A miniature single-coil driven self-locking valve

A single-coil, micro-miniature technology, applied in valve devices, valve details, engine components, etc., can solve the problems of complex production process, complex connection, difficult application, etc., and achieve the effect of reducing weight and volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

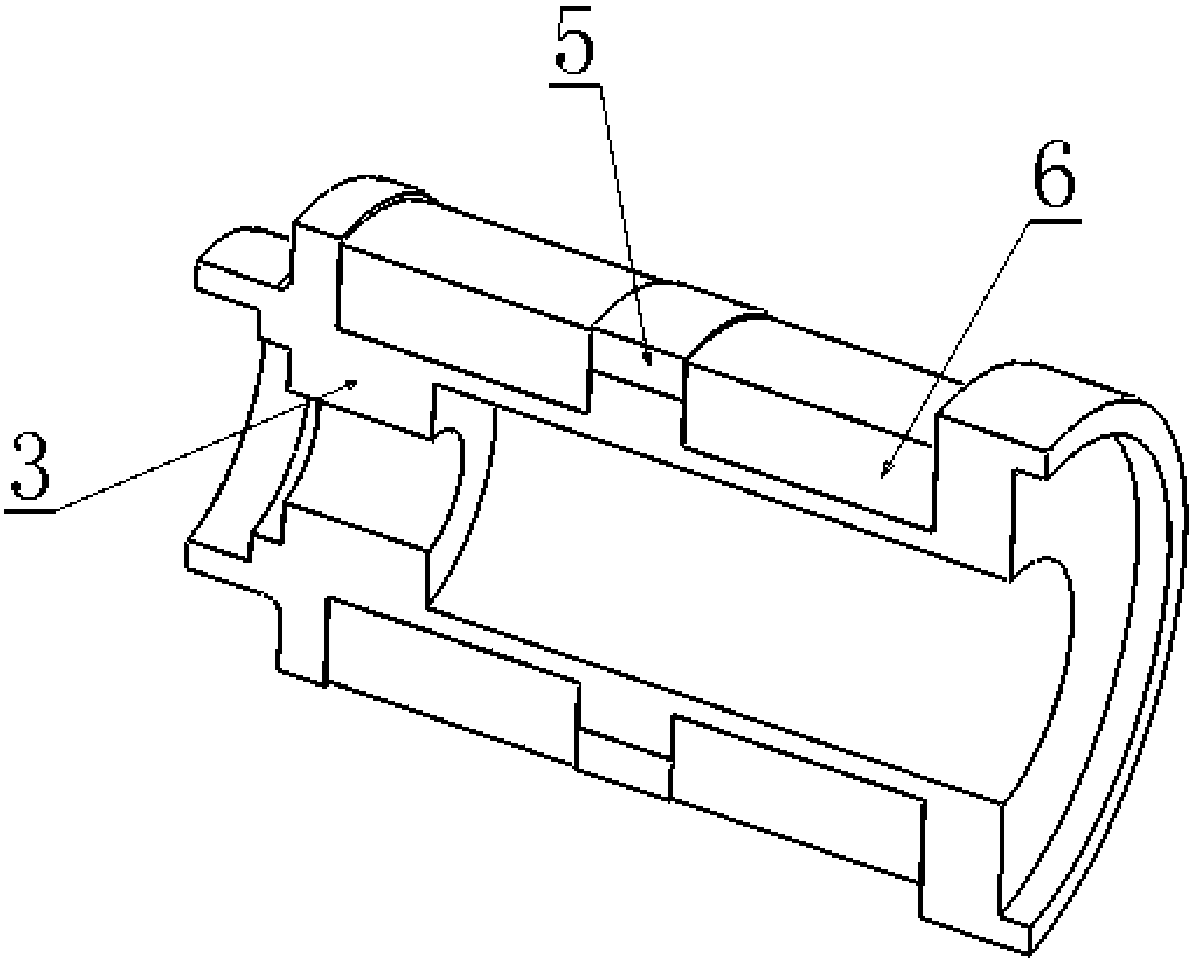

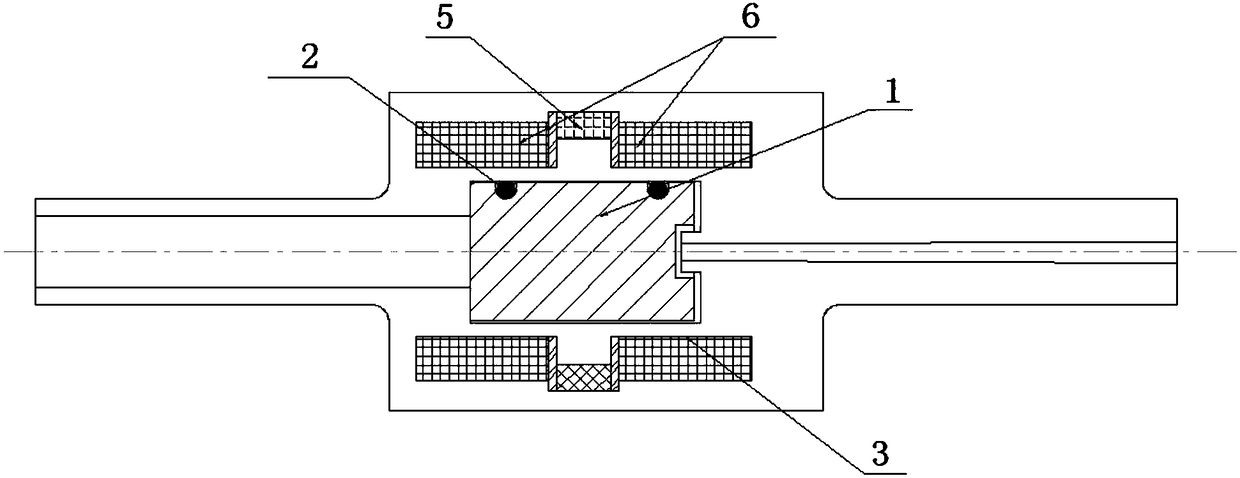

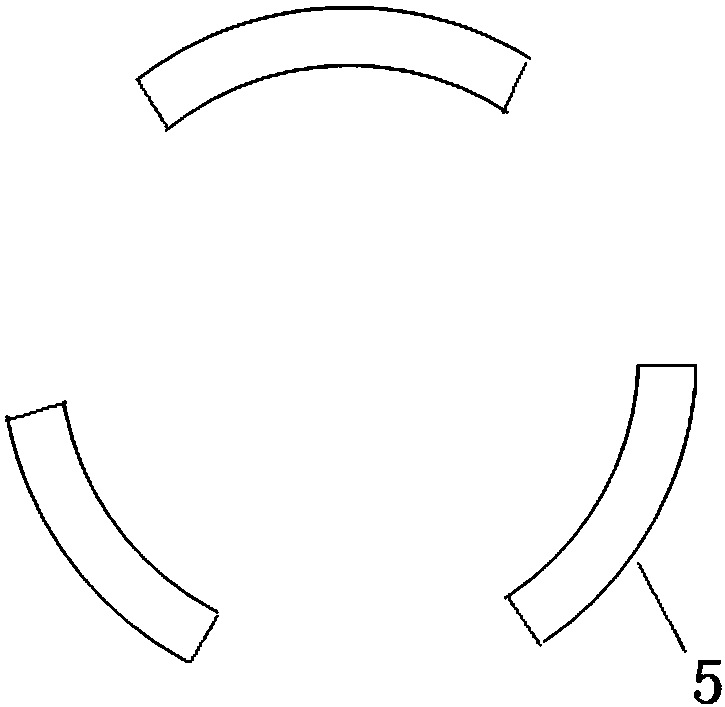

[0049] The magnetic steel 5 is set on the peripheral surface of the valve body 3, and divides the peripheral surface of the valve body 3 into two regions. Two coils 6 are respectively wound in the two regions and connected in series to form a coil with 800 turns. The magnetic steel 5 surrounds the surface of the valve body 3 and is divided into 3 sections of magnetic steel with the same arc size, and the 3 sections of magnetic steel are evenly distributed around the surface of the valve body 3, and the arc of each section of magnetic steel is 60°, such as image 3 shown. The magnetic steel 5 is arranged at the middle position of the valve body along the axial direction of the valve body 3 , and the width of the magnetic steel 5 along the axial direction of the valve body 3 is 2 mm. The two coils 6 on both sides of the magnetic steel 5 are connected in series at the gap between two adjacent sections of the magnetic steel to form a coil.

[0050] Such as Figure 4 a. Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com