorrosive coating and a preparation method thereof. The coating comprises a component A capable of forming a film in a curing mode and a component B containing a curing agent, wherein the component A is prepared from 14.64-20.24% of epoxy resin, 0.33-0.56% of graphene, 19.63-37.67% of zinc powder, 23.74-40.37% of filler, 1.41-2.0% of silicon dioxide and the balance a solvent. The component B is prepared from 50% of polyamide and 50% of butanol. Graphene is added into the anticorrosive coating, the anticorrosive effect is improved and the content of the zinc powder is greatly reduced by means of selection of the components, the anticorrosive mode, at the cost of zinc powder, of zinc-rich coating is avoided, zinc oxide fog generated during welding is greatly reduced, and the coating is environmentally friendly. The novel composite coating is good in anti-corrosive effect, free of toxin and pollution and wide in application range.

Owner:TIANJIN XITENG SCI & TECH CO LTD

Engine coolant

ActiveCN101629070APrevent precipitationGuaranteed anti-corrosion performanceHeat-exchange elementsSodium nitrateDefoaming Agents

The invention relates to an engine coolant, which comprises the following compositions in portion by weight: 100 portions of glycol, 60 to 160 portions of deionized water, 1.0 to 1.6 portion of sodium benzoate, 1.0 to 1.4 portion of sodium tetraborate, 0.1 to 0.5 portion of sodium nitrate, 0.5 to 0.9 portion of phthalic acid, 0.3 to 0.6 portion of sodium silicate, 0.03 to 0.06 portion of silicate stabilizer, 0.3 to 0.4 portion of sodium hydroxide, 0.1 to 0.3 portion of pyrrodiazole, 0.01 to 0.06 portion of defoaming agent and 0.005 to 0.02 portion of coloring agent; the engine coolant is characterized in that: the coolant does not contain molybdate, amine, nitrite, phosphate and other substances which are harmful to the environment and human body and has excellent anticorrosive and protective function on red copper, brass, steel, cast iron, soldering tin, cast aluminum and other metals of a cooling system and magnesium alloy adopted in an engine; and the coolant has strong anti-hard water capacity and low cost, meets the requirement of SH / T0521-1999 standard and is applicable to industrialized production.

Owner:PETROCHINA CO LTD

Antibacterial austenitic stainless steel

ActiveCN1664154APrevent chromium depletionGuaranteed anti-corrosion performanceChemical compositionKitchen utensils

The invention relates to a sort of austenitic antibiotic stainless steel, characterized in that it saves the nickel and chromium. The percentage by weight of its chemical composition is: C: 0.03-0.15, Cr: 11-15, Ni: 1.0-3.5, Mn: 7.0-15.0, N: 0.06-0.3, Cu: 1.0-3.0, Ag: 0.01-0.1, Nb: 0-0.10, S<=0.02, P<=0.03, Si: 0.1-1, the balance is Fe. Said invention uses cuprum as the carrier and makes the silver crossing the passivating film, which improves the antibiotic ability through the coupulation of the cuprum and silver, and fills manganese, carbon, columbium to ensure the steel has enough corrosion resistance and austenite tissue. The invention can be used for making water supply pipes, kitchen utensils, medical equipments, architectural electric appliances and so on.

Owner:YONGXING SPECIAL STAINLESS STEEL

Preparation method of graphene anticorrosive paint

ActiveCN105086758AImprove anti-corrosion performanceExtended service lifeAnti-corrosive paintsEpoxy resin coatingsEpoxySolvent

A zinc-rich epoxy anti-corrosion coating, including a component A, capable of being cured into a film, and a component B containing a curing agent; component A contains, by weight percentage, graphene (0.1-5wt%), zinc powder (0-35wt%), filler (30-70wt%), 10-20wt% epoxy resin having 54wt% solids content, and solvent (10-20wt%), wherein the sum of the weight percentages of the graphene, zinc powder and filler is 60-80wt% and the sum of the weight percentages of all components of compenent A is 100wt%. The present invention adds graphene into an anti-corrosion coating, thus decreasing the thickness of the coating film, increases the anti-corrosion effect while decreasing zinc powder contents, reduces the amount of zinc oxide vapor generated during welding, and is environmentally friendly.

Owner:THE SIXTH ELEMENT CHANGZHOU MATERIALS TECH

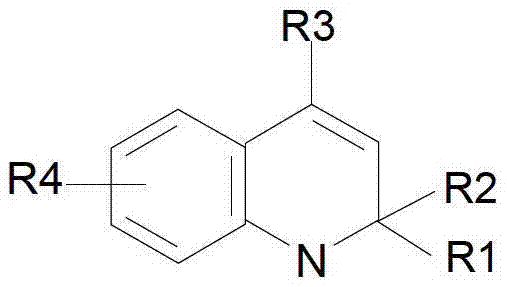

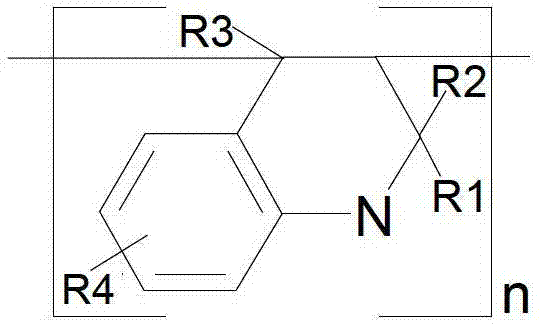

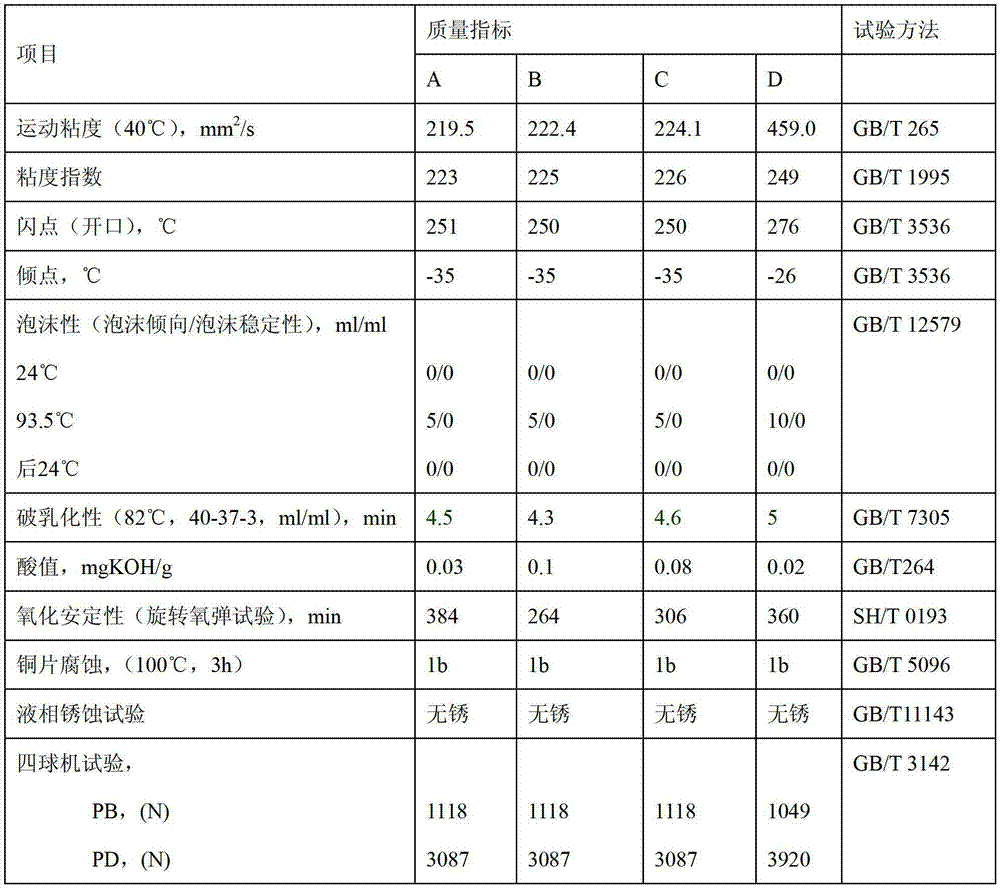

Gear oil composition and preparation method thereof

The invention provides a gear oil composition and a preparation method thereof. The gear oil composition comprises lubricating oil base oil and a 2, 2, 4-trialkyl-1, 2-bihydroquinoline antioxygen and a metal deactivator. The gear oil composition provided by the invention has excellent oxidation stability and extreme pressure antiwear property, and meanwhile has excellent low temperature mobility, viscosity-temperature characteristics, shearing stability and anti-bubbling property, good comprehensive performance, and is simple in preparation method and wide in application range.

Owner:SHANGHAI HITECRUN SPECIAL LUBRICATE SCI & TECH

Phosphorus-free film forming agent and preparation method thereof

ActiveCN101643898AImprove anti-corrosion performanceStrong adhesionMetallic material coating processesHydrofluoric acidAlcohol

The invention relates to a phosphorus-free film forming agent comprising the following components by weight percent: 0.5-4 percent of silane coupling agent, 0.5-2 percent of titanate coupling agent, 1-10 percent of fluozirconate or zircon salt, 3-5 percent of alcohol solvent, 0.5-2 percent of hydrofluoric acid or fluorid, 1-5 percent of hydrogen peroxide, 0.5-2 percent of notric acid or nitrate and the balance of deionized water or tap water. The phosphorus-free film forming agent is environment-friendly and can increase adhesive force and corrosion resistance.

Owner:CHANGZHOU JUNHE TECH

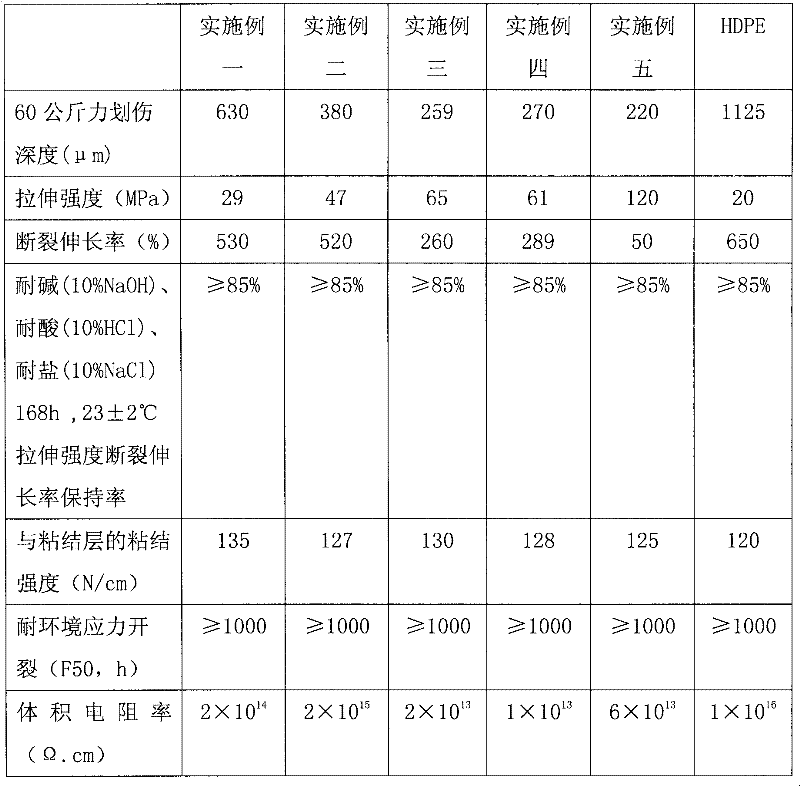

Novel crossing pipeline outer layer material and preparation method

The invention relates to a novel crossing pipeline outer layer material and a preparation method. The material is used for replacing the outermost polyolefin material in the traditional 3PE (Polyethylene) structure. The material has higher intensity and good lubrication performance while ensuring anti-corrosion performance. The scratch resistant performance of the material can be effectively increased. A crossing protective layer is unnecessary to be additionally increased. Due to a certain polarity, the material is capable of increasing bonding performances of a bottom layer material and a stuffing material and reducing a shielding action on cathodic protection current. Compared with the traditional a fritting epoxy coating, the material has better toughness, and the coating is difficult to fall off.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Special anticorrosion conductive powder coating for vertical shaft fluidized bed dip-coating as well as preparation method and application of coating

ActiveCN104710908AHigh glass transition temperatureLight weightAnti-corrosive paintsPolyurea/polyurethane coatingsNano al2o3Conductive materials

The invention relates to a special anticorrosion conductive powder coating for vertical shaft fluidized bed dip-coating. The special anticorrosion conductive powder coating is prepared from the following raw materials in parts by weight: 500-900 parts of film-forming resin and curing agent, 0-200 parts of glass flakes, 0-350 parts of filler, 15-50 parts of auxiliaries, 5-100 parts of conductive material and 1-5 parts of nanometer aluminum oxide or nano fumed silica. The powder coating has the characteristics of a high glass transition temperature, low specific gravity which is generally less than or equal to 1.1g / cm<3>, and easiness for fluidization; even though hundreds of tons of powder is added to a 20m deep well, the powder can be fluidized easily and uniformly; in case of too high specific gravity and difficult fluidization, the vertical shaft dip-coating method can not be utilized; the powder aims at a hot-dip coating construction process, and the film formed by the coating has surface conduction characteristics and high temperature water boiling resistance, and therefore, the coating is suitable for anti-corrosion coating of long linear workpieces such as mine mining anti-explosion gas pipelines, natural gas pipelines and liquefied gas pipelines; the coating is adaptive to the vertical shaft fluidized beds as deep as 20m, and still has good fluidity, which cannot be realized by common powders easily.

Owner:阜阳市诗雅涤新材料科技有限公司

Polynary composite water treatment agent

ActiveCN1565994AIncrease the effective concentrationIncrease the concentration factorScale removal and water softeningChemistryCorrosion inhibitor

The invention relates to a polynary composite water treatment agent which mainly comprises terpolymer containing sulfonic acid radicals, organophosphorus acids, zinc salts and metal inhibitors, wherein the effective concentration weight ratio being 20-40 : 1-10 : 0.5-4 : 0-3.

Owner:PETROCHINA CO LTD

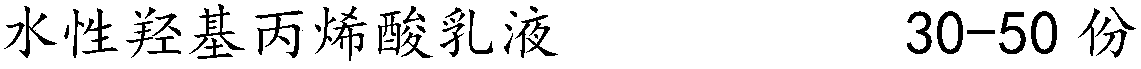

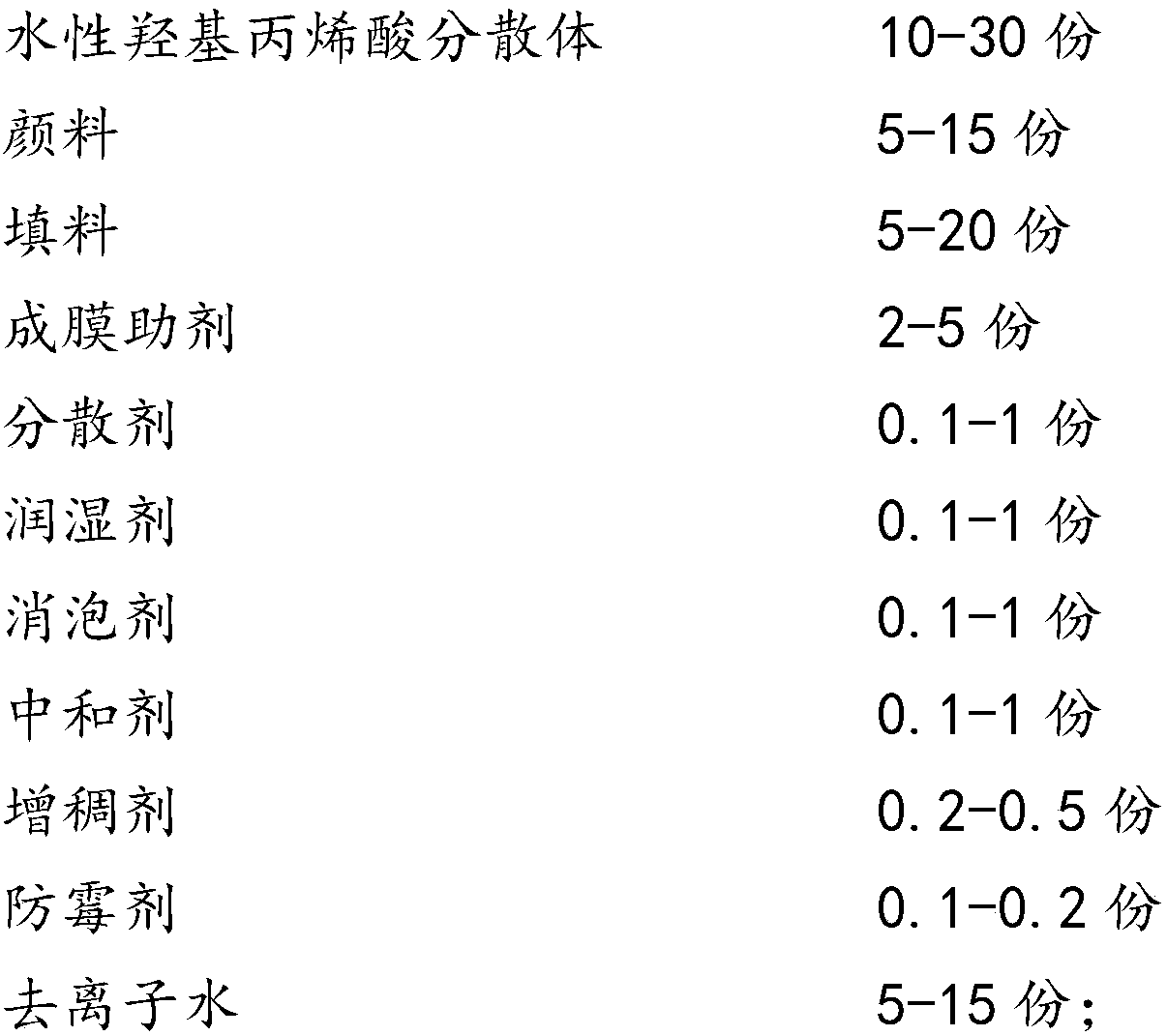

Composition for producing waterborne coating and coating system prepared from composition

ActiveCN108034346AIncrease crosslink densityImprove anti-corrosion performanceAnti-corrosive paintsPolyurea/polyurethane coatingsEmulsionCoating system

The invention discloses a composition for producing a waterborne coating. The composition comprises a component A and a component B, wherein the component A comprises a waterborne hydroxyl acrylic emulsion and a waterborne hydroxyl acrylic dispersion, and the component B comprises a waterborne isocyanate curing agent. By using the coating prepared from the composition disclosed by the invention, apaint film has excellent corrosion resistance even if no antirust coatings are provided, and the problem of system instability caused by hydrolysis of antirust filler is avoided; and meanwhile, the paint film is enabled to have excellent construction performance on the premise that the corrosion resistance of the paint film is guaranteed.

Owner:WANHUA CHEMICAL (NINGBO) CO LTD +2

Bamboo chopstick processing method

InactiveCN105291238ASave energyGuaranteed anti-corrosion performanceWood treatment detailsReed/straw treatmentSulfurMildew

The invention discloses a bamboo chopstick processing method. The bamboo chopstick processing method comprises the following steps: a bamboo is sawn to a bamboo cylinder; the bamboo cylinder is processed to a bamboo piece, and is processed to a bamboo chopstick blank; one end of the bamboo chopstick blank is sharpened; the wet disinfection and the blenching are performed; the preservative treatment is performed; the carbonizing treatment is performed; the drying and the disinfection are performed; the polishing is performed; and the sorting and the packing are performed. Compared with the mildew prevention and the disinfection of chopsticks smoked by sulfur and boiled by hydrogen peroxide, the bamboo chopstick processing method is safer and more reliable; as ozone cannot leave any poisonous substances on the chopsticks, and an ozone disinfection method saves more energy, the excellent mould preventing, bleaching and disinfecting effects can be obtained only by consuming less electric energy without needing heating; bamboo chopsticks are dip in paraffin liquid or tung oil under high temperature, so that the corrosion preventing effect of the chopsticks in later use is effectively guaranteed; the bamboo chopsticks prepared by the method has such performances as corrosion prevention, insect prevention, mildew prevention and damp prevention, and such natural colors as faint yellow and brown are given to the bamboo chopsticks; and the bamboo chopstick processing method increases the mechanical degree, quickens the production speed, and improves the production efficiency.

Owner:安徽泓浩竹科技股份有限公司

De-rusting and spraying intelligent robot in pipeline

InactiveCN104959263AReduce weightReduce volumeLiquid surface applicatorsSpraying apparatusTactile senseEngineering

The invention discloses a de-rusting and spraying intelligent robot in a pipeline. The robot comprises a control case, a driving mechanism, a de-rusting mechanism, a spraying mechanism and a cable. The control case is connected to the driving mechanism, the de-rusting mechanism and the spraying mechanism through the cable. The driving mechanism, the de-rusting mechanism and the spraying mechanism are integrally connected, wherein the driving mechanism is arranged at the front position, the de-rusting mechanism is arranged between the driving mechanism and the spraying mechanism, and the spraying mechanism is arranged at the tail position. According to the invention, the de-rusting and spraying intelligent robot in the pipeline can accurately capture weld joints through a micro-current tactile sensing weld joint capture positioning wheel, good weld grinding effects can be achieved, a coating layer is uniform in thickness, and sagging defects are not caused. The robot is simple in structure, light in weight and small in size, and is convenient to manufacture.

Owner:新疆智安博克自动化装备有限公司

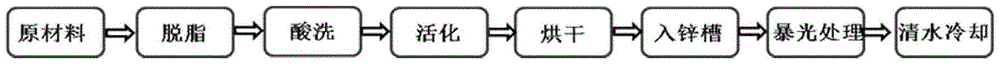

Insulation and anticorrosion method for conductive copper bars

InactiveCN102290156AGuaranteed insulation performanceGuaranteed anti-corrosion performanceCable/conductor manufactureSurface cleaningThermal insulation

The invention provides an insulation and anticorrosion method for conductive copper bars, which uses an air spraying method or an electrostatic powder coating method to coat a thermosetting epoxy powder insulation and anticorrosion coating composed of a primer coating and a surface coating on the surface of the copper bars. Layer epoxy powder electrical insulation and anti-corrosion coating to achieve the purpose of copper bar insulation and anti-corrosion. Its insulating and anti-corrosion coating coating process is: 1) workpiece surface cleaning, 2) infrared heating, 3) spraying, 4) curing coating, 5) cooling, 6) inspection, the qualified ones are the copper bars after insulation and anti-corrosion treatment product. The method of the invention not only improves the insulation, chemical resistance, weather resistance and other properties of the copper bar, but also reduces the labor intensity and saves the cost, improves the service life of the copper bar, and solves the problem of wrapping insulation and heat shrinkage. The flaws and deficiencies of the two methods of suiting.

Owner:NINGBO KEXIN CORROSION CONTROL ENG

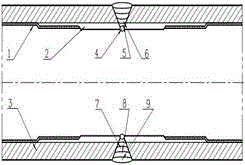

Compound welding method for large-diameter compound steel pipe with pipe ends provided with corrosion resistant alloy through surfacing

InactiveCN106270933AGuaranteed anti-corrosion performanceImprove continuityArc welding apparatusCorrosion resistant alloySteel pipeline

The invention discloses a compound welding method for a large-diameter compound steel pipe with pipe ends provided with corrosion resistant alloy through surfacing. The compound welding method is suitable for continuous corrosion preventing treatment for the inner wall of a weld of a joint of a large-diameter steel pipeline with the inner wall provided with a corrosion resistant layer. The compound welding method is characterized in that during pipeline welding construction of the compound steel pipe with the inner walls of the steel pipe ends provided with the corrosion resistant alloy through surfacing and with the inner wall coated with a corrosion resistant coating, argon-filling-free stainless steel or a nickel-based flux-cored wire and argon are adopted for double protection, and a positioned back welding layer is welded semi-automatically; certain carbon steel components are fused through large welding parameters in a semi-automatic welding mode by adopting argon-filling-free stainless steel or a nickel-based flux-cored wire and argon for double protection, and a transition weld layer with a certain ferritic structure is formed; metal of a filling weld layer and metal of the transition weld layer diffuse mutually through a low-carbon steel flux-cored self-shielded welding wire in a semi-automatic welding mode; and through a cosmetic weld layer with low-carbon steel welding materials, metallurgical fusion between a stainless steel or nickel-based alloy weld layer and a surfacing layer is achieved, metallurgical fusion between the low-carbon steel weld layer and the stainless steel or nickel-based alloy weld layer is achieved, the restricted zone of welding and fusing low-carbon steel welding materials on a stainless steel or nickel-based alloy material is broken, and pipeline welding construction quality and efficiency for the large-diameter surfacing compound steel pipe are improved.

Owner:胜利油田金岛工程安装有限责任公司 +2

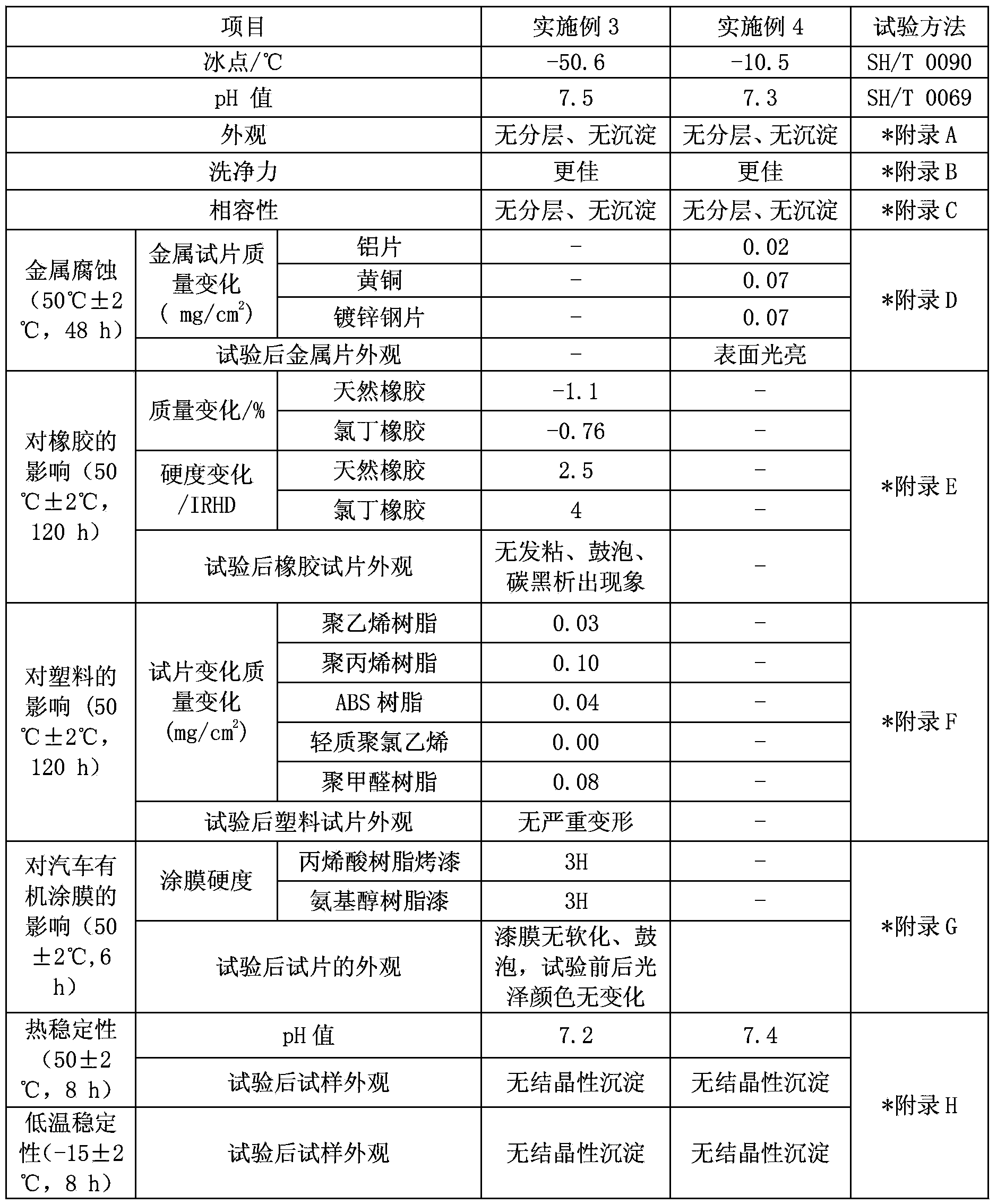

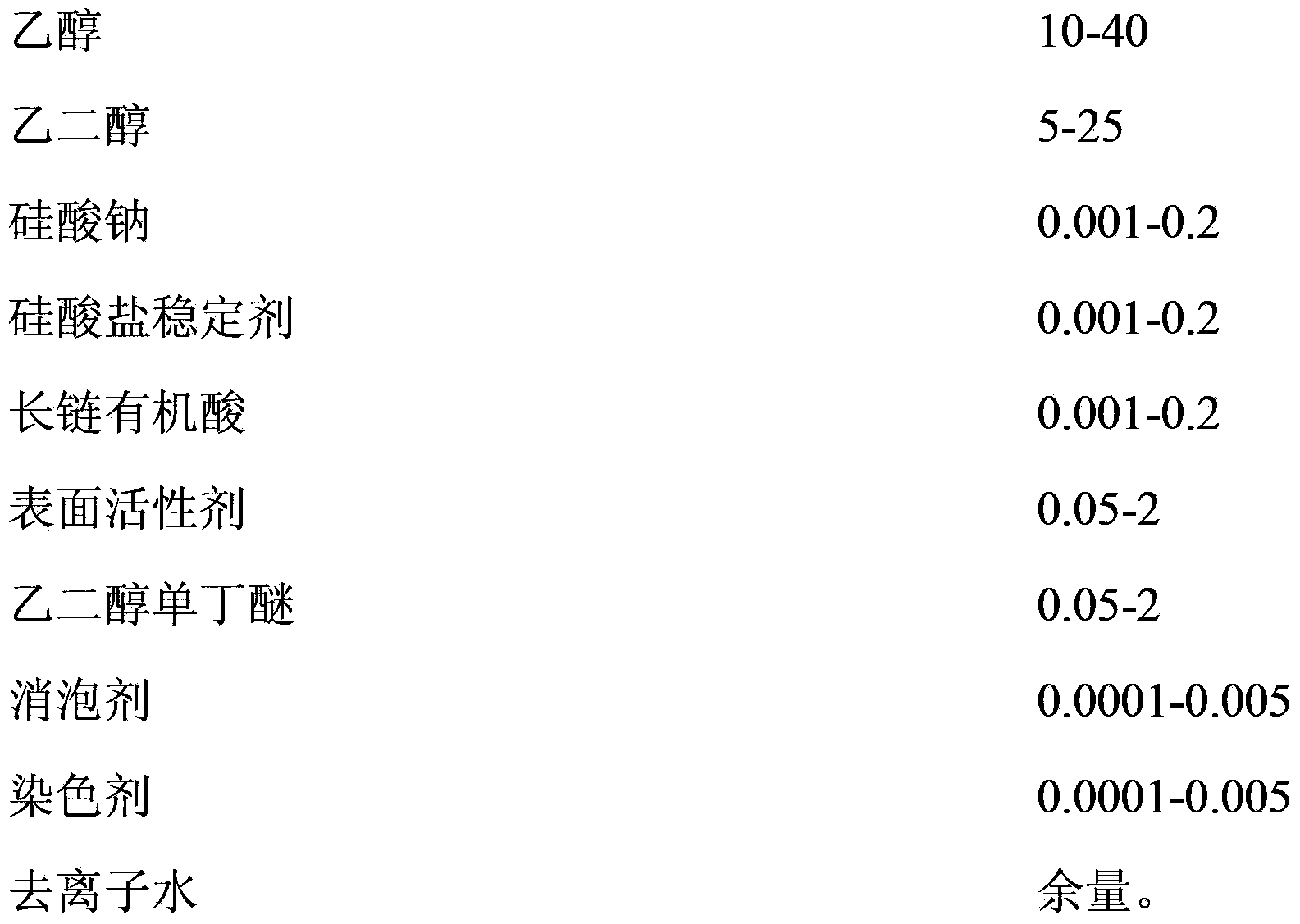

Automobile windshield cleaning fluid

InactiveCN104277924AAvoid harmEfficient removalOrganic detergent compounding agentsSurface-active detergent compositionsSolventChemistry

The invention relates to an automobile windshield cleaning fluid. The automobile windshield cleaning fluid is prepared from the following components in percentage by mass: 10-40% of alcohol, 5-25% of ethylene glycol, 0.001-0.2% of sodium silicate, 0.01-0.2% of a silicate stabilizer, 0.001-0.2% of long-chain organic acid, 0.05-2% of a surfactant, 0.05-2% of ethylene glycol monobutyl ether, 0.0001-0.005% of a defoaming agent and 0.0001-0.005% of a colorant. Alcohol and ethylene glycol are adopted as a solvent, so that harms of methanol on a human body are effectively avoided; dust and blot on the automobile windshield surface can be quickly cleaned, and thus, the automobile windshield cleaning fluid has performances of being anti-freezing, anti-fogging and lubricant; by virtue of rational compatibility, the cleaning agent has anti-corrosive and inhibiting effects on various metals such as cast aluminum, steel and copper; meanwhile, the adjustment of a pH value of the cleaning agent is realized, so that the automobile windshield cleaning fluid has relatively stable performances, and a simple and practical formula.

Owner:PETROCHINA CO LTD

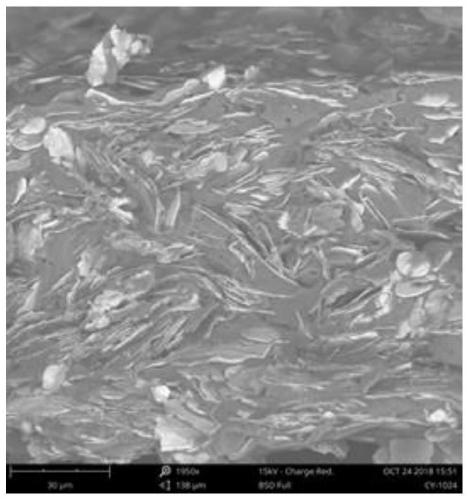

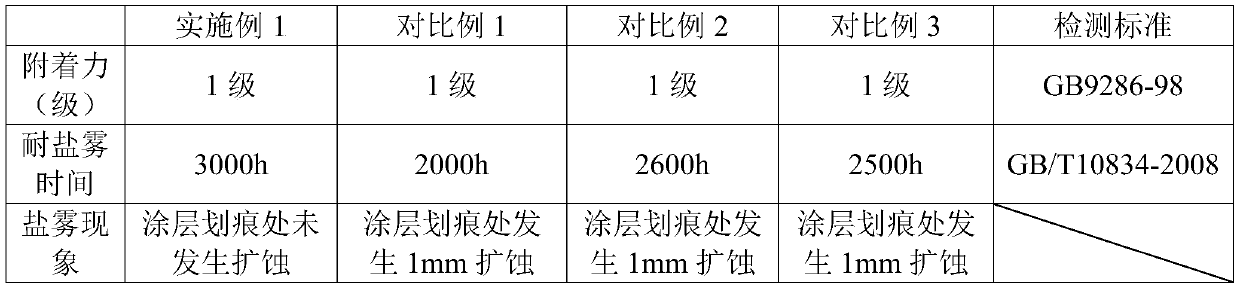

Water-based inorganic zinc-rich anticorrosive paint and preparation method thereof

InactiveCN110437654AGuaranteed anti-corrosion performanceAdd lessAlkali metal silicate coatingsAnti-corrosive paintsWater basedGraphene

The invention discloses water-based inorganic zinc-rich anticorrosive paint and a preparation method thereof. The water-based inorganic zinc-rich anticorrosive paint comprises 30-50 wt% of a silicate,45-70 wt% of a two-dimensional barrier material and 0-5 wt% of a paint assistant, wherine the modulus of a silicate solution is greater than or equal to 4.0, the two-dimensional barrier material comprises modified flaky zinc powder, modified sericite and graphene, the modified flaky zinc powder is prepared by modifying flaky zinc powder through a surface modifier, the modified sericite is prepared by modifying sericite through a surface modifier, and the surface modifier is an organosilane coupling agent. The compact two-dimensional barrier layer is formed under the combined action of the modified sericite and the graphene, and the corrosion resistance of the paint can be remarkably improved, so that the use amount of zinc powder can be reduced on the premise of ensuring the corrosion resistance of the paint, and the paint achieves the effects of low zinc powder addition amount and excellent corrosion resistance.

Owner:SHENZHEN ACAD OF AEROSPACE TECH

Rare earth permanent magnet powder, preparation method thereof, bonded permanent magnet containing same and device

ActiveCN105206366AGuaranteed MagneticGuaranteed anti-corrosion performancePermanent magnetsInorganic material magnetismRemanenceMetallurgy

The invention discloses rare earth permanent magnet powder, a preparation method thereof, a bonded permanent magnet containing the same and a device. The rare earth permanent magnet powder is composed of Fe<100-x-y-z>Nd<y>Q<z>N<x>, wherein the Q is B or B and C, the x is larger than or equal to 0.8 and smaller than or equal to 3.5, the y is larger than or equal to 5 and smaller than or equal to 15, and the z is larger than or equal to 4 and smaller than or equal to 10. The main phase of the rare earth permanent magnet powder is of an Nd<2>Fe<14>B structure, and one or more of the coercive force and the maximum magnetic energy product of the rare earth permanent magnet powder are over 95% of the performance of a corresponding magnet without nitrogen elements. According to the rare earth permanent magnet powder, the preparation method thereof, the bonded permanent magnet containing the same and the device, the main phase structure of the rare earth permanent magnet powder is the Nd<2>Fe<14>B phase, and it can be guaranteed that the rare earth permanent magnet powder has certain residual magnetism and the coercive force; the N elements are introduced, and it is defined that one or more of the coercive force and the maximum magnetic energy product of the rare earth permanent magnet powder are over 95% of the performance of a corresponding magnet without nitrogen elements, so that influences on the Nd<2>Fe<14>B structure of introduction of the N is lowered, the anti-corrosion property of the rare earth permanent magnet powder is improved without greatly lowering the magnetic performance, and the stability of the magnet is guaranteed.

Owner:GRIREM ADVANCED MATERIALS CO LTD

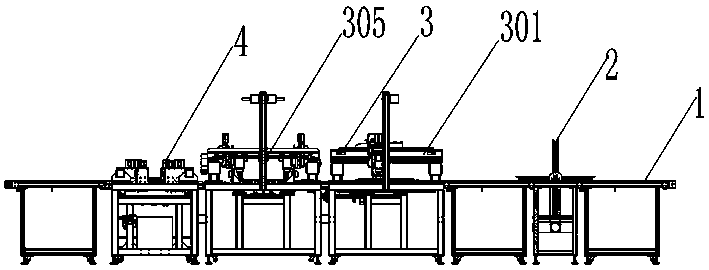

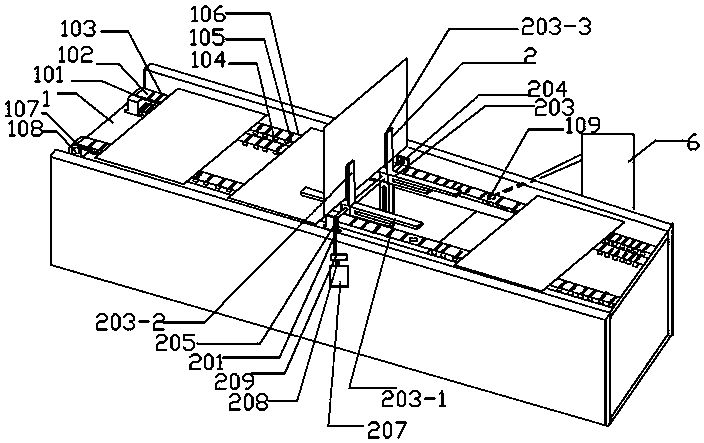

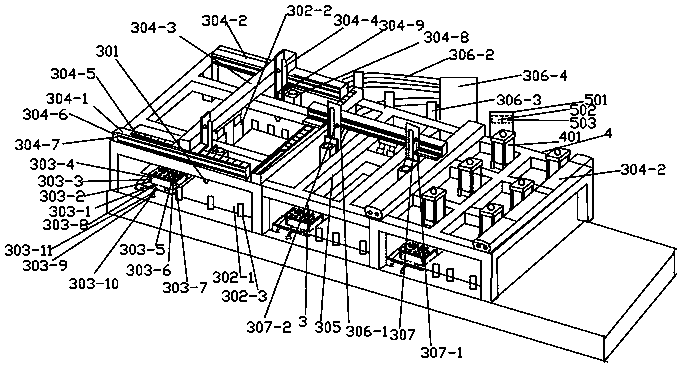

Full-automatic plate-overturning, slotting, corner-cutting and punching system

PendingCN108213192AAct as a fixed supportGuaranteed stabilityPerforating toolsMetal-working feeding devicesPunchingEngineering

The invention discloses a full-automatic plate-overturning, slotting, corner-cutting and punching system comprising an automatic feeding conveying line system, an automatic plate overturning system, an automatic slotting system and an automatic corner-cutting and punching system. The automatic plate overturning system is arranged above the automatic feeding conveying line system, the automatic slotting system is arranged on one side of the automatic plate overturning system and is connected with the automatic feeding conveying line system, and the automatic slotting system is composed of a longitudinal slotting mechanism, a clamping and positioning mechanism, a jacking and transferring mechanism, a slotting driving mechanism, a transverse slotting mechanism, a vacuum dust extracting systemand a manual fine adjusting mechanism. The automatic corner-cutting and punching system is arranged on one side of the automatic slotting system and is connected with the jacking and transferring mechanism. Transverse clamping plates and vertical clamping plates can clamp and overturn plates in all directions, slots can be formed in multiple directions, the slotting depth and the slotting angle can be effectively controlled and adjusted to adapt to composite plates of different types and different lengths, the two sides and the front and rear ends of the composite plates can be fixed, and thecomposite plates can be effectively prevented from jumping during slotting.

Owner:JIANGSU XIECHENG SCI & TECH DEV +1

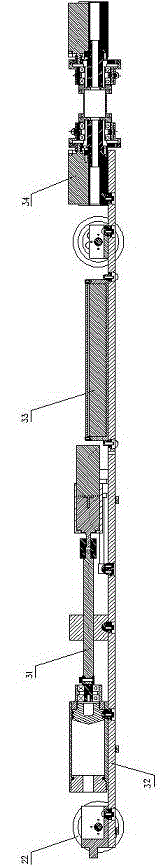

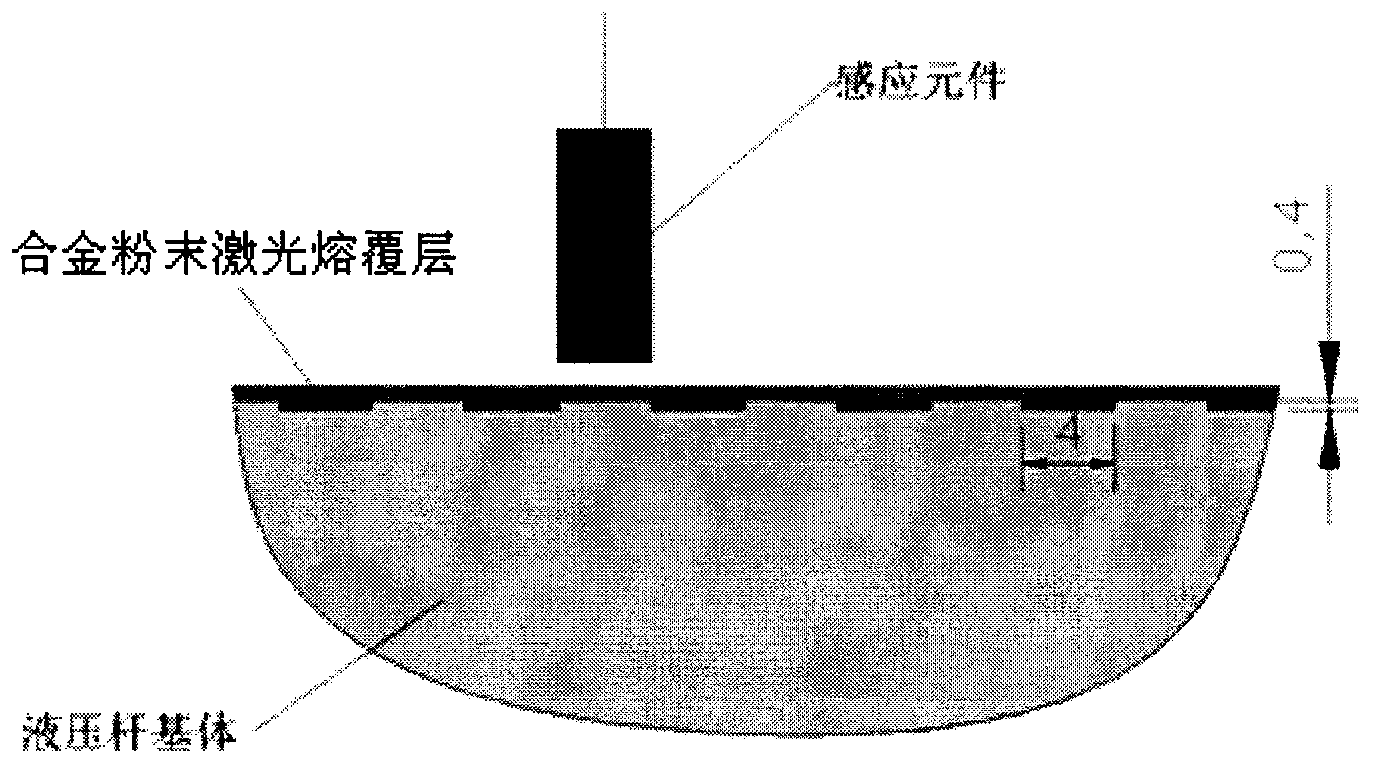

Electromagnetic type stroke measurement hydraulic hoist oil cylinder piston rod with alloy powder laser cladding surface

InactiveCN103671350AGuaranteed mechanical propertiesGuaranteed anti-corrosion performanceFluid-pressure actuatorsMetallic material coating processesAlloyWear resistance

The invention provides an electromagnetic type stroke measurement hydraulic hoist oil cylinder piston rod with an alloy powder laser cladding surface. The electromagnetic type stroke measurement hydraulic hoist oil cylinder piston rod comprises the alloy powder laser cladding surface and parallel annular electromagnetic measurement grooves below the cladding surface. The sections of the grooves can be rectangular or arc, the depth of the grooves is 0.1mm-2mm, the width of the grooves is 0.5mm-4mm, and the distance between the grooves is 0.5mm-4mm. The wear resistance and corrosion resistance of the surface of the piston rod are well combined with the stroke measurement of the piston rod, the mechanical performance, the corrosion resisting performance and the wear resisting performance of the surface of the piston rod are guaranteed, and meanwhile the accurate measurement on the stroke and speed of the piston rod is achieved.

Owner:JIANGSU CHENGUANG SUNDE HYDRAULIC EQUIP

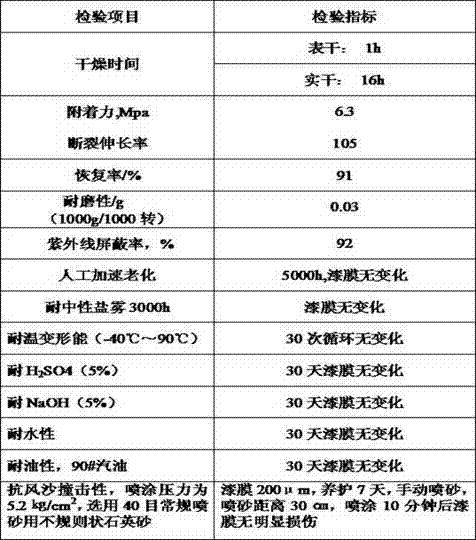

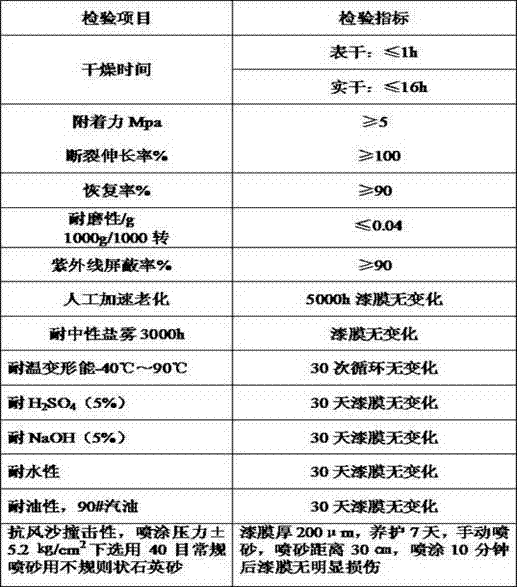

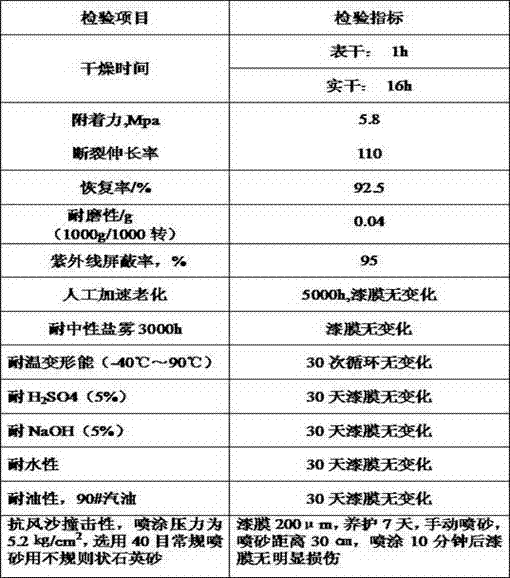

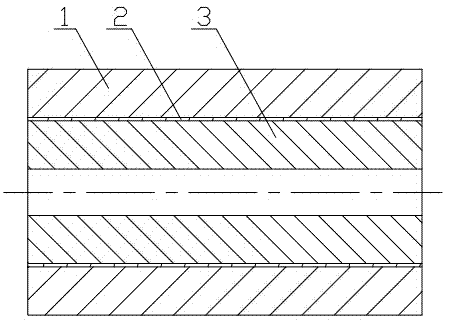

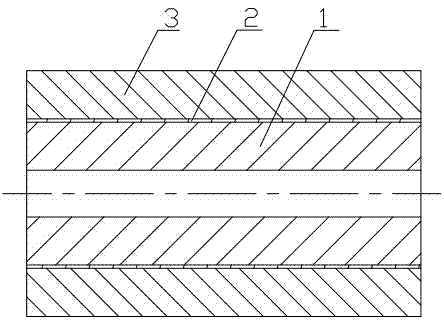

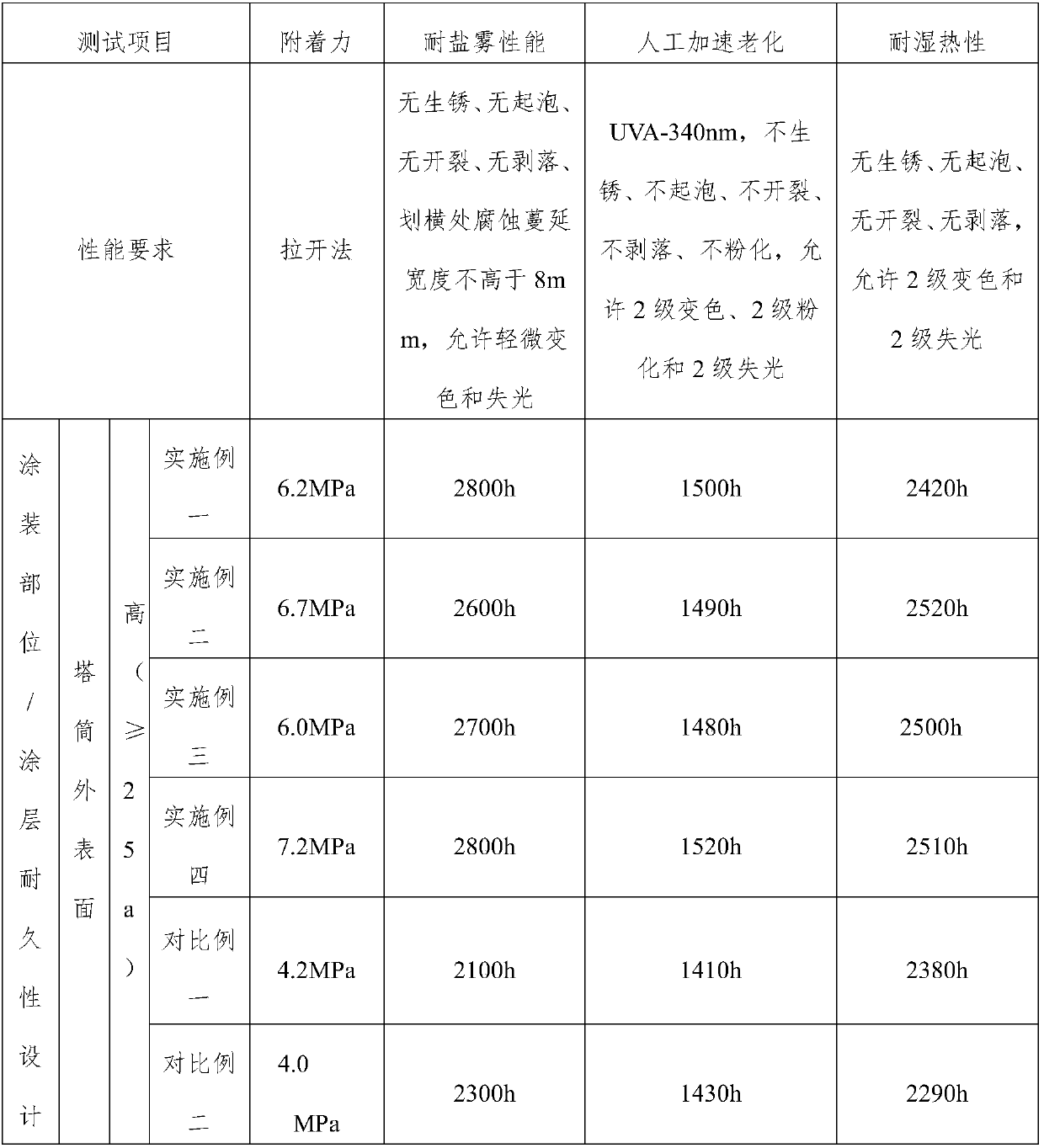

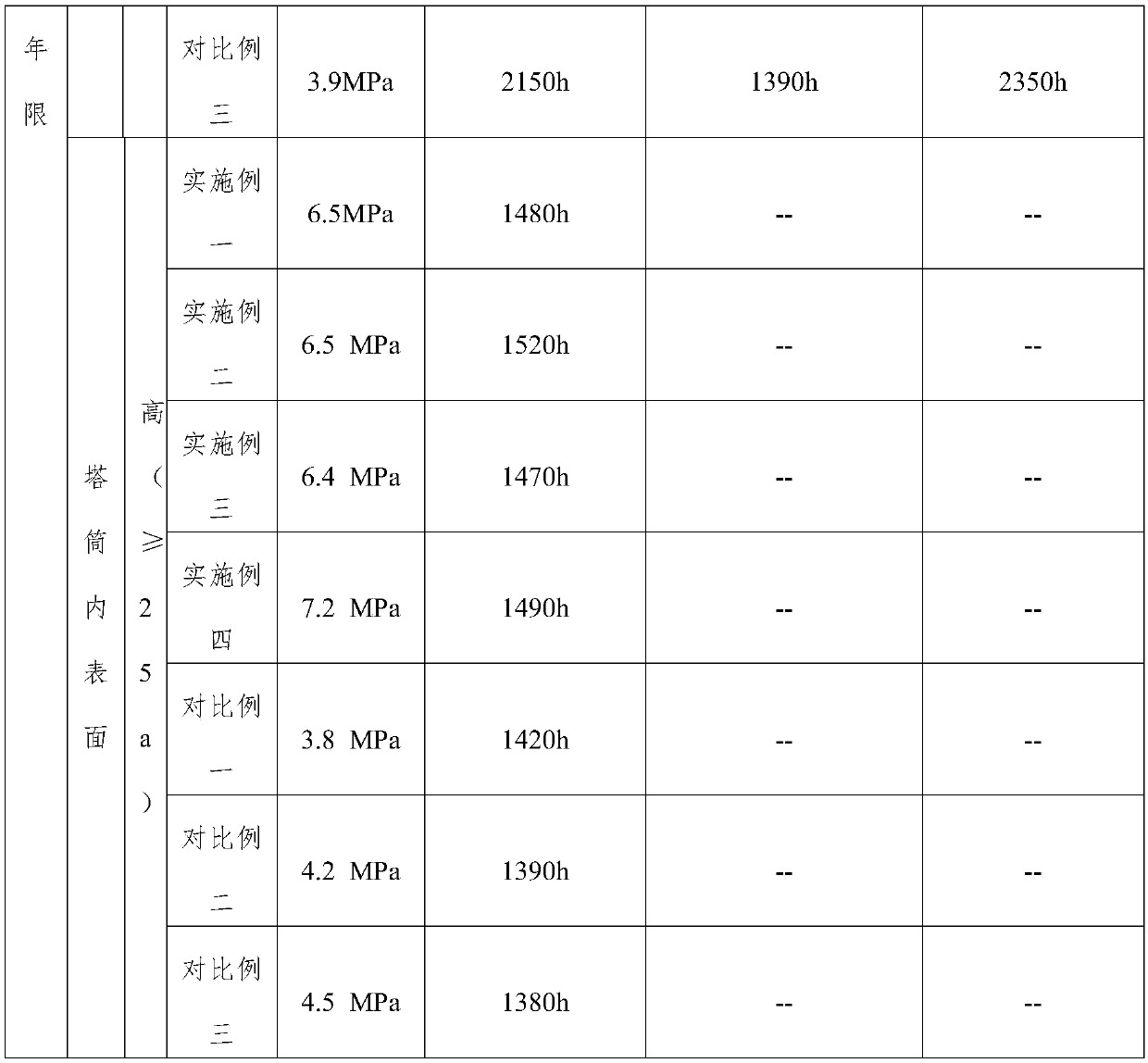

Method for preparing and spaying anticorrosion coating for western wind farm tower

ActiveCN102775877AIncrease elasticityImprove wear resistanceLiquid surface applicatorsAnti-corrosive paintsWeather resistanceSolvent

The invention discloses a method for preparing and spraying an anticorrosion coating for a western wind farm tower. The anticorrosion coating consists of priming paint, intermediate coat and finish, wherein the priming paint comprises an elastic resin A, zinc powder, a mixed solvent, an adhesion promoter, a base material wetting agent, an antifoaming agent and a curing agent A; the intermediate coat comprises an elastic resin B, a shielding impervious material, a mixed solvent, an antifoaming agent and a curing agent B; the finish comprises an elastic resin C, a weather-resistant anticorrosion material, a mixed solvent, an antifoaming agent, a wetting dispersing agent, a flatting agent and a curing agent C. The priming paint can weaken and absorb the impact stress of sand and wind on the film, the intermediate coat can weaken the impact stress from the finish, the elastic deformation capacity of the whole coating is improved, the finish has good weather resistance and has the characteristics of high elasticity, high wear resistance, high breaking elongation, high tensile strength, high sand and wind impact resistance and the like, and according to the preparing and spraying method, main performance indexes of the anticorrosion coating meet the application requirements of the western wind farm tower.

Owner:洛阳双瑞防腐工程技术有限公司

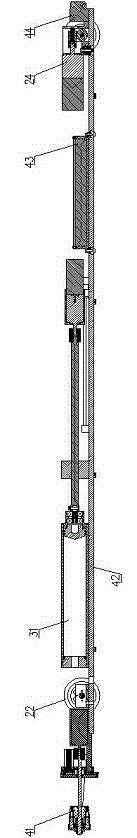

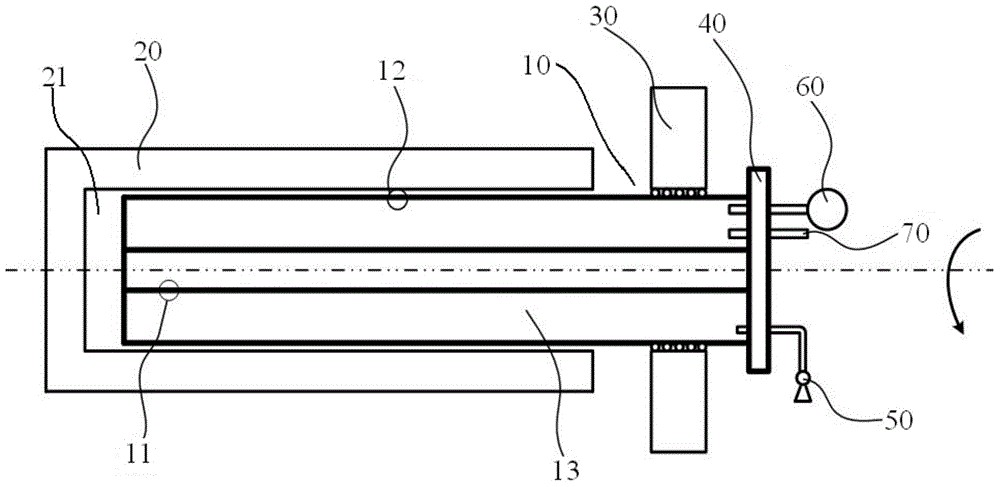

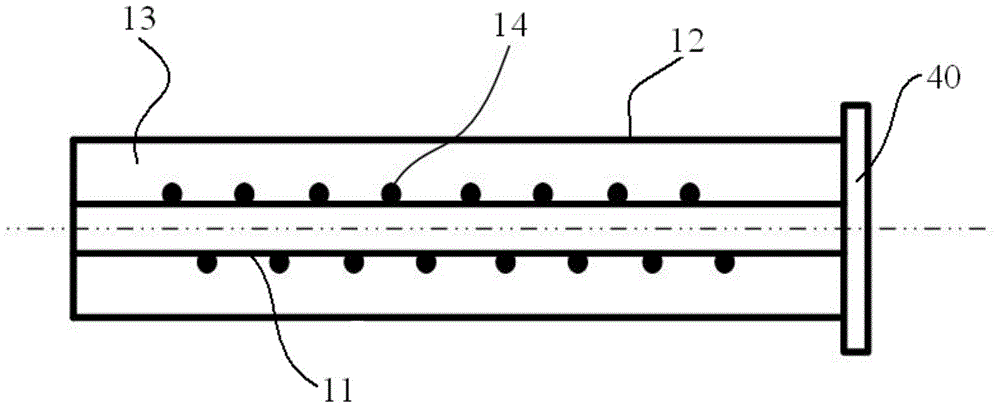

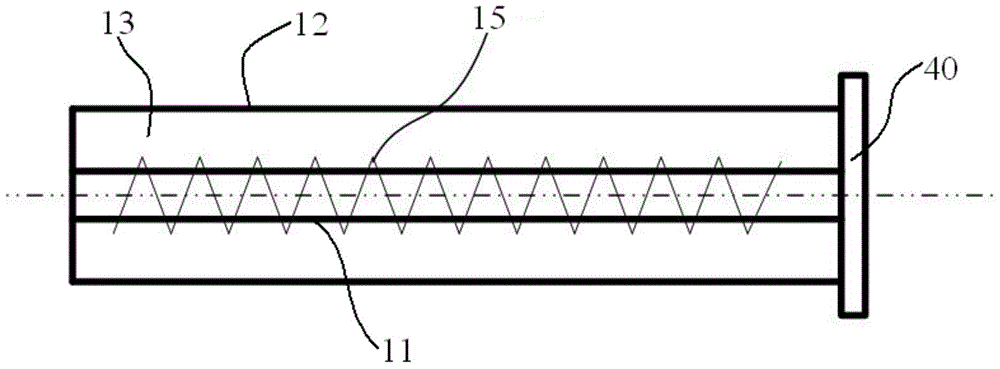

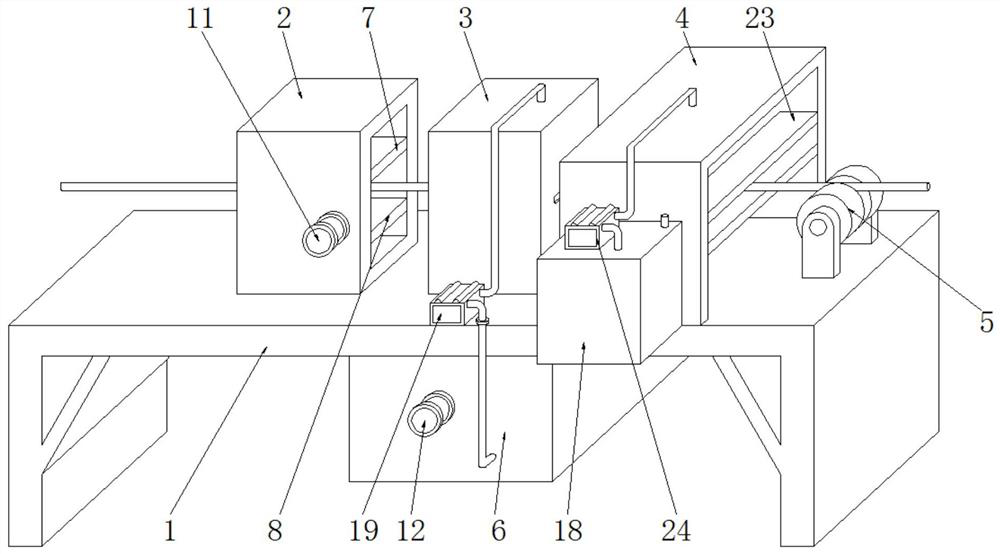

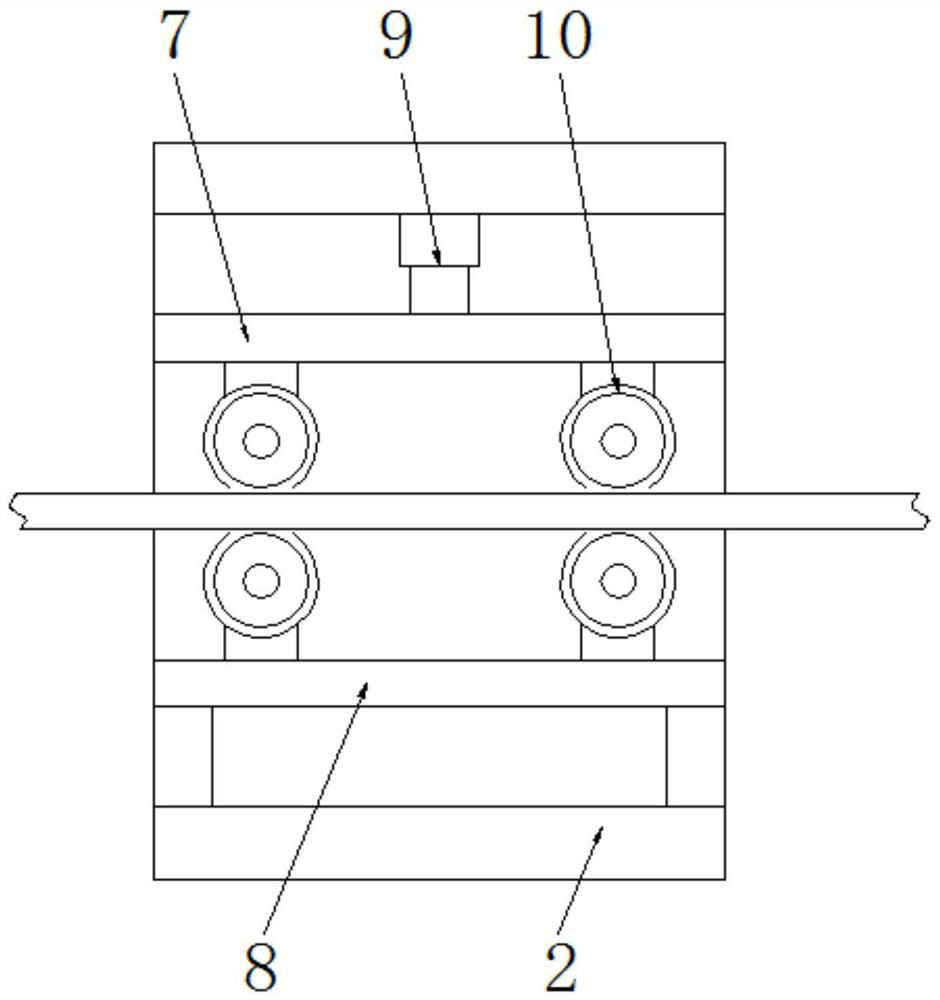

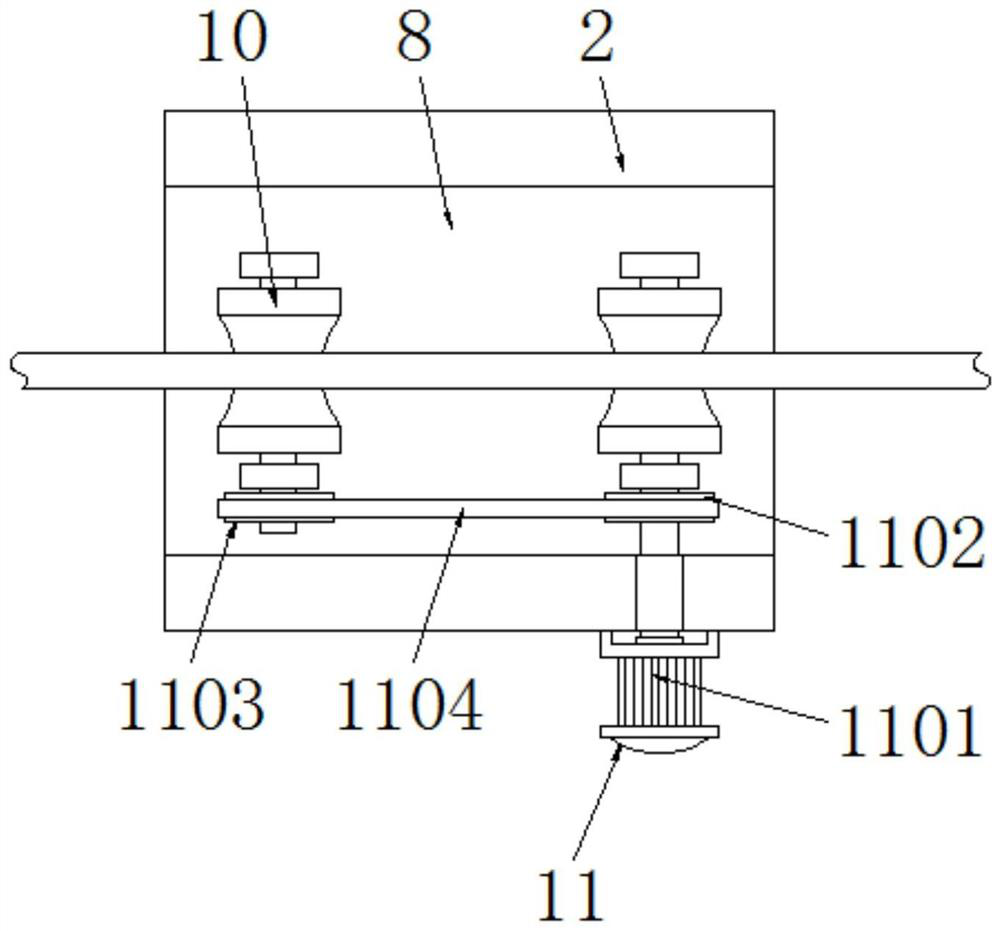

Continuous anti-corrosion treatment equipment and process for rods and wires

PendingCN112427171AGuaranteed water sprayGuaranteed anti-corrosion performancePretreated surfacesLiquid spraying apparatusWire rodReciprocating motion

The invention discloses continuous anti-corrosion treatment equipment and a process for rods and wires, and belongs to the technical field of anti-corrosion treatment of rods and wires. The continuousanti-corrosion treatment equipment comprises a workbench, wherein a conveying frame, a cleaning box, an anti-corrosion spraying frame and a supporting roller are sequentially installed on the upper surface of the workbench from left to right, a water tank is installed on the lower surface of the workbench through bolts, and a first supporting plate and a second supporting plate are arranged in the conveying frame. By arranging the conveying frame, rapid conveying of rods and wires is achieved, the structure is simple, and the conveying stability is good; water in the water tank is pumped through a high-pressure water pump and sprayed out through first spraying heads, high-pressure washing can be conducted on the surfaces of the rods and wires to remove rust, the surfaces of the rods and wires can be treated to remove the rust before anticorrosive paint is sprayed, and the anticorrosive effect of the anticorrosive paint sprayed in the later period is guaranteed; and by arranging an adjusting part and a residue filtering net, it is guaranteed that the residue filtering net reciprocates up and down to vibrate through the cooperation of cam rotation and springs to avoid mesh blockage,and therefore smooth proceeding of the residue filtering net is ensured.

Owner:河北敬业钢构科技股份有限公司

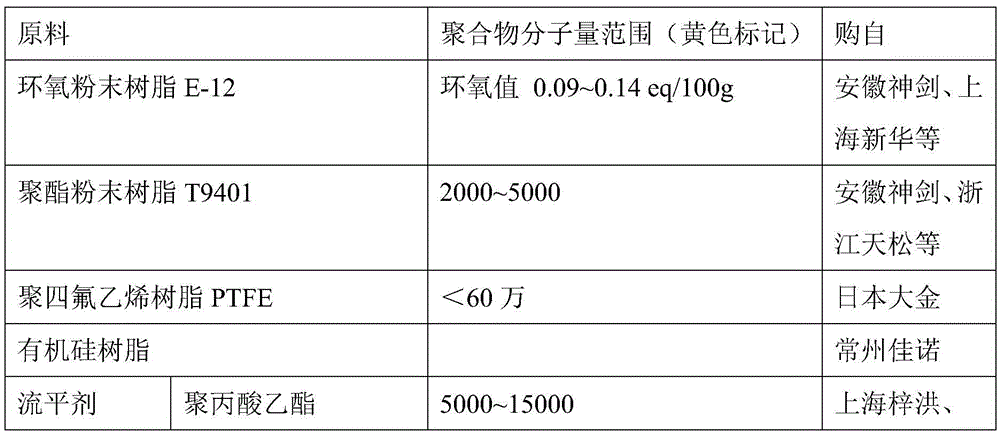

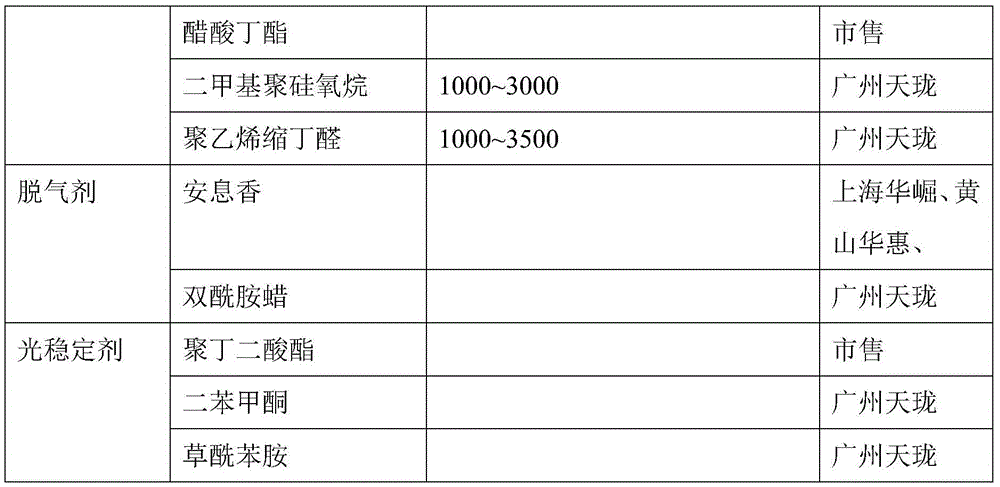

VCI powder bimetallic coating for steel structure surface protection and preparation method thereof

ActiveCN105542621AComprehensive anti-rust effectPrevent rustAnti-corrosive paintsPowdery paintsMetallic substrateMaterials science

The invention provides a VCI (Vapor Corrosion Inhibitor) powder bimetallic coating for steel structure surface protection and a preparation method thereof. The ofpowder bimetallic coating comprises the following components in parts by weight: a binder, a filler, a VCI vapor corrosion inhibitor and an auxiliary, wherein the binder comprises 15-25 parts of powdered epoxy resin, 15-25 parts of powdered polyester resin, 5-15 parts of polytetrafluoroethylene resin, and 5-15 parts of organic silicon resin; the filler comprises 30-60 parts of flake zinc powder, 1-5 parts of flake aluminum powder, 5-10 parts of aluminum triphosphate, and 5-10 parts of zinc phosphate; the auxiliary is selected from one or more of a flatting agent, a conductive agent, a degassing agent and a light stabilizer; the mass ratio of the binder to the filler is 3:1 to 1:2.5; the mass of the VCI vapor corrosion inhibitor is 5-10% of the total mass of the binder and the filler; the mass of the auxiliary is 2-10% of the total mass of the binder and the filler. The coating plays a good shielding role as a powdered coating, further plays a cathode protection role as a common zinc-rich coating, and meanwhile takes a corrosion inhibition effect as the VCI vapor corrosion inhibitor, so as to achieve the excellent protection effect for the metal binder. In addition, the powdered coating disclosed by the invention is prepared by mixing different weather-resistant resins, so that the powdered coating has better weather resistance than the common powdered coating.

Owner:JIANGSU AVIC BAIMU NEW MATERIAL TECH +1

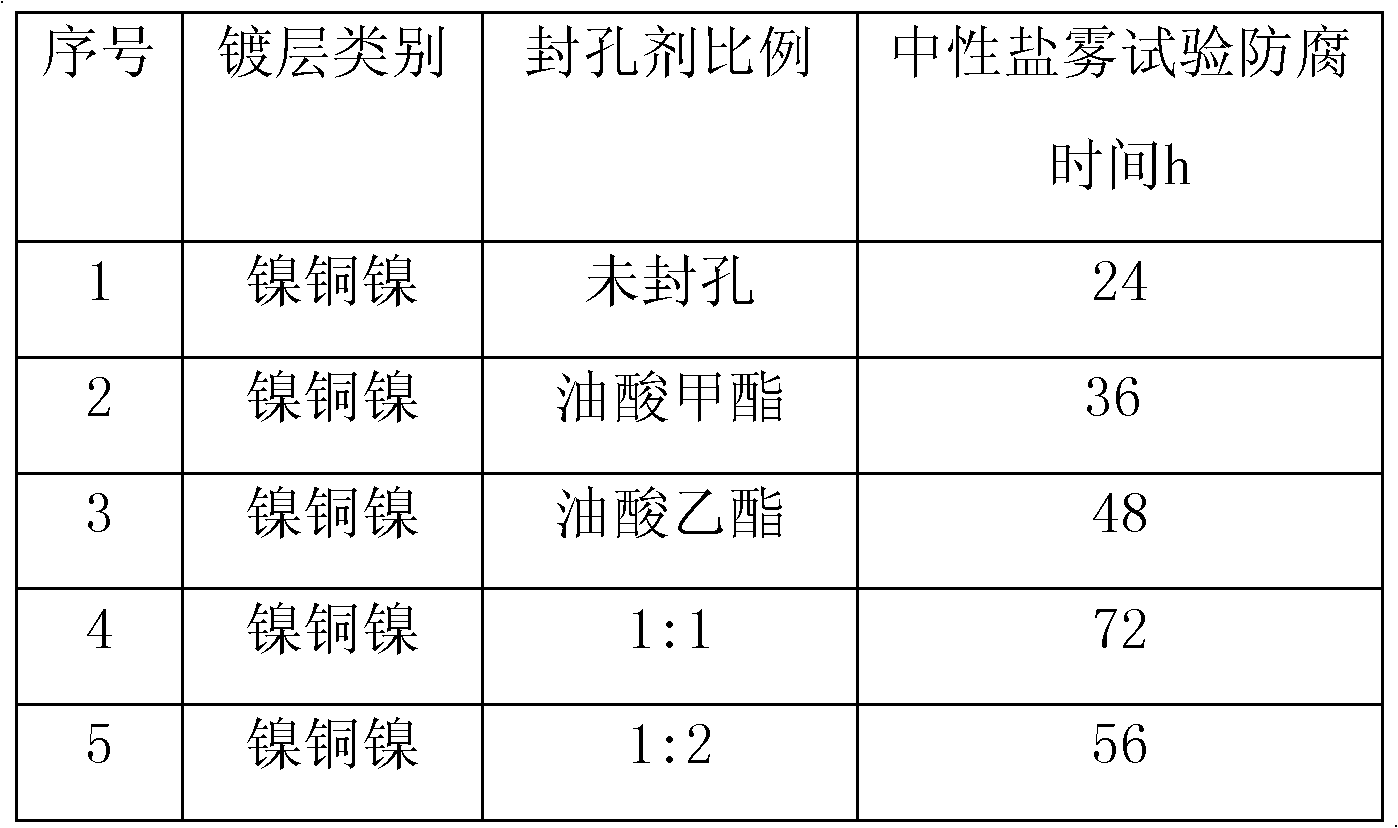

Surface hot dipping and pore sealing method of neodymium-iron-boron permanent magnet material

InactiveCN102581287AReduce erosionGuaranteed binding effectInorganic material magnetismInductances/transformers/magnets manufactureSurface corrosionCorrosion resistant

A surface hot dipping and pore sealing method of a neodymium-iron-boron permanent magnet material belongs to the technical field of surface corrosion protection of neodymium-iron-boron permanent magnet materials. The method comprises the steps of heating a neodymium-iron-boron permanent magnet at 120-240 DEG C for 1-2.5h; and impregnating the heated neodymium-iron-boron permanent magnet in a pore sealing agent and sealing micropores on the surface of the neodymium-iron-boron permanent magnet, and taking out untill the surface temperature of the neodymium-iron-boron permanent magnet is lower than 40 DEG C. The pore sealing agent is methyl oleate and / or ethyl oleate, and the ratio of methyl oleate to ethyl oleate is 1:1 or 1:2 when the pore sealing agent employs a mixture of methyl oleate and ethyl oleate. By adoption of the pore sealing method, after the heated neodymium-iron-boron permanent magnet contacts the low-temperature pore sealing agent, the volume of the surface micropores is reduced and the pressure inside the micropore is reduced, so that the pore sealing agent is sucked into the micropores and plays a role in sealing pores of the neodymium-iron-boron permanent magnet, and the corrosion reduction of acidic and basic solutions to the magnet surface is facilitated in an electroplating process. The neodymium-iron-boron permanent magnet subjected to sealing pore is uniform in surface structure, and ensures the bonding force and the corrosion resistant performance of an electroplating layer in the subsequent electroplating process.

Owner:SHENYANG GENERAL MAGNETIC

Waterborne anticorrosive coating for improving interface bonding force of rusty metal and anticorrosive coating and preparation method thereof

InactiveCN104559668AEffective dissolutionEffectively dissolves and transformsAnti-corrosive paintsEpoxy resin coatingsEmulsionFirming agent

The invention discloses a waterborne anticorrosive coating for improving the interface bonding force of a rusty metal and an anticorrosive coating. The waterborne anticorrosive coating comprises a component A and a component B in a mass ratio of (2-4): 1, wherein the component A consists of the following components in parts by mass: 40-60 parts of waterborne epoxy emulsion, 5-15 parts of rust protection padding, 5-20 parts of transformation liquid, 1-5 parts of a pH stabilizer, 1-3 parts of an aid and 10-35 parts of deionized water; and the component B consists of a curing agent and deionized water in a mass ratio of (4-6): 1. The waterborne anticorrosive coating contains the active group transformation liquid capable of converting a rust layer, the activity of the transformation liquid in the waterborne anticorrosive coating can be ensured in the presence of the pH stabilizer, and the rust layer can be effectively dissolved and transformed, so that the interface bonding force of the rusty metal and the anticorrosive coating can be greatly improved.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

Bimetallic composite steel pipe and production method thereof

InactiveCN104266003AHigh bonding strengthDamaged corrosion resistanceRigid pipesInterference fitPass rate

The invention discloses a bimetallic composite steel pipe and a production method thereof and relates to the technical field of metal rigid pipes and manufacturing methods thereof. The bimetallic composite steel pipe comprises an austenitic stainless steel pipe and a carbon steel pipe, the connection surface between the austenitic stainless steel pipe and the carbon steel pipe is provided with a nickel-based alloy joint layer formed by surfacing and turning, and interference fit is used. The production method includes the steps of selecting an outer pipe and an inner pipe or an inner bar, machining the nickel-based alloy joint layer through surfacing and turning, performing interference fit on a mechanical bushing, performing reaming and high-temperature diffusion heat treatment, and performing extrusion forming to produce the bimetallic composite steel pipe. According to the bimetallic composite steel pipe and the production method thereof, the nickel-based alloy layer is formed between the inner metal and the outer metal of the bimetallic composite steel pipe through surfacing so as to prevent carbon elements of the carbon steel from diffusing into the austenitic stainless steel to further effectively prevent the corrosion resistance of the austenitic stainless steel from being damaged, and accordingly, the joint strength is guaranteed, the pass rate is high, the compositions are stable, the quality is good, the manufacturing process is simple, and the cost of production is greatly reduced.

Owner:HANDAN XINXING SPECIAL TUBING CO LTD

Environment-friendly, thermal-insulating and corrosion-resistant coating for metal and preparation method of coating

InactiveCN106085145AExcellent metal corrosion resistancePromote environmental protectionFireproof paintsAnti-corrosive paintsGas phaseThermal insulation

The invention discloses an environment-friendly, thermal-insulating and corrosion-resistant coating for metal. The environment-friendly, thermal-insulating and corrosion-resistant coating is characterized by being prepared from raw materials in parts by weight as follows: 60-90 parts of acrylic acid modified epoxy resin, 3-8 parts of modified polyuria, 20-35 parts of a composite thermal insulation agent, 10-20 parts of nano hydroxyapatite powder, 3-6 parts of a wet dispersant, 8-15 parts of gas-phase aluminum oxide, 2-10 parts of polyacrylate type thickeners, 1-5 parts of lower-molecular polyethylene wax, 1-2 parts of zinc dihydrogen phosphate with the concentration being 1.5%, 2-8 parts of propylene glycol, 0.5-1 part of mercaptobenzothiazole, 3-20 parts of other aids and 20-30 parts of water. The invention also discloses a preparation method of the environment-friendly, thermal-insulating and corrosion-resistant coating for the metal. The coating prepared according to the raw material formula with the preparation method has good metal corrosion resistance, environmental protection performance and thermal insulation performance.

Owner:SUZHOU HONGKE METAL PROD CO LTD

Graphene anticorrosive coating, preparation method of anticorrosive coating, and method for coating wind power spindle

InactiveCN108102539AHigh curing strengthImprove corrosion resistanceAnti-corrosive paintsSpecial surfacesEpoxySolvent

The invention discloses a graphene anticorrosive coating. The graphene anticorrosive coating comprises the following components by weight percent: 0.01-7% of graphene, 35-45% of methyl-silicone, 10-15% of epoxy resin with the solid content of 50%, 5-20% of a preservative, 3-6% of an assistant, 1-3% of a silane coupling agent and the balance of a base material serving as a solvent. The invention further discloses a preparation method of the graphene anticorrosive coating and a method for coating a wind power spindle by using the graphene anticorrosive coating. The graphene anticorrosive coatinguses the fact that two-dimensional carbon nanosheet structures of graphene of thermally reduced graphene are stacked layer by layer to form a dense physical anticorrosive insulating layer; the silanecoupling agent modifying technique of the thermally reduced graphene is studied, the silane hydrolysis hydroxyl and an oxygen-containing group on the surface of the thermally reduced graphene form achemical bond, the silane amino directly participates into the curing of the epoxy resin, a dense anticorrosive film is formed through overlap joint; the synergistic activation of the graphene and a zinc powder is studied to form a conductive path protected by a metal base cathode, the excellent electrochemical protection is realized, the multi-anticorrosion technique facing the wind power spindlein the severe marine service environment is formed; the reverse thinking is adopted to change corrosion prevention into leading.

Owner:JIANGYIN ZENKUNG FORGING CO LTD

Processing method for improving durability of birch

InactiveCN107571361AHigh strengthImprove smoothnessWood treatment detailsPressure impregnationFiberPorosity

The invention mainly relates to the technical field of wood products processing, and discloses a processing method for improving the durability of birch. The processing method includes the steps of cutting, soaking, freezing, strengthening and drying; the method is simple, the strength and rigidity of the birch after being processed are improved obviously, the use range of the birch is increased,and the economic income is increased by 18.6%; birch sections are peeled and then cut, and later even processing is facilitated; the processing efficiency is improved; wood beams are placed in a preservative liquid for being soaked at high temperature, the preservative liquid is promoted to be infiltrated into the wood beams, residual bacteria and worm eggs in the wood beams are killed, mildew andmoth are avoided, and the anti-corrosion performance of the wood beams is improved; the preservative liquid is extracted from pure Chinese herbs and without any poisonous reagent, and the fact that human health is harmed in the processing and using process of the birch is avoided; after being soaked, freezing is conducted through gradually reducing the temperature, water is changed into crystalline water, the porosity between fiber of the birch is increased, the flexibility of the birch is improved, then low-temperature drying is conducted, absorption of the wood beams to a processing liquidis facilitated.

Owner:阜南佳利工艺品股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com