De-rusting and spraying intelligent robot in pipeline

A technology of an intelligent robot and a spraying mechanism, applied in the field of intelligent robots, can solve the problems of easy sagging defects, poor welding seam grinding effect, uneven coating thickness, etc., and achieves the effect of light weight, easy operation, and reduced labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

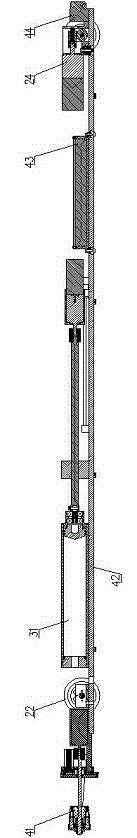

[0037] Please refer to figure 1 , in this specific embodiment, the control box (1) is connected with the drive mechanism (2), the rust removal mechanism (3), and the spraying mechanism (4) through the cable (5); the drive mechanism (2), the rust removal mechanism (3), The spraying mechanism (4) is connected with each other as a whole, the driving mechanism (2) is at the front, the derusting mechanism (3) is located between the two, and the spraying mechanism (4) is located at the tail.

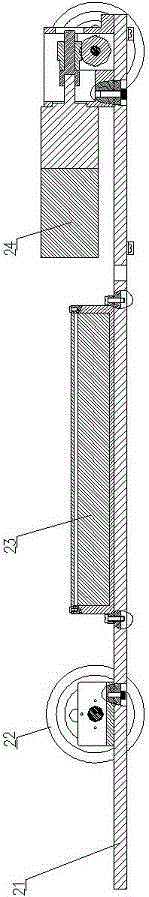

[0038] Please refer to figure 2 , in this specific embodiment, one side of the bottom plate A (21) is provided with a drive wheel component (24), and the other side is provided with a micro-current tactile sensing weld seam capture positioning wheel (22); the drive electric control system (23) is located at the drive Between the wheel part (24) and the micro-current tactile sensing welding seam capture positioning wheel (22).

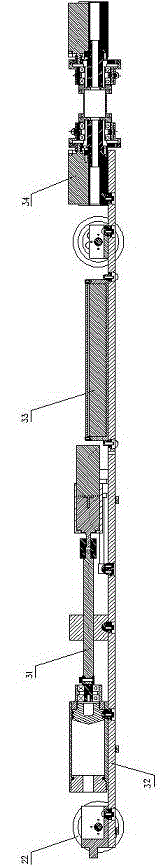

[0039] Please refer to image 3 , in this specific embodiment,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com