Styrene-conjugated diene star-shaped block copolymer and preparation method thereof

A conjugated diene star and block copolymer technology, used in adhesives and other directions, can solve the problems of polluting the environment, high equipment quality requirements, pollution, etc., and achieve the effects of good compatibility, saving equipment investment and excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

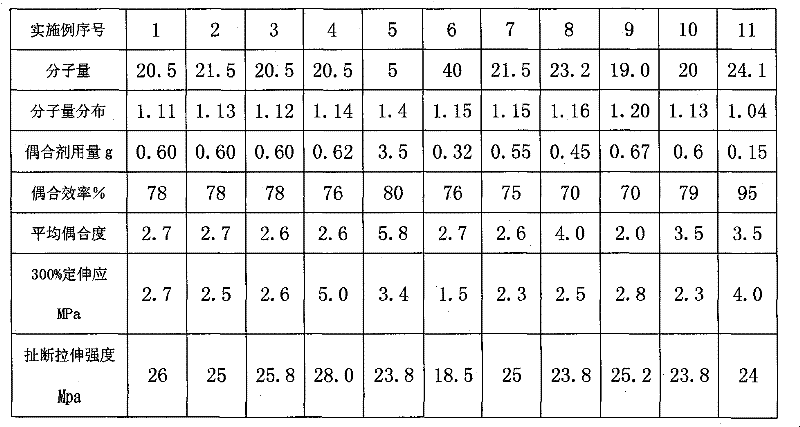

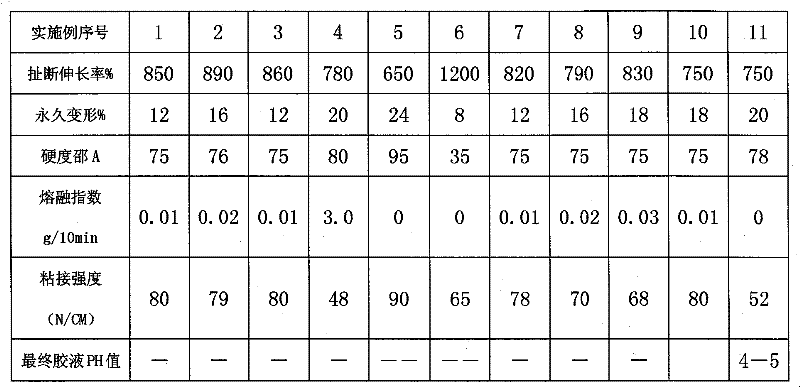

Embodiment 1

[0032] Embodiment 1: add 3000ml hexanaphthene in 5 liters of stainless steel reactors with stirring, add 100g styrene and appropriate amount of activator, be warming up to 50 ℃-70 ℃, then add 8ml (concentration is 0.4mol / l) Initiator butyllithium, reacted for 25 minutes, added 180g butadiene, after the reaction was completed, added 0.6g epoxy soybean oil (C 57 h 106 o 10 ) to carry out the coupling reaction, and the coupling time is 25-30min to discharge the material.

Embodiment 2

[0033] Embodiment 2: Polymerization method and processing condition are with embodiment 1, with epoxidized sunflower oil (C 57 h 90 o 12 ) instead of epoxidized soybean oil (C57 h 106 o 10 ) as a coupling agent.

Embodiment 3

[0034] Embodiment 3: polymerization method and processing condition are with embodiment 1, with epoxy castor oil (C 56 h 94 o 8 ) instead of epoxidized soybean oil (C 57 h 106 o 10 ) as a coupling agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com