Novel crossing pipeline outer layer material and preparation method

An outer layer material and pipeline technology, which is applied in the field of new-type pipeline outer layer materials and preparation, can solve the problems of harsh use conditions of protective materials, and achieve the effects of reducing shielding effect, improving bonding performance, and reducing processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

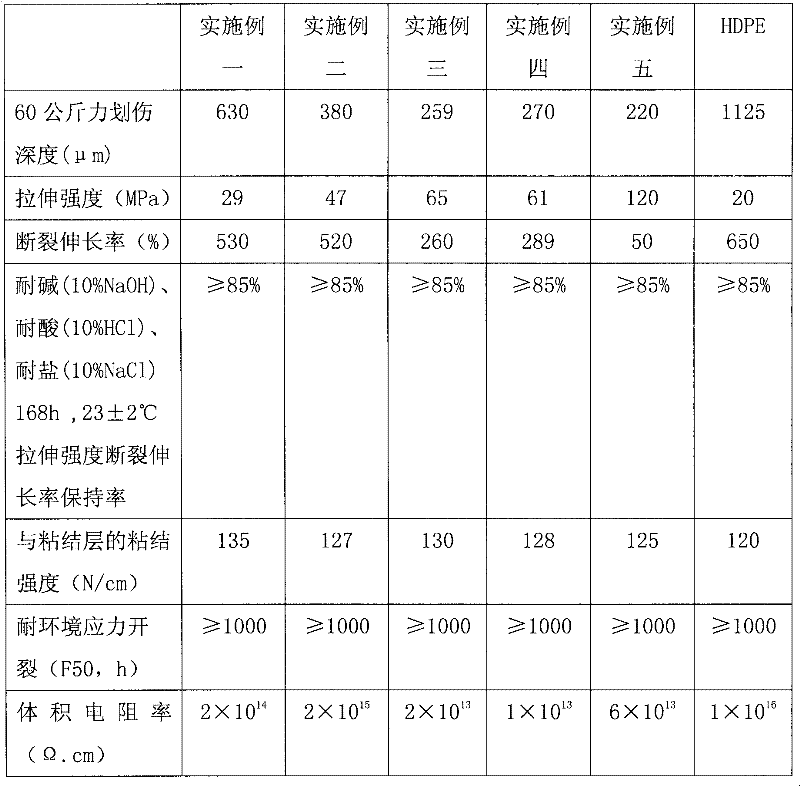

Examples

Embodiment 1

[0023] 100 parts of polymer matrix: linear low density polyethylene, 5 parts of reinforcing particles: modified carbon nanotubes, 6 parts of lubricating particles: graphite, 2 parts of polar filler: silica modified by coupling agent KH560, 3 parts Small molecule monomer: maleic anhydride, 0.3 parts of initiator: dicumyl peroxide, added into a single-screw extruder, extruded and granulated at 170° C., and the modified polymer composite material was prepared.

Embodiment 2

[0025] 100 parts of polymer matrix: polypropylene, 1 part of reinforcing particles: carbon fiber, 5 parts of lubricating particles: molybdenum disulfide, 5 parts of polar filler: cetyltrimethylammonium bromide modified silica, 5 parts 1 part of small molecular monomer: acrylic acid, 0.5 part of initiator: di-tert-butyl peroxide, added to the internal mixer, mixed at 190°C, crushed and granulated, and the modified polymer composite material was prepared.

Embodiment 3

[0027] Take 100 parts of polymer matrix: nylon 11, 10 parts of reinforcing particles: modified carbon nanotubes, 10 parts of lubricating particles: tungsten disulfide, 1 part of polar filler: silicon dioxide, 0.1 part of small molecular monomer: maleic anhydride , 0.1 part of initiator: dicumyl peroxide, 0.5 part of antioxidant: 1098, added into a twin-screw extruder, extruded and granulated at 210 ° C to prepare a modified polymer composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com